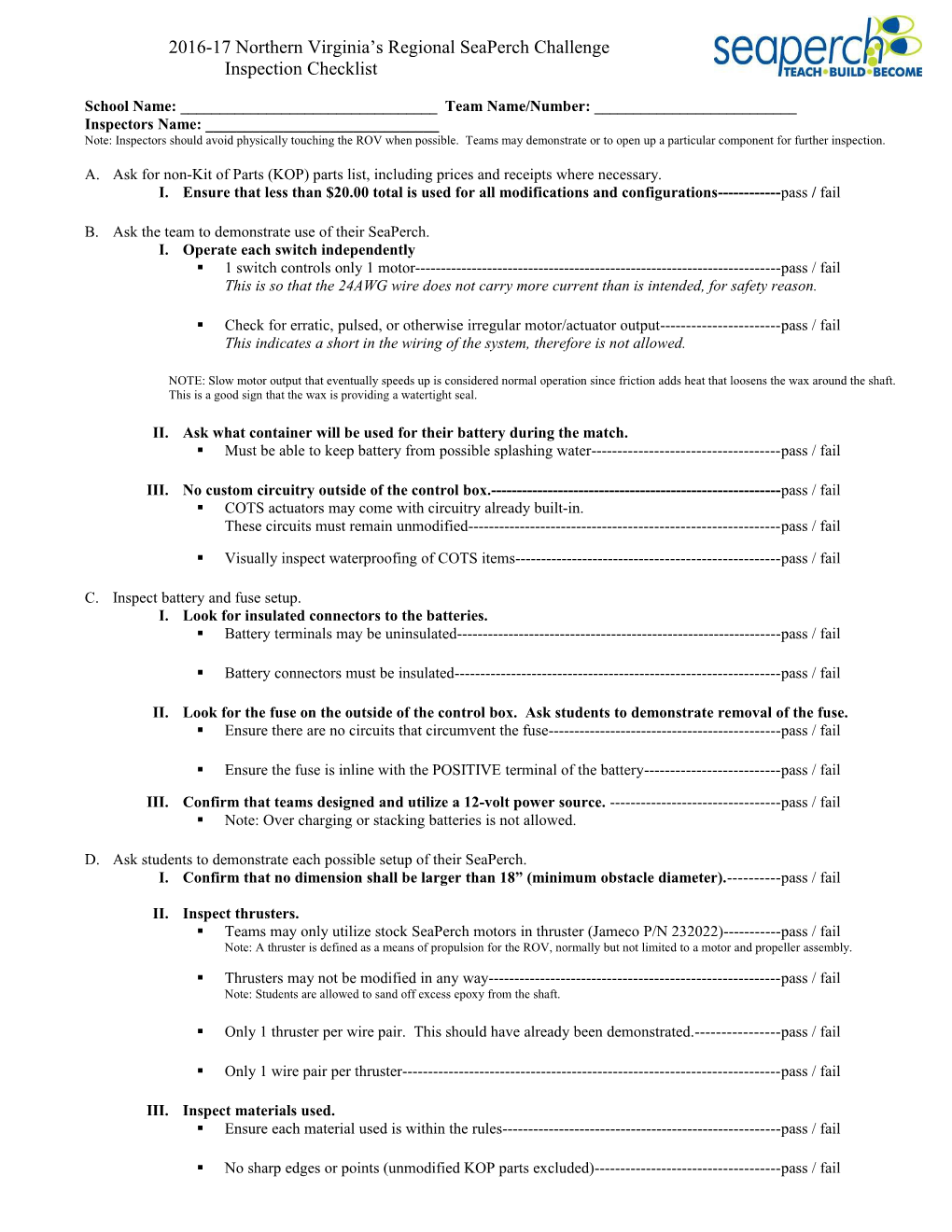

2016-17 Northern Virginia’s Regional SeaPerch Challenge Inspection Checklist

School Name: ______Team Name/Number: ______Inspectors Name: ______Note: Inspectors should avoid physically touching the ROV when possible. Teams may demonstrate or to open up a particular component for further inspection.

A. Ask for non-Kit of Parts (KOP) parts list, including prices and receipts where necessary. I. Ensure that less than $20.00 total is used for all modifications and configurations------pass / fail

B. Ask the team to demonstrate use of their SeaPerch. I. Operate each switch independently . 1 switch controls only 1 motor------pass / fail This is so that the 24AWG wire does not carry more current than is intended, for safety reason.

. Check for erratic, pulsed, or otherwise irregular motor/actuator output------pass / fail This indicates a short in the wiring of the system, therefore is not allowed.

NOTE: Slow motor output that eventually speeds up is considered normal operation since friction adds heat that loosens the wax around the shaft. This is a good sign that the wax is providing a watertight seal.

II. Ask what container will be used for their battery during the match. . Must be able to keep battery from possible splashing water------pass / fail

III. No custom circuitry outside of the control box.------pass / fail . COTS actuators may come with circuitry already built-in. These circuits must remain unmodified------pass / fail

. Visually inspect waterproofing of COTS items------pass / fail

C. Inspect battery and fuse setup. I. Look for insulated connectors to the batteries. . Battery terminals may be uninsulated------pass / fail

. Battery connectors must be insulated------pass / fail

II. Look for the fuse on the outside of the control box. Ask students to demonstrate removal of the fuse. . Ensure there are no circuits that circumvent the fuse------pass / fail

. Ensure the fuse is inline with the POSITIVE terminal of the battery------pass / fail

III. Confirm that teams designed and utilize a 12-volt power source. ------pass / fail . Note: Over charging or stacking batteries is not allowed.

D. Ask students to demonstrate each possible setup of their SeaPerch. I. Confirm that no dimension shall be larger than 18” (minimum obstacle diameter).------pass / fail

II. Inspect thrusters. . Teams may only utilize stock SeaPerch motors in thruster (Jameco P/N 232022)------pass / fail Note: A thruster is defined as a means of propulsion for the ROV, normally but not limited to a motor and propeller assembly.

. Thrusters may not be modified in any way------pass / fail Note: Students are allowed to sand off excess epoxy from the shaft.

. Only 1 thruster per wire pair. This should have already been demonstrated.------pass / fail

. Only 1 wire pair per thruster------pass / fail

III. Inspect materials used. . Ensure each material used is within the rules------pass / fail

. No sharp edges or points (unmodified KOP parts excluded)------pass / fail 2016-17 Northern Virginia’s Regional SeaPerch Challenge Inspection Checklist . No tape except for what is called for in the KOP tutorial------pass / fail

IV. Review ballast weights. . Inspect attachment device to ensure it is safe & secure. ------pass / fail