1994 Dodge Ram 2500 Axle Shaft, Bearing & Seal Removal & Installation . Chrysler 7 1/4 In. (184mm) Axle . Dana 44 Models . Dana 60 . Model 44 With Full-Time 4-Wheel Drive . Models With Full-Time 4-Wheel Drive

Chrysler 7 1/4 In. (184mm) Axle . Left Side Shaft . Right Side And Intermediate Shaft PATH: Driveline > Front Drive Axle/Differential > Axle Shaft, Bearing & Seal > Removal & Installation > Chrysler 7 1/4 In. (184mm) Axle > Left Print Side Shaft

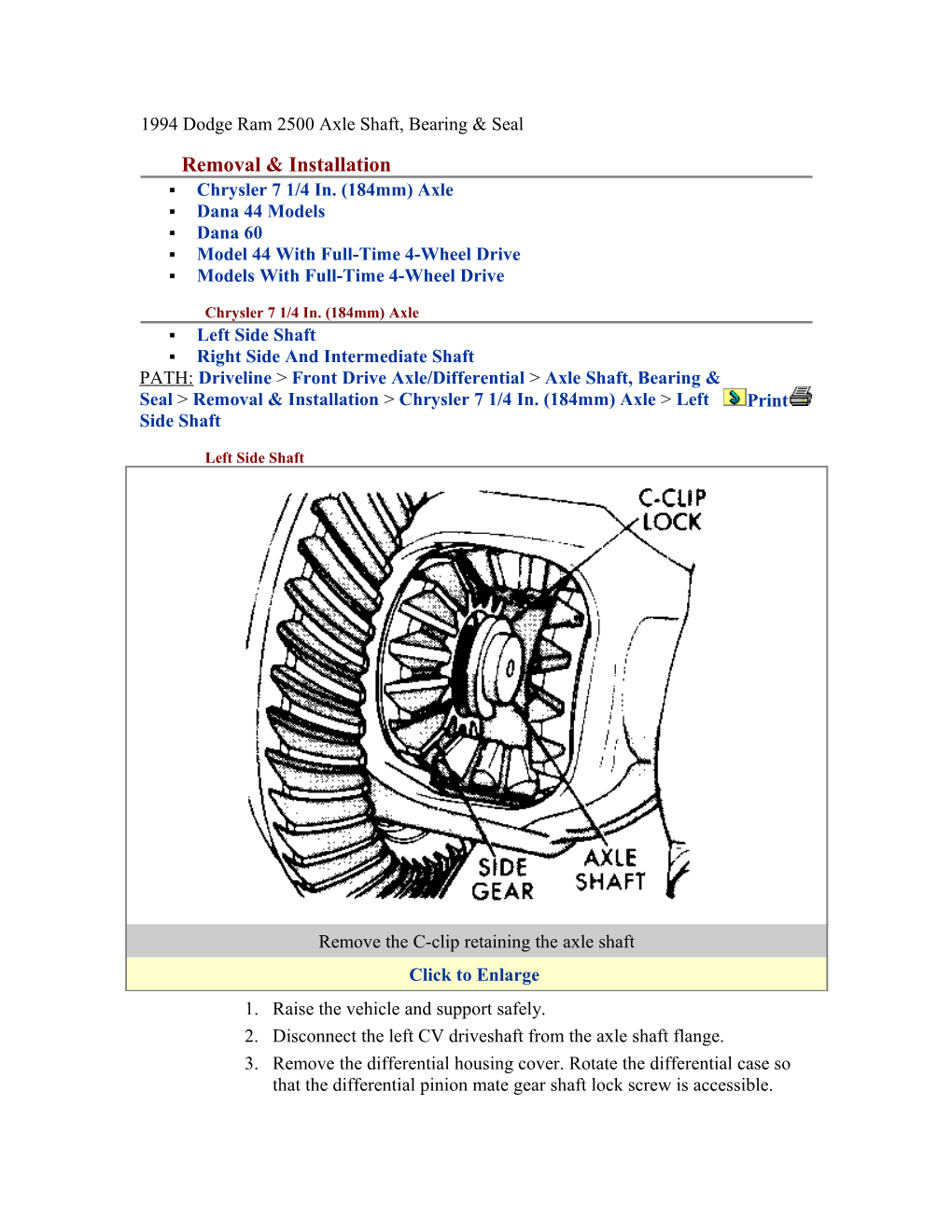

Left Side Shaft

Remove the C-clip retaining the axle shaft Click to Enlarge 1. Raise the vehicle and support safely. 2. Disconnect the left CV driveshaft from the axle shaft flange. 3. Remove the differential housing cover. Rotate the differential case so that the differential pinion mate gear shaft lock screw is accessible. Remove the lock screw and the pinion mate gear shaft from the differential case.

Exploded view of the left axle shaft, seal and bearing on the 71/4 in. axle Click to Enlarge 4. Force the left axle shaft toward the center of the vehicle and remove the shaft C-clip lock from the recessed groove in the axle shaft. 5. Remove the axle shaft from the differential housing. Inspect the axle shaft bearing contact surface for brinelling, spalling and pitting. If any of these conditions exist, replace the axle shaft and bearing. 6. Remove the axle shaft seal from the end of the housing bore with a suitable pry bar. Remove the axle shaft bearing only if it being replaced; do not reinstall used bearings. Use removal tool C-4167 and slide hammer tool C-637, or their equivalents, to remove the bearing. To install: 7. Thoroughly clean and dry the bearing bore in the differential housing. 8. Insert the new bearing into the pilot of bearing installation tool C-4198, or equivalent, and attach to the handle. Insert the bearing to the housing until it is seated against the bore shoulder. 9. Install the new seal using tool C-4203, or equivalent, with the flat side of the tool facing the seal. When the installation tool contacts the housing flange face, the seal is installed to the correct depth. Install the axle shaft seal using a hammer and the special install driver, or equivalent Click to Enlarge 10. Lubricate the bearing bore and seal lip, insert the axle shaft into the housing and engage the splines. With the shaft in place, install the C- clip lock and push the shaft outward to seal the lock. 11. Install the mate shaft, align the hole in the shaft with the lock screw hole in the differential case and install the lock screw. Tighten the lock screw to 8 ft. lbs. (11 Nm). 12. Thoroughly clean and dry the case cover, mating surface, bolts and bolt holes. Apply silicone sealer to the cover and install. Correct sealant application on the housing cover Click to Enlarge 13. Connect the CV driveshaft. 14. Level the vehicle and fill the differential with multi-purpose gear lubricant. 15. Road test the vehicle and check for leaks and correct front axle operation.

Submit Query

PATH: Driveline > Front Drive Axle/Differential > Axle Shaft, Bearing & Seal > Removal & Installation > Chrysler 7 1/4 In. (184mm) Axle > Right Print Side And Intermediate Shaft

Right Side And Intermediate Shaft 1. Raise the vehicle and support safely. 2. Remove the tire and wheel assembly. 3. Remove the cotter pin, nut lock and spring washer from the stub shaft. Remove the hub nut and washer. 4. Remove the bolts that attach the inner CV-joint to the axle shaft flange. Right axle shaft assembly on the disconnect axle Click to Enlarge 5. Separate the stub shaft splines from the hub bearing splines and remove the CV-joint shaft. 6. Remove the differential housing cover. 7. Disconnect the 4WD indicator lamp switch and the vacuum tube from the shift motor. Remove the shift motor, housing cover and gasket from the shift motor housing.

Exploded view of the disconnect housing cover assembly Click to Enlarge 8. Remove the bearing seal/retainer attaching screws accessible via the holes in the axle shaft flange. 9. Remove the outer axle shaft from the differential housing. 10. Remove the snapring and the splined gear from the outer axle shaft. Separate the bearing and seal from the outer axle shaft.

Use a puller to remove the bearing and seal assembly from the axle shaft Click to Enlarge 11. Remove the shift collar from the shift motor housing. 12. Rotate the differential case so that the different pinion mate gear shaft lock screw is accessible. Remove the lock screw and the pinion mate gear shaft from the differential case. 13. Force the intermediate shaft toward the center of the vehicle and remove the shaft C-clip lock from the recessed groove in the axle shaft. Remove the intermediate shaft from the differential housing and tube. To install: 14. Insert the axle shaft into the tube and housing and engage the splines. With the shaft in place, install the C-clip lock and push the shaft outward to seal the lock. 15. Install the mate shaft, align the hole in the shaft with the lock screw hole in the differential case and install the lock screw. Tighten the lock screw to 8 ft. lbs. (11 Nm). 16. Install the shift collar to the intermediate shaft.

Mounting position of the shift collar in relation to the inner axle shaft and bearing Click to Enlarge 17. Install a new seal to the seal retainer and install to the outer shaft. Press on the new bearing, install the splined gear and the snapring. 18. Insert the outer axle shaft into the shift motor housing. Tighten the attaching screws to 17 ft. lbs. (23 Nm). 19. Install the shift motor housing cover and gasket. Ensure that the shift fork is correctly engaged in the collar groove. Install the cover bolts. Connect the vacuum tubes to the shift motor and the connector to the 4WD lamp switch. 20. Thoroughly clean and dry the case cover, mating surface, bolts and bolt holes. Apply silicone sealer to the cover and install. 21. Lubricate the contact surface area of the CV driveshaft wear sleeve with grease and install the CV driveshaft. Tighten the hub nut to 190 ft. lbs. (258 Nm). Install the spring washer, nut lock and a new cotter pin. 22. Level the vehicle and fill the differential with multi-purpose gear lubricant. 23. Road test the vehicle and check for leaks and correct front axle operation.

Submit Query

Dana 44 Models . Left Side Axle Shaft . Right Side Axle Shaft PATH: Driveline > Front Drive Axle/Differential > Axle Shaft, Bearing & Print Seal > Removal & Installation > Dana 44 Models > Left Side Axle Shaft

Left Side Axle Shaft 1. Raise and support the front end on jackstands. 2. Remove the wheel.

Special tools required for axle housing service Click to Enlarge 3. Remove the caliper and support it up and out of the way. DO NOT DISCONNECT THE BRAKE LINE! 4. Remove the inboard brake pad. 5. Remove the hub-rotor assembly. 6. Unbolt and remove the splash shield and spindle from the knuckle. It may be necessary to tap the spindle loose with a soft mallet. 7. Disconnect the vacuum lines and wire at the disconnect housing on the axle. 8. Remove the disconnect housing cover, gasket and shield. 9. Carefully pull the intermediate shaft through the seal and out of the axle housing. 10. Remove the shift collar from the disconnect housing. 11. Drive out the inner axle shaft seal and remove it from the disconnect housing. Discard the seal. Some axles may have a seal guard. Replacement seals do not use a guard. 12. Remove the needle bearing from the intermediate shaft using tool D- 330 or equivalent.

Remove the bearing from the intermediate shaft using the special tool Click to Enlarge 13. Remove the differential cover. Allow the oil to drain into a drain pan. 14. While pushing inward on the inner shaft, remove the C-lock from the groove on the shaft. 15. Remove the inner shaft with tools D-354-4 and adapter D-354-3 or equivalents. 16. Remove the bearing from the inner shaft with tools D-354-4, D-354-1 and C-637, or equivalents. 17. Thoroughly clean and inspect all parts. Replace any worn or damaged parts. To install: 18. Using tools D-354-4, D-354-2 and C-637 or equivalents, install a new bearing on the inner shaft. 19. Position the inner shaft in the axle housing using tools D-354-4 and adapter D-354-3, or equivalents. 20. Carefully slide the shaft into position and install the C-lock. Details of the axle housing assembly Click to Enlarge 21. Place a new axle shaft seal on tool D-5041-1 and position the assembly in the disconnect housing. Screw threaded bar 5041-2 through the seal and into tool 5041-1. Place tool 5041-3 and the nut on the end of the bar and tighten the nut until the tool reaches the shoulder of the bar. 22. Install the shift collar onto the splined end of the inner shaft. 23. Using tool D-328 and handle C-4171 or equivalents, install the needle bearing into the intermediate shaft. 24. Coat the splined end of the intermediate shaft with multi-purpose chassis lube and install it through the inner axle seal. Avoid damage to the seal!

Lubricate the lip seal with multi-purpose chassis grease Click to Enlarge 25. Install the disconnect housing cover and gasket. Make sure that the shift fork indexes the groove in the shift collar. 26. Tighten the cover bolts to 10 ft. lbs. (14 Nm). 27. Connect the vacuum lines and wire. Install the clip securely around the 4-wheel drive indicator switch connector. 28. Install the splash shield and spindle. Use new nuts tightened to 30 ft. lbs. (40 Nm). 29. Install the hub and bearings. 30. Install the spacer, drive gear and snapring. 31. Apply RTV sealant on the mating edge of the cap and install it. 32. Install the inboard brake pad and caliper (see Section 9). 33. Thoroughly clean the carrier cover mating surfaces and install the cover using a bead of RTV sealant in place of a gasket. Tighten the cover bolts to 40 ft. lbs. (54 Nm). 34. Fill the axle with fluid. 35. Install the wheel.

Submit Query

PATH: Driveline > Front Drive Axle/Differential > Axle Shaft, Bearing & Print Seal > Removal & Installation > Dana 44 Models > Right Side Axle Shaft

Right Side Axle Shaft 1. Raise and support the front end on jackstands. 2. Remove the wheel. 3. Remove the caliper and support it up and out of the way. DO NOT DISCONNECT THE BRAKE LINE! 4. Remove the inboard brake pad. 5. Remove the hub-rotor assembly. 6. Unbolt and remove the splash shield and spindle from the knuckle. It may be necessary to tap the spindle loose with a soft mallet. 7. Remove the caliper adapter from the knuckle. 8. Carefully pull the axle shaft from the housing. 9. Thoroughly clean and inspect all parts. Replace any worn or damaged parts. The axle U-joint can be rebuilt in the same manner as a driveshaft U-joint, as previously described. To install: 10. Install a new seal on the axle shaft stone shield with the lip facing the shaft splines. 11. Carefully slide the shaft into the housing, avoiding damage to the seal at the side gears. 12. Install the spindle and splash shield. Tighten the nuts to 30 ft. lbs. (40 Nm). 13. Install the hub/rotor assembly. 14. Install the spacer, drive gear and snapring. 15. Apply RTV sealer to the mating edge of the grease cap and install the cap. 16. Install the caliper adapter and tighten the bolts to 85 ft. lbs. (116 Nm). 17. Install the inboard pad and caliper (see Section 9). 18. Install the wheel.

Submit Query

PATH: Driveline > Front Drive Axle/Differential > Axle Shaft, Bearing & Print Seal > Removal & Installation > Dana 60

Dana 60 1. Raise and support the front end on jackstands. 2. Remove the caliper from the knuckle and wire it out of the way. 3. Remove the locking hub. 4. Remove the front wheel bearing (see Section 1). 5. Remove the hub and rotor assembly. 6. Remove the spindle-to-knuckle bolts. Tap the spindle from the knuckle using a plastic mallet. 7. Remove the splash shield and a caliper support. 8. Pull the axle shaft out through the knuckle. 9. Using a slidehammer and bearing cup puller, remove the needle bearing from the spindle. 10. Clean the spindle bore thoroughly and make sure that it is free of nicks and burrs. If the bore is excessively pitted or scored, the spindle must be replaced. To install: 11. Insert a new spindle bearing in its bore with the printing facing outward. Drive it into place with a driver. Install a new bearing seal with the lip facing away from the bearing. 12. Pack the bearing with waterproof wheel bearing grease. 13. Pack the thrust face of the seal in the spindle bore and the V-seal on the axle shaft with waterproof wheel bearing grease. 14. Carefully guide the axle shaft through the knuckle and into the housing. Align the splines and fully seat the shaft. 15. Place the bronze spacer on the shaft. The chamfered side of the space must be inboard. 16. Install the splash shield and caliper support. 17. Place the spindle on the knuckle and install the bolts. Tighten the bolts to 50-60 ft. lbs. (68-82 Nm). 18. Install the hub/rotor assembly on the spindle. 19. Assemble the wheel bearings. 20. Assemble the locking hub.

Submit Query

PATH: Driveline > Front Drive Axle/Differential > Axle Shaft, Bearing & Seal > Removal & Installation > Model 44 With Full-Time 4-Wheel Print Drive

Model 44 With Full-Time 4-Wheel Drive 1. Remove the wheel cover. 2. Remove the cotter pin and loosen the axle shaft nut.

Remove the wheel bearing adjusting nut from the Model 44 front axle Click to Enlarge 3. Raise the support the front end on jackstands. 4. Remove the wheels.

Exploded view of the Model 44 wheel bearing adjusting nut, retaining washer and locknut in their correct relationship Click to Enlarge 5. Unbolt the caliper and support it out of the way. DO NOT DISCONNECT THE BRAKE LINE! 6. Remove the inboard brake pad. 7. Remove the axle shaft nut and washer. 8. Through the hole provided in the rotor, remove the six retainer bolts. 9. Position pull C-4358, or equivalent, over the wheel lugs and install the lug nuts. Tighten the main screw of the puller to remove the hub, bearings, retainer and outer seal as an assembly. 10. Insert a prybar through the U-joint and wedge the shaft inward as far as it will go. Make sure that it is wedged securely and can't be moved. 11. Install the hub, rotor and bearing assembly and tighten the retainer bolts to 30 ft. lbs. (40 Nm) in a crisscross pattern. 12. Install the brake adapter. Tighten the bolts to 85 ft. lbs. (115 Nm). 13. Remove the prybar form the U-joint. 14. Install the axle shaft nut and tighten it to 100 ft. lbs. (136 Nm), then continue tightening it to align the cotter pin holes. Install the cotter pin. 15. Using the lube fitting, fill the knuckle with NLGI, Grade 2, multi- purpose EP grease until the grease is seen flowing through the inner seal. Lubrication fitting location on the rotor top hat Click to Enlarge 16. Install the inner brake pad and caliper (see Section 9). 17. Install the wheels and tighten the lug nuts to 110 ft. lbs. (150 Nm).

Submit Query

PATH: Driveline > Front Drive Axle/Differential > Axle Shaft, Bearing & Print Seal > Removal & Installation > Models With Full-Time 4-Wheel Drive

Models With Full-Time 4-Wheel Drive 1. Remove the wheel cover. 2. Remove the cotter pin and loosen the axle shaft nut. 3. Raise and support the front end on jackstands. 4. Remove the wheels. 5. Unbolt the caliper and support it out of the way. DO NOT DISCONNECT THE BRAKE LINE! 6. Remove the inboard brake pad. Remove the Model 60 shaft and joint from the hub assembly Click to Enlarge 7. Remove the axle shaft nut and washer. 8. Through the hole provided in the rotor, remove the six retainer bolts. 9. Position puller C-4358, or equivalent, over the wheel lugs and install the lug nuts. Tighten the main screw of the puller to remove the hub, bearings, retainer and outer seal as an assembly. 10. Remove the puller. 11. Remove the caliper adapter from the knuckle. 12. Place a pry bar behind the inner axle shaft yoke and push the bearings out of the knuckle. 13. Some knuckles have and O-ring. If so, remove and discard it. 14. Carefully pull the axle shaft from the axle. Remove the seal and slinger from the shaft. 15. The U-joint can now be disassembled in the same manner as a driveshaft U-joint, explained earlier in this section. To install: 16. If you removed the brake dust shield, install it now. Tighten the mounting bolts to 15 ft. lbs. (20 Nm). 17. Apply RTV silicone sealer to the sealing surfaces of the axle shaft. 18. Using a driver, install the slinger onto the shaft. 19. Install a new seal on the slinger with the lip toward the splines. 20. Carefully insert the shaft into the axle housing, being careful to avoid damage to the differential side gear seal. 21. Insert a prybar through the U-joint and wedge the shaft inward as far as it will go. Make sure that it is wedged securely and can't be moved. 22. Using adapter tool C-4398-2 and driver, or equivalents, install the seal cup in the knuckle until it is bottomed. A small amount of wheel bearing grease on the adapter will help hold the cup in position. Leave the tool in position for the time being. 1 23. Apply a /4 in. (6mm) bead of RTV sealant to the retainer face on the chamfer. 24. Carefully remove the seal installing tool so that the outer shaft remains centered. If the shaft is touched, make sure that the seal lip is still riding inside the cup. 25. Position the bearing retainer on the knuckle so that the lube fitting is facing directly forward. This is extremely important! 26. Install the hub, rotor and bearing assembly and tighten the retainer bolts to 30 ft. lbs. (40 Nm) in a crisscross pattern. 27. Install the brake adapter. Tighten the bolts to 85 ft. lbs. (116 Nm). 28. Remove the prybar from the U-joint. 29. Install the axle shaft nut and tighten it to 100 ft. lbs. (136 Nm), then continue tightening it to align the cotter pin holes. Install the cotter pin. 30. Using the lube fitting, fill the knuckle with NLGI, Grade 2, multi- purpose grease until the grease is seen flowing through the inner seal. 31. Remove the grease gun and rotate the hub several times. 32. Install the grease gun and continue filling the knuckles until grease appears around at least 50 percent of the seal circumference. 33. Install the inner brake pad and caliper (see Section 9). 34. Install the wheels and tighten the lug nuts to 110 ft. lbs. (150 Nm).

Submit Query