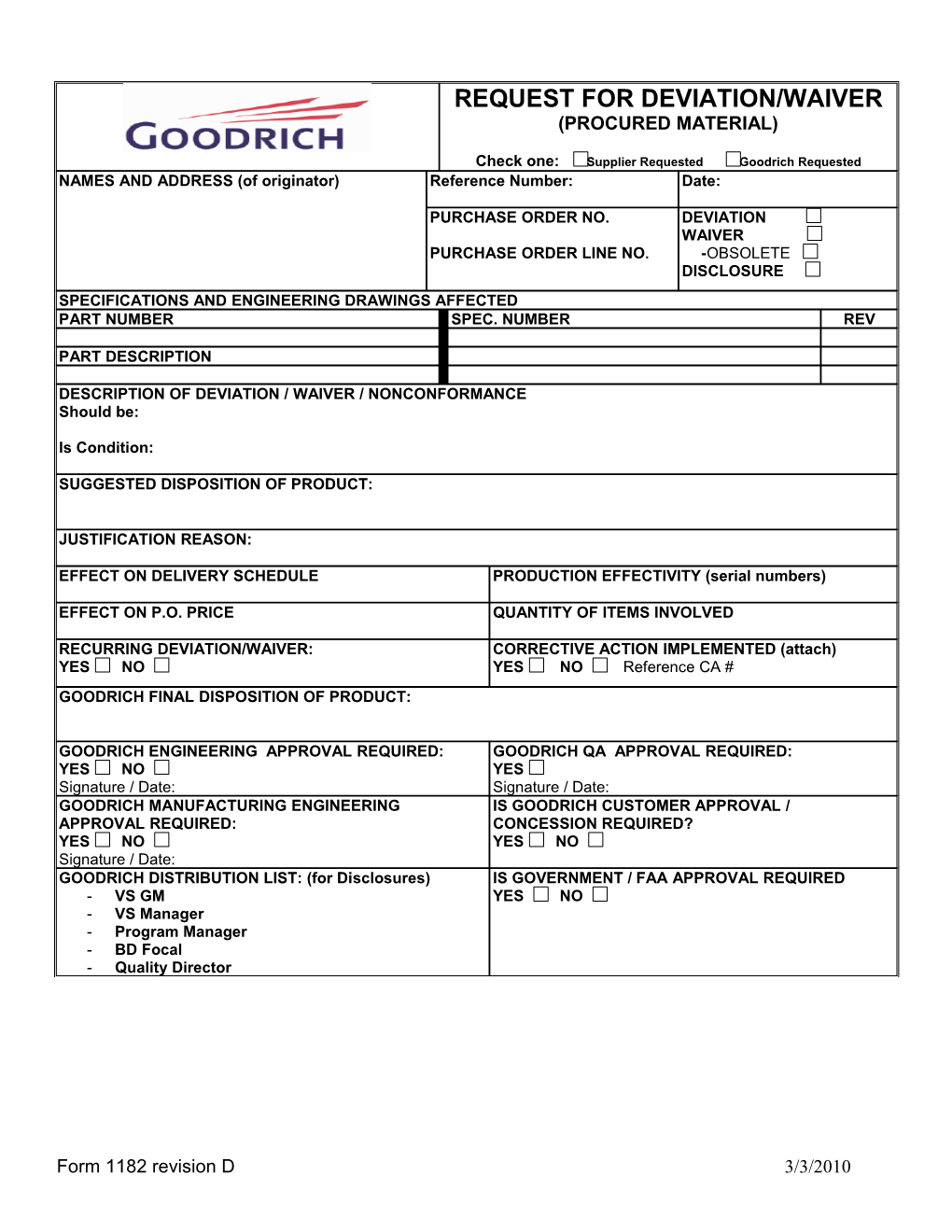

REQUEST FOR DEVIATION/WAIVER (PROCURED MATERIAL)

Check one: Supplier Requested Goodrich Requested NAMES AND ADDRESS (of originator) Reference Number: Date:

PURCHASE ORDER NO. DEVIATION WAIVER PURCHASE ORDER LINE NO. -OBSOLETE DISCLOSURE SPECIFICATIONS AND ENGINEERING DRAWINGS AFFECTED PART NUMBER SPEC. NUMBER REV

PART DESCRIPTION

DESCRIPTION OF DEVIATION / WAIVER / NONCONFORMANCE Should be:

Is Condition:

SUGGESTED DISPOSITION OF PRODUCT:

JUSTIFICATION REASON:

EFFECT ON DELIVERY SCHEDULE PRODUCTION EFFECTIVITY (serial numbers)

EFFECT ON P.O. PRICE QUANTITY OF ITEMS INVOLVED

RECURRING DEVIATION/WAIVER: CORRECTIVE ACTION IMPLEMENTED (attach) YES NO YES NO Reference CA # GOODRICH FINAL DISPOSITION OF PRODUCT:

GOODRICH ENGINEERING APPROVAL REQUIRED: GOODRICH QA APPROVAL REQUIRED: YES NO YES Signature / Date: Signature / Date: GOODRICH MANUFACTURING ENGINEERING IS GOODRICH CUSTOMER APPROVAL / APPROVAL REQUIRED: CONCESSION REQUIRED? YES NO YES NO Signature / Date: GOODRICH DISTRIBUTION LIST: (for Disclosures) IS GOVERNMENT / FAA APPROVAL REQUIRED - VS GM YES NO - VS Manager - Program Manager - BD Focal - Quality Director

Form 1182 revision D 3/3/2010 Goodrich Quality Work Instruction De-Icing & Specialty Systems Division Page 2 of 2 Form 1182 Request for Deviation / Waiver

1. Scope 1.1. This work instruction provides guidance for preparation and submission of requests for deviations or waivers from engineering drawings, specifications, Acceptance Test Work Procedure, Process Specifications, or other technical requirements imposed by a purchase order.

2. Definitions 2.1.1. Deviation- A planned variance from the configuration documentation specified on the PO which requires specific written authorization, granted prior to the manufacture of an item for a specific number of units or a specified period of time. 2.1.2. Waiver- An unplanned variance from the configuration documentation specified on the PO requiring written authorization to accept an item which, during manufacture, or after having been submitted for inspection or acceptance (including test), is found to depart from specified requirements, but nevertheless is considered suitable for use "as is" or after repair by an approved method. 2.1.3. Disclosure – A formal notification to affected customers of a delivered nonconforming product condition. 2.1.4. Production Effectivity – a list of the serial numbers or manufacturing / processing dates of affected product. Also identifies a condition when the deviation is expected to end.

3. Specification / Requirements 3.1. Deviations affecting safety shall not be submitted. 3.2. Authorized Deviations / Waivers are temporary departures from requirements and do not constitute a change to the configuration documentation identified on the PO. 3.3. Items shall not be delivered incorporating a known departure from documentation unless a request for a deviation / waiver has been processed in accordance with the requirements of this work instruction. 3.4. Customer contract and quality requirements must be met in reference to disposition of affected product.

4. Instruction

Follow work Nonconformance Has NO Does identified instruction for Nonconforming product nonconfor Material shipped to ming a product customer need to ship YES YES

QA or PM: Notify the Originator: Complete affected customers form 1182 and submit to (FAA) within 24 hours of the appropriate VS defining the issue and Quality person effectivity Corrective action, Nonconformance Safety of flight issue Safety issue QA: Review, provide Dwg violation (cust suggested disposition approved) and document as Cust contract needed END

Contract requiremen ts YES Does Goodrich hold MRB authority

QA: Provide response to NO Originator

QA: Obtain customer decision / disposition

Form 1182 revision B