Attribute Control Chart Examples Fall 2011

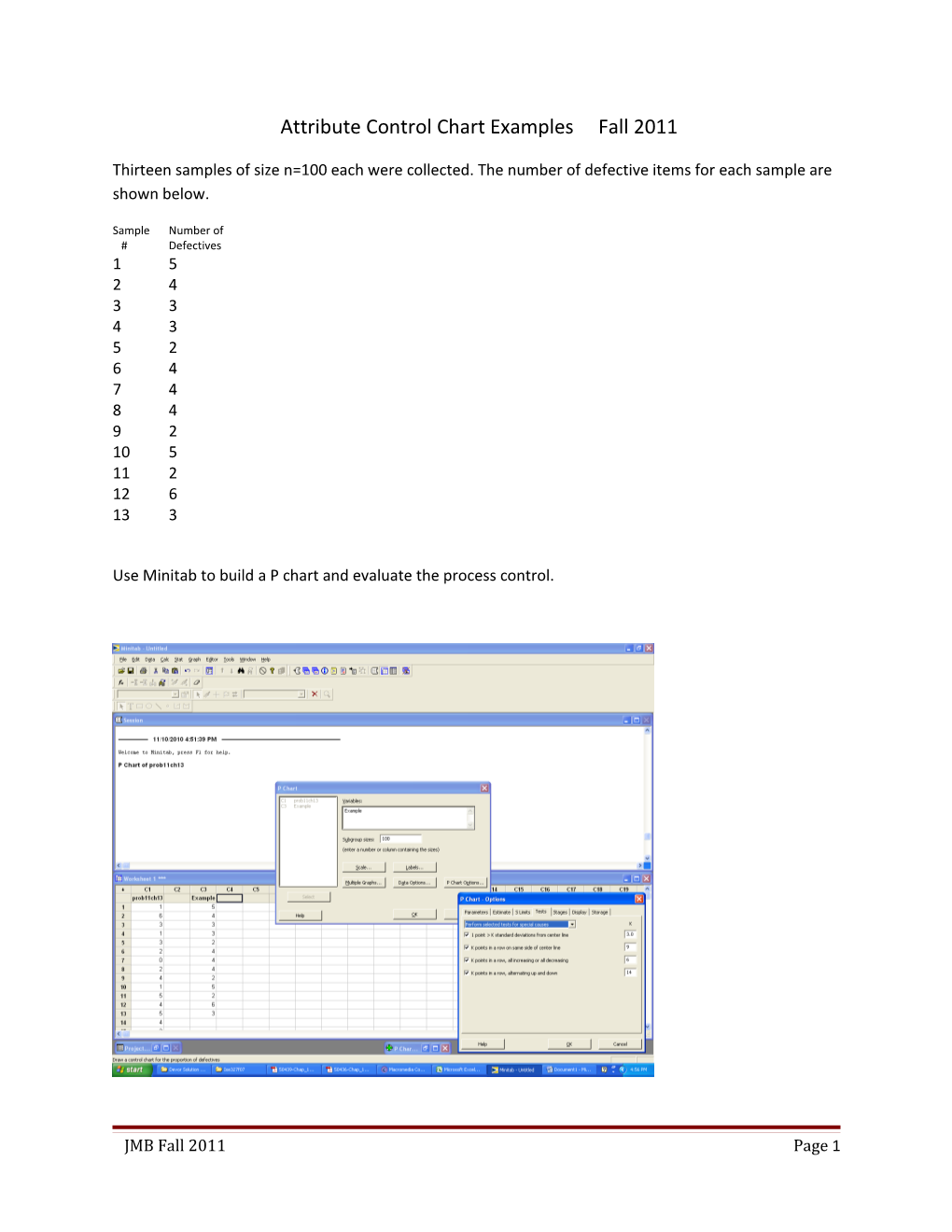

Thirteen samples of size n=100 each were collected. The number of defective items for each sample are shown below.

Sample Number of # Defectives 1 5 2 4 3 3 4 3 5 2 6 4 7 4 8 4 9 2 10 5 11 2 12 6 13 3

Use Minitab to build a P chart and evaluate the process control.

JMB Fall 2011 Page 1 Results:

The y-axis of the P chart is the proportion defective for each sample.

P Chart of Example

0.09 UCL=0.0922

0.08

0.07

0.06 n o i t

r 0.05 o p

o 0.04 _ r

P P=0.0362 0.03

0.02

0.01

0.00 LCL=0

1 2 3 4 5 6 7 8 9 10 11 12 13 Sample

The process does not exhibit any out-of-control characteristics.

JMB Fall 2011 Page 2 Given the following data on defects and sample size, use Minitab to build a C chart and evaluate the process control.

Example

DataC SizeC

2 50

1 50

3 50

4 50

2 50

4 50

6 50

4 50

2 50

5 50

2 50

5 50

3 50

Note that there were 13 samples of size n=50 taken.

JMB Fall 2011 Page 3 Note that Minitab does not ask for the sample size. As is the case for P charts, you are given the option of performing tests for special causes.

Results:

Sum of ExampleData_C = 43

Mean of ExampleData_C = 43/13 = 3.30769 = cbar

Square root of cbar = 1.81871

UCL = cbar+ 3 sqrt cbar = 8.76381

Note that the sample size information is not used for calculating C bar or the control limits. C bar is calculated as the sum of the defects divided by the samples taken. In this example C bar = 31/13.

JMB Fall 2011 Page 4 C Chart of ExampleData_C 9 UCL=8.764 8

7

6 t n u

o 5 C

e l

p 4 _ m

a C=3.308

S 3

2

1

0 LCL=0

1 2 3 4 5 6 7 8 9 10 11 12 13 Sample

C Chart of ExampleData_C with Four Tests 9 UCL=8.764 8

7

6 t n u

o 5 C

e l

p 4 _ m

a C=3.308

S 3

2

1

0 LCL=0

1 2 3 4 5 6 7 8 9 10 11 12 13 Sample

Note the label on the y-axis of the Minitab C chart. The Sample Count is the number of defects in each of the thirteen samples.

JMB Fall 2011 Page 5 Given the following data on defects and sample size, use Minitab to build a U chart and evaluate the process control. The U chart measures defects per unit and is used when the number of units inspected varies from one sample to another.

DataU SizeU

5 50

4 60

3 40

5 40

5 50

5 60

5 30

4 30

3 30

1 30

1 30

6 50

3 50

2 50

5 60

2 60

JMB Fall 2011 Page 6 The centerline of the U chart is the overall U bar (total defects / total items sampled).

JMB Fall 2011 Page 7 U Chart of ExampleData_U Four Tests Applied 0.25

0.20 UCL=0.1928 t i n U

r

e 0.15 P

t n u o C

0.10

e _ l

p U=0.0819 m a S 0.05

0.00 LCL=0

1 3 5 7 9 11 13 15 Sample

U Chart of ExampleData_U 0.25

0.20

t UCL=0.1928 i n U

r

e 0.15 P

t n u o C 0.10 _ e l

p U=0.0819 m a

S 0.05

0.00 LCL=0

1 3 5 7 9 11 13 15 Sample Tests performed with unequal sample sizes

Note the label on the y-axis of the U charts (defects per unit). Also note that the two charts appear to be alike, even though one tested for all special causes and the other tested for none.

JMB Fall 2011 Page 8