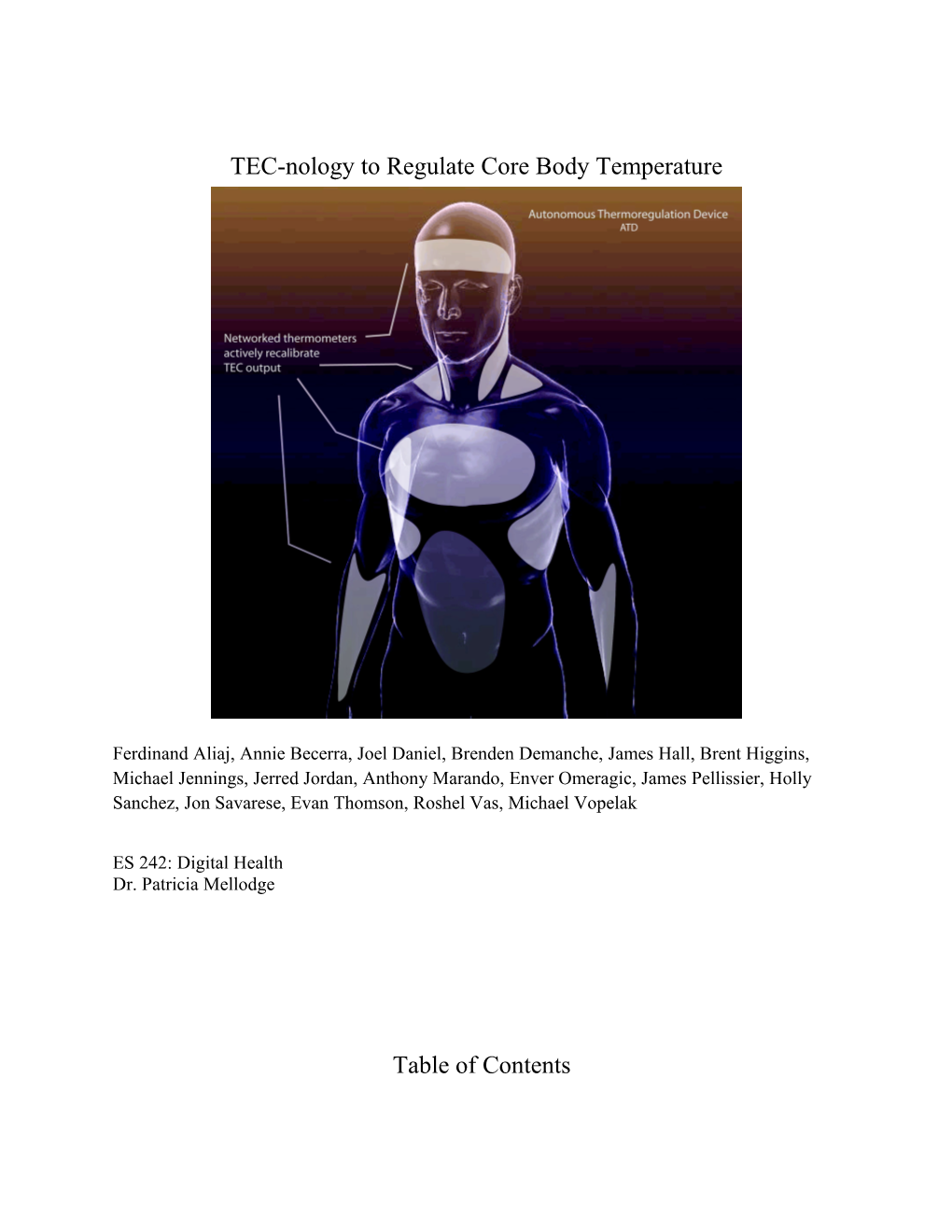

TEC-nology to Regulate Core Body Temperature

Ferdinand Aliaj, Annie Becerra, Joel Daniel, Brenden Demanche, James Hall, Brent Higgins, Michael Jennings, Jerred Jordan, Anthony Marando, Enver Omeragic, James Pellissier, Holly Sanchez, Jon Savarese, Evan Thomson, Roshel Vas, Michael Vopelak

ES 242: Digital Health Dr. Patricia Mellodge

Table of Contents SECTION PAGE #s

Abstract p. 3

Introduction p. 4

Objective p. 5-7

Our Impact p. 8-11

Moral Issues p. 12

Design

Ducting

Hot/Cold Sep p.

Testing Methods p.

Results p.

Conclusion p.

References p.

Appendix: p.

A: Parts List p.

B: Circuit Schematics p.

C: Mechanical Schematics p.

D: Programming Code p. Abstract An unanimous decision concluded ES 242’s decision to pursue an Autonomous Thermoregulation Device. At its core, the appliance uses the “switching” capabilities of a thermoelectric device to both heat and cools the body in the effort to regulate the body’s core temperature when it exceeds the body’s normal operational conditions. Contemporary methods used to regulate core body temperature involve the use of large external equipment as well as a heat transfer medium such as water. Positioning this appliance at key points aims to maximize the efficiency of the device area and minimize bulk. Our preliminary testing and our results support our design and show that our device is capable of affecting core body temperature at several points on the body when connected to the arm including fingertips, upper arm, lower arm, and core body temperature.

Introduction Digital health is a fast evolving field in which technology and healthcare meet to better human lives. The ES-242: Engineering by Design class at the University of Hartford called upon a group of engineers-to-be to create a new and innovative product in the Digital Health Field. The device constructed is a twist to the idea of using cooling to keep swelling from expanding. The goal of the concept is to become an Autonomous Thermoregulator Device or ATD. The ATD would regulate cooling a person’s body without any user input in order to maintain an optimum health level. The ATD accomplishes this through utilizing Thermo-Electic Coolers (TECs) which use current to create the a cooling affect. This effect is very similar to the way ice packs utilize frozen water to create a cooling affect on the body. The class was required to do extensive research on all angles to accomplish the goal. Examples of what requirements had to be met were: determine the best location to place TECs, temperatures that could be harmful to the body, power required to run a full system, and most importantly determine the required parts that would be in the ATD system. Once these requirements were met, the group was able to continue moving forward towards a prototype of the ideal system.

Objective Controlling core body temperature: Through external contact we are ultimately trying to regulate core body temperature. Cooling extremities such as fingers, arms and legs is by far much simpler than cooling the core of the human body. The human core can be cooled quickly using ice baths and extreme temperatures but these methods are either bulky or not humanly controllable. Small devices such as ice packs usually do not work on a large scale to the point where it cools the core body temperature simply because it is too small to affect the body. Also the human body reacts to cold temperatures by contracting and pulling blood away from extremities to regulate the temperature of the core. Therefore small systems such as ice packs lose their effect before the core temperature can be changed. With our Thermo-Electrically Cooled system we are trying to use the flow of blood to help us with the cooling of the core body temperature. By placing our system on major arteries and areas with a large amount of blood flow we are trying to use the circulation of blood to help distribute the cooling throughout the body and ultimately to cool down the core temperature. Most of the cooling will be concentrated in the area of placement of the device which is the reason why we will need multiple devices to spread the cooling to a larger surface area for a greater effect and for quicker cooling of the core temperature. Unlike other systems, this device is controllable. The output of the device can be altered depending on how much cooling is desired. Also the system is able to cool for an extended period of time depending on the source providing power to the system. As long as there is power going into the system it’s able to cool allowing it to be used to induce controlled hypothermia for extended periods of time. Reasons for wanting to control it: The reason we want to have varying control on our autonomous thermo-regulatory device is so that it can be used for many applications. We do not only want to be able to regulate the ATD but we want it to be self regulating depending on the temperature of the body at different locations along with the allowable temperatures of the system itself. In other words, we also don’t want the device to operate at excessive temperatures which may become harmful to the body. Through various temperature sensors we want to both regulate the power output of the TECs, as well as verify that the device is working properly and doesn’t become dangerous to the user. Controlled cooling and heating can be widely applied in medicine, physical activities, body- temperature sustainability. Sports medicine uses cooling to prevent further injury on muscles and to stop pain. Heat on the other hand is used to help repair muscle quicker and to relax. This device could also be used to warm up the body of an athlete before rigorous activities to prevent injury, and muscle strains. A slow, controlled warming of the body by a few degrees will help the athlete be ready to perform their best. In the ideal design if the system becomes small enough to be completely wearable, light, and flexible the device could be worn under clothes to cool and regulate the temperature of the body while performing physical activities. Keeping the body from overheating during physical activities will give the individual more endurance and sustainability. Soldiers could use this device in battle to have more endurance and to prevent fatigue. In extreme weather, whether hot or cold, this device could be used by people for many uses. Subarctic researchers could handle more extreme temperatures for a longer period of time, soldiers could sustain extreme temperatures in the heat of battle, and explorers, hikers, and outdoorsman could use this device for a much more comfortable experience. Both Hot and Cold applications possible: Both hot and cold applications are possible with this device. Because the way thermo-eclectic coolers work, there is a hot and a cold side to every TEC. Heat is extracted from one side making it cold while the other side heats up to compensate for the temperature difference. The physics of a TEC’s behavior is explained later in the design of the project. Why focus on cooling first: We are focusing on cooling because we found that there is more interest and application with cooling then heating. This is because cooling therapy is utilized to help prevent trauma and the progression of injuries. Once cooling was completed, it would just be an easy conversion to figure out and be able to control the heating application of this device. Cooling is slightly harder of the two options to understand and to apply to the human body, not only because it is fighting against the body natural temperature but also against the temperature of the surroundings. At room temperature the cooling is difficult to achieve, but the same problem would come about in the heating application if in an environment with temperatures well below zero. Instead of heat exhaustion at room temperature the effort needs to be concentrated on the exhaustion of the cold air coming off the cold side of the TEC.

Impact The number of deaths resulting from brain injury is estimated at 52,000 people a year and 275,000 are approximated to be hospitalized. Nearly 75 % of people that have TBI (Traumatic Brain Injury) are from concussions and other mild forms of TBI. This problem not only affects health but also effects peoples wallets. “Direct medical costs and indirect costs such as lost productivity of TBI totaled an estimated $60 billion in the United States in 2000“(statistics) In statistics reported by the CDC, falls are the leading cause of TBIs and cause TBIs in adults 65 and older and accounts for 61% of their TBIs. Falls account for 50% TBIs in children ages 0-14. (causes) When you get a concussion it’s due to the violent nature in which your brain is rattled around in your skull. In a traumatic experience such as this it can cause brain swelling. Excessive swelling can then cause brain damage or even result in death. The system that has been developed, an autonomous thermo-regulation device to aid in controlling an individual's core body temperature using TECs, would greatly impact the statistics that were briefly mentioned in the beginning of this report. This ATD can be placed on the head to cool down tissue and effect the brain. Hopefully, the effect would be significant enough to prevent brain trauma from becoming more severe. The advantage of this device is that it is supposed to be a light weight, maneuverable, and cost effective solution to help prevent deaths as mentioned above and to prevent hospitalizations. This device would also reduce health bills, helping to cut down on the strain of disability cost, including but not limited to: hospital care, special care due to brain impairment, necessary equipment to help with brain impairment, lost wages, physical therapy, funereal cost and etc. Other then the use in traumatic brain injuries this device can be used for other medical applications as well. Through this thermo-electrically regulated device we will ultimately be able to regulate human core body temperature to a safe temperature either above or below the healthy human body temperature. This application could be widely used in many sports to regulate the temperature of athletes, applying either to their core body temperature or to the temperature of an injured body part. This device will be used to prevent injuries with the possibility to warm and cool the human body to help prevent injuries and restrict the injuries that occur from getting worse. This device could ideally be used by professional and amateur athletes as a device that will be portable, light, and self adjusting. The application of this system could first be used on soldiers to be tested in the roughest and most extreme conditions. Soldiers could use this device as a way to regulate their temperature in the harshest of weather so they could sustain more extreme temperatures in the heat of battle. Also along with core temperature regulation they could use this device for bodily injuries and brain injuries to retard inflammation and swelling on injured body parts. This will maximize recovery time for soldiers whose occupation is dependant on their mobility. The autonomous thermo-regulation device will most likely be desirable in small places such as ambulances. It would be ideal in those close quarters, where there is no room for larger machines that could be used to cool the body. Our small device could be placed near the area of trauma to preserve body tissue in large injuries or to reduce swelling in smaller or internal injuries. The first design will be somewhat costly to manufacture due to design flaws, accidents, reworking of design, and the purchasing of equipment and tools. After the final design has been confirmed and the prototype has been made, the physical design and programming will be easily reproducible. This should allow for a working system to be built quickly and in an affordable manner. The self regulated TEC device should be affordable for all hospitals and be able to be purchased by the average American. The final device will be extremely safe, it will be encased in plastic, rubber, and completely insulated. No wires or power source will have contact with the body. Therefore it will be very unlikely that a user could be electrically shocked by this device. If by any reason the device malfunctions and is broken to where the internal components are exposed, there will be a cutoff switch that will shut down any power to the system. At this point in time, there are no known negative health side effects associated with the operation of this device. The only precaution that will strictly need to be followed is: when not under direct supervision, the device should not be in the same location on the body for more than thirty minutes. External skin damage might occur if precautions are not followed. The design does not target any extremely sensitive areas; therefore no instantaneous damage will be possible. In the possibility of malfunction or overheating the system will be programmed to cut all power to the TEC and continue running the fan to remove heat from the TEC. This will prevent skin damage from extreme heat in the problem area. The autonomous thermo-regulatory device doesn’t break any social ethical responsibilities. However it may violate some professional ethics if the device is used by professional athletes. The athletes my utilize it while performing their sport to gain more endurance and to reduce fatigue. This would be unethical because it could extend the natural abilities of the athlete. An opponent who chooses not to utilize the device would then be at a loss against someone who does. This imbalance between competitors may create an ethical choice to be decided in the future world of sports.

Design The ATD made use of Thermoelectric Coolers (TECs), an Arduino Board, Dallas Temperature Sensors, Mosfet switches, and heatsinks with fans. To begin, a look at the TEC shows there are essentially two metal plates connected together, and when a current is run between them, the TEC can produce heat on one side, and cold on another side, an affect known as the peltier effect. With the cold side of the TEC is attached to the individual, the heat will escape through the heat sink and removed by the fan. Should the current ever be switched, the surface that was once cold will become hot and the surface that was once hot will become cold.

Figure C.2 A thermoelectric device’s schematic showing the way heat is absorbed and rejected; taken from http://en.wikipedia.org/wiki/File:Thermoelectric_Cooler_Diagram.svg.

IR picture of a the cold side of a thermoelectric cooler as contrasted against the hand and body temperature. The TEC chosen was the TEC1-12705 Thermoelectric Peltier Cooler from Crazyconn (Part number 22 in Appendix B). Prior to this selection a round TEC with a maximum input of source was considered but price became an issue. Therein came the square TEC which operates at 77W that came from Crazyconn. It allowed the greatest surface coverage to maximize skin contact that gave the best results. One of the benefits of this TEC include the requirement of only 12 volts to operate it while it will provide 77 watts of power. Originally, the round TEC idea had a lower operating voltage so therefore it wouldn’t cool as quickly. This square TEC became more powerful and was able to reach deeper layers of the skin at faster rates than the previous TEC choice. The TEC is given a constant amount of power, but is controlled through the combination of the Arduino and the Mosfet as to how much cooling or heating it will give to the body.

The Arduino controls the whole operation of the system. All the coding went to this microcontroller which autonomously told the system what to do depending on temperature readings. Arduino boards come in all shapes and sizes, but for this particular concept the Arduino Lilypad best suited. It is a small, light and thin micro controller that doesn’t add much bulk but performs the necessary tasks when programed. At the same time, should we choose to apply this board directly to clothing, it is completly possible as it has the necessary holes to allow it to be sewed onto clothing. On the board itself, there are 14 pins, with 6 of them being pulse width modulation. The use of the Pulse width is such that we can control how often something is running. For example, the TEC is to only be on for only 50% of the time, then we would set the pulse Width for that particular pin to which the TEC is coordinated with to only run 50% of the time. In effect the pin is a variable on/off switch. There is also a set of pins which go to a break- out board to allow connections to the computer via micro-usb ports or to allow an external power supply. A diagram of the Arduino Board is bellow:

http://arduino.cc/en/Main/ArduinoBoardLilyPad The micro controller reads in the temperature of the interface between the user and the device and adjusts the output to the TEC accordingly. This is controlled partly through a component called a mosfet. A mosfet is an electronic switch triggered by a voltage. when voltage is input to the mosfet it allows a current to flow from one side to the other. If no voltage is put through then there is no current running through to the output. The mosfet switches are turning on and off at a rate dependant upon the temperature reading. The mosfets are the interface used to control the connection between the micro controller the TEC and the power source. In this situation a temperature is read in, should that reading be too high then a pulse wave is sent out of the arduino to the mosfet at a fast rate, this allows the power to flow from the power source to the TEC.

As for the temperature sensors, the design had a flip flop on which sensor to choose from the list. Primary stages of the ATD had the choice to use the LM34 Temperature sensors since they were able to run individually. This individuality caused the LM34s to become too bulky for the ATD and was scrapped for the Dallas Sensors. Below is a picture of the LM34 sensor.

http://www.parallax.com/Store/Sensors/TemperatureHumidity/tabid/174/CategoryID/49/List/0/S ortField/0/Level/a/ProductID/87/Default.aspx

The big design issue that this creates when creating a small device is the number of wires required to have it become operational. Therein came the Dallas Temperature sensors. which solved this problem. The requirements of the Dallas connections call for a lower number of wires, this in turn will help clean up the number of outputs coming from the micro controller. However this simplicity in hardware caused a complexity in software. This can be seen in the code below.

Behind this simplified wire scheme, the code for the Arduino must know how to communicate with the design. This means reading in the unique 8 bit address assigned to each Dallas temperature sensor, saving that specific temperature reading and converting it to a common scale(Celsius) for output. Following the diagram below, we are able to achieve our goal of a “parasite connection” with the Dallas Temperature Sensors, which allows to have as many sensors as we want. This in turn will give more temperature readings, however the downside is that with each sensor added there is a delay in the amount of time it takes to get a reading. For a parasite hookup to work a power source is connected to the data wire through a resistor. This data wire is connected in series to the middle pin on each sensor within the parasite connection. There is also a common ground that is connected in series to every sensor within the parasite connection. This can be seen in the figure below.

http://www.google.com/imgres? imgurl=http://www.strangeparty.com/wordpress/uploads/2010/12/DS18B20.png&imgrefurl=htt p://www.strangeparty.com/2010/12/13/arduino-1-wire-temperature- sensors/&usg=__lTAYs0efYz5U7k4oqhJF6Dn9ajQ=&h=250&w=500&sz=15&hl=en&start=0 &zoom=1&tbnid=tCup0qEORWL4lM:&tbnh=122&tbnw=244&ei=6Fe6TdOjEubs0gHFt4HGA Q&prev=/search%3Fq%3DDallas%2BTemperature%2Bsensor%2Bparasite%2Bconnection %26um%3D1%26hl%3Den%26rlz%3D1C1SKPC_enUS410US410%26biw%3D1064%26bih %3D748%26tbm %3Disch&um=1&itbs=1&iact=hc&vpx=406&vpy=117&dur=4042&hovh=159&hovw=318&tx =168&ty=94&page=1&ndsp=20&ved=1t:429,r:2,s:0

http://www.google.com/imgres? imgurl=http://www.retorte.ch/public/arduino_temperature_sensor/maxim_ds18b20.png&imgref url=http://www.retorte.ch/tools/experiments_and_snippets/arduino_temperature_sensor/&usg=_ _Q1fEmSGsdVIcRMWH8mHk4PdnY84=&h=98&w=370&sz=8&hl=en&start=40&zoom=1&t bnid=cv6QwMZZzEHpJM:&tbnh=51&tbnw=192&ei=Y1a6TcDcDczegQfevezODw&prev=/se arch%3Fq%3DDallas%2BTemperature%2Bsensor%26hl%3Den%26rlz %3D1C1SKPC_enUS410US410%26biw%3D1064%26bih%3D748%26site%3Dsearch%26tbm %3Disch0%2C1562&um=1&itbs=1&iact=hc&vpx=317&vpy=154&dur=413&hovh=52&hovw =196&tx=94&ty=23&page=3&ndsp=20&ved=1t:429,r:11,s:40&biw=1064&bih=748 Schematic of our Whole Circuit The diagram below shows up our circuit is all connected as previously explained in each section. The 14.7V power supply connects directly to the two TECs in parallel. In parallel with those as well is two 12V regulators which are each connected to a CPU fan. These fans and TECs are each connected to their own MOSFET which is connected to ground. The Mosfets are connected to the "Pulse Width Modulation" ports on the arduino as well in order to regulate them. There is also the Arduino power supply which is connected only to the Arduino and ground. The last component is the temperature sensors. These are powered by the Arduino. These are also connected to a digital input port on the Arduino lilypad so it can read the digital temperature readings that they output as well. Due to the large number of components, there are a lot of wires which may look confusing on a diagram of the whole circuit setup.

Controller sitting on the vacuum table, in process… Notice mosfets wrapped in rubber bands. Controller wrapped in a compact form. Notice the mosfe-to-power grounds have not been connected yet… The peltier device is held in a PVC casing. In addition to providing hosing for the thermoelectric, fan, heat sink, and temperature sensors it provides for the three following actions imperative to the success of this idea:

-Heat removal (ducting) -Hot side/ Cold side separation -Compression

The heat sink is "attached" with a high performance, silver based thermal paste with a high rate of heat transfer. Any form of permanent attachment to the heat sink must be conscientious of the fact that interfering or introducing other epoxy or super glue material will have an effect, most likely negative, on the heat transfer characteristic between the ceramic surface of the hot side and the metal body of heat sink. Even in small drops of glue placed at all corners hardened and expanded increasing the amount of space between the heat sink and hot side surface. The PVC armature allows us just to use the thermal paste without any form of permanent or externally based attachment. Attached to the top of the heat sink is a fan. The means of attachment is super glue. Blue and red LEDs are super glued to the side of the fan. A temperature sensor is super glued as close as possible to the base of the heat sink so as to minimize intrinsic error of the bulk temperature sensors we used, see Immersion Sensors vs Topical Sensors*.

Heat Removal (ducting) *Ducting can be accomplished using aluminum flashing and bending it with a bending tool. See glossary for the stencil that will yield the dimensions of a duct perfect for a 40mm by 40mm thermoelectric and heatsink. Notice the DS18B20 fitted on the corner of the fan to measure air intake temperature. The white wire is a fan speed sensor that is intended for a computer mother board. Reasonably information could be collected from this wire to a microcontroller. This could be relevant to objects entering the fan and stopping the blade, i.e. hair or a finger. Designing in a short amount of time modifications must remain relevant to the time imperative completion objective of the device. *The above shows a base armature design that was later scrapped because it presented difficulties when vacuum forming and overall, was more labour intensive to make than the PVC housing - as recommended by Enver O.

*Aluminum foil, exacto knife used to cut it, and the base cut out pictured on the right side. This base is a high impact resin, heat transfer characteristic of the base is unknown however plastic is commonly considered an insulator. Hot side/ cold side separation is important because our objective is to make the device pull heat out of the body. if these systems are crossed, rate of tissue cooling would be drastically lowered. If the case did not provide this separation, hot air that is blown off of the heat sink will waft over the body area we are trying to cool resulting in useless cyclical operation.

A more permanent arrangement of all these internal components: heat sink, fan and sensors could be made by milling a custom plastic case in the milling machine.

This PVC armature with all included internal components is then drapped in hot plastic through the vacuum forming process. This is more art than process and resulted in multiple issues, see Vacuum Forming*.

PVC Casing

Small movement will occur between the heat sink and the surface of the peltier device until the thermal compound has completely dried and solidified. At this point it is likely that the heat transfer characteristic will as well be affected negatively and the ability of the heat sink and fan to remove heat will drop off, though by how much is undetermined. For now the PVC allows small movement while protecting these internal components from large impact. Though in a large impact such as dropping it from a table, the heat sink will likely detach from the hot side surface.

Testing Methods

As Arduino is open source there are some libraries that are distributed for others to tweak and share as they see so fit, one such library used was the Dallas Temperature library. This library allowed information to be obtained from each sensor, information like the address and data output from each sensor were vital to the parasite connections efficiency. As the end design of our overall project is ever changing the need for more or less temperature sensors changes as well. The code used is easily adaptable to the change in number of sensors used. So as the project grows and takes form there is not much work needed in the end to adjust to the new physical set up of the hardware.

Due to the fact that the Dallas Temperature Library was not our original work the exact implementation was vague. The documentations written by the creators became very helpful. References through Arduino website proved to be useful as well.

Code Explained

Below, is have a screenshot of the working code gathering temperature readings from two sets of smaller systems. Data and Analysis Water Interface Test At the end of this test which lasted approximately 10 minutes and 30 seconds the testers right middle finger registered a temperature of 32.4 degrees whereas the tester’s left middle finger measured a temperature of 27.6 degrees Celsius. The larger slopes indicative of a greater rate of change are seen at the beginning of this test and at the end of this test. This data would have been more beneficial in terms of yielding insight into the feasibility of the water interface had the TEC been at maximum operation for the duration of the test.

Observing the graph, the power sent to the TEC was gradually increased over a time span of 10:30s. However what this test does provide is evidence towards the feasibility of a water interface medium which would increase the effective interface surface area of the TEC and allow it to permanently operate at maximum potential. Increasing interface surface area has the potential to increase overall rate of bodily heat removal. Importantly, this test highlights the slow response characteristic of a water interface medium.

Multi-Point Water Interface Test *Note the size of this water interface. A water interface with this mass of water would not be able to cool efficiently with regards to time. The water interface pouch used in this test contained approximately 34 grams of water and is pictured in the previous photo. This is the capstone test of this project bearing evidence of its function and ability to reduce the temperature of the body. Just one TEC was responsible for the cooling observed in the interface temperature readings as well as the middle finger temperature readings seen above. In this test the TEC was placed just above the brachial artery at a compression level of greater than .22 lbs. The Dynatron DF124028_U Fans ran at 12 volts and 52 milliamps and the TEC was run at 9 volts and 3.07 amps. A water interface pouch weighing ***grams was placed in-between the cold surface of the TEC and the tester’s skin. Temperature was recorded using the Infrared Pocket Thermometer from Radioshack. The water interface pouch was at room temperature at the start of this experiment.

Temperature was taken at the exact same location for each of the 5 locations listed above. Core temperature was measured just under the neck, upper arm temperature was measured just above the bicep, lower arm was taken below the module on the outside of the arm, interface temperature was taken through a small hole on the top of the arm band and lastly middle finger temperature was taken at the tip of the right hand middle finger.

The same small pouch of water that was used in the previous water interface test was used in the Multi- Point Water Interface Test. The interface temperature reading was affected by the warm evacuation side of the module, so the data appears with this systematic error. When the device was taken off at the end of the test, the temperature of the bag was immediately recorded at 14.2 degrees C and the area of skin underneath the bag registered topically at 17.6 degrees C. A 14.2 degree C contact surface is well outside the range that might induce injury, 3-4 degrees C 1 Chulalongkorn University.

Though the device is powerful enough for immediate local cooling without the water pouch, it is apparent that one TEC with a water pouch was not enough to significantly impact cooling of the upper arm or core body temperature when considering the body’s homeostatic ability as well as the directional flow of the blood in the arteries on which the TEC was positioned directly above. If tested over a longer period of time, without the water interface and if test readings were taken in different locations relative to the underlying blood vessels and not over muscle tissue as they were, the rate of heat transfer would be greater and likely more evident in upper body locations. As the device sat on a blood vessel (brachial)

1 Prawit Janwantanakul, Department of Physical Therapy, Faculty of Allied Health Sciences, Chulalongkorn University that was delivering oxygenated blood to the hand, the results of the loss of heat in the tester’s right hand was within predictions. The final two temperature readings of the right hand middle finger were 24.2, 23.6 degrees C and the corresponding temperatures on the left hand middle finger were 29.2 and 29.8 degrees C.

Also given the results of the previous water interface test, it is likely that the water pouch impacted the rate of cooling negatively and significantly, however it was deemed proper in the case of prevent injuring and increasing comfort for the tester for the duration of the 30 minute test cycle.

In conclusion one TEC when run at the maximum respective of the capability of our hardware and interfaced with a water pouch, placed at the brachial artery of the right arm of a 21 year, old male, 160lb tester was capable of cooling the tester’s middle finger at a distance of approximately 30 inches from the test location on the testers brachial artery by at least 5.7 degrees C.

As stated in the design, the final product has one micro controller(Arduino) controlling a left and right side. both sides consist of two TECs and various temperature sensors. The software is designed to complement the hardware design. There are several temperature sensors on each system, each recording something different and specific. There is a sensor reading temperature for the heatsink to prevent damage to the device. Temperature is read in from the TEC to ensure that it is operating as intended. Temperature is read in from the interface between the TEC and the user’s skin to prevent frostbite or other damage to the user. Each of these temperature readings are recorded and processed to ensure that these components are running within a specified range. Should any of these components operate outside the specified temperature range the entire device will either shut off or adjust its output until it is operating properly again.

Controlling our MOSFETs The mosfet, as mentioned previously in the design section is the main switch for the TEC. Due to the fact that the TEC is not controlled directly from the micro controller to the TEC there is no code for TEC control, per say. Instead there is a code written to control the pulse wave output to the mosfets. Below is a section of the code which controls the mosfet with our predetermined equations along with an on/off button which is coded in as the pressure sensor.

Pressure Sensor controlling TEC and Fan

Fans and TECs being set to values

First the pressure sensor is read to determine whether there is a force applied or not. Pressure is an indication that the device is properly connected to the user and is in use, an absence of pressure indicates that the user is wearing the device improperly or the device is not in use at all. If pressure is applied then we cycle through the rest of the code reading in temperatures from specific sensors. This temperature reading is processed, from here the micro controller determines how fast the pulse wave should be output to the mosfet switch. The mosfet is then activated at said rate and power is driven to the TEC. As more temperature readings are coming in the output pulse speed is adjusted accordingly to maintain safe use. As interface temperature rises mosfet switches faster, as temperature lowers mosfet switches slower. This ratio of temperature to mosfet switch speed is predetermined through a specific equation that takes in the converted temperature reading and outputs the speed at which the pulse wave should operate.

Finally, we have our fans that work directly on the TECs. as said earlier these are indirectly controlled from the micro controller via the mosfet switches. Originally the fans were to operate at full while the device was operating and run for an extra ten seconds after the device has been shut off. However this proved to be a waste of energy and inefficient. Instead the fan operated dependant upon the temperature reading of the heatsink. The hotter the heatsink was the faster the fan would run the cooler the heatsink got the slower the fan would run. By having the fan idle when not needed we can save power drawn from the battery, giving the device longer operation time. This control can be seen in the code below. The operation of the TEC is similar to that of the fan. As temperature rises work harder as temperature cools work less, however the ideology and reasoning is different. The fan was slowed down to preserve battery life and efficiency, the TEC is slowed down due to safety reasons. The TECs could have been run while the temperature is above a certain range and shut off when below a certain range but this is inefficient and gives a very broad spectrum. With the use of pulse wave module and mosfet switches the device is able to better control the temperature output, ensuring that it operates within the specified, predetermined range. The code was pieced together by calling the various methods, each method controls a unique component. After one component’s method is called its output is then used as an input to another component’s method. This can be seen in the flow chart below. Appendix C contains the reference code used to learn how to code the device in part A and the full functional code in part B.

Results During prelimary test of the device, a bulkier powersupply than the desired option was utilized. The figure below is that of BK precision. With this device, and our system set up, different voltage and current options were allowed to be tested to see just how the TECs and Fans respond. A device like this began to shape the concept as it could reveal what appropriate voltages and currents should be applied onto the end result system. Once the given requirements of the Arduino board, TECs and Fans were in place, the portable solution to the battery needs was created. Below is a figure of what the portable battery pack may look like. Below the picture itself contains the data for our battery that was chosen.

Average Power Consumption Estimation TECs Fans Voltage Sent 14.7 12V V Duty Cycle 50% 100% Average Voltage 7.35 12V Consumed V Average Current 2.0A 0.7A Multiplied by 2 for each 4.0A 1.4A component

With the given data, calculations were done on the battery life of a system: Maximum mAh used in one hour = 4.0A + 1.4A = 5.4A Equation to determine how long this battery will last:c5400mAh / 60mins = 4400mAh / battery life Battery Life = 48.88mins.”

Due to constraints of time, near the end of the class this particular battery option was not readily available and therefore had to be scrapped for at least the proof of concept. Without this battery the original idea, the PK precision power supply was used for demonstration purposes. A continuation of issues with time constraints, the final code was not implemented in time for the demonstration although it had been finished. The final product was a wrist band that was able to hold one TEC and one fan. This was far from the original goal; however this did create something that was tangible. For the power supply, like mentioned before it had a BK precision power supply with test code to run for the demonstration.

Conclusion

In the end, the ES242 worked to obtain a proof-of-concept of an ATD which would advance the Digital Health field. The class worked to find proper calculations for a desired device to which it then obtained the parts which would fill the calculations best. Once these parts were obtained, coding was designed specifically for the product which became a proof-of- concept. From there, a stepping stone for what this device could ultimately become was born. In the future, a device like this has a possibility of ending up not only in the medical facilities but also in the household setting. Further advancements in this proof-of-concept can be in the locations of housing and parts. The idea behind housing is how the device is supposed to be worn, attached, or where it is placed along the body. Different sections of the body are going to have to require different sizes of the contraption in order to obtain its desired operation. In order to make the device more usable in all parts of the body, it would have to be smaller and therefore changes to the wire size, controller size, and casing size would need to be shrunk down to more applicable sizes. A powerful controller is always a benefit to have when collecting a lot of data and running two sets of TECs so the current 8mhz chip may not be sufficient for future-proofing the design. A class as such provided valuable lessons, though given implicitly, for future engineer fields. As an example, this class allows students to understand just what it may be like to communicate with other people, although they may be doing different things, each person needs to be able to coordinate with others as one whole group. This was a valuable simulation of the possibility of the lives some of the students may live, and therefore important to experience such events while in an educational scope as apposed to a scope in which jobs and money are on the line. The results could also be measured in many things such as a responsibility, a new found importance for respect, and friendship. The growth that took place in terms of being an adult was immeasurable for some. The ability to sit down and design something together and also get a result is wonderful, especially because of the lack of direction originally provided. This project was for students, for young engineers. All of the project failures and successes were leaned onto the young engineers. Much like the real world there was no safety net, if the project was not done then the project was not finshed. Any kind of issue pertaining to parts, labor, or the like was soely vested onto the students who worked on the project. This type of class taught implicitly just what it means to work on a project as a true engineer. That may well be the best lesson anyone could learn at such a young age. Appendix A: Works Cited

Works Cited

All-Battery.com - Rechargeable Batteries & Chargers. Web. 09 May 2011. battery.com/>. Amazon.com: Online Shopping for Electronics, Apparel, Computers, Books, DVDs & More. Web. 09 May 2011. "Answers.com - What Is the Lowest and Highest Tempatures Humans Can Survive under." WikiAnswers - The Q&A Wiki. Web. 09 May 2011. survive_under>. "Arduino - ArduinoBoardLilyPad." Arduino - HomePage. Web. 09 May 2011. "Arduino - FAQ." Arduino - HomePage. Web. 09 May 2011. "Arduino - Software." Arduino - HomePage. Web. 09 May 2011. "Arduino Playground - OneWire." Arduino - HomePage. Web. 09 May 2011. "CDC - Injury - TBI - Statistics." Centers for Disease Control and Prevention. Web. 09 May 2011. 2011. "Charting Your Basal Body Temperature Information and FAQ - Fertility Plus." FertilityPlus: Information Written by Patients, for Patients. Web. 09 May 2011. "Digital Humidity Sensor SHT21 - Smallest Humidity Sensor for Demanding Measurements - Sensirion AG." Relative Humidity Sensor, Gas Flow Sensor, Mass Flow Sensor and Liquid Flow Sensor Solutions - Sensirion AG. Web. 09 May 2011. dity_sensor_sht21.htm>. "EFunda: Theory of Thermocouples." EFunda: The Ultimate Online Reference for Engineers. Web. 09 May 2011. Orderby=Seebeck0C>. "FSR, Force Sensing Resistor, Robot Force Sensors, Robot Pressure Sensor, Robot Touch Sensor." Trossen Robotics - World's Leading Robot Shop for Robot Kits and Robot Parts! Web. 09 May 2011. Force-Sensing-Resistor-FSR-.aspx>. "FSR Sensor Tutorial." Limor. Web. 09 May 2011. The GNU Operating System. Web. 09 May 2011. "Is Lithium-ion the Ideal Battery? – Battery University." Battery Information from Battery University. Web. 09 May 2011. "Leah Buechley - LilyPad Arduino - Introduction." MIT Media Lab. Web. 09 May 2011. "Level1 Thermocouple Skin Temperature Sensor, 20/bx." Medical Supplies | Surgical Supplies | Medical Equipment | Medex Supply. Web. 09 May 2011. 47441/Level1ThermocoupleSkinTemperat.htm?zmam=34602484>. "Medical Emergency." Wikipedia, the Free Encyclopedia. Web. 09 May 2011. "Model 1672 - Triple Output Quad Display DC Power Supply ((2) 0-32V, 0-3A/(1)5V, 3A) - B&K Precision." B&K Precision Manufactures a Range of Electronic Test & Measurement Instruments. Web. 09 May 2011. power-supply-2-0-32v-0-3a-15v-3a.html>. Number, Part. "Heat Sinks Information on GlobalSpec." GlobalSpec - Engineering Search & Industrial Supplier Catalogs. Web. 09 May 2011. onic_Cooling/Heat_Sinks>. "OneWire Arduino Library, Connecting 1-wire Devices (DS18S20, Etc) to Teensy." PJRC: Electronic Projects with Components Available Worldwide. Web. 09 May 2011. "Parts Needed." Instructables - Make, How To, and DIY. Web. 09 May 2011. pock/step1/controlling-from-a-terminal-in-windows>. Piatek, Anton. "Arduino 1-wire Temperature Sensors « Strangeparty." Strangeparty. Web. 09 May 2011. sensors/>. "Polymer Lithium Ion Battery - 110mAh - SparkFun Electronics." News - SparkFun Electronics. Web. 09 May 2011. Retorte.ch – News. Web. 09 May 2011. RobotShop | Robot Store | Robots | Robot Parts | Robot Kits | Robot Toys. Web. 09 May 2011. Sorin, Trimbitas. "How to Use the DS18S20 and DS18B20 Temperature Sensors with Arduino." Dedication to DIY and Programming. Web. 09 May 2011. sensors-with-arduino.html>. Thermoelectric, Peltier Cooler. Web. 09 May 2011. "Under Armour Clothing under Armour Mens Fire Retardant H - Www.MidwestHuntersOutlet.com." Hunting, Rifle, Deer Hunting, 22 Rifle, Game Hunting, Hunting Accessories, Hunting Rifle, Hunting Guns. Web. 09 May 2011. "Used Temperature Sensor." Bio-medical.com | Products. Web. 09 May 2011. medical.com/products/used-temperature-sensor.html>. WidgetWorks Unlimited. Web. 09 May 2011. "WiFly Wireless SpeakJet Server - SparkFun Electronics." News - SparkFun Electronics. Web. 09 May 2011. Appendix B: Parts list 1) Part #and Name-$19.90 - PRT-10217 - LiPo Charger Basic ($9.95 ea.) Quantity- 2 units Manufactures-N/a Vendor-SparkFun Link to data Sheet-http://www.sparkfun.com/products/10161 Product description -The USB LiPo Charger is a basic charging circuit that allows you to charge 3.7V LiPo cells at a rate of 500mA or 100mA per hour. It is designed to charge single-cell Li-Ion or Li-Polymer batteries. 2)Part #and Name- $11.85 - PRT-09771 - Theragrip Thermal Tape ($3.95 ea.) Quantity- 3 units Manufactures-N/a Vendor-SparkFun Link to data Sheet-http://www.sparkfun.com/products/10161 Product description- Thermalloy Theragrip is a double sided tape for ceramic or metal heatsink packages. Theragrip provides both good thermal performance and excellent electrical isolation. 3)Part #and Name-$11.85 - COM-10256 - MOSFET Power Control Kit ($3.95 ea.) Quantity- 3 units Manufactures-N/a Vendor-SparkFun Link to data Sheet-http://www.sparkfun.com/products/10161 Product description- -This MOSFET power control kit is basically a breakout for RFP30N06LE which is a very common MOSFET with very low on-resistance and a control voltage (aka gate voltage) that is compatible with any 3-5V micro controller or mechanical switch. 4)Part #and Name-$20.85 - PRT-00731 - Polymer Lithium Ion Battery - 110mAh ($6.95 ea.) Quantity- 3 units Manufactures-N/a Vendor-SparkFun Link to data Sheet-http://www.sparkfun.com/products/731 Product description--This is a very small, extremely light weight batty based on the new Polymer Lithium Ion chemistry. This is the highest energy density currently in production. Each cells outputs a nominal 3.7V at 110mAh! Comes terminated with a standard 2-pin JST connector - 2mm spacing between pins. 5)Part #and Name-$44.85 - DEV-08786 - LilyPad LiPower ($14.95 ea.) Quantity- 3 units Manufactures-Leah Buechle Vendor-SparkFun Link to data Sheet-http://www.sparkfun.com/products/8786 Product description--A small, but very mighty power supply. This board was designed to be as small and inconspicuous as possible. The nice thing about LiPower is the ability to use rechargable Lithium Polymer batteries. These batteries are smaller, flatter, and last much longer than a AAA battery. Attach a single cell LiPo battery, flip the power switch, and you will have a 5V supply to power your LilyPad network. Good up to 150mA. Short circuit protected. 6)Part #and Name -922007094-02 Dynatron DF124028_U 40x40x28MM SLEE (9.78EA Total with S&H = $34.54) Quantity- 1 unit Manufactures- www.dynatron-corp.com/ Vendor- www.compuvest.com/ Link to data Sheet- http://www.dynatron-corp.com/en/product_detail_1.aspx?cv=&id=46&in=0 Reason for purchase -This CPU fan was purchased to be a heat sink for our TECs. It will disperse the heat that accumulates on it. 7)Part #and Name -67-3AIT-R2BW 12"x12" Vacuum Form Machine ($129.95) Quantity- 1 unit Manufactures- http://www.widgetworksunlimited.com/ Vendor- http://www.amazon.com/ Link to data Sheet- http://www.widgetworksunlimited.com/12_x12_Hobby_Vacuum_Former_p/vf-12x12- vac_former.htm Reason for purchase -This vacuum form machine was purchase to serve as a means to assemble the fans and TECs together as one component. 8)Part #and Name – COM-10256 MOSFET Power Control Kit (3.95) Quantity - 3 units Manufactures- N/A Vendor- http://www.sparkfun.com/ Link to data Sheet- http://www.sparkfun.com/datasheets/Components/General/MOSFET-Power-Control-v10.pdf Reason for purchase -This Mosfet is used as a switch by the lilypad to regulate the power flowing to the TECs and Heat Sinks. 9)Part #and Name -DEV-08786 Lilypad LiPower($14.95) Quantity - 3 units Manufactures- http://www.arduino.cc/en/Main/ArduinoBoardLilyPad Vendor- http://www.sparkfun.com/ Link to data Sheet- http://www.sparkfun.com/datasheets/DevTools/LilyPad/LilyPad-PowerSupply-Lipo.pdf Reason for purchase -This device is built to function as a 5V power supply to the lilypad microcontroller when connected to a battery. 10)Part #and Name -DEV-09266 Lilypad Arduino 328 Main Board ($21.95) Quantity - 3 units Manufactures- http://www.arduino.cc/en/Main/ArduinoBoardLilyPad Vendor- http://www.sparkfun.com/ Link to data Sheet- http://www.atmel.com/dyn/resources/prod_documents/8271S.pdf Reason for purchase – This Lilypad is the microcontroller for our operation. It will read the temperature data and operate the TECs using the mosfet and code. 11)Part #and Name -DEV-09716 FTDI Basic Breakout 5V ($14.95) Quantity - 3 units Manufactures- Leah Buechley and SparkFun Electronics Vendor- http://www.sparkfun.com/ Link to data Sheet- http://www.sparkfun.com/datasheets/DevTools/Arduino/FTDI%20Basic-v21-5V.pdf Reason for purchase -This breakout board helps supply the battery power to the lilypad and has indication LEDs to show whether it is operational. 12)Part #and Name -PRT-00731 Polymer Lithium Ion Battery – 110mAh ($6.95) Quantity - 3 units Manufactures- N/A Vendor- http://www.sparkfun.com/ Link to data Sheet- http://www.sparkfun.com/datasheets/Batteries/UnionBattery-110mAh.pdf Reason for purchase -This is the 3.7V power supply for the lilypad which is raised to 5v by the breakout. 13)Part #and Name -SEN-00245 One Wire Digital Temp Sensor ($4.25) Quantity - 8 units Manufactures- http://www.maxim-ic.com/ Vendor- http://www.sparkfun.com/ Link to data Sheet- http://datasheets.maxim-ic.com/en/ds/DS18B20.pdf Reason for purchase -This is the temperature sensor which will gather data about our targets temp. The data is sent to the lilypad which uses it to determine when to operate the TECs. 14) Quantity 2 - $29.90 Part #and Name - DEV-10275 - Lilypad FTDI Basic Breakout - 5V ($14.95 ea.) Vendor- http://www.sparkfun.com/ 15) Quantity 1 - $1.95 Part #and Name - PRT-09599 - Heat Sink Compound Vendor- http://www.sparkfun.com/ 16) Quantity 1 - $14.95 Part #and Name - DEV-08937 - LilyPad XBee Vendor- http://www.sparkfun.com/ 17) Quantity 1 - $4.95 Part #and Name - ROB-08449 - Vibration Motor Vendor- http://www.sparkfun.com/ 18) Quantity 4 - $17.00 Part #and Name - SEN-00245 - One Wire Digital Temperature Sensor - DS18B20 ($4.25 ea.) Vendor- http://www.sparkfun.com/ 19) Quantity 4 - $23.80 Part #and Name - SEN-09673 - Force Sensitive Resistor - Small ($5.95 ea.) Vendor- http://www.sparkfun.com/ 20) Quantity 4 - $3.80 Part #and Name - COM-00529 - Super Bright LED - Blue - 1pcs ($0.95 ea.) Vendor- http://www.sparkfun.com/ 21) Quantity 3 - $65.85 Part #and Name - DEV-09266 - LilyPad Arduino 328 Main Board ($21.95 ea.) Vendor- http://www.sparkfun.com/ 22) Quantity 6 - $29.34 Part #and Name - TEC1-12705 Thermoelectric Peltier Cooler 40 mm x 40mm 12V 77 Watt Vendor- http://www.sawsmiter.com/detail/p_B002UQKEU8/Best-deal-TEC1-12705-Thermoelectric-Peltier-Cooler- 40-mm-x-40mm-12V-77-Watt-onsale.html SUBTOTAL COST : $685.90 Shipping/Handling : $24.99+ $14.77 GRAND TOTAL: $725.66 Appendix C: Source Code Below is sample code from the Arduino Playground of the OneWire setup: Part A) Part B) Below is our Final Code: Appendix D: Circuits Schematic Appendix E: GNU Open Source Software used herein is unique to the project. Though it may be a derivative of software published under the GNU licence, it is code that can only be used with the corresponding mapping that we generate and therefore has to be modified to fit any other device with different hardware or physical architecture. It is the unique functional correlation between devices and their respective code that makes this summation of this device a unique and creative generation of our own. The code that was referenced will be properly sourced. The GNU and GPL licence states the following; The freedom to run the program, for any purpose (freedom 0). The freedom to study how the program works, and adapt it to your needs (freedom 1). Access to the source code is a precondition for this. The freedom to redistribute copies so you can help your neighbor (freedom 2). The freedom to improve the program, and release your improvements to the public, so that the whole community benefits (freedom 3). Access to the source code is a precondition for this. As cited from http://www.gnu.org/home.html All Arduino hardware is also open source and claims the following; Open-source hardware shares much of the principles and approach of free and open-source software. In particular, we believe that people should be able to study our hardware to understand how it works, make changes to it, and share those changes. To facilitate this, we release all of the original design files (Eagle CAD) for the Arduino hardware. These files are licensed under a Creative Commons Attribution Share-Alike license, which allows for both personal and commercial derivative works, as long as they credit Arduino and release their designs under the same license. The Arduino software is also open-source. The source code for the Java environment is released under the GPL and the C/C++ microcontroller libraries are under the LGPL. As cited from http://arduino.cc/en/Main/FAQ