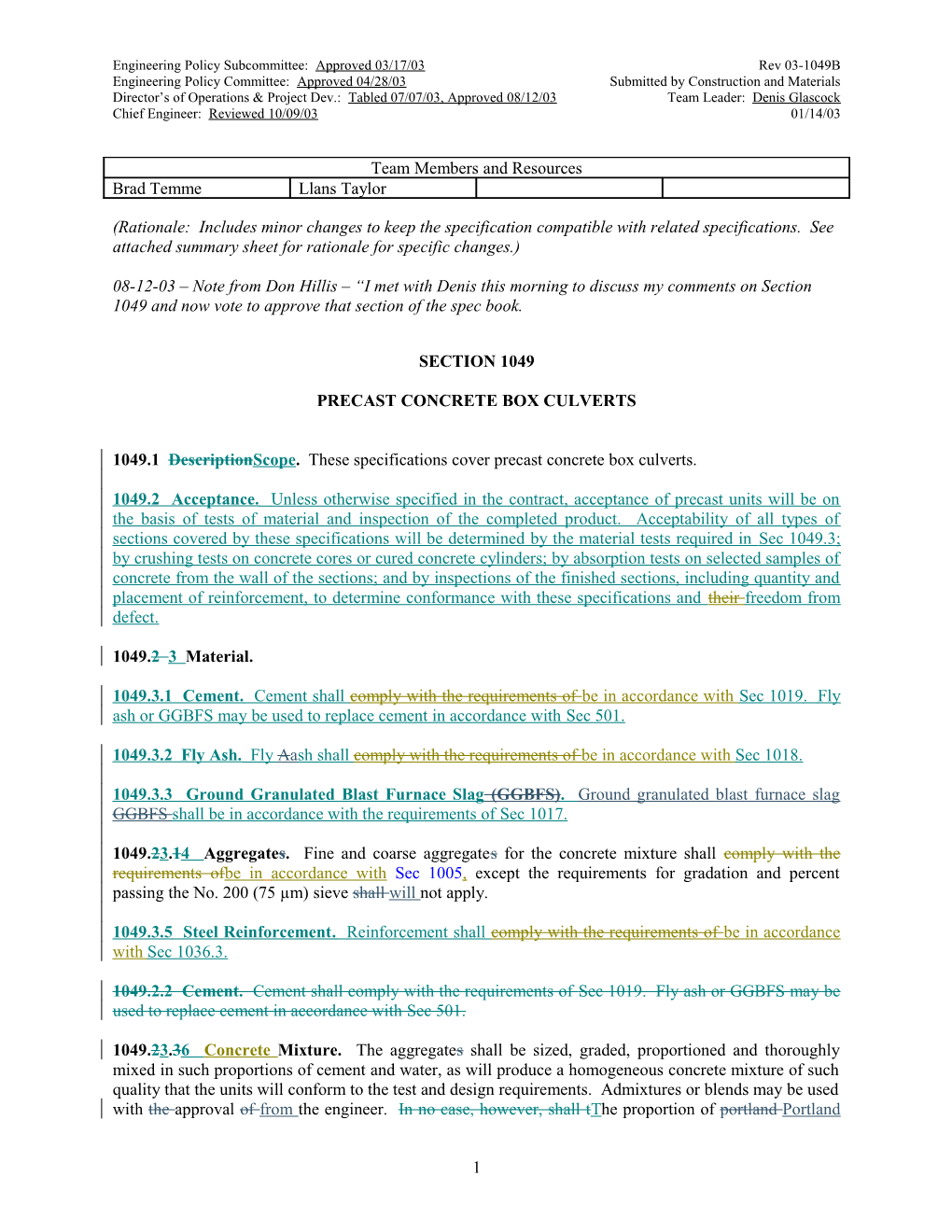

Engineering Policy Subcommittee: Approved 03/17/03 Rev 03-1049B Engineering Policy Committee: Approved 04/28/03 Submitted by Construction and Materials Director’s of Operations & Project Dev.: Tabled 07/07/03, Approved 08/12/03 Team Leader: Denis Glascock Chief Engineer: Reviewed 10/09/03 01/14/03

Team Members and Resources Brad Temme Llans Taylor

(Rationale: Includes minor changes to keep the specification compatible with related specifications. See attached summary sheet for rationale for specific changes.)

08-12-03 – Note from Don Hillis – “I met with Denis this morning to discuss my comments on Section 1049 and now vote to approve that section of the spec book.

SECTION 1049

PRECAST CONCRETE BOX CULVERTS

1049.1 DescriptionScope. These specifications cover precast concrete box culverts.

1049.2 Acceptance. Unless otherwise specified in the contract, acceptance of precast units will be on the basis of tests of material and inspection of the completed product. Acceptability of all types of sections covered by these specifications will be determined by the material tests required in Sec 1049.3; by crushing tests on concrete cores or cured concrete cylinders; by absorption tests on selected samples of concrete from the wall of the sections; and by inspections of the finished sections, including quantity and placement of reinforcement, to determine conformance with these specifications and their freedom from defect.

1049.2 3 Material.

1049.3.1 Cement. Cement shall comply with the requirements of be in accordance with Sec 1019. Fly ash or GGBFS may be used to replace cement in accordance with Sec 501.

1049.3.2 Fly Ash. Fly Aash shall comply with the requirements of be in accordance with Sec 1018.

1049.3.3 Ground Granulated Blast Furnace Slag (GGBFS). Ground granulated blast furnace slag GGBFS shall be in accordance with the requirements of Sec 1017.

1049.23.14 Aggregates. Fine and coarse aggregates for the concrete mixture shall comply with the requirements ofbe in accordance with Sec 1005, except the requirements for gradation and percent passing the No. 200 (75 µm) sieve shall will not apply.

1049.3.5 Steel Reinforcement. Reinforcement shall comply with the requirements of be in accordance with Sec 1036.3.

1049.2.2 Cement. Cement shall comply with the requirements of Sec 1019. Fly ash or GGBFS may be used to replace cement in accordance with Sec 501.

1049.23.36 Concrete Mixture. The aggregates shall be sized, graded, proportioned and thoroughly mixed in such proportions of cement and water, as will produce a homogeneous concrete mixture of such quality that the units will conform to the test and design requirements. Admixtures or blends may be used with the approval of from the engineer. In no case, however, shall tThe proportion of portland Portland

1 cement in the mixture shall not be no less than 564 470 pounds per cubic yard (335280 kg/m3) of concrete. Fly ash may be used to replace cement in accordance with the applicable provisions of Sec 501, except approved Class C or F fly ash may be used to replacesubstituted for a maximum of 25 percent of Type I or II cement on an equivalent weight (mass) basis.

1049.2.4 Admixtures. Admixtures may be used with the approval of the engineer.

1049.3 4 Design.

1049.34.1 Except as otherwise specified herein, the precast concrete box sections for the culvert shall be in accordance with the requirements of AASHTO M 259 for culverts with 2 feet (600 mm) or more of cover, or AASHTO M 273 for culverts with less than 2 feet (600 mm) of cover with, both subject to HS20 live loading, Table 1.

1049.34.2 Substituted precast concrete box culvert sections shall be designed for the earth cover shown on the plans for the cast-in-place box culvert and shall be equal in height and cross sectional area or as approved by the engineer.

1049.34.3 The manufacturer may request approval of modified designs which differ from the designs in AASHTO M 259 or AASHTO M 273. The request for such modified or special designs shall fully describe any deviations from those standards, including a drawing showing wall thickness, concrete design strength, the type, size and placement of reinforcement, and inside or outside dimensions of both of the box sections.

1049.34.4 The following requirements shall also apply.

1049.34.4.1 The minimum barrel length for box or end section shall be 2 feet (600 mm).

1049.34.4.25 End sections may be precast or cast-in-place. If precast, the barrel, floor and wing walls shall be cast as an integral unit. In either case they the end sections shall be constructed to the same dimensions, shapes, and with the same reinforcement as shown in on the standard plans for cast-in-place culvert.

1049.34.4.36 Segmented end sections may be provided, but arewill be considered to be a modified design and will require approval as such.

1049.34.4.47 Toe walls shall be provided on both the upstream and downstream ends as shown on the standard plans and may be cast-in-place or precast. Precast toe walls shall be connected to the end section floor.

1049.4 5 Manufacture.

1049.45.1 Curing shall be in accordance with the applicable provisions of Sec 1026 until the concrete has developed the specified compressive strength.

1049.45.2 Hot or cold weather concreting and concrete testing equipment shall be in accordance with the applicable provisions of Sec 703.

2