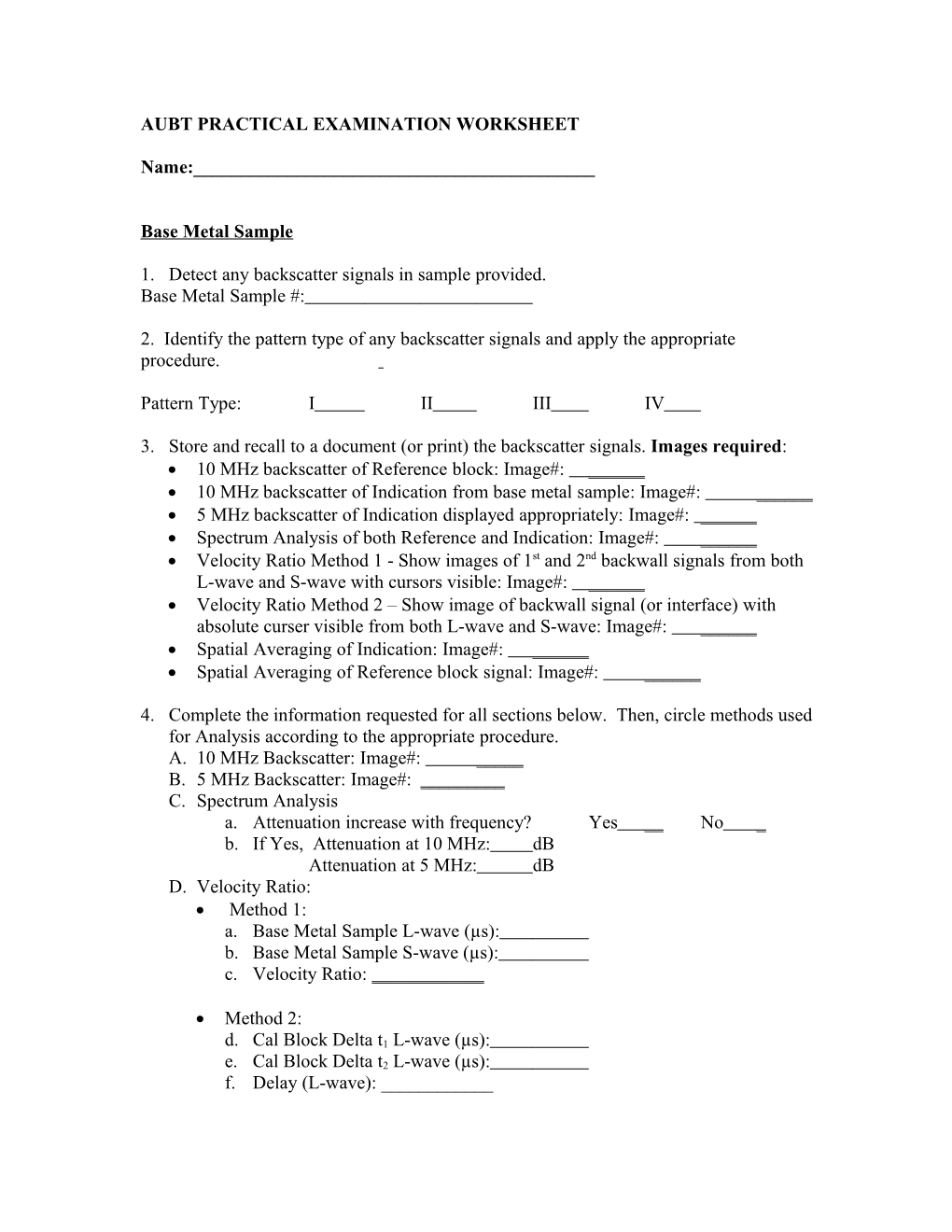

AUBT PRACTICAL EXAMINATION WORKSHEET

Name:______

Base Metal Sample

1. Detect any backscatter signals in sample provided. Base Metal Sample #:

2. Identify the pattern type of any backscatter signals and apply the appropriate procedure.

Pattern Type: I II III IV

3. Store and recall to a document (or print) the backscatter signals. Images required: 10 MHz backscatter of Reference block: Image#: ______ 10 MHz backscatter of Indication from base metal sample: Image#: ______ 5 MHz backscatter of Indication displayed appropriately: Image#: ______ Spectrum Analysis of both Reference and Indication: Image#: ______ Velocity Ratio Method 1 - Show images of 1st and 2nd backwall signals from both L-wave and S-wave with cursors visible: Image#: ______ Velocity Ratio Method 2 – Show image of backwall signal (or interface) with absolute curser visible from both L-wave and S-wave: Image#: ______ Spatial Averaging of Indication: Image#: ______ Spatial Averaging of Reference block signal: Image#: ______

4. Complete the information requested for all sections below. Then, circle methods used for Analysis according to the appropriate procedure. A. 10 MHz Backscatter: Image#: _____ B. 5 MHz Backscatter: Image#: ______C. Spectrum Analysis a. Attenuation increase with frequency? Yes __ No _ b. If Yes, Attenuation at 10 MHz: dB Attenuation at 5 MHz: dB D. Velocity Ratio: Method 1: a. Base Metal Sample L-wave (µs): b. Base Metal Sample S-wave (µs): c. Velocity Ratio: ______

Method 2: d. Cal Block Delta t1 L-wave (µs): e. Cal Block Delta t2 L-wave (µs): f. Delay (L-wave): ______g. Cal Block Delta t1 S-wave (µs): h. Cal Block Delta t2 S-wave (µs): i. Delay (S-wave): ______

j. Base Metal Sample uncorrected L-Wave (µs): ______k. Base Metal Sample uncorrected S-Wave(µs): ______l. Velocity Ratio (corrected): ______E. Spacial Avaraging

Base Metal Flaws Detected: Yes No ___ Circle Flaw Type(s) Detected: HTHA, Laminations, Inclusions Base Metal HTHA Detected: Yes No ____ Height of HTHA if Detected: ______

Weld HAZ Samples

1. Detect any weld HAZ indications. 2. Use ABSA procedure to make the correct call. 3. Store and recall (or print) all relevant supporting data. Images required: A-Scan with wedge delay and ID cursors set a. Wedge Delay in µs: ______b. Sample Thickness in µs: ______c. Sample Thickness in inches: ______Sizingd. ID ConventionCursor Value in µs: ______ Spectrum0 analysis of reference and suspect signal Cross section Flaws Detected: Yes No ___ Circle Flaw Type(s) Detected:Depth

HTHA, ID Crack, Lack of Penetration ( LOP ), Lack of ThicknessFusion ( LOF ), Porosity, Slag Height Weld/HAZ HTHA Detected: Yes No ___ Flaw Size: Start Length a. Start location: ______b. Length: ______c. Height: ______d. Depth: ______