RSF18/24 - 01 Fan Assembly & Maintenance Manual

Please read the complete Assembly and Maintenance section of these instructions before operating this fan.

Assembly

1. Remove the fan and accessories from the shipping carton and inspect for shipping damage.

2. Remove the plastic protective slip covers from the fan and frame members. Unfold both sets of feet into the proper position after loosening their two bolts slightly. Secure with two additional hex bolts and locking nuts (from accessories box) as shown in Fig. 1. Tighten all four bolts securely.

3. Undo the two Velcro straps that secure the motor air line. Cut the ¼” diameter nylon air line to length and attach it to your speed control (shut off) valve at the outlet of your FRL (Filter/Regulator/Lubricator). This fan requires an air filter, regulator and automatic inline lubricator feeding the air motor. Air supply should be filtered to 5 microns, regulated to 100 PSI maximum and must include a mist oiler (lubricator).

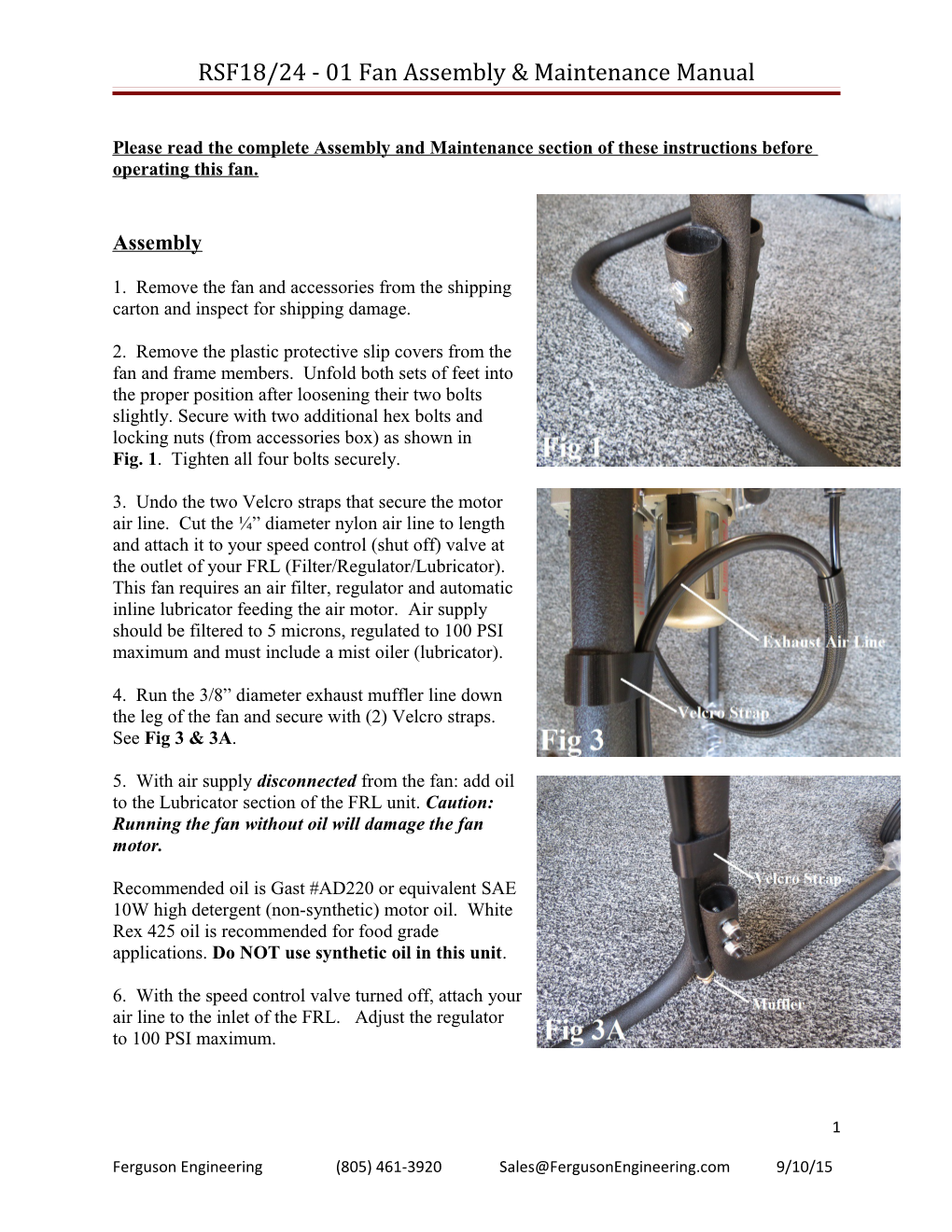

4. Run the 3/8” diameter exhaust muffler line down the leg of the fan and secure with (2) Velcro straps. See Fig 3 & 3A.

5. With air supply disconnected from the fan: add oil to the Lubricator section of the FRL unit. Caution: Running the fan without oil will damage the fan motor.

Recommended oil is Gast #AD220 or equivalent SAE 10W high detergent (non-synthetic) motor oil. White Rex 425 oil is recommended for food grade applications. Do NOT use synthetic oil in this unit.

6. With the speed control valve turned off, attach your air line to the inlet of the FRL. Adjust the regulator to 100 PSI maximum.

1

Ferguson Engineering (805) 461-3920 [email protected] 9/10/15 RSF18/24 - 01 Fan Assembly & Maintenance Manual

7. Check oil flow rate: The oil flow rate for your fan must be set before use. Run the fan at top speed, speed control valve turned all the way open, and observe oil drops at the sight glass. Most lubricators have a sight glass at the top of the lubricator that allows you to monitor oil droplets as they are entering the compressed air stream going to the motor. Gast recommends an oil rate of 1 drop of oil per 50 cubic foot of air usage. At full fan speed (6 CFM) this equates to 1 drop every 7 minutes or less for your fan. Adjust the oil flow rate as needed. Periodically check that the lubricator is functioning properly. Running the fan without oil will damage the fan motor.

8. Your fan is now ready for operation. Open or close the speed control handle as needed to regulate the speed of the fan. Keep in mind that opening the valve only as much as needed for adequate air flow will conserve compressed air.

9. Two optional rubber bushings are supplied that can be applied, if desired, to one of the cross members of the stand feet. See Fig. 5.

Maintenance

Caution: Disconnect the air supply from the fan before performing any maintenance on the unit.

Caution: When adjusting fan tilt, always retighten black knobs on either side of fan guard securely to ensure that they do not work their way loose during operation.

Caution: The air motor on this fan is equipped with an ”over-speed” fitting. The S.S. pipe fitting threaded directly into the motor inlet port is equipped with an internal throttling orifice. Do NOT run fan without this fitting or the blade will turn at excessive speed which could result in fan damage and personal injury. If the orifice in this fitting is suspected of being blocked, remove the ¼” diameter air line at the “instant fitting” and use a thin probe up through the center of the fitting to clear the opening (1/16” Allen wrench, or similar object can be used.)

1. Lubrication. Check the oil level in the lubricator each time the fan is used and replenish as needed (see oil filling and adjusting instructions in the Assembly section above). Do NOT use synthetic oil in this unit.

Running the fan without oil will damage the fan motor.

2. Cleaning. To clean fan blades: Disconnect air supply from the fan. Remove the screws/clips that secure the front half of guard and lift off. Clean fan blades with a mild detergent (being careful not to bend the fan blades) dry, and then reassemble the guard.

3. Air Filter Drain. Check and drain any moisture that is trapped in the air filter bowl regularly. 2

Ferguson Engineering (805) 461-3920 [email protected] 9/10/15 RSF18/24 - 01 Fan Assembly & Maintenance Manual

4. Dry Air Supply. The air supply to this fan should be a free of water. Excess moisture can cause rusting of the air motor internals and lead to fan motor failure.

5. Grounding. Grounding. In applications where it is considered necessary to ground the fan we recommend dual grounding. Utilizing one of the (3) socket head machine screws that fasten the motor to the back of the fan guard. Remove the screw (3/16” hex key), add the grounding wire, terminated with a correctly sized electrical eyelet (for ¼” screw), and retighten the screw to 100 in-lbs. In addition, the wire guard itself should also be grounded. Behind the rear guard identification plate there is an opening that is predrilled for grounding. Carefully cut out the foil label around the opening (just to the right hand side of the “Ferguson Engineering” text) and use a self-tapping screw & star washer to attach a ground wire to the sheet metal of the wire guard.

6. Gast motor instructions are included with these instructions for reference.

3

Ferguson Engineering (805) 461-3920 [email protected] 9/10/15