Application of the quenching and partitioning treatment to a low-carbon martensitic stainless steel J. Tobata 1, N. Nakada2, T. Tsuchiyama2, S. Takaki2 1Graduate School of Engineering, Kyushu University, 744 Motooka, Nishi-Ku, Fukuoka, 819-0395, Japan. 2Dept. Material Science and Engineering, Graduate School of Engineering, Kyushu University. email: [email protected]

The Quenching and Partitioning (Q&P) treatment was applied to a commercial low carbon martensitic stainless steel, AISI Type 410, to improve its mechanical properties by using transformation-induced plasticity (TRIP) effect. In this study, the optimum quenching temperature and condition of partition treatment for retaining a sufficient amount of austenite were clarified. The mechanical property was then examined by tensile testing to reveal the efficiency of retained austenite. The specimens were austenitized at 1273K for 1.8ks and then quenched to 513K, which is a temperature between Ms (585K) 20 and Mf (485K) temperatures. 623K 723K Subsequently, the specimens were % . l 15 reheated and held at different temperature

o f v o

/

, n ranging between 623K and 723K for the e o t i i t c n a e partition treatment, followed by water- t r 10 f s

e u

a cooling to room temperature.

m d u l e o

n Fig.1 shows the change in volume v i

a 5 t e

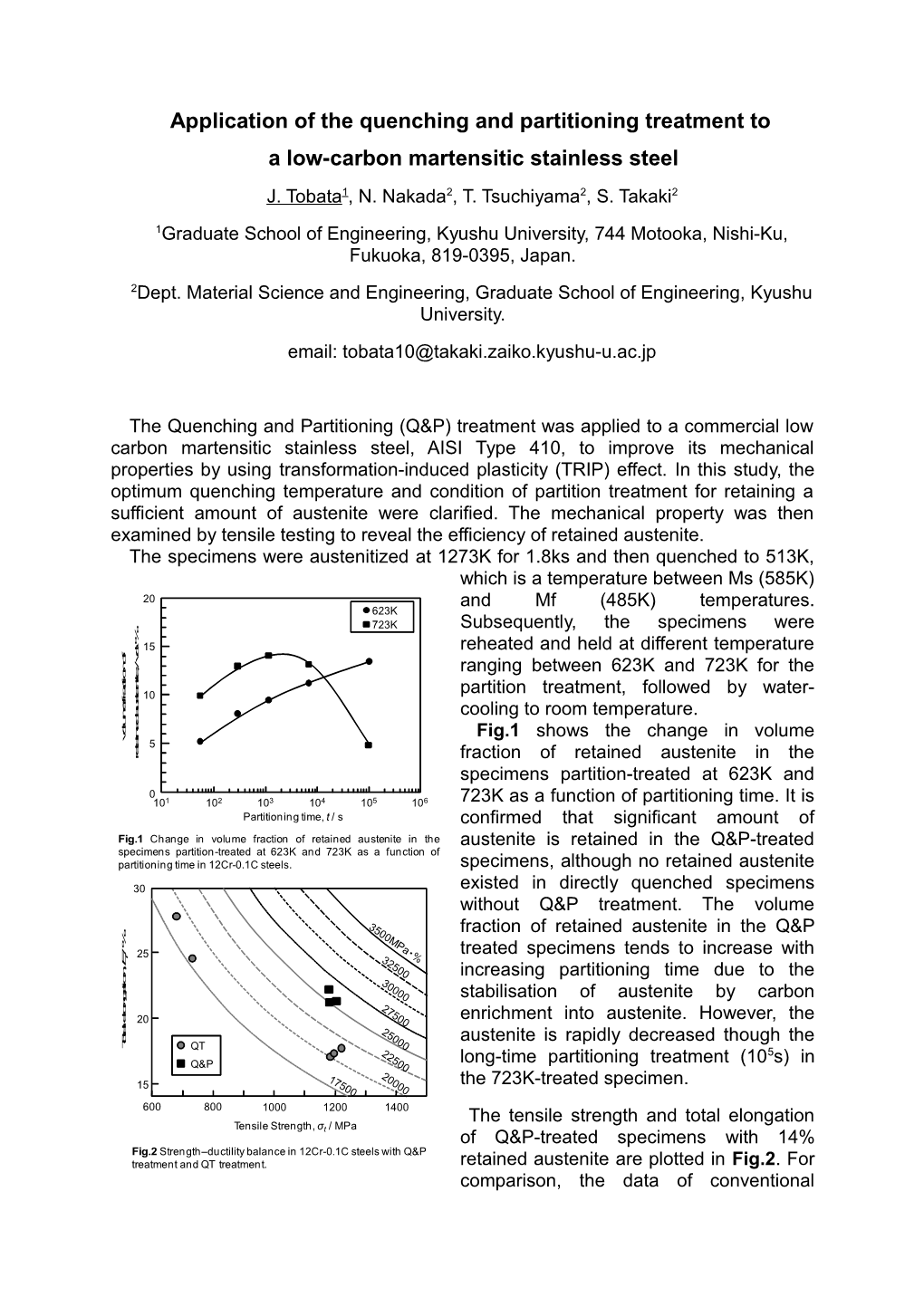

r fraction of retained austenite in the specimens partition-treated at 623K and 0 101 102 103 104 105 106 723K as a function of partitioning time. It is Partitioning time, t / s confirmed that significant amount of Fig.1 Change in volume fraction of retained austenite in the austenite is retained in the Q&P-treated specimens partition-treated at 623K and 723K as a function of partitioning time in 12Cr-0.1C steels. specimens, although no retained austenite

30 existed in directly quenched specimens without Q&P treatment. The volume fraction of retained austenite in the Q&P %

/ treated specimens tends to increase with

t 25 E

,

n increasing partitioning time due to the o i t

a stabilisation of austenite by carbon g n o l enrichment into austenite. However, the e 20 l a t

o austenite is rapidly decreased though the

T QT 5 Q&P long-time partitioning treatment (10 s) in 15 the 723K-treated specimen. 600 800 1000 1200 1400 The tensile strength and total elongation Tensile Strength, σ / MPa t of Q&P-treated specimens with 14% Fig.2 Strength–ductility balance in 12Cr-0.1C steels with Q&P treatment and QT treatment. retained austenite are plotted in Fig.2. For comparison, the data of conventional quenching and tempering (QT) is also included in the same figure. It is clearly shown that the Q&P steels express an improved strength-ductility balance compared with Q&T steels. Such a tendency of improving strength-ductility balance was confirmed to be derived from TRIP effect.