SPOT THE SAFETY VIOLATION: Best Practices for Avoiding Entanglement in Drills

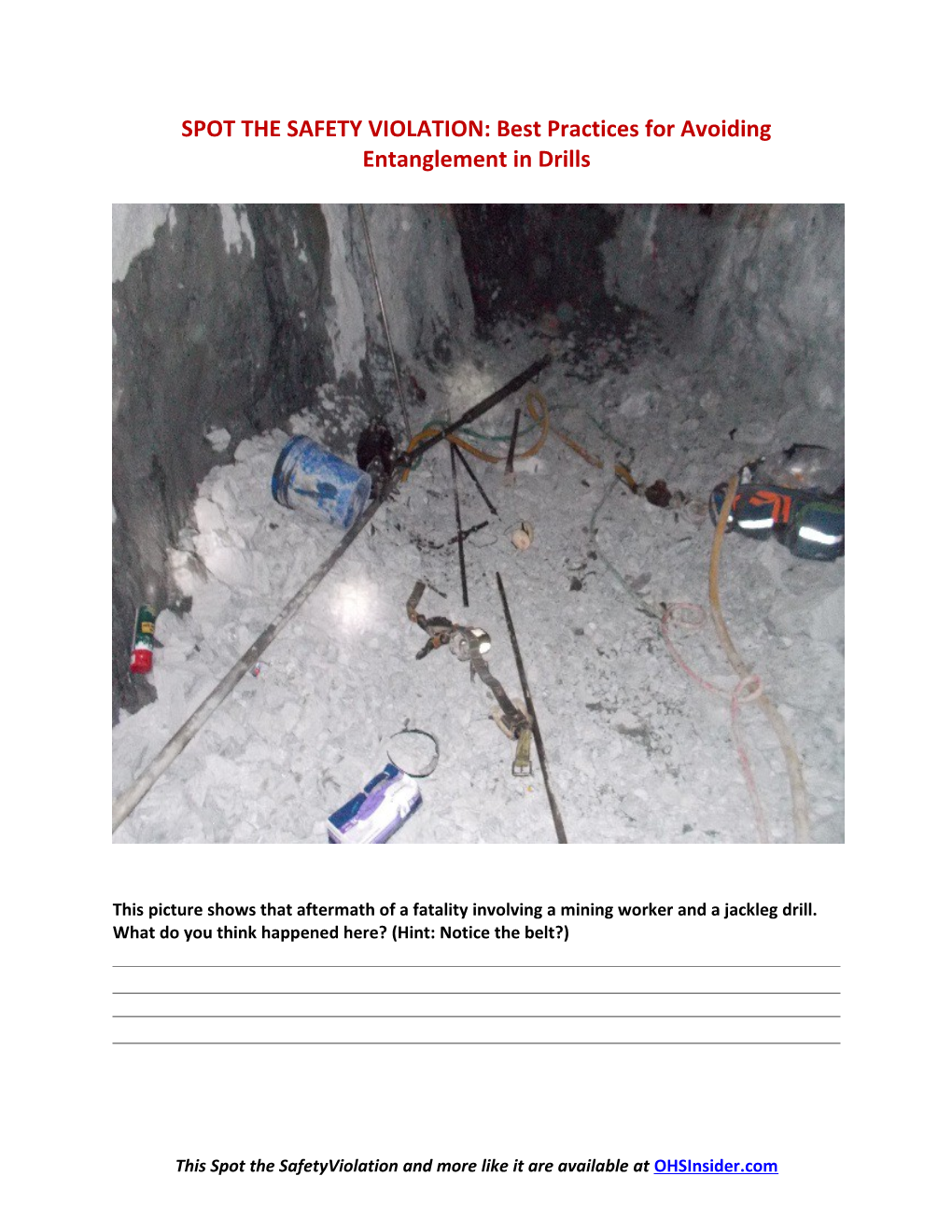

This picture shows that aftermath of a fatality involving a mining worker and a jackleg drill. What do you think happened here? (Hint: Notice the belt?)

This Spot the SafetyViolation and more like it are available at OHSInsider.com If appropriate safety measures aren’t in place, workers’ clothing, hair, jewellery and even PPE can get caught in moving parts of equipment. Entanglement in machinery can result in broken bones, amputations—and even deaths.

This picture from the US Mine Safety and Health Administration (MSHA) is of the aftermath of a fatality in a gold mine in Nevada. A 53-year-old worker was killed when he got entangled in the 6-foot drill of a jackleg drill. A co-worker found his coveralls entangled in the drill, which was still operating when he was found. The cause of death was attributed to compressive asphyxia.

Because drills utilize rotating parts, entanglements in them are far too common. For example, the MSHA noted these similar incidents: A 22-year old rock drill operator was fatally injured when his clothing got entangled in a rotating drill while spot drilling at a dimension stone quarry. A 53-year old miner with 32 years of experience died in an underground metal mine when his clothing became entangled while he was operating a jackleg drill.

Of course, entanglements involving clothing are hardly unique to the US—or to drills.

Example: A certified machinist in New Brunswick was operating a lathe when his sleeve got caught on the spinning metal. His hand and arm were pulled between the spinning jaws and chuck, and a fixed part of the lathe. He pressed the emergency stop button on the machine and pulled his arm out. But he sustained deep cuts to his left palm and the top of his left forearm.

BEST PRACTICES FOR DRILLS

If your workers use drills or other equipment similar to the one involved in the incident in the picture, make sure you take all reasonable steps to ensure that they don’t become entangled in that equipment. And be sure that you comply with any applicable requirements in the OHS laws in your jurisdiction.

Also consider adopting some of these best practices from the MSHA for the safe use of drills: Examine the drill and the surrounding work area before beginning drill operations. Ensure that the area is free from tripping hazards and that drilling materials are safely arranged and well-organized to prevent incidents. The MSHA investigation of the incident from the picture found that management failed to ensure procedures were established to ensure the workplace was kept clean and orderly. For example, the stope contained large rocks, air and water hoses, drill steels, and an oil container, exposing the deceased worker to slip, trip and fall hazards as he moved about while drilling. Establish written policies for the type of clothing and methods to secure clothing when working around drills and assure the policies are followed. For example, bar workers from wearing loose-fitting or bulky clothing when working around drilling machinery. Avoid using objects that could get entangled with or thrown from moving or rotating parts.

This Spot the SafetyViolation and more like it are available at OHSInsider.com Stay clear of augers and drill stems that are in motion. Stop the drill rotation when performing tasks near the rotating steel. Never pass under or step over a moving drill stem or auger. Drill from a position with good footing and access to the controls. Never manually thread the drill steel while the drill head is rotating. Don’t hold the drill steel when collaring holes, or rest your hands on the chuck or centralizer. Assure that machine controls and safety devices such as emergency shutdowns operate effectively. Never nullify or bypass machine control safety equipment or remove any protective guards. Place emergency shut-down devices, such as panic bars, slap bars, rope switches, two- handed controls, etc., in easily accessible locations. Safely position hoses and cables on and around drilling equipment. Design proper hangers, guides, stand-offs and entrances to eliminate the necessity of handling hoses or cables in close proximity to rotating or moving equipment. Communicate regularly and frequently with drillers to assure they’re safe and well. Workers who are alone may not be able to get help when needed. For example, the investigation of the incident from the picture found that the deceased worker was working alone in an area where he couldn’t be seen or his cries for help could be heard by another worker.

This Spot the SafetyViolation and more like it are available at OHSInsider.com