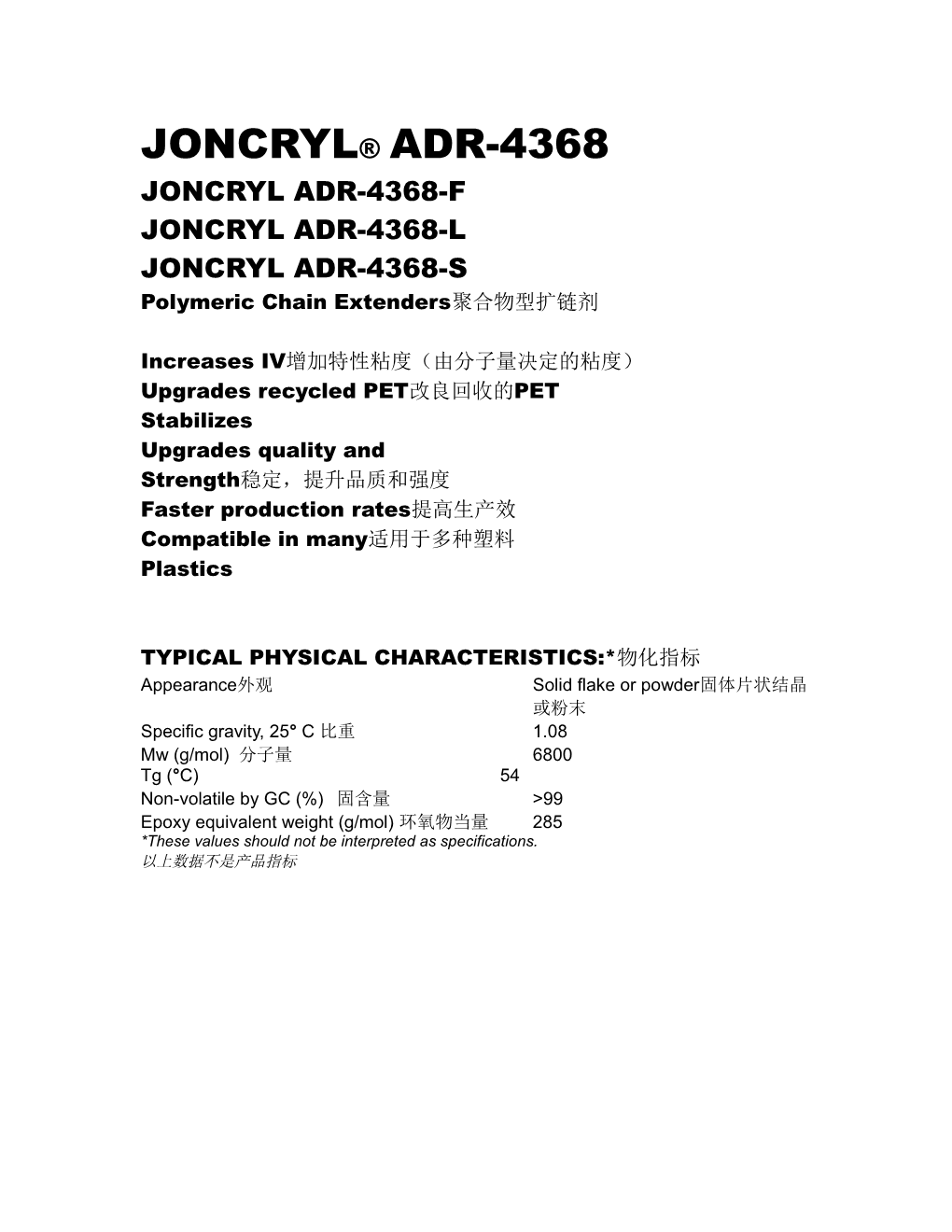

JONCRYL® ADR-4368 JONCRYL ADR-4368-F JONCRYL ADR-4368-L JONCRYL ADR-4368-S Polymeric Chain Extenders聚合物型扩链剂

Increases IV增加特性粘度(由分子量决定的粘度) Upgrades recycled PET改良回收的PET Stabilizes Upgrades quality and Strength稳定,提升品质和强度 Faster production rates提高生产效 Compatible in many适用于多种塑料 Plastics

TYPICAL PHYSICAL CHARACTERISTICS:*物化指标 Appearance外观 Solid flake or powder固体片状结晶 或粉末 Specific gravity, 25° C 比重 1.08 Mw (g/mol) 分子量 6800 Tg (°C) 54 Non-volatile by GC (%) 固含量 >99 Epoxy equivalent weight (g/mol) 环氧物当量 285 *These values should not be interpreted as specifications. 以上数据不是产品指标 JONCRYL® ADR-4368 is a multi-functional reactive polymer designed to reverse the degradation of PET, polycarbonate, nylon and other condensation polymers. It is a polymeric coupling agent that reacts with degraded polymers to restore the original molecular weight as well as I.V. (intrinsic viscosity) and melt viscosity. This means low quality recycle can be upgraded or that good quality recycle can be treated more robustly. J4368是一种多功能反应型聚合物,用于逆转PET、聚碳酸酯、尼龙和其它缩聚物的降 解。它是通过与已降解聚合物进行化学反应,恢复其原来的分子量和特性粘度,增大熔 融粘度。从而改良低品质的回收塑料或者是改善回收塑料的加工性能。

JONCRYL ADR-4368 can be used during processing to increase the melt strength of polyesters or polyamides (nylon). This is useful in extrusion application such as film, sheet, tape fiber, thermoforming and blow molding. J4368在塑料加工过程中使用,可以提高聚酯或聚酰胺(尼龙)的熔融强度,有利于 它们的挤出成型加工,如薄膜、板材、纤维,加热成型加工和吹塑成型加工。

JONCRYL ADR-4368 has clearance under the European Economic Community’s food contact rule, Commission Directive 2002/72/EC or “Plastic Directive.” JONCRYL ADR-4368 contains glycidyl methacrylate GMA which is subject to a QMT of 5 mg/kg for the final product. For more detailed information on national level, please contact your Johnson Polymer representative. J4368通过了欧盟的食品接触法规,Commission Directive 2002/72/EC or “Plastic Directive.” J4368含GMA(甲基丙烯酸缩水甘油脂),最终产品中含量5mg/kg。对于具体国家的 相关指标,请与庄臣公司代表联络。 1. PRODUCT FORM产品形态 JONCRYL ADR-4368 is a solid oligomeric chain extender. It is offered in several different forms, as a flake, as a large coarse powder, as a small fine powder, and as several masterbatches. The masterbatches are available from Clariant Corporation. JONCRYL ADR-4368 can also be melted and handled as a hot liquid. J4368是固体的低聚物扩链剂。产品以多种形态提供,片状结晶,较大颗粒的粉末,细 颗粒粉末,以及母粒形式。母粒由科来恩公司提供。J4368也可以在熔融后以热的液体 使用。

Particle Size1/ Form 形态 Physical Description 说明 Characteristics 粒径 1 Efficient for dry-blending with cold plastics Flake 片状结 2.5 – 4.0 mm mean pellets or flake; or for separate feed 晶 <2% (w/w) smaller than operations.可有效地与冷态塑料粒子或片在干燥状态 ADR-4368-F 0.15mm 下混合或者是应用于单独加料 Powder, Efficient for dry-blending with cold plastics large 1.0 – 2.5 mm mean pellets or flake, separate feed, or down stream particle siz <5% (w/w) smaller than feeding operations.可有效地与冷态塑料粒子或片在 较大颗粒粉末 0.15 mm 干燥状态下混合,或者是应用于单独加料,或者是在下游 ADR-4368-L 加料 Powder, Recommended for dry-blending operations with small 0.5 – 1.5mm mean cold or hot (post-dryer) solid plastic. Requires particle <10% (w/w) smaller proper dust handling equipment.建议与固体塑料在 size 小颗粒 than 0.15 mm 冷态或热态(干燥后),干燥状态下混合.需要添加防尘设 粉末 ADR- 备. 4368-S Temp C Viscosity Liquid2, Poise The liquid may be pumped directly into feed zone melted form 100 18600 or downstream liquid port. 熔融液体可直接泵入加 of ADR-4368 150 100 料区或下游液体加料口 熔融状态 200 6.4 250 0.9 Recommended for hot and cold dryblending, for Masterbatch co-feed, and for downstream feed. Some grades Standard sized Pellets3 are preferred for hot addition. Consult your cylindrical pellets 标 色母粒 Johnson Polymer representative.建议热态和冷态干 准规格的圆柱形粒子 CESA®-extend 式混合,适用于共同加料和下游加料. 有些等级的产品 更适用于热态加料. 1. Particle size distribution may shift towards smaller particle sizes with handling due to the brittle nature of this additive.由于其易碎特性,在处置过程中颗粒会变小 2. Joncryl ADR-4368 can be melted on-site to form a medium viscosity liquid in conventional steam or hot oil heated tanks.通过一般的蒸汽或热油加热槽,可以在加工现场将J4368熔化 为中等粘度的液体来使用. 3. A variety of masterbatch products with carriers including polyolefines, styrenics, and PET, with active Joncryl ADR- 4368 loads ranging from 20 to 80% by weight are available from Clariant Masterbatches.科来恩母粒公司提供多种规格,采用包括聚烯烃,丙乙烯类和PET 为载体的母粒产品,其中用效J4368含量从20%到80%不等. 2. RECOMMENDED DOSAGE for JONCRYL ADR-4368推荐用 量 With deep understanding that every chain extension problem is unique, our Technical Service experts will help you define the right dosage for your specific system. The guide below may be used as a reference for typical ranges of dosage of Joncryl chain extenders. 因为深知任何一种扩链所遇到的问题都是独特的, 我们的技术服务人员将 协助您按您所采用的特定加工设备确定正确的使用剂量。下表仅供参考。 Recommended Plastic 塑料类别 Application 应用类别 Dosage (% w/w) 推荐用量 Polyesters (PET) Fiber (staple and filament)纤维 0.1 to 0.4 聚酯 Injection/blow molding bottle 注塑/吹塑瓶 0.2 to 0.6 Sheet, tape and profile extrusion 板材,带和挤出成型加 0.4 to 0.8 工 Film and bottle blow molding 薄膜和瓶吹塑 0.4 to 1.0 Strapping 0.4 to 1.2 Compatibilization PET/PA-nylon 0.5 to 1.5 Polyesters Injection molding 0.1 to 0.2 (PETG, PBT, other) Fibers 0.1 to 0.4 Profile extrusion 0.2 to 0.6 Sheet and film 0.3 to 1.0 Branching 0.5 to 1.0 Polyamides Injection molding 0.1 to 0.2 (nylon, PA 6 & Profile extrusion 0.3 to 0.8 6,6, other) Sheet, film and tape 0.4 to 1.0 聚酰胺 Branching 起梗,出纹 0.5 to 1.0 Compatibilization polyester/PAnylon 0.5 to 1.5 Polycarbonates Injection molding 0.1 to 0.2 (PC) Hydrolytic stabilization 防水解 0.3 to 1.0 聚碳酸酯 Sheet and film 0.4 to 1.2 Branching 0.5 to 1.5 Other condensation Melt strength 熔融强度 0.2 to 0.8 thermoplastics Stabilization 稳定 0.2 to 1.0 (TPU, POM) 3. METHODS OF DOSAGE投料方式 Operation Procedure 1. Dry-blending干态混合 a) Flake, masterbatch or coarse powder forms can be dryblended with pre-dried and cold (< 40C) plastic pellets or flakes with the aid of a low shear mixer such as a tumble mixer or conical mixer. 采用低剪切力的翻斗式混料器或锥形混合器,将片状晶体、色母粒或是大颗粒粉末与已 干燥处理,低温(< 40C )的塑料粒子或片进行混合。 b) All solid forms of Joncryl ADR-4368 can be mixed with other materials on a high shear mixer such as a Henschell mixer below 50ºC. Cold mixing may be aided with 0.2% of Joncryl ADP-1200, acrylic plasticizer. 所有固体形态的J4368均可以与其他的物料在高剪切力混和器中,如Henschell,在低 于50ºC的条件下混和。在冷态混料过程中可以加入0.2% Joncryl ADP-1200丙烯酸类增 塑剂以提高效率。 c) CESA®-extend polyester masterbatch may be dryblended with hot plastic pellets or flakes. CESA母粒可以与热的塑料颗粒或片材进行混料。

2. Addition of Joncryl ADR-4368 on a single-screw extruder, twins crew extruder or kneader.在单螺杆压出机,双螺杆压出机或伴合机中添加J4368 a) Dry-blends prepared as in (1) can be volumetrically, gravimetrically or flood fed directly into the mixing zone of the extruder (see temperature recommendations in the Processing Conditions section on page 7). 按步骤1混合好的物料可按体积计量或重量计量,或一次性直接投料到压出机的混合区 (温度条件,参见第七页“加工条件”) b) Separate gravimetric or volumetric feed metering systems can be used to feed any solid product form in a parallel stream with the plastic directly into the feeding zone of the extruder. Belt feeders are particularly recommended for the powder form. 固态产品通过独立的体积计量或重量计量投料装置与塑料同时进入压出机的投料区。粉 末产品建议使用传送带式投料装置。 c) Side feed systems and other types of forced dosing extruders may be employed with all solid product forms, except the fine powder, to feed the products downstream. Residence time recommendations are given below in reference to downstream feeds. 除粉末产品外,其他形态的产品均可以采用附加投料装置和其他类型的强制式定量给 料压出机将物料投到下游区域。关于停留时间,参见下文的“下游投料”部分。 d) Direct gravimetric/volumetric addition of the chain extender in any form to the plastic melt may be carried out through any suitable downstream venting or degassing port. 任何形态的扩链剂直接按体积/重量计量投料时,可以通过下游合适的放空口或放气口 进入塑料熔体。 e) With the aid of a melting tank, Joncryl ADR-4368 becomes pumpable at temperatures about 120 - 140C and very thin at temperatures approaching 200C. Once in liquid form the extender can be added at any suitable place, as described in (b) or (d). 通过熔融槽,J4368在大约120 - 140C时就可以用泵来抽送了,在接近200C.时它会 会变得非常稀。扩链剂一旦成为液态,即可按(b) 或 (d)所述投料方法投料到任何合适 的区域。

3. Addition during injection molding and combined injection-blow molding operations. 在注塑成型和注坏吹塑成型加工中添加 a) Dry-blends prepared as in (1) can be volumetrically gravimetrically, or flood-fed directly into the feeding zone of the injection molder (see temperature recommendations in the operating conditions section on page 7). 按步骤1混合好的物料可按体积计量或重量计量,或一次性直接投料到注射模型成形机 的投料区(温度条件,参见第七页“加工条件”) b) Separate gravimetric or volumetric feed metering systems can be used to feed Joncryl ADR-4368 in a parallel stream with the plastic directly into the feeding zone of the injection molder. Belt feeders are particularly recommended for the powder form. J4368通过独立的体积计量或重量计量投料装置与塑料同时进入注射模型成形机的投 料区。粉末产品建议使用传送带式投料装置。 c) With the aid of a melting tank, Joncryl ADR-4368 becomes pumpable at temperatures about 120 –140°C and very thin at temperatures approaching200°C. Once in liquid form Joncryl ADR-4368 can be added directly into the feeding zone of the injection molder as described in (b). 通过熔融槽,J4368在大约120 - 140C时就可以用泵来抽送了,在接近200C.时它会 会变得非常稀。扩链剂一旦成为液态,即可按(b)所述投料方法直接投料到注射模型成 形机的投料区。

4. Addition during polymerization and in other chemical reactors. 在聚合过程中或其他化学反应器中添加 a) Additions of Joncryl-ADR-4368 directly into polymerization reactors are feasible for some systems. Nevertheless, care should always be exercised when adding highly functional extenders to polymerization systems to prevent extensive branching and crosslinking. Prior to any work including the use of ADR-4368 in polymerization, we encourage you to discuss your system with our technical representatives. 对有些体系,可以将J4368直接添加到聚合反应釜中。然而,当在聚合反应体系中添 加高功能性的扩链剂时必须谨慎,以防止过度的分歧和交联。在添加J4368到聚合反 应过程中之前,请务必与我们的技术人员交流。 4. PROCESSING CONDITIONS加工条件 Operation Procedure Pre-drying 预干燥处理 Pre-dry the base plastic at manufacturer’s recommended c onditions. 遵循厂家推荐的条件对塑料进行预干燥处理。 In some instances small amounts of Joncryl chain extenderscan compensate for poor/incomplete drying, thus bringing robustness and savings to your operations. For example in polyesters, degradation brought about by 100 ppm of moisture can be compensated by 0.3 % of Joncryl ADR-4368. 在有些场合,庄臣公司的扩链剂可以补偿由于干燥不好或不彻底带来的问题,从而给 加工过程带来好处。例如,对于含100ppm水份的聚酯,添加0.3%J4368即可起作用。

Hygroscopicity: there is no evidence of bulk absorption of moisture over extended periods of time. 吸湿性:并没有证据表明,有长期吸湿作用 At normal conditions of temperature and relative humidity (i.e. 77F and 50% RH) its surface reaches equilibrium saturation through adsorption at less than 0.25% moisture. 一般温度和相对湿度(如77F ,50% RH)条件下,其表面吸湿小于0.25%就达到平 衡饱和状态。 At extreme conditions (i.e. fine powder at 95F and 100% RH) its surface reaches equilibrium saturation at less than 0.50 % of moisture. 在极端条件下(如:细粉末产品,95F /100% RH),其表面吸湿小于0.50 %即达到 平衡饱和状态。 This means that Joncryl ADR-4368 can generally be processed without any drying, even after long exposure to drastic conditions bringing no more than 5 ppm moisture per every 0.1% used. 这表明J4368通常不需要任何干燥处理就可以使用。既使长期放置于极端条件,每0.1% 的用量最多也只会带入5ppm的水份。 In systems where moisture sensitivity is extreme, Joncryl ADR-4368 can be dried with dry air at 30C for 1 hour, prior to use. 对于那些对水份极端敏感的体系,J4368在使用前可以用30C的热空气干燥1个小时。

Masterbatches of Joncryl ADR-4368, generally do not require drying, except when polyester is used as carrier 除非是采用聚酯做为载体,通常J4368母粒不需要进行干燥处理。

Extruder/injection molder temperature profile 压出机/注射模型成形机的温度条件 When feeding solid Joncryl ADR-4368 in any solid form, except masterbatch, into the 1st zone of the extruder or injection molder, we recommend operating this zone at 20C to 40C lower temperature than normal. This will prevent early melting and agglomeration of the additive. Refer to the Cesa-extend literature for instruction with J oncryl ADR-4368 masterbatches 除母粒外,任何固的J4368以固态投料到压出机或注射模型成形机的第一段时,我们 建议本段的操作温度应比常规低20-40C。这将防止扩链剂过早熔化和凝聚。关于母粒 的使用,请参照科来恩公司关于Cesa-extend的技术说明。 All other zones should employ normal processing conditions as recommended by the plastic’s manufacturer. 加工机器其他段应保持塑料生产者推荐的正常操作温度。

Additive thermal stability 扩链剂的热稳定性 Neat ADR-4368 is thermally stable up to 320°C (<0.5% evolution in TGA @ 10°C/min in N2). Above this temperature additive decomposition may occur. PET compounded with 1% of ADR-4368 showed identical thermal behavior as PET (TGA, 10°C/min. in N2). 纯J4368在低于320°C以下稳定 (<0.5% evolution in TGA @ 10°C/min in N2)。高于此 温度,本产品会分解。添加1%J4368的PET,其热性能与纯PET相同。

Therefore, melt temperature should not exceed 330°C. 因此,熔融温度不应超过330°C

Residence time 停留时间 Joncryl ADR-4368 reacts quickly. Its reaction will be over 99% complete if at least 30 sec residence time is provided at 200°C in a well mixed system. Alternatively, 10 sec residence time at 300°C will provide 99% completion. These limits accommodate most extrusion and injection molding processes for the recommended thermoplastics and applications. J4368反应速度很快。在一个充分混和的体系中,200°C 时,如果提供至少30秒钟的停 留时间,99%以上的反应就可以完成;相应的,在300°C,停留10秒钟反应可以完成 99%。这确保了本产品,对所适用的热塑性塑料及制成品,在大多数压出成型加工和注 射成型加工时均可使用。

For use in polymerization reactors where residence time is over 5 minutes, see recommendations on page 6. 当在停留时间超过5分钟的聚合反应釜中使用时,参见第6页的说明。

Maximum temperature最高温度 JONCRYL ADR-4368 should not be processed at temperatures higher than 330°C (see thermal stability section on page 7). J4368的使用温度不可以超过330°C(见第7页的热稳定性说明部分) 5. EXTRUDER PRESSURE EFFECTS对压出机的压力影响 The use of JONCRYL ADR-4368 in reactive extrusion or reactive injection molding operations produces significant increases in molecular weight of the plastic being modified. This increase in molecular weight raises the melt viscosity, which in turn raises the pressure observed in the equipment. 在反应型挤出加工或注塑加工中 添加J4368将极大地提高被加工塑料的分子量,增大了熔融粘度,使得设备中的压力 增高。

The table below exemplifies the large increases in die pressure that are observed in PET as JONCRYL ADR-4368 is added to a large extruder. Similar increases are expected in other plastics.下表是添加J4368到加工PET的压出机时所观察到的模压力。 类似的现象在使用于其他塑料时也可以观察到。

It is important that operators be aware of these expected pressure changes. Alarms, automatic shut-offs, screen purging set-points, and other operation variables should be adjusted to accommodate these normal and expected pressure increases. 设备操作人员应知道压力变化的现象。报警、自动切断、滤网吹扫设定值以及其他操作应 做调整,因为压力增大在操作过程中的是正常。

Extruder Variable PET Control 0.50% 1.00% 1.50% 压出机变量 Joncryl Joncryl Joncryl ADR-4368 ADR-4368 ADR-4368 Pressure @ die 11.45-1.65 1.90-2.30 2.20-2.60 Pressure @ screen 11.45-1.65 1.90-2.30 2.20-2.60 Motor power draw 11.08-1.10 1.13-1.18 1.17-1.21

As shown, pressure increases both at the die and in front of the screen system may be 50% to 160% higher than typical operating pressure for higher usage levels. 如上所示,在大剂量使用扩链剂时,在模头和滤网系统前端的压力可能估比通常的操 作压力高出50% 到160%。

Instantaneous pressure variations and spikes are due to large instantaneous changes in melt viscosity. At constant temperature, changes in melt viscosity are often due to variable feed rate and/or poor mixing. 瞬间的压力变化及峰值出现是由熔融粘度瞬间变化导致的。温度恒定时,熔融粘度变化 通常是由于投料速率变化和/或混和不均导致的。 To illustrate the effect of variable feed rate, the pressure and power draw changes with fluctuations in feed rate are calculated on the table below. For example, a variation of 20% in the feed rate causes a 9% increase or decrease in pressure, which is a variability range of 18%. 为说明投料速率变化的影响,压力和功率随投料速率变化而变化的情形计算如下表所 示。例如,投料速率变化20%导致压力增加或减小9%,变化幅度为18%。

Extruder Steady feed Unsteady feed Unsteady feed Variable within 5 % of within 10 % of within 20 % of 压出机变量 target value target value target value 稳定投料,为目 不稳定投料,为 不稳定投料,为 标值 5%以内 目标值 10%以内 目标值 20%以内 Pressure at die +/- 2.0 % +/- 4.3 % +/- 9.0 % Pressure at scree +/- 2.5 % +/- 4.5 % +/- 9.2 % Power draw +/- 0.4 % +/- 0.8 % +/- 1.75 %

Fluctuations in the feed rate of JONCRYL ADR-4368 larger than 10% of the target value may cause large instantaneous extruder pressure spikes. J4368投料速度变化比目标值超过10%将导致压出机压力巨大变化。 To attain steady and consistent pressure, homogenous dry blends or robust co-feed systems are essential. The selection of the screen pack can influence the pressure. 为确保稳定恒定的压力,混料均匀或者采用高效投料装置是必要的。对过滤系统的选择 也将影响设备的压力。 Finer screen mesh will produce even higher pressures when used with JONCRYL ADR-4368. 添加J4368时,过细的滤网会产生更高的压力

6. TROUBLESHOOTING问题解决 In Case of Unexpectedly High Pressure: 万一出现意外的高压时 1. Decrease the feed rate of JONCRYL ADR-4368 降低J4368的投料速率 2. Decrease the RPM. This decreases pressure on single screw extruders and flood- fed twin-screw extruders, and will decrease heating on starve-fed twin- screw extruders. 降低设备转速。这将降低单螺杆压出机和一次性投料双螺杆压出机的压力,可以降低间 歇式双螺杆压出机的温度。 3. Slowly increase the temperature, starting from the die and then from the last to the first zone. 慢慢提高温度,从模头开始,然后从最后加工段向第一段。 In a typical extruder with an L/D > 24 normally most of the extension reaction takes place in the first half of the extruder length. Increasing the temperature in the zones of the final half of the extruder will generally result in lower viscosity and pressure. 在一个常规的L/D>24压出机上,绝大部分的延续反应发生在压出机长度的前半部分。 提高压出机后半部分区域的温度一般可以增大粘度和提高压力。 4. With pressure under control, increase the Joncryl ADR-4368 feed slowly. 压力得到控制后,慢慢加大J4368的投料。

5. For steady operation follow recommendations given in the section 5 above. 为稳定操作,请遵循上述第5部分的要求。

Keep in mind that chain extension will always result in higher pressure at constant extruder settings。 请记住,在压出机设定不变的情况下,扩链反应一定会导致压力的升高。