Page 1 (15)

PROCEDURE AND REQUIREMENTS FOR INSTALLATION OF ELECTRICAL EQUIPMENT

Heading Designation

General Requirements MBE 101

Version

5 en

Content

1 GENERAL...... 2 1.1 Introduction ...... 2 1.2 Scope ...... 2 1.3 Document Structure, Content ...... 3 2 DEFINITIONS...... 4 3 REGULATIONS...... 7 4 PROCESS CONTROL...... 8 4.1 Process Flow ...... 8 4.2 MBE's Function in Preparation for Electrical Installation ...... 9 4.3 Professionalism and Requirements for Authorisation, Certification ...... 9 4.4 New Regulations and Instructions ...... 10 5 SEPARATION...... 10 5.1 General ...... 10 5.2 Non-Hazardous Areas

Designation Version Date Replaces MBE 101 5 en 2007-03-20 4 en

09 年 10 月 9 日 (0498a477d16780251028807a378d015c.doc) MBE 101 Version 5 en Page 2 (15)

...... 12 5.3 Hazardous Areas ...... 12 5.4 Marking ...... 12 6 ENVIRONMENTAL ENDURANCE...... 12 7 SEISMIC REQUIREMENTS...... 13 8 INSTALLATION REQUIREMENTS...... 13 9 CABLE CLASSIFICATIONS...... 13 9.1 Power Cables ...... 13 9.2 Instrumentation and Control Cables ...... 13 10 ITEM DESIGNATIONS...... 13 11 MARKING AND SIGNPOSTING...... 14 11.1 CE-marking...... 14 12 DRAWING SYMBOLS...... 14

1 GENERAL

1.1 Introduction MBE and MKE is a documentation system intended to control the processes, which influence the technical/quality workmanship of electrical installation in plants Oskarshamn/ Forsmark 1, 2, 3, CLAB and SFR. MBE is a Swedish acronym for procedure and requirements for Installation of Electrical equipment, and MKE refers to the corresponding inspection requirements. The purpose is to ensure the quality of the electrical installation and by that fulfil the assembly requirements on the equipment so that the electrical function will fulfil the requirements in totally e.g. in certain circumstances be qualified to manage DBE/DBA. A uniformity way of workmanship with use of standards in design and materials makes it possible to reduce the time and cost for the installation. MBE is entirely focused on installation. Related questions referring to design, manufacture or other matters than those contained in the role of working with electrical installation in the FKA/OKG organisation, are controlled by other documents, to which MBE refers as necessary. All electrical installation shall be planned in installation binders, using MBE. After preparation, the installation binder forms complete technical documentation of the electrical installation, for approval that the workmanship is according the requirements.

09 年 10 月 9 日 (0498a477d16780251028807a378d015c.doc) MBE 101 Version 5 en Page 3 (15)

MBE and MKE assume that those who lead, prepare and carry out work on electrical installation have the basic professional competence and craftsmanship needed for the work.

1.2 Scope MBE contains requirements for electrical installation in conjunction with maintenance, modification and new plant components. Please refer to item 8 below.

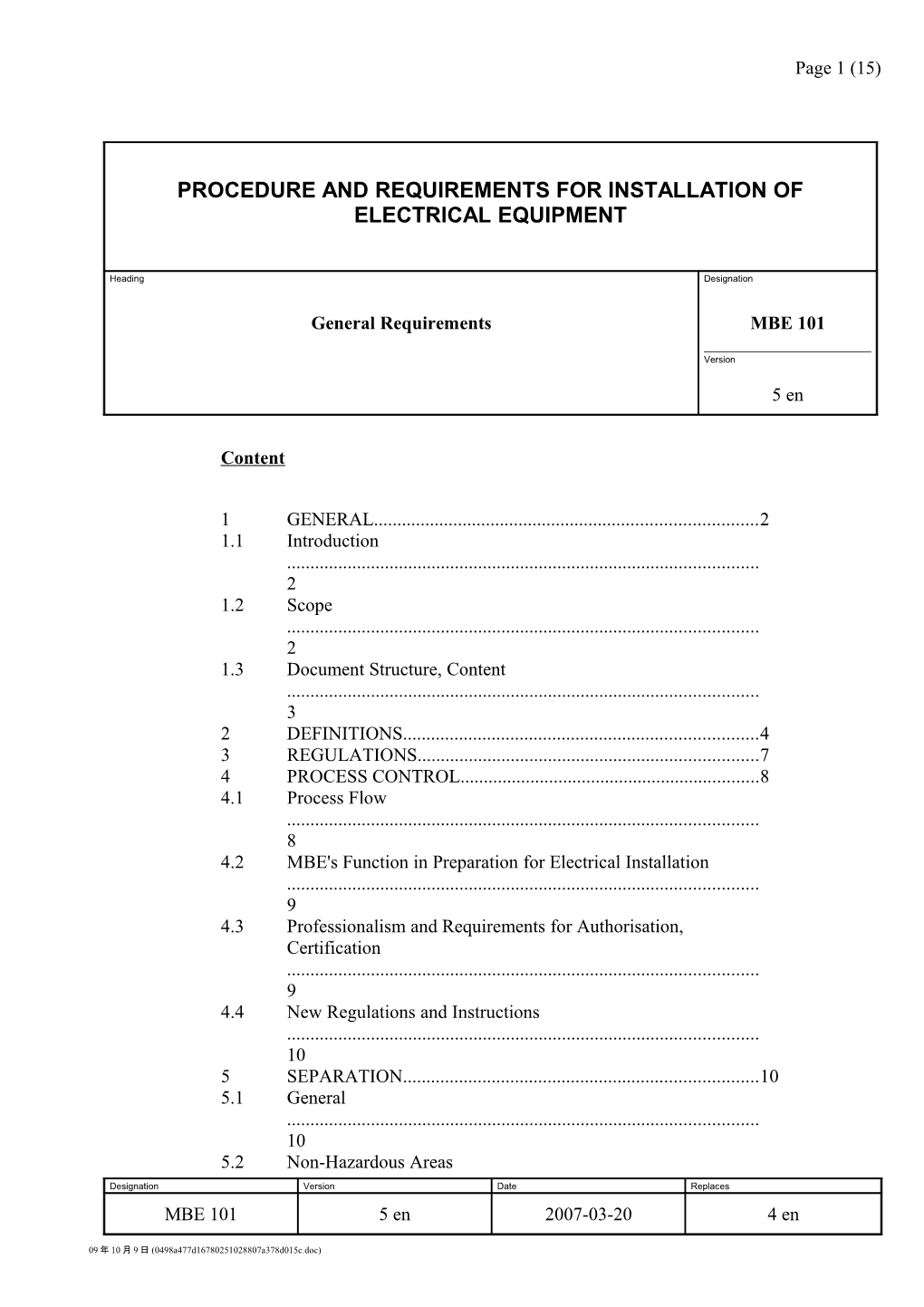

1.3 Document Structure, Content The various documents in the MBE jointly indicate standardised solutions for covering requirements, depending on the function requirements which apply to various environments, DBE/DBA, other electrical and mechanical requirements and opportunities for carrying out the installation work. The document structure is explained in Figure 1

Figure 1, “Installation regulations for electrical equipment and Installation inspection regulations for electrical equipment “

MBE HA is an administration instruction intended to be a help when MBE is used in installation planning. MBE 101 is a summary document to use together with other MBE documents. MBE 201-901 specifies basic requirements with supplementary requirements for seismic design and installation in severe environments. They are primarily aimed at personnel who prepare and supervise electrical installation. It is used in preparing detailed installation instructions or new MBE MI.

09 年 10 月 9 日 (0498a477d16780251028807a378d015c.doc) MBE 101 Version 5 en Page 4 (15)

MBE MI is the installation instructions, which specify detailed requirements for a specific installation. They are primarily aimed at those who carry out electrical installation work. In order to avoid updating in both the MBE and MBE MI, some facts are only noted in the MBE MI. The intention is also that the information should also embody documentation in the installation binder and should be easy to use by the person doing the plant installation. Where facts are required, the MBE refers to the MBE MI.

2 DEFINITIONS There is no complete and uniformly defined definition standard for the activities related to plant installation. If MBE is to work as intended, it is thus necessary to define various central terms. These definitions only have the ambition of applying to MBE, however.

Associated Component (circuit) Components, which are not safety classified, can become associated through Direct electric connection to safety classified components or other associated components. Proximity to other safety classified or other associated component without sufficient physical separation. [Adapted from IEEE Std 384-1992]

DBE/DAB – Design Basis Event/Accident Postulated events/accidents in the plant used in the design to establish the performance requirements of the structures and systems

Electrical Equipment Room An area, which is only intended for electrical equipment, and which does not contain hot or pressurised process components. Corresponds to the operation room in the main voltage Swedish regulations for design and maintenance. [TBE 100]

Electrical Function Class 1E Electrical safety functions refer to IEEE 384 2E Electrical operation functions refer to IEEE 384 3E Electrical service functions refer to IEEE 384 Cat A Safety functions refer to IEC 61226 Cat B Safety relation function refer to IEC 61226 Cat C Safety relation function refer to IEC 61226 Cat 0 Of no account for the safety refer to IEC 61226

09 年 10 月 9 日 (0498a477d16780251028807a378d015c.doc) MBE 101 Version 5 en Page 5 (15)

Electrical Installation at Plant Installation in conjunction with new construction, maintenance or modifications to existing plant, with the requirements for workmanship which ultimately apply to operation and maintenance MBE.

09 年 10 月 9 日 (0498a477d16780251028807a378d015c.doc) MBE 101 Version 5 en Page 6 (15)

Environmental Endurance The ability to perform as intended in various environmental conditions. Environmental conditions are divided into three (basic) levels of severity. Severity A: equipment outside the reactor containment Severity B: equipment in hot process areas outside the reactor containment Severity C: equipment in the reactor containment Please refer to MBE 103 as well [TBE 101]

Hazardous Area Is divided in 3 categories Non-hazardous: an area with control- and instrument functions, but with only power supply for its own power requirements. Limited hazardous area: similar to a high risk area, without its restrictions, but outside the risk free area Hazardous area: area in or in the vicinity of equipment which contains high power energy, such as switchgear, transformers, rotating machinery where faults in pipes, consequential water hammer, pipe failure with flooding, missiles, steam jets and/or pipe whip or explosions/fire could occur.

Hot Component Components that through heat emission from e.g. process pipe the wide cable's connection point is set for temperature in excess of +50°C outside reactor inclusion alternative +70°C in reactor inclusion must be connected with special adapted to environmental demand materials.

Installation 1. To join together various electrical and mechanical components to a functional unit. 2. All activities required to physically implement a change (carry out installation) in the plant under the given conditions, quality, time and cost.

Installation Inspection Check that the installation work carried out complies with the stated quality requirements. See MKE 101

Installation Binder One binder for each individual section of installation in a project. The binder shall contain all documentation the fitter needs to do the work correctly. General installation instructions do not need to be included. An inspection plan with subordinate inspection plans including necessary reports shall be included. There is a detailed description in MBE HA.

09 年 10 月 9 日 (0498a477d16780251028807a378d015c.doc) MBE 101 Version 5 en Page 7 (15)

Jeopardy Incident/state, which occurs due to no fault of the component, affected. Influence over or damage to equipment, which is caused by other equipment not qualified for the task or environment, to cause consequential damage.

Preparation All activities, which create the background for allowing electrical installation to result in approved workmanship as specified, i.e. correct quality. This is subdivided into three main activities Work preparation using OKGs/FKAs administrative procedures. Preparation of materials using MBE and technical documentation, e.g. TBE. Preparation of installation using MBE. The result of preparation shall be summarised in one or several installation binders, depending on the scope and type of work.

Preparation of Installation Activity where all tasks in the work of installation are identified and the background conditions created which are required for creating approved installation with the workmanship requested. The necessary documentation and instructions shall be summarised in an installation binder.

Preparation of Materials Activity where all requisite material is identified and compiled for purchase, and that the documentation for material kits is compiled in the installation binder. [MBE]

Qualified Component or Function Status given to a component or function, on condition that it complies with certain specified requirements. An electrical qualified component together with adjusted electrical construction installation qualified to manage the DBE/DBA requirements, compose a qualified electrical function.

Self-Inspection Inspection of own work. To be done and documented by the person or persons who have done the work. Shall be documented and carried out before installation inspection.

09 年 10 月 9 日 (0498a477d16780251028807a378d015c.doc) MBE 101 Version 5 en Page 8 (15)

Separation To isolate safety classified sections of the plant from other safety classified or operationally classified sections physically or functionally, to create independent, redundant safety functions. During electrical installation, separation is achieved by isolating safety classified sections from other safety classified sections or operationally classified sections of the plant, by installing them with sufficient distance between, or by putting up barriers.

Work Preparation Activity in which all necessary background material is created to allow the installation work to be done at the plant, such as work permits, decontamination, scaffolding, access etc. The documentation shall be compiled in each installation binder for electrical installation.

3 REGULATIONS The result of electrical installation in OKGs/FKAs plants must comply with the requirements in the Swedish national electrical regulations, and are thus tied to Swedish Standards. The work shall comply with the National Institute of Occupational Health regulations, ESA contractor, and FKAs/OKGs local regulations etc. In addition to these requirements, there are also installation requirements specific to nuclear power stations. The general application of these requirements for electrical installation is found in the MBE. In special cases, such as electrical installation in hazardous areas, the regulations shall be interpreted applied by the responsible designer, who will create documentation to govern the electrical installation.

09 年 10 月 9 日 (0498a477d16780251028807a378d015c.doc) MBE 101 Version 5 en Page 9 (15)

4 PROCESS CONTROL

4.1 Process Flow The result of electrical installation, approved to the required standard, can be seen as a product of processes and activities in a flow, which contains both influence and feedback. Figure 2 illustrates this flow.

Need of Installation

Maintenance Modification AU New FU Management- and support Design functions for Document the process. governing the process. Preparation Purchase Adm. TBE Management KBE Planning KA Installation Following-up MBE Service MKE

Control/Testing

Documentation

Taking over Operation experiences

Figure 2, “Electrical installation seen as a process flow”

09 年 10 月 9 日 (0498a477d16780251028807a378d015c.doc) MBE 101 Version 5 en Page 10 (15)

4.2 MBE's Function in Preparation for Electrical Installation Preparation for installation is done to create the correct conditions for electrical installation, please refer to Figure 3

Installation binder DocumDocum entation entation for for Installation binder electricalelectrical construction construction Preparation Complete documentation for installationsinstallations Preparation Complete documentation for approvalapproval of of required required Includ Includ performanceperformance eses electrielectri cal,cal, Figure 3, “Preparation ofmecha Installation”mecha nicalnical andand buildin During preparation, decisionsbuildin are made about what is to be done and the MBE contains gg notes about how the measuqualitymeasu will be achieved. There are basically three levels of requirements, as shownresres in Figure 4, where basic professionalism is assumed and necessary, and the MBE, which species more stringent demands in general and special demands for seismic design and requirements for work in harsh environments.

MBE Severe environm . and seism ic requirem . MBE Basic requirem ents

Basic professionalism

Figure 4, "Competence Requirement Levels for Electrical Installation Works

4.3 Professionalism and Requirements for Authorisation, Certification Basic professional competence is required of all personnel who participate in the process, in addition to the MBE, to ensure that installation quality leads to approved workmanship to the required standard The person who does electrical installation without supervision must have good documented training and experience from such work. The person who plans and leads the work shall have good, documented experience from similar work in industry and power plants, preferably from nuclear power plants. This also means that they must be able to work independently, formulate problems related to work themselves, and preferably be able to train others as necessary, please refer to Table 1.

09 年 10 月 9 日 (0498a477d16780251028807a378d015c.doc) MBE 101 Version 5 en Page 11 (15)

The professionalism or the professional person is defined in the Swedish national regulations ELSÄK-FS chapter 2. 1§ 3, as a person who also has sufficient knowledge and experience to be able to preclude the risks associated with electricity. This means that they must know about the operation conditions and the external influences to which objects might be subjected, and the measures need to counteract this. This can refer to high or low ambient temperature, damp, presence of water or corrosive substances, radiation, mechanical damage, vibration etc. Installation shall be done in such a way that the objects are accessible for maintenance and modifications.

Area of competence Leader/Planner Fitter

Regulations/ESA/ Demands in each unit. Demands in each unit. SAFEM Should be able to read Should be able to understand Documentation functional demands. the orientation of list items. Must know the practical Must understand the contents Material difference in the use of of TBE/MBE. different materials. Must understand the Shall know the specific demands on processes/ Processes/Methods demands of different methods in various processes/methods. environments. Must be able to use the entire Must be able to use the MBE/MKE MBE and understand the installation binder MBE MI. connection to MKE.

Table 1, “Competence Requirements for Supervisors and Fitters”

Authorisation is needed for certain tasks, such as soldering, terminal installation, termination of high voltage cables, installation of expanding fasteners; certification based on training which has been carried out and participation in tests whose results are approved. During project planning, these tasks shall be identified so that the people doing the assignments have the appropriate competence.

4.4 New Regulations and Instructions If there is no suitable regulation in the MBE, new ones shall be drafted in accordance with OKG’s/FKA instructions and advice. If there is no suitable instruction in the MBE MI, a new one shall be drafted in accordance with the MBE

5 SEPARATION

5.1 General Separation in electrical installation means physically separating components with different safety classifications and operation classifications to permit independence. Each such safety-classified section is called a sub. They are designated A; B; C; or D.

09 年 10 月 9 日 (0498a477d16780251028807a378d015c.doc) MBE 101 Version 5 en Page 12 (15)

Components which are not safety classified or operationally classified are normally designated M or N. Separation shall function so that if a fault or other malfunction occurs in any section of the plant during operation, it shall not have any adverse effect on any other section, which is safety classified. Physical separation is installing equipment with sufficient distance between the various components or putting up barriers. If it is not possible to separate operationally classified and safety classified equipment belonging to a particular sub, the operationally classified equipment will be associated with the safety classified equipment. This means that the equipment must be handled as if it was safety classified and belonging to the sub. See example in Figure 5. Association should be avoided if possible. If a situation occurs where it can not be avoided, the responsible designer should be contacted to request a new design solution or to ensure that a special analysis is carried out to determine what effect this has on safety, and any measures which need to be taken in consequence.

Inuti kapsling Delad- eller närhet till kabelväg Säkerhetsklassad Säkerhetsklassad kabel nr3 Kabelstege för säkerhets- utrustning klassad kabel

Hjälpkontakt

Associerad < D kabel nr 4 < D

Kabelväg Associerad kabel nr 5 D

Driftsklassad kabel nr 6 Driftsklassad kabelstege Associerad Associerad Säkerhets kabel nr 7 kabel nr 2 Kabelstegar för klassad < D associerade kablar kabel nr1 D= Minsta separationsavstånd Drifts- Säkerhets- och/eller barriär klassad klass Kabel Funktionsklass Anledning till associering 1 Säkerhet 2 Drift Närhet till kabel nr 1 3 Säkerhet 4 Drift Delad kabelstege 5 Drift Kabelstegens närhet till kabelstege med säkerhetsklassad kabel 6 Drift 7 Drift Kabelstegens närhet till kabelstege för associerad kabel innehållande kabel nr 5.

Figure 5, "Separation"

09 年 10 月 9 日 (0498a477d16780251028807a378d015c.doc) MBE 101 Version 5 en Page 13 (15)

5.2 Non-Hazardous Areas In non-hazardous areas or limited hazardous areas, separation of safety classified components is achieved by means of the standardised rules which specify demands for distance between the subs, operationally classified sections and/or various barriers, please refer to the figure and table. The application of these rules is described in MBE 201. The rules are based on the risk of internal faults, which could occur in cables or other equipment. If any deviation is made from these rules, the responsible engineer must ensure that a particular analysis is carried out to determine whether the requirement for independence is still met. It is also important to avoid turning non-hazardous areas into hazardous areas by incorrect installation of equipment. Such as incorrectly installing conventional lighting so that it would risk falling down in an earthquake and damage equipment which is safety classified, so-called jeopardy.

5.3 Hazardous Areas During planning of electrical installation in hazardous areas, a special safety analysis shall be carried out, which should give answers about where cables and other equipment can be located in the area without risk of influence from fire, pipe hammer, missiles or other high energy events which could cause damage. The responsible designer must ensure that this analysis is carried out. When electrical installation is planned in such an area, the exact areas, which entail a risk of damage to the installed equipment, must be specified in the background material. Measures must be taken to ensure that installation is carried out outside the hazardous area, that some form of barrier is put up to protect against damage, or other solution which ensures that independence is obtained/maintained. The necessary documentation must be prepared in collaboration between the responsible designer and the installation planner in order to succeed with electrical installation in such areas.

5.4 Marking All objects must be marked to clearly indicate the sub to which they belong. Within the area it must be easy to see the marking.

6 ENVIRONMENTAL ENDURANCE Electrical installation shall be carried out in such a way that the desired properties of the equipment are achieved. This means clarifying the environmental conditions and adapting installation thereafter. Important environmental conditions and additions shall be noted in TBE 101/102 via the technical specification. The MBE specifies how installation must be carried out in environments with differing basic severity and also specifies any supplementary requirements. Please refer to MBE 103.

09 年 10 月 9 日 (0498a477d16780251028807a378d015c.doc) MBE 101 Version 5 en Page 14 (15)

7 SEISMIC REQUIREMENTS There are no general rules for seismic requirements, which can be used for planning electrical installation. Apart from certain seismic designs noted in the MBE, the installation shall be done in accordance with mechanical drawings. The workmanship of the installation shall finally be assessed and approved by the responsible mechanical designer. The central controlling document is GIP, Generic Implementation Procedure for Seismic Verification of Nuclear Plant Equipment.

8 INSTALLATION REQUIREMENTS Primarily the specifications in the design documentation for the electrical installation shall be followed. If design documents are missing, the performance shall fulfil the requirements in the MBE-documents or new documents according to paragraph 4.4. Requirements on verification and documentation of performed work are given in MKE 101 paragraph 6.

9 CABLE CLASSIFICATIONS

9.1 Power Cables Power cables are subdivided into two categories. Class 1 Cables for voltages over 1000 V. Class 2 Cables for voltages below 1000 V, but over 250 V.

9.2 Instrumentation and Control Cables Instrumentation and control cables comprise cables for measurement, control, and signal purposes. Class 3 Cables for voltages below 250 V, but over 60 V, which can not be included in, class 4. Class 4 Cables for analogue measurement signals and sensor signals, and cables for voltages below 60 V. Class 5 Neutron flux measurements. Class 6 Opt cables.

10 ITEM DESIGNATIONS The principles for item designations are based on various systems of design and documentation systems for Forsmark/Oskarshamn 1, 2, 3 CLAB , SFR and other sites. The design instructions for each installation describe how the item designations are specified. A summary of the principles is given in the MBE MI

09 年 10 月 9 日 (0498a477d16780251028807a378d015c.doc) MBE 101 Version 5 en Page 15 (15)

11 MARKING AND SIGNPOSTING It is a requirement that marking should be carried out so that the subs to which the various components in the plant belong are clearly visible. Each insert of the MBE MI describes how marking and signposting should be carried out.

11.1 CE-marking. CE marking in accordance with OKG’s/FKA rules

12 DRAWING SYMBOLS The appearance and significance of drawing symbols varies, depending on the drawing standard or design system under which the documentation has been prepared. The symbols are described in each standard, system description or manual.

09 年 10 月 9 日 (0498a477d16780251028807a378d015c.doc)