ADDITIONAL L.P. EXERCISES

A Production Routing Problem

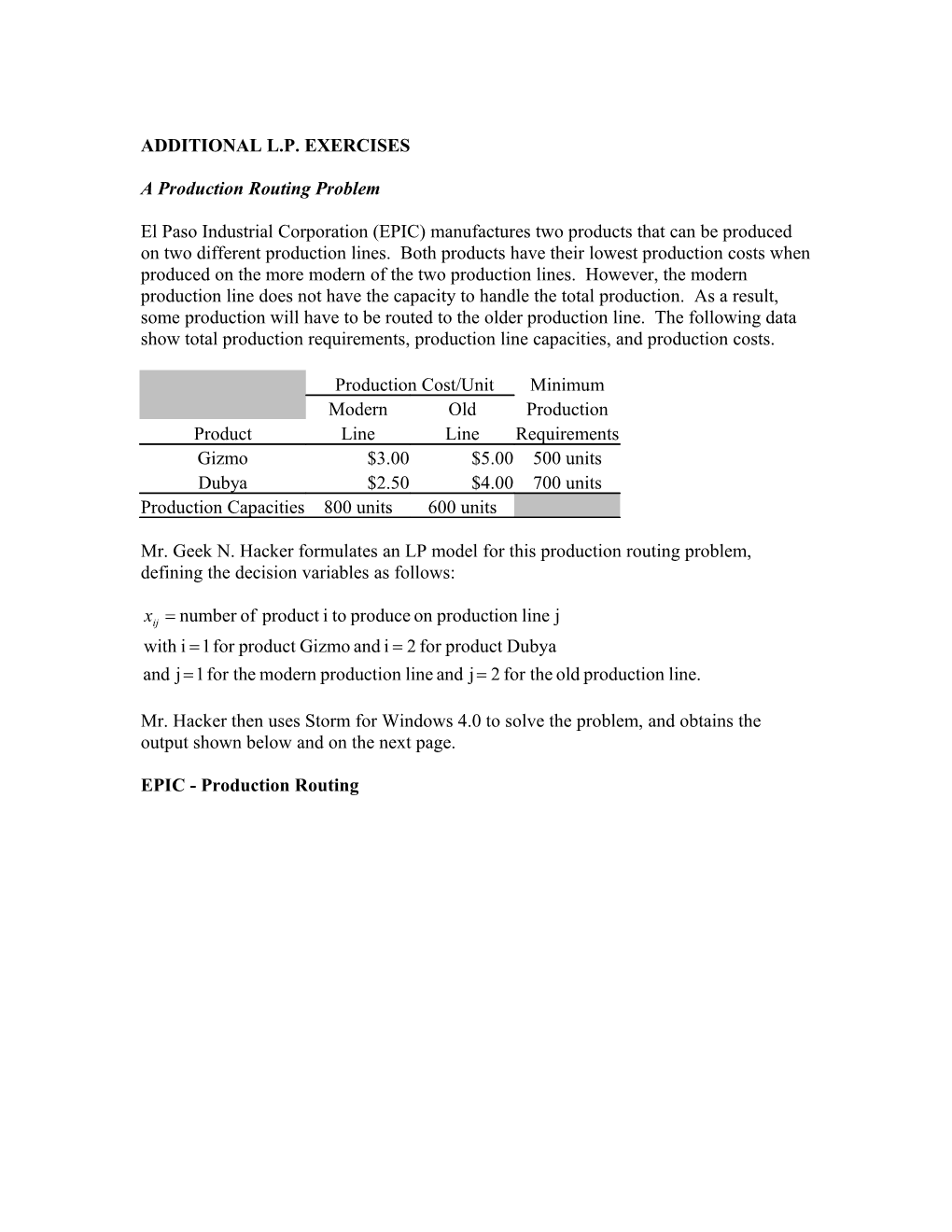

El Paso Industrial Corporation (EPIC) manufactures two products that can be produced on two different production lines. Both products have their lowest production costs when produced on the more modern of the two production lines. However, the modern production line does not have the capacity to handle the total production. As a result, some production will have to be routed to the older production line. The following data show total production requirements, production line capacities, and production costs.

Production Cost/Unit Minimum Modern Old Production Product Line Line Requirements Gizmo $3.00 $5.00 500 units Dubya $2.50 $4.00 700 units Production Capacities 800 units 600 units

Mr. Geek N. Hacker formulates an LP model for this production routing problem, defining the decision variables as follows:

xij number of product i to produce on production line j with i 1 for product Gizmo and i 2 for product Dubya and j 1 for the modern production line and j 2 for the old production line.

Mr. Hacker then uses Storm for Windows 4.0 to solve the problem, and obtains the output shown below and on the next page.

EPIC - Production Routing PROBLEM DATA IN EQUATION STYLE

Minimize 3 X11 + 5 X12 + 2.5 X21 + 4 X22

Subject to CONSTR 1 1 X11 + 1 X12 >= 500 CONSTR 2 1 X21 + 1 X22 >= 700 CONSTR 3 1 X11 + 1 X21 <= 800 CONSTR 4 1 X12 + 1 X22 <= 600

0 <= X11 0 <= X12 0 <= X21 0 <= X22

2 EPIC - Production Routing OPTIMAL SOLUTION - DETAILED REPORT Variable Value Cost Red. cost Status

1 X11 500.0000 3.0000 0.0000 Basic 2 X12 0.0000 5.0000 0.5000 Lower bound 3 X21 300.0000 2.5000 0.0000 Basic 4 X22 400.0000 4.0000 0.0000 Basic

Slack Variables 5 CONSTR 1 0.0000 0.0000 4.5000 Lower bound 6 CONSTR 2 0.0000 0.0000 4.0000 Lower bound 7 CONSTR 3 0.0000 0.0000 1.5000 Lower bound 8 CONSTR 4 200.0000 0.0000 0.0000 Basic

Objective Function Value = 3850

EPIC - Production Routing OPTIMAL SOLUTION - DETAILED REPORT Constraint Type RHS Slack Shadow price

1 CONSTR 1 >= 500.0000 0.0000 4.5000 2 CONSTR 2 >= 700.0000 0.0000 4.0000 3 CONSTR 3 <= 800.0000 0.0000 -1.5000 4 CONSTR 4 <= 600.0000 200.0000 0.0000

Objective Function Value = 3850

EPIC - Production Routing SENSITIVITY ANALYSIS OF COST COEFFICIENTS Current Allowable Allowable Variable Coeff. Minimum Maximum

1 X11 3.0000 -1.5000 3.5000 2 X12 5.0000 4.5000 1.9531E+34 3 X21 2.5000 2.0000 4.0000 4 X22 4.0000 2.5000 4.5000

EPIC - Production Routing SENSITIVITY ANALYSIS OF RIGHT-HAND SIDE VALUES Current Allowable Allowable Constraint Type Value Minimum Maximum

1 CONSTR 1 >= 500.0000 100.0000 700.0000 2 CONSTR 2 >= 700.0000 300.0000 900.0000 3 CONSTR 3 <= 800.0000 600.0000 1200.0000 4 CONSTR 4 <= 600.0000 400.0000 Infinity

3 a. Provide a brief interpretation of the optimal solution in the language of the given problem—i.e., a “real world solution” specified in English. b. Write out the LP model in standard form. c. Surplus variables pertain to (encircle letter corresponding to the right answer):

A. constraints 1 and 2. B. constraints 3 and 4. C. all four constraints. D. none of the four constraints. d. Identify which of the four constraints are binding constraints. e. Provide a brief interpretation in the language of the problem—in English—of the “slack” of 200.000 reported for constraint 4. f. If the cost of producing product Dubya on the modern production line is actually $4.50 per unit, will the optimal solution change? Explain briefly why or why not. g. If the cost of producing product Gizmo on the old production line is actually $7.50, will the optimal solution change? Explain briefly why or why not. h. If the capacity of the modern production line were to be increased to 1,000 units, then the optimal VOF would ______[increase or decrease?]. By how much? Explain/show computation for your answers. i. If the requirement for Dubyas were to be increased to 800 units, by how much would the optimal VOF change? Explain/show computation for your answer. j. If the requirement for Gizmos were to be increased to 800 units, by how much would the optimal VOF change? Explain/show computation for your answer.

4 A Project Investment Portfolio Problem*

Bubba Corporation has $30 million available for the coming year to allocate to its three subsidiaries. Because of commitments to stability of personnel employment and for other reasons, the corporation has established a minimal level of funding for each subsidiary. These minimal funding levels are $3 million, $5 million, and $8 million, respectively. Owing to the nature of its operation, subsidiary 2 cannot utilize more than $17 million without major new capital expansion. The corporation is unwilling to undertake such expansion at this time. Each subsidiary has the opportunity to conduct various projects with the funds it receives. A rate of return (as a percent of investment) has been established for each project. In addition, certain of the projects permit only limited investment. The data of each project are given.

Rate of Upper Limit Subsidiary Project Return of Investment 1 8% $6 million A 2 6% $5 million 3 7% $9 million 4 5% $7 million B 5 8% $10 million 6 9% $4 million 7 10% $6 million C 8 6% $3 million

a. Formulate this problem as a linear programming model. (It is suggested that 000,000 be dropped when specifying investment figures in your model.)

b. Solve the problem using Storm for Windows 4.0.

c. If the rate of return on project 1 were only 7.5%, would the optimal investment portfolio change—all other figures remaining the same?

d. If the rate of return on project 2 were only 7.5%, would the optimal investment portfolio change—all other figures remaining the same?

e. Interpret the nonzero shadow prices reported in the Storm output. What is the meaning of a negative shadow price?

* Problem borrowed from Linear Programming and Network Flows, 2/e, by Bazaraa, Jarvis and Sherali (Wiley, 1990).

5 A Machine Scheduling Problem*

El Paso del Norte Steel Corporation produces four sizes of I beams: small, medium, large, and extra large. These beams can be produced on any of three machines: A, B, and C. The lengths in feet of the I beams that can be produced on the machines per hour are as follows:

I-Beam Machine Size A B C Small 300 600 800 Medium 250 400 700 Large 200 350 600 Extra Large 100 200 300

Each machine can be used up to 40 hours per week, and hourly operating costs of machines A, B, and C are $30.00, $50.00, and $80.00, respectively. Weekly requirements of the different sizes of I beams are 10,000, 8,000, 6,000, and 6,000 feet.

a. Formulate the machine scheduling problem as an LP model.

b. Solve the problem using Storm for Windows 4.0.

* Problem borrowed from Linear Programming and Network Flows, 2/e, by Bazaraa, Jarvis and Sherali (Wiley, 1990).

6