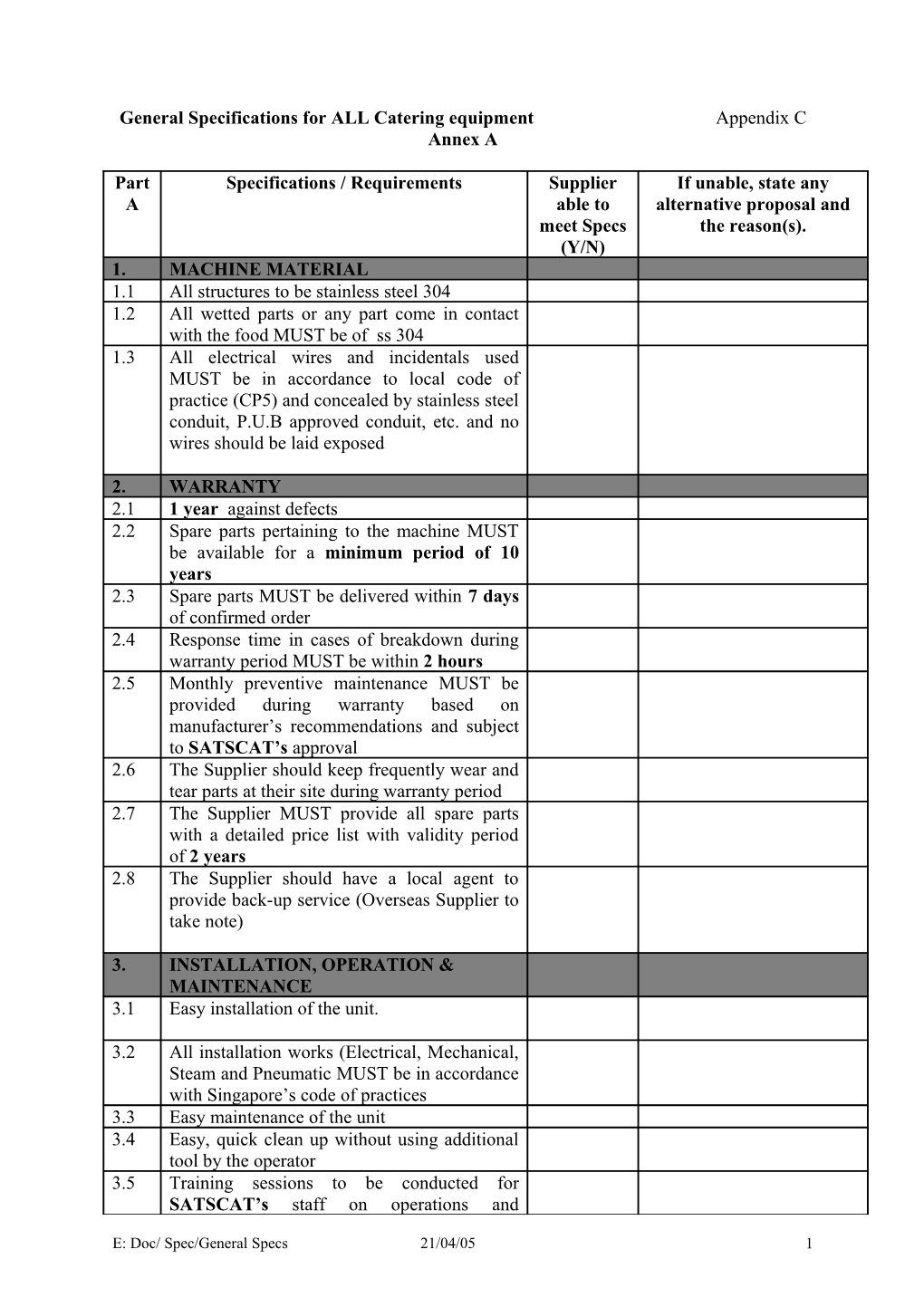

General Specifications for ALL Catering equipment Appendix C Annex A

Part Specifications / Requirements Supplier If unable, state any A able to alternative proposal and meet Specs the reason(s). (Y/N) 1. MACHINE MATERIAL 1.1 All structures to be stainless steel 304 1.2 All wetted parts or any part come in contact with the food MUST be of ss 304 1.3 All electrical wires and incidentals used MUST be in accordance to local code of practice (CP5) and concealed by stainless steel conduit, P.U.B approved conduit, etc. and no wires should be laid exposed

2. WARRANTY 2.1 1 year against defects 2.2 Spare parts pertaining to the machine MUST be available for a minimum period of 10 years 2.3 Spare parts MUST be delivered within 7 days of confirmed order 2.4 Response time in cases of breakdown during warranty period MUST be within 2 hours 2.5 Monthly preventive maintenance MUST be provided during warranty based on manufacturer’s recommendations and subject to SATSCAT’s approval 2.6 The Supplier should keep frequently wear and tear parts at their site during warranty period 2.7 The Supplier MUST provide all spare parts with a detailed price list with validity period of 2 years 2.8 The Supplier should have a local agent to provide back-up service (Overseas Supplier to take note)

3. INSTALLATION, OPERATION & MAINTENANCE 3.1 Easy installation of the unit.

3.2 All installation works (Electrical, Mechanical, Steam and Pneumatic MUST be in accordance with Singapore’s code of practices 3.3 Easy maintenance of the unit 3.4 Easy, quick clean up without using additional tool by the operator 3.5 Training sessions to be conducted for SATSCAT’s staff on operations and

E: Doc/ Spec/General Specs 21/04/05 1 maintenance of the unit. 2 sessions for operators and 3 sessions for Technical staff. The training must include theory and practical 3.6 To provide 3 sets of Installation, Operation, Maintenance,Troubleshooting and Servicing Manuals(English/Chinese Versions)inclusive of routine maintenance and preventive maintenance checklists supplied by the manufacturer. Awarded supplier has to submit their maintenance schedule and particulars of the staff working at SATSCAT 3.7 Operating procedures and safety instructions have to be clearly labeled onto the machine imprinted on stainless steel plate including cleaning method. Stainless steel ID tag must be provided 3.8 Must provide a proper chemical or cleaning procedure attached with Material Standard Data Sheet

4. SAFETY FEATURES 4.1 All safety features MUST comply with local and international ISO standards 4.2 Mechanical and electrical installations and safety devices to be provided and MUST comply with local safety rules and regulations 4.3 Any noise generated by the machine MUST be within the MOM guideline without hearing protector aid, when installed at SATSCAT 4.4 All electrical controls and the mechanical moving parts must be covered 4.5 Safety devices for covers/doors must be incorporated 4.6 The covers of the machine must be fitted with limit switches for areas that may lead to accident i.e. cutting area, moving chains/roller conveyors

5. OTHERS 5.1 Video pertaining to the general operation of the machine 5.2 Machine MUST be at an ergonomic working height for SATSCAT workers 5.3 If compressed air is needed, the unit must be equipped with filter, lubricator and regulator 5.4 Good Local Support

6. OPTIONAL ITEMS (To submit by Suppliers) 6.1

E: Doc/ Spec/General Specs 21/04/05 2 6.2

Supplier MUST provide the following items in a separate attachment in details:

Part DESCRIPTION ATTACHMENT C REFERENCE NO. 1 To provide brief description of how the unit operates. 2 To provide installation floor area needed inclusive of maintenance and operation accessibility. 3 To provide installation manual. 4 To provide manufacturer recommended maintenance schedule based on 8 hour working shift, 12 hour shift and 24 hour shift. 5 To provide spare parts/accessories list and unit price in SGD. (Indicate most critical and wear and tear parts as spare parts). 6 To provide detailed dimensions of the whole machine in isometric and schematic drawings. 7 To provide all M and E services requirements eg. drainage, exhaust, ventilation and capacity of the compressed air supply needed. Also, to provide any other additional accessories or components needed. 8 To submit as-built drawings. 9 To provide clear brochures (preferably coloured) of your proposed equipment. 10 To provide the list of standard components/tools that are part of the machine. 11 To list and quote for optional fittings.

Supplier MUST provide the details in the Remarks column provided:

Part DESCRIPTION Remarks D 1 Unit Price (exclude GST and OPTIONAL ITEMS) Inclusive of delivery, installation and commissioning and ALL essential features for machine to function properly.

A) By Air : B) By Sea : 2 Brand/Model 3 Country of Origin 4 Warranty Period 5 Lead-time A) SIN B) Ex-Factory/Port

NOTE for Suppliers : · You are to indicate if each specification could be met. If not, you are to provide an alternative proposal (if any) - i.e. the specs from the unit that you are proposing.

E: Doc/ Spec/General Specs 21/04/05 3 · Failing to comply and to specify the required information above accordingly and accurately will render you to be disqualified automatically. · NO alteration is allowed to be made on the specifications.

NAME OF COMPANY :

CONTACT PERSON / NUMBER. :

SIGNATURE :

COMPANY STAMP :

E: Doc/ Spec/General Specs 21/04/05 4