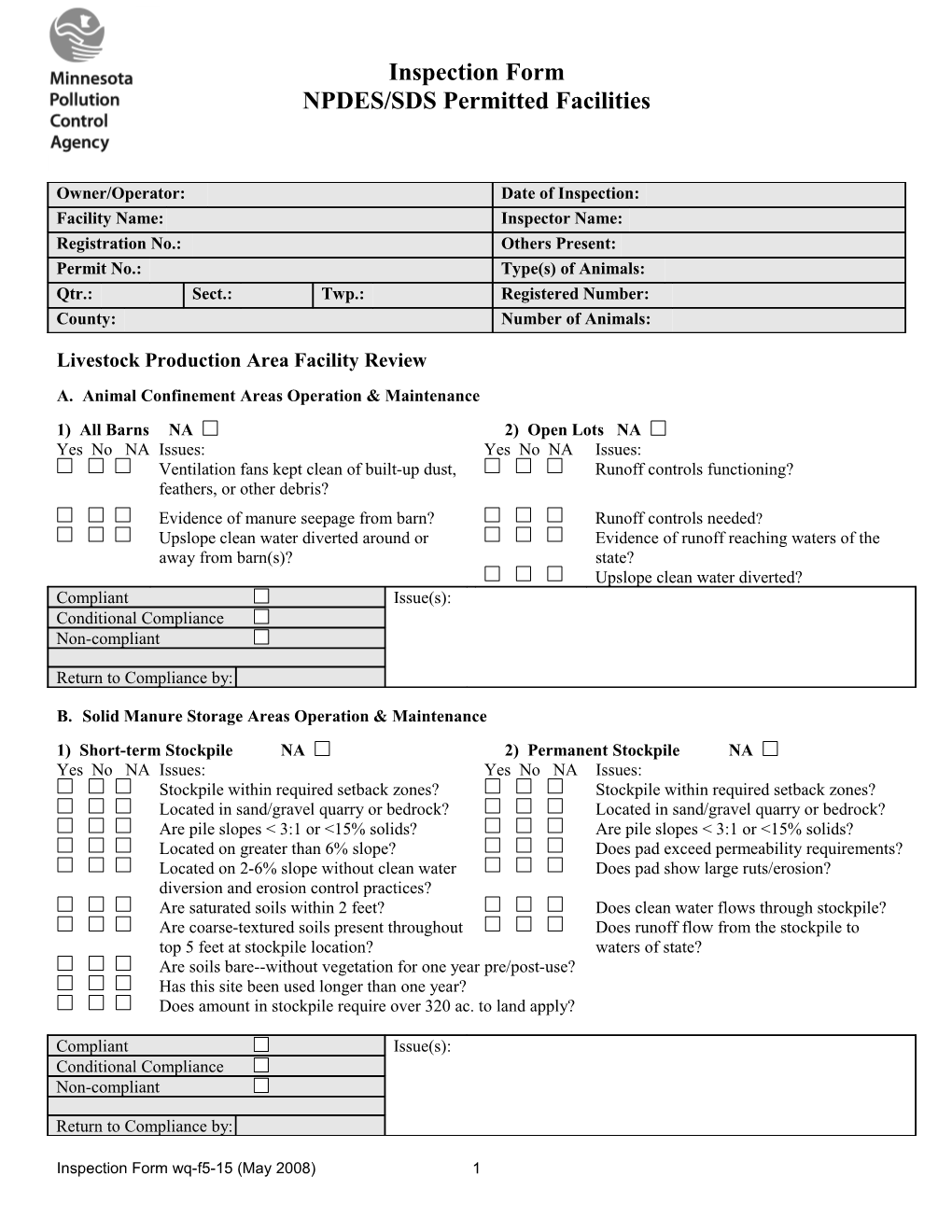

Inspection Form NPDES/SDS Permitted Facilities

Owner/Operator: Date of Inspection: Facility Name: Inspector Name: Registration No.: Others Present: Permit No.: Type(s) of Animals: Qtr.: Sect.: Twp.: Registered Number: County: Number of Animals:

Livestock Production Area Facility Review A. Animal Confinement Areas Operation & Maintenance

1) All Barns NA 2) Open Lots NA Yes No NA Issues: Yes No NA Issues: Ventilation fans kept clean of built-up dust, Runoff controls functioning? feathers, or other debris? Evidence of manure seepage from barn? Runoff controls needed? Upslope clean water diverted around or Evidence of runoff reaching waters of the away from barn(s)? state? Upslope clean water diverted? Compliant Issue(s): Conditional Compliance Non-compliant

Return to Compliance by:

B. Solid Manure Storage Areas Operation & Maintenance

1) Short-term Stockpile NA 2) Permanent Stockpile NA Yes No NA Issues: Yes No NA Issues: Stockpile within required setback zones? Stockpile within required setback zones? Located in sand/gravel quarry or bedrock? Located in sand/gravel quarry or bedrock? Are pile slopes < 3:1 or <15% solids? Are pile slopes < 3:1 or <15% solids? Located on greater than 6% slope? Does pad exceed permeability requirements? Located on 2-6% slope without clean water Does pad show large ruts/erosion? diversion and erosion control practices? Are saturated soils within 2 feet? Does clean water flows through stockpile? Are coarse-textured soils present throughout Does runoff flow from the stockpile to top 5 feet at stockpile location? waters of state? Are soils bare--without vegetation for one year pre/post-use? Has this site been used longer than one year? Does amount in stockpile require over 320 ac. to land apply?

Compliant Issue(s): Conditional Compliance Non-compliant

Return to Compliance by:

Inspection Form wq-f5-15 (May 2008) 1 C. Liquid Manure Storage Areas Operation & Maintenance

1) Concrete Pit NA 2) Earthen Basin NA Yes No NA Issues: Yes No NA Issues: If open-air, depth marker installed? If open-air, has depth marker installed? Located under building? Is the basin covered? Freeboard/capacity shortage? Is the cover maintained? Cracks in need of repair? Are they flaring captured gases? Sloughing/flaking of concrete? Is an anaerobic digester present? Exposed rebar? Freeboard/capacity shortage? Nonfunctional perimeter tile outlet (if Basin modified without approval? constructed after 2000)? Barn constructed prior to 2000? Low spots in berm? Odorous/discolored liquid in perimeter tile Evidence of overflows? (if monitoring port present)? Evidence of seepage from pit? Odorous/discolored liquid in perimeter tile (if monitoring port present)? Build up of manure near pumpouts? Excessive gully erosion in basin walls? Pumpouts exposed (not covered)? Anti-scour device around pipe outlet absent? Woody/deep rooted vegetation growing near Pumpout area maintenance problems? pit walls? Is an anaerobic digester present? Woody/deep rooted vegetation growing on basin walls? Rodent burrows in berm? Evidence of seeping on exterior wall?

3) Synthetic-lined Basin NA 4) Slurry Store or Above-ground Tank NA Yes No NA Issues: Yes No NA Issues: If open-air, has depth marker installed? If open-air, has depth marker installed? Is the basin covered? Is the structure covered? Is the cover maintained? Is the cover maintained? Are they flaring captured gases? Freeboard/capacity shortage? Is an anaerobic digester present? Structure is leaking and/or overflowing? Freeboard/capacity shortage? Evidence of past leak and/or overflow? Basin modified without approval? Transfer valve not properly maintained? Low spots in berm? Evidence of overflows? Liner torn or damaged? Odorous/discolored liquid in perimeter tile (if monitoring port present)? Evidence of seeping on exterior wall? Pumpout area maintenance problems? Woody/deep rooted vegetation growing on basin walls?

Inspection Form wq-f5-15 (May 2008) 2 5) Manure Storage Area Emergency Response Plan Yes No NA Issues: Has site plan showing release points to surface water (surface tile intakes, road ditches, etc.)? Has plan of action for emergency spill response at facility and during transport to land application? Trains employees?

Compliant Issue(s): Conditional Compliance Non-compliant

Return to Compliance by:

6) Air Emission Notification for Exemption Yes No NA Is notification made for exemption during agitation and pumping for land application activities?

D. Other Production Area Features Operation & Maintenance 1) Feed Storage Area NA 2) Milkhouse Wastewater NA Yes No NA Issues: Yes No NA Issues: Piles of spoiled feed around storage bin? Discharges to land surface? Exposed feed or spillage on storage pad? Discharging to surface water? Clean water flows through feed area? Other: Silage leachate can flow to waters? Problems with leachate collection system?

3) Permanent Stormwater Controls NA Yes No NA Issues: Required permanent stormwater controls in place? Compliant Adequate permanent vegetation? Issue(s): Conditional ComplianceFreeboard on control structure absent? Non-compliant Structure outlets eroding?

Return to Compliance by:

E. Carcass Disposal

1) Rendering NA 2) Incineration NA Yes No NA Issues: Yes No NA Issues: Offsite pickup site accessible to scavengers? Structure designed for this purpose? Carcasses present more than 72 hours No afterburner? non-refrigerated?

Inspection Form wq-f5-15 (May 2008) 3 3) Composting NA 4) Burial NA Yes No NA Issues: Yes No NA Issues: Impervious pad not present? Carcasses not covered? Exposed carcasses? Coarse-textured soils? Temperature not measured daily? Within 5 feet of water table? Leachate not contained? Within shoreland zone?

Compliant Issue(s): Conditional Compliance Non-compliant

Return to Compliance by:

F. Non-Feedlot Operation & Maintenance

1) Well NA 2) On-site sewage system NA Yes No NA Issues: Yes No NA Issues: Un-used wells are MDH sealed? Straight-piped to surface water? (Report) Anti-backflow protection on waterline Discharging to ground surface? (Report) connections? Toilet plumbed to manure storage area?

3) Burn Barrels NA 4) Sharps Disposal NA Yes No NA Issues: Yes No NA Issues: Solid waste burned on site? Stored in heavy-duty plastic container for later disposal?

5) Chemicals, Gas, and Oil Storage NA Yes No NA Issues: Yes No NA Issues: Chemicals leaking onto ground? Monitored underground tank over 1,100 gal? Pesticide containers accumulating?

Compliant Issue(s): Conditional Compliance Non-compliant

Return to Compliance by:

Facility Record-Keeping Review

G. Land Application of Manure Level I Level II Level III Attach review form

Yes No NA Issues: Rainfall amounts when runoff from land application sites occurs?

Compliant Issue(s): Conditional Compliance Non-compliant

Return to Compliance by:

Inspection Form wq-f5-15 (May 2008) 4 H. Facility Records Review

1) O & M Records 2) Facility & Maintenance Records Yes No NA Issues: Yes No NA Issues: Water lines checked daily? Current design of all LMSAs? Weekly stormwater diversion devices? LMSA maintenance? Weekly runoff diversion structures? Soil-lined poultry barn floor soil test results? Weekly devices channeling runoff to SWPPP maintenance & modification? containment area(s)? Weekly of all LMSAs? Improvements to runoff control & barns? Weekly LMSA depth marker(s) readings? Activities that alter site or increase pollution potential? Weekly examinations of LMSA drain tile line(s)? Periodic inspections of land application equipment?

3) Short-term Stockpiling Records NA 4) Composting Records: Mortality or Manure NA Yes No NA Issues: Yes No NA Issues: Location information? Quantities of materials delivered to site? Date stockpile formed? Temperature of compost? Volume of manure stored? Retention time of compost? Analysis of finished compost?

Compliant Issue(s): Conditional Compliance Non-compliant

Return to Compliance by:

Inspection Form wq-f5-15 (May 2008) 5