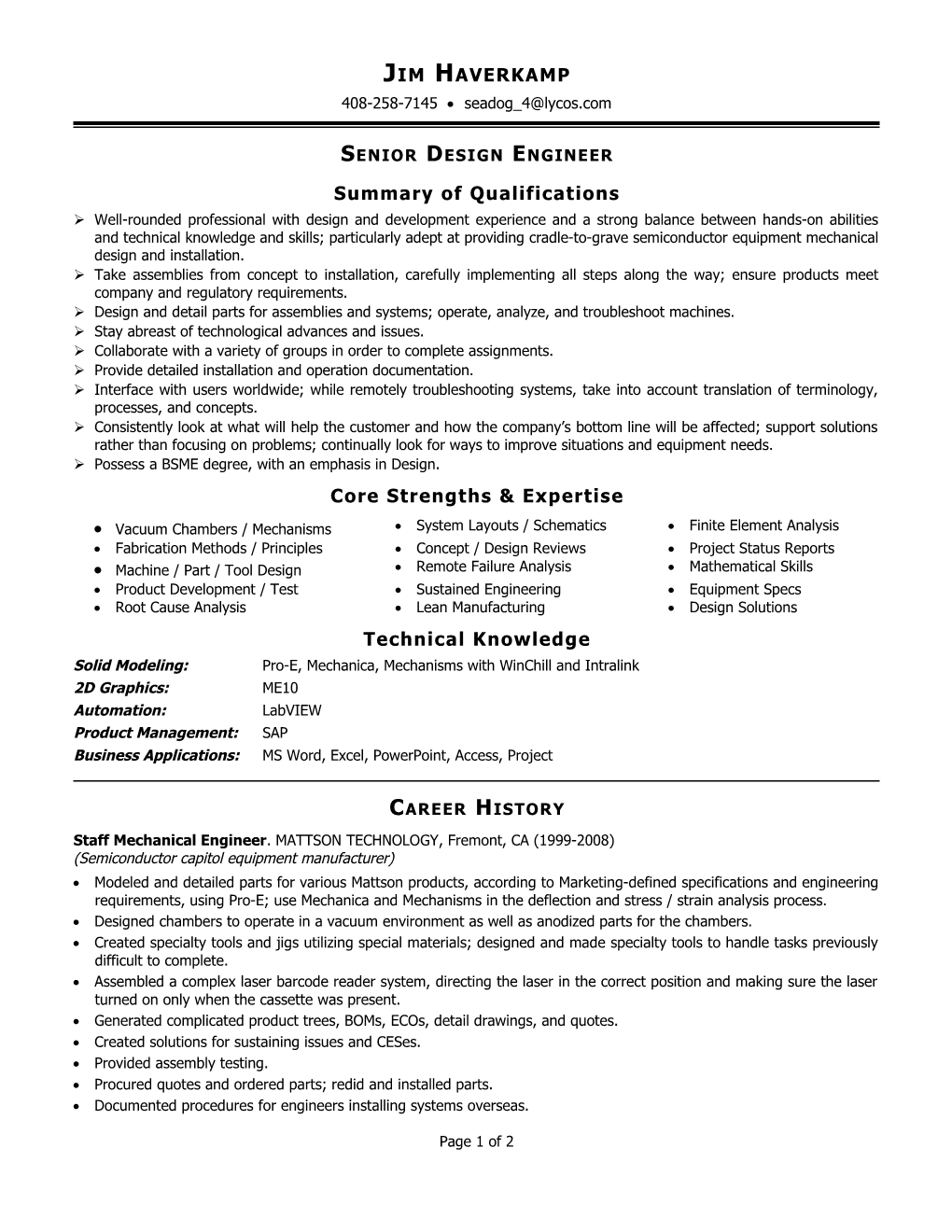

JIM HAVERKAMP 408-258-7145 [email protected]

SENIOR DESIGN ENGINEER

Summary of Qualifications Well-rounded professional with design and development experience and a strong balance between hands-on abilities and technical knowledge and skills; particularly adept at providing cradle-to-grave semiconductor equipment mechanical design and installation. Take assemblies from concept to installation, carefully implementing all steps along the way; ensure products meet company and regulatory requirements. Design and detail parts for assemblies and systems; operate, analyze, and troubleshoot machines. Stay abreast of technological advances and issues. Collaborate with a variety of groups in order to complete assignments. Provide detailed installation and operation documentation. Interface with users worldwide; while remotely troubleshooting systems, take into account translation of terminology, processes, and concepts. Consistently look at what will help the customer and how the company’s bottom line will be affected; support solutions rather than focusing on problems; continually look for ways to improve situations and equipment needs. Possess a BSME degree, with an emphasis in Design. Core Strengths & Expertise

Vacuum Chambers / Mechanisms System Layouts / Schematics Finite Element Analysis Fabrication Methods / Principles Concept / Design Reviews Project Status Reports Machine / Part / Tool Design Remote Failure Analysis Mathematical Skills Product Development / Test Sustained Engineering Equipment Specs Root Cause Analysis Lean Manufacturing Design Solutions Technical Knowledge Solid Modeling: Pro-E, Mechanica, Mechanisms with WinChill and Intralink 2D Graphics: ME10 Automation: LabVIEW Product Management: SAP Business Applications: MS Word, Excel, PowerPoint, Access, Project

CAREER HISTORY Staff Mechanical Engineer. MATTSON TECHNOLOGY, Fremont, CA (1999-2008) (Semiconductor capitol equipment manufacturer) Modeled and detailed parts for various Mattson products, according to Marketing-defined specifications and engineering requirements, using Pro-E; use Mechanica and Mechanisms in the deflection and stress / strain analysis process. Designed chambers to operate in a vacuum environment as well as anodized parts for the chambers. Created specialty tools and jigs utilizing special materials; designed and made specialty tools to handle tasks previously difficult to complete. Assembled a complex laser barcode reader system, directing the laser in the correct position and making sure the laser turned on only when the cassette was present. Generated complicated product trees, BOMs, ECOs, detail drawings, and quotes. Created solutions for sustaining issues and CESes. Provided assembly testing. Procured quotes and ordered parts; redid and installed parts. Documented procedures for engineers installing systems overseas.

Page 1 of 2 JIM HAVERKAMP 408-258-7145 • [email protected]

CAREER HISTORY (continued) Senior Mechanical Engineer. MATHESON TRI-GAS SYSTEMS, San Jose, CA (1998-1999) (Gas-delivery cabinet manufacturer) Performed R&D design of gas delivery systems using ME10; developed an automated gas valve testing system using LabVIEW. Company relocated to the East Coast. Mechanical Engineer. WOLFE ENGINEERING, Sunnyvale, CA (1998) (Gas-delivery cabinet manufacturer) Hired by company owner for this temporary assignment—based on reputation gained at Watkins Johnson—after being affected by a WJ RIF. Provided R&D design of a safe delivery system that targeted implanters. Field Engineer. WATKINS JOHNSON, Scotts Valley, CA (1989-1998) (Semiconductor capitol equipment manufacturer) Interfaced directly with customers in the field, traveling to Taiwan, Singapore, Korea, and Hong Kong to solve machine design issues; was often offsite for months at a time. Maintained a 100% problem resolution record. Worked primarily with atmospheric pressure CVD. Provided project management; interfaced with managers and negotiated timelines with other groups in order to complete projects on time. Installed an entire machine into a fab for a high-profile customer, with a scheduled project time of 6 months; completed the project in 4 months. Received President’s Award for direct work with a customer that resulted in increasing uptime from 45% to 80% and the customer ordering $4 million in additional equipment.

EDUCATION B.S. Mechanical Engineering – Emphasis in Design. UNIVERSITY OF CALIFORNIA, BERKELEY, Berkeley, CA. A.A. General Education. CHABOT COLLEGE (currently Las Positas), Livermore, CA.

MILITARY SERVICE U.S. Navy, Pacific Fleet - Hull Maintenance Technician, Second Class. Received hands-on experience using tools and machines. Honorable Discharge

COMMUNITY ACTIVITIES AND INTERESTS Community Activities: On Water Guide Volunteer. Santa Clara County Parks and Recreation Department. Work closely with rangers to maintain safety of kayakers using Santa Clara County’s lakes. Volunteer. National Oceanic and Atmospheric Administration (NOAA). Provide ocean education and help maintain adequate distance between kayakers and wildlife in various ocean locations. Interests: Avid kayaker Enjoy playing guitar

Page 2 of 2