A green alliance between coal and biomass Alex E. S. Green, ICAAS-CCTL University of Florida, Gainesville FL. 32611-2050

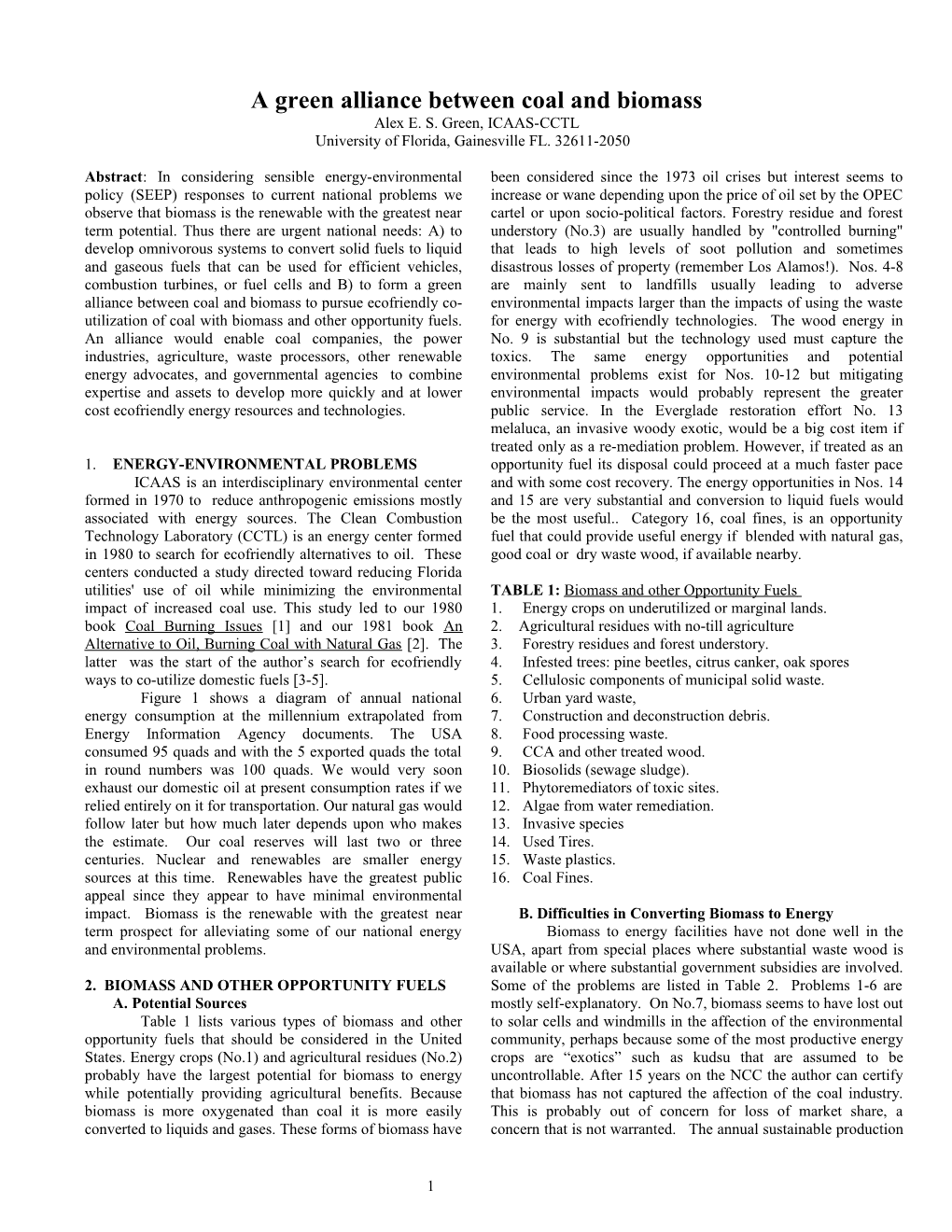

Abstract: In considering sensible energy-environmental been considered since the 1973 oil crises but interest seems to policy (SEEP) responses to current national problems we increase or wane depending upon the price of oil set by the OPEC observe that biomass is the renewable with the greatest near cartel or upon socio-political factors. Forestry residue and forest term potential. Thus there are urgent national needs: A) to understory (No.3) are usually handled by "controlled burning" develop omnivorous systems to convert solid fuels to liquid that leads to high levels of soot pollution and sometimes and gaseous fuels that can be used for efficient vehicles, disastrous losses of property (remember Los Alamos!). Nos. 4-8 combustion turbines, or fuel cells and B) to form a green are mainly sent to landfills usually leading to adverse alliance between coal and biomass to pursue ecofriendly co- environmental impacts larger than the impacts of using the waste utilization of coal with biomass and other opportunity fuels. for energy with ecofriendly technologies. The wood energy in An alliance would enable coal companies, the power No. 9 is substantial but the technology used must capture the industries, agriculture, waste processors, other renewable toxics. The same energy opportunities and potential energy advocates, and governmental agencies to combine environmental problems exist for Nos. 10-12 but mitigating expertise and assets to develop more quickly and at lower environmental impacts would probably represent the greater cost ecofriendly energy resources and technologies. public service. In the Everglade restoration effort No. 13 melaluca, an invasive woody exotic, would be a big cost item if treated only as a re-mediation problem. However, if treated as an 1. ENERGY-ENVIRONMENTAL PROBLEMS opportunity fuel its disposal could proceed at a much faster pace ICAAS is an interdisciplinary environmental center and with some cost recovery. The energy opportunities in Nos. 14 formed in 1970 to reduce anthropogenic emissions mostly and 15 are very substantial and conversion to liquid fuels would associated with energy sources. The Clean Combustion be the most useful.. Category 16, coal fines, is an opportunity Technology Laboratory (CCTL) is an energy center formed fuel that could provide useful energy if blended with natural gas, in 1980 to search for ecofriendly alternatives to oil. These good coal or dry waste wood, if available nearby. centers conducted a study directed toward reducing Florida utilities' use of oil while minimizing the environmental TABLE 1: Biomass and other Opportunity Fuels impact of increased coal use. This study led to our 1980 1. Energy crops on underutilized or marginal lands. book Coal Burning Issues [1] and our 1981 book An 2. Agricultural residues with no-till agriculture Alternative to Oil, Burning Coal with Natural Gas [2]. The 3. Forestry residues and forest understory. latter was the start of the author’s search for ecofriendly 4. Infested trees: pine beetles, citrus canker, oak spores ways to co-utilize domestic fuels [3-5]. 5. Cellulosic components of municipal solid waste. Figure 1 shows a diagram of annual national 6. Urban yard waste, energy consumption at the millennium extrapolated from 7. Construction and deconstruction debris. Energy Information Agency documents. The USA 8. Food processing waste. consumed 95 quads and with the 5 exported quads the total 9. CCA and other treated wood. in round numbers was 100 quads. We would very soon 10. Biosolids (sewage sludge). exhaust our domestic oil at present consumption rates if we 11. Phytoremediators of toxic sites. relied entirely on it for transportation. Our natural gas would 12. Algae from water remediation. follow later but how much later depends upon who makes 13. Invasive species the estimate. Our coal reserves will last two or three 14. Used Tires. centuries. Nuclear and renewables are smaller energy 15. Waste plastics. sources at this time. Renewables have the greatest public 16. Coal Fines. appeal since they appear to have minimal environmental impact. Biomass is the renewable with the greatest near B. Difficulties in Converting Biomass to Energy term prospect for alleviating some of our national energy Biomass to energy facilities have not done well in the and environmental problems. USA, apart from special places where substantial waste wood is available or where substantial government subsidies are involved. 2. BIOMASS AND OTHER OPPORTUNITY FUELS Some of the problems are listed in Table 2. Problems 1-6 are A. Potential Sources mostly self-explanatory. On No.7, biomass seems to have lost out Table 1 lists various types of biomass and other to solar cells and windmills in the affection of the environmental opportunity fuels that should be considered in the United community, perhaps because some of the most productive energy States. Energy crops (No.1) and agricultural residues (No.2) crops are “exotics” such as kudsu that are assumed to be probably have the largest potential for biomass to energy uncontrollable. After 15 years on the NCC the author can certify while potentially providing agricultural benefits. Because that biomass has not captured the affection of the coal industry. biomass is more oxygenated than coal it is more easily This is probably out of concern for loss of market share, a converted to liquids and gases. These forms of biomass have concern that is not warranted. The annual sustainable production

1 for energy of biomass (oxygenated coal) in the USA is region midO or MiO would be good for sub-bituminous and much smaller than the economic annual production of lignite. These terms might help foster better communications than biomass coalified (de-oxygenated) naturally over the past in today's Tower of Babel. New ranking systems are used for 300 million years. Problem 9 is related to USA's low football, figure skating, universities and many other purposes. energy cost strategy which is the main problem of biomass Why not solid fuels? (see Conclusion). Higher heating values of various fuels measured with Paar calorimeters are usually given in proximate analysis reports. Table 2: Problems with Biomass Utilization Approximate HHVs in metric units for the six representative 1. Biomass is hard to feed or mechanically process. CHOs are given in the fifth column in Table 3. These numbers 2. Low density limits economic transport distances are based upon a compromise between Dulong formulas used in 3. Seasonal availability presents problems off-season the coal and biomass sectors [6-10] which is given at the bottom 4. The high moisture content of plant matter of Table 3. The carbon energy contribution (A[C]/3) is generally 5. Herbaceous forms have higher alkali metal content that much larger than the hydrogen energy contribution (6A). Oxygen fosters ash melting (slagging/fouling) contributes negatively, (-A [O]/8). 6. Difficult to exploit economy of scale The sixth column gives representative "total volatiles", 7. Has not gained the affection of environmentalists VT, as determined by an American Standard Test Measurement 8. Has not gained the affection of the coal industry Method (ASTM)). A coal sample is heated (pyrolyzed) in an 9. Does not compete with coal or natural gas in the USA inert atmosphere using a platinum crucible at 950 oC for seven minutes. The weight percent loss between the sample and its char 3. TECHNICAL ASPECTS is the total volatile yield. The increasing trend in V T from high to A. Ultimate and Proximate Analysis low rank "coals" is important. An approximate equation for VT is Table 3 shows major categories of coals and some given at the bottom of Table 3. The numbers in the seventh properties that have measured by the coal industry for over a column of Table 3 are for the complementary fixed carbon (FC = century. Also shown are the properties of wood. The 100 – VT for pure CHO materials). The patterns in Tables 3 and ultimate and proximate analyses numbers listed are Figures 2, are crying out "We are Family". corrected to apply for dry, ash, nitrogen, and sulfur free The eighth column gives nominal densities for the various feedstock (DASNF) i.e. pure carbon, hydrogen, and oxygen CHO fuels. The ninth column gives the product of columns 5 and (CHO) materials. Figure 2 is a plot of [H], the wt% of 8, the energy density (E/vol in MJ/liter). Its rapid decline of from hydrogen (solid diamonds with values read on the left scale) LoO to HiO fuels is what limits the transportation distance for vs [O], the wt % of oxygen, for 185 representative DANSF biomass. The tenth column gives the relative char re-activities CHO materials taken from ultimate analysis data available (RelchR). The eleventh column gives a qualitative picture of the in the technical literature [6-9]. The bottom scales give free H and OH radicals that are released in high temperature conventional coal ranks, some potential names for the pyrolysis. Since high char reactivity and free radicals facilitate biomass region and some names that might foster more thermo-chemical processes, HiO materials have advantages over friendly discussions. This [H] vs [O] coalification plot loOs. Blending HiOs with LoOs provides a simple way of shows that apart from the anthracite region all natural applying useful properties of one rank to assist thermal processing DANSF feedstock have hydrogen wt% that are close to 6%. of another, a valuable technical reason for co-utilization. The Also shown on Fig. 2 by the open squares (read on right twelfth column suggests quantitative coal rank designations. scale) are the data for [C] vs[O]. The near constancy of [H] Approximate equations for various properties vs [O] are given and the smooth decline of [C] with increasing [O] provide below the table. strong reasons for treating peat and biomass simply as lower B. What's in the Volatiles? rank coals. It was recognized throughout the 20th century that The differing coal classification systems used volatiles from solid fuels are very important properties that throughout the world causes confusion in R&D and in influence the design of solid fuel combustion, gasification or global coal trade. Thus it would be good to develop some liquification systems. Nevertheless, at the beginning of the 21st simple quantitative ranking system for natural carbonaceous century we still cannot predict what gaseous compounds are in (CHO) fuels. The oxygen weight percentage (i.e.. 10-O for the volatiles released in proximate analysis measurements. Nor bituminous, 44-O for wood) as given in Table 3, perhaps can we predict the rate constants for their release [10]. If the with the hydrogen weight percentage with one decimal volatiles were mostly CO2 or H2O vapor they would have little place (i.e. 5.7-H) would seem to provide an unambiguous fuel value. On the other hand if the volatiles are mostly CO, CH4, quantitative index. Words or numbers could be used to give and H2 they could be suitable for many applications. The physical characteristics and the moisture, ash and minor problem is largely due to the complexity of the liquids and tars species content. Using 34-O for peat called "turf" in Ireland [11-13] among pyrolysis products. Nevertheless, the primative might help reduce emotional responses state of the basic-applied science that underlies humankind’s associated with the many “turf wars” manifested in fuel oldest technologies, the extraction of energy out of wood and sector competitions and also in energy-environmental coal, suggests that some misplaced priorities have been used in confrontations. For qualitative discussions high O coal, HiO national R&D funding. coal, or HiO CHO or just HiO for biomass and low O coal In our efforts to systematize the many pyrolysis or LoO, for the coal region could be used. For the middle products we have developed analytic formulas that can generate

2 output tables for the hundreds of products that have been used in times of high demand or sold to nearby utilities or observed in pyrolysis. We have presented them at technical industry. Technologies for improving the shelf life of these society meetings [14--16] not with the claim that they pyrolysis liquids are under development. Co--liquifying biomass accurately represent reality since little quantitative data is with coal would bring more abundant resources into the "pot" and available but rather as a challenge to specialists in the coal use the reactive properties of the HiOs to facilitate the conversion and biomass fraternities to develop better formulas. of the LoOs [20]. Among the commercial organizations working on 4. NATIONAL CO-UTILIZATION BENEFITS pyrolysis of biomass to liquid fuels and chemicals only a few are A. The Co-firing Option based in the USA. Generating ethanol via fermentation of corn to Several of the problems noted in Table 2 associated produce high value gasoline additives probably consumes more with exclusive use of the biomass noted in Table 1 can be liquid fuel than it generates. It might do more for our liquid fuel overcome if these fuels were co-fired at a nearby utility or deficit if the residue, xylage, were also converted to liquid fuels industrial plant in relatively small proportions (say 5-15% perhaps with co-liquefying technology. Using the xylage for by energy) with the coal or natural gas normally used. cattle feed might lead to over-production of beef and foster Some problems might develop such as increased slagging, obesity, a national epidemic. however, several of the major forms of biomass listed in Another form of liquid co-utilization would be to blend used Table 1 can be handled at standard industrial or utility plants vegetable oil with pyrolysis liquids for use in diesel engines. with modest retrofit costs. Developing technologies for blending vegetable oil with pyrolysis There are many variations of co-firing technology. liquids from HiO-LoO mixtures would substantially multiply the For smaller utilities, factory fabricated robust solid fuel impact of the used vegetable oil. systems can serve a valuable role. Since biomass is relatively easy to gasify one could build a separate HiO D. Phytoremediation gasifier at the coal or NG plant and direct its gaseous The use of plants as pollution sponges to cleanse toxic sites products into a suitable combustion zone of the coal or and contaminated bodies of water has a very large potential [21]. natural gas flame. Co-firing biomass or biomass generated Special plants can: 1. remove metal contaminants, 2. Treat gas in the coal fireball can lower NOx emissions. organic contaminants, 3. Remove radioactive contaminants and 4. Extract contaminants from sewage sludge. The technology is B. The Co- gasification Option growing rapidly and with all the toxic sites that need re-mediation The omnivorous feedstock conversion system the plant matter produced should be very substantial. mentioned earlier is needed to change solid fuels into The mining community could benefit by developments in gaseous or liquid forms to make them suitable for use with phytoremediation and corresponding plant processing advances. efficient energy systems. Examples are combustion In addition to re-mediation of used mine lands, the industry could turbines, co-gen systems, combined cycle systems, fuel cells make use of phyto-mining, a new technology for extraction of and even fuel cell-turbine combinations. A major valuable metals that will also benefit from the development of environmental advantage of the co-gasification option phytoremediation technologies. The author is a co-investigator comes when disposing of materials laden with toxic on a small NSF grant with Professor Lena Ma, who discovered a substances. Here it should be possible to condense out, fern that thrives on arsenic. Pyrolysis/gasification is the only chemically scrub or adsorb toxic metallics such as arsenic, promising proposed way to dispose of toxic laden biomass mercury, lead etc.. after the gasifier but before the turbine. without re-contaminating the environment. Since widely The volume of gas that must be scrubbed is then much differing plants are used for phytoremediation it is essential to smaller than the volume involved if one combusts the gas bring order into the chaotic science of pyrolysis. Spiking the and then srubs the stack gases [17,18]. A recent economic phyto-remediating plant material with a higher heating value analysis indicating that coal's mercury problem can be feedstock (i.e. a MiO or LoO CHO material) could improve the brought under control with much lower capital costs via the process and the gaseous products. Knowing what's in the volatiles gasification route rather than direct combustion route would facilitate LoO-HiO blending decisions in thermo-chemical supports this general conclusion [19]. processing of toxic laden biomass. Our excessive reliance on liquid imported fuels is 5. CONCLUSIONS the main energy problem of the USA (see Figure 1). With 9/11, the Enron bankruptcy, the recession, the C. Biomass Liquifaction unemployment rate, the trade and budget deficits it is imperative Liquifiers of biomass, mostly under development that citizens of the USA close ranks on a sensible in Europe and Canada provide a complementary path to energy/environmental policy (SEEP). Because of the many gasification for biomass utilization [11-13]. Because of their potential sources of easily converted solid fuels (see Table 1) and high oxygen content biomass is easier and requires less their adverse environmental impacts if not utilized with energy to bring into liquid (or gaseous) forms. Liquids are ecofriendly technologies a natural component of a SEEP is “A easier to store than gaseous fuel and to use than solid fuels. green alliance between coal and biomass”. The author borrowed These advantages, well recognized in the transportation this title from an EU program that began in 1992 (see Europa and sector, can also apply to industries and utilities. Thus when Netherland links), however, this "Green" has been trying, liquid production exceeds needs the pyrolysis liquifier can unsuccessfully, to forge such an alliance since joining the NCC in be maintained at its full production rate and the stored fuel 1986. In the European Union where energy is highly taxed the

3 competition with fossil fuels is not as severe. Thus EU co- 3. Urban forestation (elms) utilization programs, rather than socio-economic-political 4. Wood buildings and carbon products problems, have mainly focused on technical problems and 5. Reforestation abroad have brought forth many technological innovations [22-32]. D. Phytoremediation In the USA Integrated Gasifier Combined Cycle (IGCC) 1. Remediate toxic sites systems, developed mainly for the use with coal (LoOs and 2. Restoration of mined lands MiOs), have dealt with some co-gasification problems. 3. Foster phyto-mining However, most IGCC developments do not take advantage E. Provide opportunities and challenges for of the ease and low energy costs of gasifying and liquifying coal companies and coal-based power generation HiO materials. Table 4 list mutual advantages to the coal, companies to develop ecofriendly solar energy power and biomass industries and particularly to the United resources and technologies in the public interest States of "a green alliance between coal and biomass” (Gabcab). II. What can Coal do for Biomass? From the standpoint of the NCC report on “Increasing A. Make Opportunity fuels economically competitive Coal Fired Generation (ICFG) Through 2010” we believe 1. Lower capital cost of co-utilization (co-firing) the alliance would support ICFG and provide. opportunities 2. Foster use with turbine generators (co-gasifying) and challenges to broaden the base of ICFG. Such B. Provide economic agricultural alternatives supporters could include the agricultural community waste 1. Energy crops processors, environmentalists, and other sectors that could 2. Use of agricultural residues benefit by solving the problems the alliance could undertake 3. Disposition of problem plant matter (see Table1) (seeTable 4). As a member of the WW II generation whose 4. Overcome biomass-use problems (see Table 2) way of life was immediately altered by the attack of 12/7/41 [33] he is aghast at the lack of rank closing following the III. What can Serious Cooperation do for the U.S.A.? more visceral attack of 9/11/01. A green alliance between A. Foster ecofriendly use of existing coal facilities coal and biomass would: 1. Develop a biomass market and the fuel supply infrastructure Make it possible to pursue energy and environmental 2. Enable biomass to make substantial liquid fuel contributions goals without being considered SCHIZOPHRENIC. 3. Foster the chemical and liquid fuel factory development Deem those still against best available ecofriendly use B. Mitigate anti-environmental image of USA of all domestic energy sources just plain NUTS. 1. Lower CO2 emissions 2. Lower pollution and toxic emission problems 5. ACKNOWLEDGEMENTS 3. Foster advanced environmental technologies This work was supported by a grant from the Mick 4. Foster phyto-remediation, phyto-mining A. Naulin Foundation, part of a National Science C. Help level the research and innovation playing field Foundation Grant for the disposal of phyto-remediators, the 1. Improve competition with high energy cost countries College of Engineering and Green Liquids and Gas 2. Foster the long overdue development of pyrolysis science Technologies. The author thanks Professor John Cameron, 3. Foster a quantitative ranking system for all “coals” Dr. Evan Hughes, Mr Andrew Hines Jr, and Professor 4. Foster development of more general fuel co-utilization Sanford Berg for helpful comments. D. Facilitate a sensible energy-environmental policy

Footnote: A two-day International Conference (IC) specialized on technical aspects of Co-utilization of Domestic Fuels (CDF) will be held at the University of Florida, February 5 and 6, 2003 6. REFERENCES Table 4: Benefits of "A green alliance of coal and 1. A. Green, ed. (1980), Coal Burning Issues, University biomass" Presses of Florida. 2. A. Green, ed. (1981), An Alternative to Oil, Burning Coal I. What can Biomass do for Coal? with Gas, University Presses of Florida. A. Co-firing Biomass with Coal 3. A. Green, et al., (1986), “Coal-Water-Gas, An All American 1. Lower CO2, SO2 and NOx emissions Fuel for Oil Boilers”, Proc. of the Eleventh Intern. Conf. on 2. Extend life of coal facilities Slurry Technology, Hilton Head, SC. 3. Foster ecofriendly use of coal facilities 4. A. Green, ed. (1988), Co-Combustion, Fuel and Combustion 4. Foster IGCC, IG-cogen, CHP and chemical Technology (FACT) Div. of the American Society of factories. Mechanical Engineers (ASME), New York, B. Co-gasifying Biomass with Coal 5. A. Green, ed. (1991), Solid Fuel Conversions for the 1. Facilitate conversion to gases and liquids Transportation Sector, ASME-FACT, New York, NY. 2. Provide important environmental roles for coal 6. S. Stultz, J. Kitto, ed. (1992), Babcock & Wilcox, Steam 40th 3. Facilitate capture of mercury and other toxics Edition, Barberton, Ohio. C. CO2 Sequestration, Nature's Way 7. J. Singer, ed. (1981), Combustion-Fossil Power Systems, pp. 1. Federal land reforestation, new national parks 16-23 Combustion Engineering Inc., Windsor. 2. Interstate highway plantings

4 8. S. Gaur, T. Reed, ed. (1998), Thermal Data for Natural Mixtures, European Union Clean Coal Technology and Synthetic Fuels, Marcel Dekker Inc., New York. Programme 1992-1994, Stuttgart. 9. D. Klass, (1998), “Biomass for Renewable Energy, 23. R. Van Ree (1997), "Cogasification of Coal and Biomass Fuels, Chemicals”, 234-236. Academic Press, San Waste in Entrained-Flow Gasifiers, Phase 1: preliminary Diego, CA. study " ECN-C-97-021 10. P. Solomon, M. Serio, E. Suuberg, (1992) “Coal 24. R Korbee, S. Eenkhoorn, P. Heere, J.. Kiel, "Co-gasification Pyrolysis Experiments Kinetic Rates and Mechanisms”, of coal and biomass waste in entrained-flow Gasifiers, Phase Progress Energy and Combustion Sciences Vol. 18, 2: Exploratory Lab scale Experimentation" ECN-C-98-056 pp135-220. 25. H den Uil, P. Bergman, A. Boersma, "CASST A new process 11. T. Milne, N. Abatzoglou, R. Evans, (Nov 1998), for biomass Gasification" ECN CX-01-030 “Biomass Gasifier 'Tars'": NREL/TP-570-25357. 26. C. Storm,. H. Rudiger, H., Spliethoff, and K. Hein., (1998), 12. T. Milne, R. Overend, (1994), “Fast Pyrolysis, Biomass Co-Pyrolysis of Coal/Biomass and Coal/Sewage Sludge and Bioeneregy”, Vol 7, No.1-6. Mixtures”,International Gas Turbine and Aeroengine 13. A. Bridgewater, A. Peacocke, (2000), "Fast Pyrolysis Congress & Exhibition, Stockholm, June 2-5, proceedings Processes for Biomass, Renewable & Sustainable 98-GT-103. ASME New York, NY. Energy Reviews”,v. 4,1 1-73. 27. A. Collot, A. Megaritis, A. Herod, D. Dugwell and 14. A. Green, J. Mullin, (Oct 1998), “Feedstock Blending R. Kandiyoti, (1998) Co-pyrolysis of coal and biomass in a Studies with Laboratory Indirectly Heated Gasifiers”, pressurized fixed bed reactor ibid [31] Jour. Eng for Gas Turbines and Power, V121, pg. 1-7 28. C. Guanxing, Y., Qizhuang, C. Brage, C. Rosén, C., and 15. A. Green, P. Venkatachalam, M. Sankar, (2001), K. Sjöström, , (1999), "Co-Gasification of Coal/Biomass “Pyrolysis Systematics for Co-utilization Applications”, Blends in a Pressurized Fluidized Bed Reactor,” ASME IASTED’s Power and Energy Systems Conf., Tampa, TURBO-EXPO 99 paper 99-GT-191. FL. 29. E. .Kurkela, (1996), "Recent Results and Plans Concerning 16. A. Green, P. Venkatachalam, M. Sankar, (2002c), Co-Gasification of Biomass and Coal- An Overview," Proc. “Feedstock Blending in Gasifiers/Liqufiers”, Proc. Biomass for Energy and the Environment, 9th EU Bioenergy ASME Turbo Expo 2002, Amsterdam. Conference. 17. .A. Green, G. Schaefer,(1999), “Feedstock Blending in 30. A. Minchener, (1999), "Syngas Europa,” Mechanical Indirectly Heated Gasifiers/liqueifers ”, Paper 99-GT- Engineering, ASME, New York, N.Y. 81, Turbo Expo, 1999, Indianapolis, IN. 31. Y. Pan.., G. Velo, X. Roca, J. Manya and L. Puigjaner 18. D. Nilsson, A.Green (1999), "Thermal Disposal of (2000) Fluidized-Bed Co-gasification of Residual CCA Treated Wood" Paper 99-938, Air and Waste Biomass/Poor Coal Blends for Fuel Gas Production, Fuel 79 Management Conf. June , Sr Louis, Missouri 32. A. Bridgewater (2001) ThermoNet =PyNe + Gas Net, No. 12 19. M. Klett, M. Rutkowski, (2002), “The Cost of Mercury 33. A.Green, (2001), “A Physicist with the Air Force in World Removal in an IGCC Plant”, Letter Report prepared for War II”, Physics Today, Aug., pp. 40-44. See link 4. The United States Department of Energy. 20. F. Karaca, E. Bolat, (2000), “Coprocessing of Turkish Links lignite with a cellulosic waste material”, Fuel Process 1. http://europa.eu.int/comm/research/success/en/ene/0060e.html ‘the Technology, v. 64: n1-3 pp. 47-55. green alliance of coal and biomass’ 2. http://www.ecn.nl/library/reports/1997e/c97021.html is the link of 21. The Science Times, NY Times of March 6, 2001 Energy research Centre of the Netherlands, The Netherlands 22. J. Bemtgen, K. Hein, A. Minchener, (1994), 3. http://plaza.ufl.edu/aesgreen/icaas/ the web link for ICAAS-CCTL Cogasification of Coal/Biomass and Coal/Waste 4. http://www.physicstoday.org/pt/vol-54/1ssp40.html

Table 3: ASTM classification of coals by rank (for DASNF fuels) USA Energy Renewables 4 Renewables Table 3Ultimate AnalysisProximate4 AnalysisOther properties123456789101112Name[C][H] ConsumptionFigure Domestic1: (Left) OilTotal 14 Annual USA energy consumption in quads at the millennium (Right) Renewables [O]HHVV FCChDensE/volRelchRH,OH RadQ - RankAnthracite9433367931.6581.5v. low3 CoalT 21.5 Hydro Electric 3.6 -OBituminous855103533671.4495low103 -OSubHydro Bitum755203051491.23616med20 Electric 3.6 -OLignite7052527584212750interm25 -OPeat606342369310.818150high343 -OWood497441881190.611500v. high44 -O Ultimate,[H] = 6 [1-exp -[O]/2], Proximate VBiomass = 62 hx1/2 where3.5 h=[H]/6 and x=[O]/25, HHV = A {[C]/3 + [H] -[O]/8}, T Biomass 3.5 Imported Oil 23 Renewable 7.5 2 Geothermal 0.3 where A=1.08MJ/Kg, Density= 1.68- 0.64x2 ; E/ vol = 70 exp -x , RelchRGeothermal = exp 3.7x 0.3

Nuclear 7.5 Solar 0.07 1 Solar 0.07 1 Natural Gas 21.5 Wind 0.03 Wind 0.03 at the 5 Millennium 0 0 0 10 20 30 40 50 10 100

C =100- H - O 8 80

6 60

H=6(1-exp(-O/2)) 4 40

2 20

Lo O Mi O Hi O 0 0

metaant subanth bita mvbit hvbitb subitb ligniteb leonard peatb bark wooda woodb ag waste

carbon anthr lvbit bitb hvbita subita lignitea brown peata peatc shells agric Ecrop COALS OLD MATURE ADULT YOUNG DEVELOPING INFANT COALS Figure 2: Weight percentages of hydrogen [H] vs [O] for 185 DASNF carbonaceous materials (black diamonds) vs oxygen wt% (read left scale) the upper curve and data shows [C] (open squares) vs [O] (read right scale)

6