Jacob Feldman Instructions 4/4/2018

Sentry Safe Dual Hose Filler Assembly Instructions

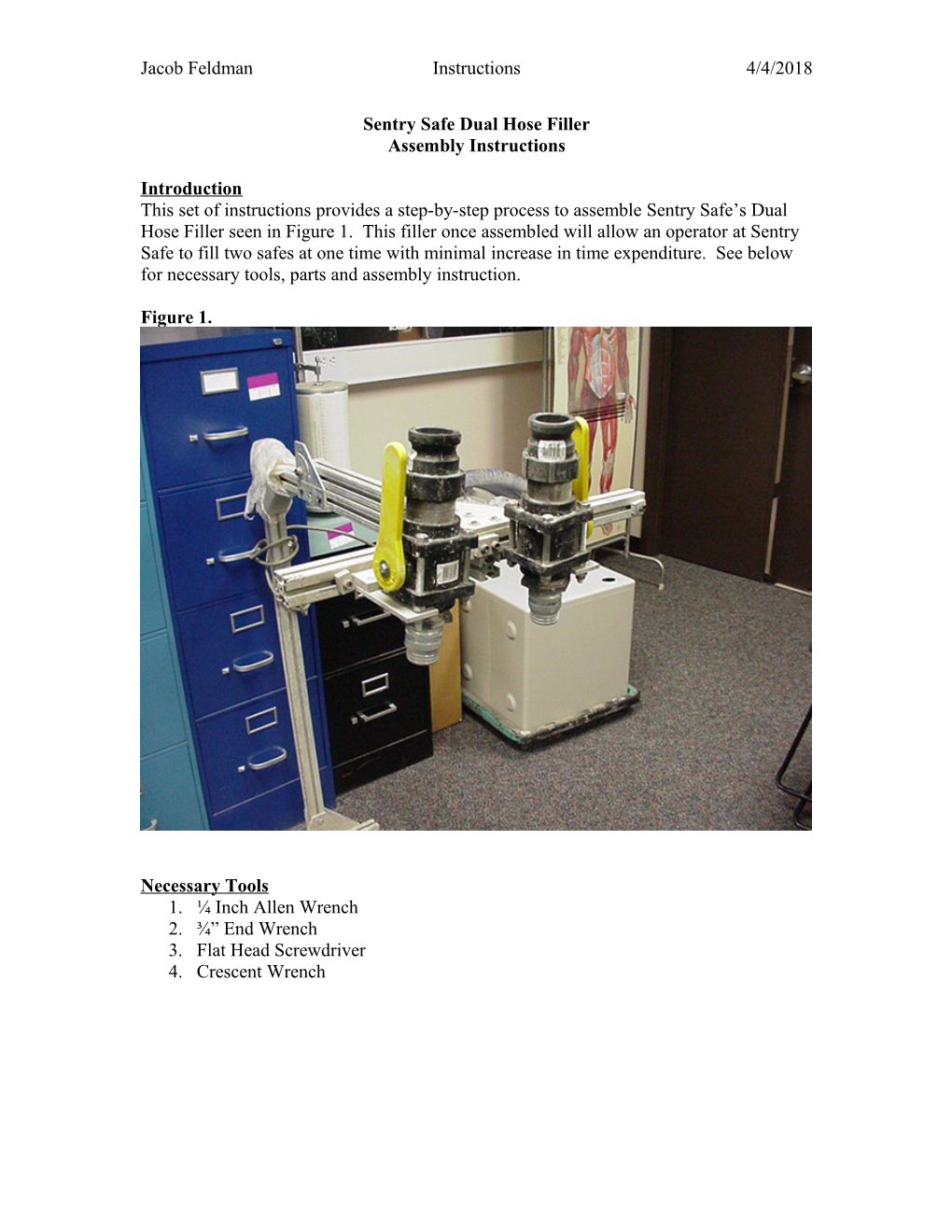

Introduction This set of instructions provides a step-by-step process to assemble Sentry Safe’s Dual Hose Filler seen in Figure 1. This filler once assembled will allow an operator at Sentry Safe to fill two safes at one time with minimal increase in time expenditure. See below for necessary tools, parts and assembly instruction.

Figure 1.

Necessary Tools 1. ¼ Inch Allen Wrench 2. ¾” End Wrench 3. Flat Head Screwdriver 4. Crescent Wrench Jacob Feldman Instructions 4/4/2018

Assembly Parts Please see chart below and Figure 2. for pictorial representations of parts and assembly. 1. Nozzle Bracket x2 2. Slider A x1 3. Slider B x1

4. Restrictor x4 5. Bracket Screw x4 6. Bracket Washer x4

7. Bracket Nut x4 8. Stopper Bolt x4 9. Stopper Nut x4

10. 80-20 Bar Stock x1 11. Ball Valve Left 12. Ball Valve Right

Figure 2. Jacob Feldman Instructions 4/4/2018

Assembly Instructions Throughout this process refer to parts chart and Figure 2. for parts information and proper orientation.

Initial 1. Open plastic bags containing necessary bolts and screws. Check against quantity listed in the parts chart. If parts missing contact supplier. 2. Open all boxes and unwrap bubble wrap from remaining parts. Check against quantities listed in the parts chart. If parts are missing contact supplier.

Stoppers Figure 3.

1. Using one Stopper Bolt 5., insert the bolt into the hole of one Restrictor Block 4. 2. Orientate Stopper Nut 9. behind the Restrictor Block and thread nut onto bolt leaving loose. Leaving nut loose will assist in placement into 80-20 bar slot later. 3. Repeat steps 1 and 2 for remaining 3 sets of stoppers. Jacob Feldman Instructions 4/4/2018

Brackets Figure 4.

1. Place Slider A 2. on top of Nozzle Bracket 1. aligning the pre-drilled holes as shown in Figure 2 and Figure 4. 2. Insert two Bracket Screws 5. down into the Slider holes and through the Nozzle Bracket. 3. Picking up the combined bracket unit, with out disrupting the seated screws flip over the bracket and place one Bracket Washer 6. on each of the Bracket Screws.

Note: Locktight may be applied to any nut and bolt to prevent unwanted unscrewing.

4. Thread one Bracket Nut 7. onto each Bracket Screw until finger tight. Using a flat head screw driver and crescent wrench tighten the nut snug to bottom of washer preventing the Slider from moving on the Nozzle Bracket.

Note: Orientation of parts for second bracket is crucial for proper function. Orientate parts as seen in Figure 2.

5. Orientating the remaining Bracket Parts as seen in Figure 2., repeat steps 1-4 to assemble second Bracket. Jacob Feldman Instructions 4/4/2018

Ball Valve and Bracket Assembly

Note: Orientation of ball valve to bracket is crucial for proper function. See Figure 5. for proper orientation of first assembly.

Warning: Over tightening of ¾” bolts will prevent lever from operating.

Figure 5.

1. Taking Ball Valve Left 11. and Bracket with Slider A orientation, remove the two bolts holding the Ball valve together as illustrated below in Figure 6. with a ¾” end wrench.

Figure 6. Jacob Feldman Instructions 4/4/2018

2. Align bracket assembly to the ball valve holes as shown in Figure 6. and reinsert bolts. 3. Thread both nuts to reinserted bolts and tighten with ¾” end wrench making sure yellow handle operates smoothly. 4. The second ball valve and bracket assembly with Slider B can be assembled by repeating steps 1-3 while maintaining proper orientation shown in figure 2.

Final Assembly Note: The order by which the sub assemblies are inserted into the bar stock is crucial to proper function. The following sub assemblies are inserted into same bar stock slot from the same end. See Figure 8. for pictorial representation of final assembly.

Figure 7.

1. Taking the 80-20 Al. Bar Stock 10., insert one stopper assembly by sliding the back nut into the slot. 2. Insert the right ball valve assembly by sliding the notched end of bracket assembly into the bar stock slot. 3. Insert the second stopper assembly same as before. 4. Insert the third stopper assembly same as before. 5. Insert the left ball valve assembly by sliding notched end of bracket assembly into bar stock slot. 6. Insert the final stopper assembly same as before. 7. After insertion of all assemblies tighten stoppers with Allen wrench in locations operator wishes. This prevents ball valve assemblies from slipping along bar.

Conclusion and Trouble Shooting This completes the Dual Hose Filler Assembly instructions. If Dual Hose Filler does not function properly see Figure 2. and check for proper orientation. If orientation isn’t correct fix that section.