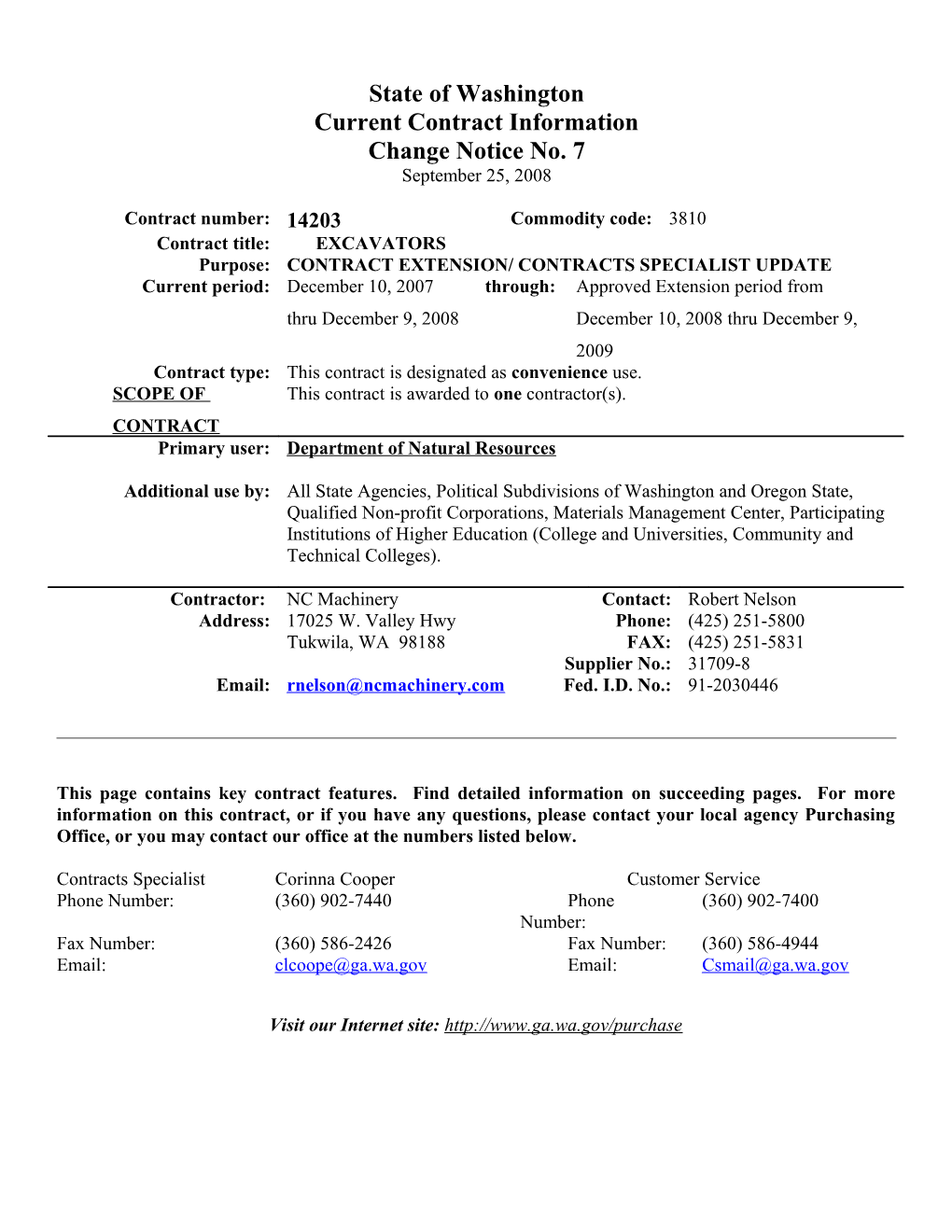

State of Washington Current Contract Information Change Notice No. 7 September 25, 2008

Contract number: 14203 Commodity code: 3810 Contract title: EXCAVATORS Purpose: CONTRACT EXTENSION/ CONTRACTS SPECIALIST UPDATE Current period: December 10, 2007 through: Approved Extension period from thru December 9, 2008 December 10, 2008 thru December 9, 2009 Contract type: This contract is designated as convenience use. SCOPE OF This contract is awarded to one contractor(s). CONTRACT Primary user: Department of Natural Resources

Additional use by: All State Agencies, Political Subdivisions of Washington and Oregon State, Qualified Non-profit Corporations, Materials Management Center, Participating Institutions of Higher Education (College and Universities, Community and Technical Colleges).

Contractor: NC Machinery Contact: Robert Nelson Address: 17025 W. Valley Hwy Phone: (425) 251-5800 Tukwila, WA 98188 FAX: (425) 251-5831 Supplier No.: 31709-8 Email: [email protected] Fed. I.D. No.: 91-2030446

This page contains key contract features. Find detailed information on succeeding pages. For more information on this contract, or if you have any questions, please contact your local agency Purchasing Office, or you may contact our office at the numbers listed below.

Contracts Specialist Corinna Cooper Customer Service Phone Number: (360) 902-7440 Phone (360) 902-7400 Number: Fax Number: (360) 586-2426 Fax Number: (360) 586-4944 Email: [email protected] Email: [email protected]

Visit our Internet site: http://www.ga.wa.gov/purchase Current Contract Information Change Notice No. 7 Contract No. 14203 Page 2

Ordering information: See page 2 Note III Ordering procedures: See page 2 Note II Special notes: See Below Payment address: 17025 W. Valley Hwy Tukwila, WA 98188 Order placement address: 17025 W. Valley Hwy Tukwila, WA 98188 Minimum orders: None Delivery time: 120 days After Receipt of Order (ARO) Payment terms: 0.02 % 30 days Shipping destination: Free On Board (FOB) Destination to DNR. All other orders FOB Dealer. Freight: Prepaid and included in unit pricing Contract pricing: See pages Attachment “A” Term worth: $334,081.00 $0.00 MBE $0.00 WBE $334,081.00 OTHER $0.00 EXEMPT Current participation: MBE 0% WBE 0% OTHER 0% EXEMPT 0%

NOTES: I. Best Buy: The following provision applies to mandatory use contracts only. This contract is subject to RCW 43.19.190(2) & RCW 43.19.1905(7): which authorizes state agencies to purchase materials, supplies, services, and equipment of equal quantity and quality to those on state contract from non-contract suppliers. Provided that an agency subsequently notifies the Office of State Procurement (OSP) State Procurement Officer (SPO) that the pricing is less costly for such goods or services than the price from the state contractor.

If the non-contract supplier's pricing is less, the state contractor shall be given the opportunity by the state agency to at least meet the non-contractor's price. If the state contractor cannot meet the price, then the state agency may purchase the item(s) from the non-contract supplier, document the transactions on the appropriate form developed by OSP and forwarded to the SPO administering the state contract. (Reference General Authorities document)

If a lower price can be identified on a repeated basis, the state reserves the right to renegotiate the pricing structure of this agreement. In the event such negotiations fail, the state reserves the right to delete such item(s) from the contract.

II. State Agencies: Submit Order directly to Contractor for processing. Political Subdivisions: Submit orders directly to Contractor referencing State of Washington contract number. If you are unsure of your status in the State Purchasing Cooperative call (360) 902-7415.

III. Only authorized purchasers included in the State of Washington Purchasing Cooperative (WSPC) listings published and updated periodically by OSP may purchase from this contract. It is the contractor’s responsibility to verify membership of these organizations prior to processing orders received under this contract. A list of Washington members is available on the Internet https://fortress.wa.gov/ga/apps/coop/Default.aspx,. Contractors shall not process state contract orders from unauthorized users.

085c850859eeffaff03b3d94ee81c312.doc 2 Current Contract Information Change Notice No. 7 Contract No. 14203 Page 3

SPECIAL CONDITIONS:

1. Current Contract Information (CCI) This Current Contract Information (Change Notice No. 7) extends contract 14203 for another term with NC Machinery from 12/9/08 to 12/9/09. Also, the Contracts Specialist and Customer Services information has been updated to reflect Corinna Cooper as the new Contracts Specialist and Customer Service as an additional point of contact.

2. Certificate of Insurance Contractor to furnish to the State Procurement Officer, a copy of a valid Certificate of Insurance listing the State as beneficiary (See Original Bid Document, Section II, Paragraph 1) within Fifteen (15) days after Contractor receipt of award notice. Certificate is to list contract number Contract 14203

3. Warranty See Specifications Attachment “B”.

4. Sales and Subcontractor Report A quarterly Sales and Subcontractor Report (attached) shall be submitted in the format provided by the Office of State Procurement. You can get the report electronically at https://fortress.wa.gov/ga/apps/CSR/login.aspx. Total purchases for each State Agency, University, Community and Technical Colleges must be shown separately. Total purchases for all political subdivisions and non-profit organizations may be summarized as one customer. Additionally, all purchases by the State of Oregon or other purchasers must be reported as an aggregate total.

The report shall include sales information (Section A) and amounts paid to each subcontractor during the reporting period (Section B)

Reports should be rounded to nearest dollar. Contractors will be provided with all necessary sample forms, instructions, and lists. Reports are due thirty (30) days after the end of the calendar quarter, i.e., April 30th, July 31st, October 31st and January 31st.

085c850859eeffaff03b3d94ee81c312.doc 3 Current Contract Information Change Notice No. 6 Contract No. 14203 Attachment “A”

PRICE SHEETS

Req. Comm. Description Unit Unit Price Item Code 3810 Excavator 36,000-37,000 lbs class with options 1-9. Refer to EA 1. Section 3.3 Specifications, DNR pages 1-13.

Provide Price of Base Machine: $98,854.00

Provide Price for options 1-9: $15,846.00

Product Bid: Mfg.: _CAT Brand/Model: ___315DL

2. NOTE: Vendor shall deliver new machine(s) to the locations stated Lot $855.00 on page 1 of these specifications.

(1) A backhaul of same class excavator from Sedro Woolly, WA (or within region boundary) shall be transported to DNR Olympia compound at 8410 Martin Way E. Lacy, WA

(2) A backhaul of same class excavator from Forks, WA (or within region boundary) to Pape’s Equipment Yard at Tacoma, WA State total delivery price for both machines including backhauls:

4 Current Contract Information Change Notice No. 6 Contract No. 14203 Attachment “A”

PRICE SHEETS

Req. Comm. Description Unit Unit Price Item Code 3. 3810 Excavator 30,800-32,500 lbs class with options 1-10. Refer to EA Section 3.3 Specifications, DNR pages 1-13.

Provide Price of Base Machine: $88,007.00

Provide Price for options 1-10: $9,746.00

Product Bid: Mfg.: ______CAT______Brand/Model: ______314 DR______

4. NOTE: Vendor shall deliver new machine to the Lot $488.00 Locations stated on page 1 of these specifications with a back haul of like excavator from Forks, WA. and/or within region boundary to DNR compound at 8410 Martin Way E. Lacy, WA State delivery price with backhaul:

5 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “A”

OPTIONS ADDED 10/25/04 Model 315

Item and Requirements Pricing Under contract section VII. HYDRAULIC SYSTEMS, add an option for a combination hydraulic hoe pack to run hydraulic thumb, hammer and compactor attachments. $7,568.00

Under contract section VIII. Structure Design/Undercarriage; add an option for a hydraulic wedge lock coupler (model 198-4430). $6,381.00

Under contract section IX. CAB; add an option for polycarbonate windows in the cab. STD

Under contract section X. PERFORMANCE SPECIFICATIONS, add an option for a 10’ 2” arm (stick) length as an alternative to the 8’6” arm length currently in the contract. $1,034.00

Under contract section XIII. Attachment Options, add an option for a Heavy Duty 48” ditching bucket with a bolt-on edge. The bucket shall be of standard manufacture (without increased Hardox 500 BHN material) and shall fit a wedge lock $6,051.00 coupler.

OPTIONS ADDED 10-17-05 Model 314 8 foot 2 inch Stick $1,146.00 Ditching Bucket, W/Bole on Edge, 60 inches $6,970.00 Dozer Blade $11,250.00 Thumb $8,932.00 Wedge Type Quick Disconnect $6,971.00 $5,973.00 Digging Bucket 24 inches $8,062.00 Combination Hydraulics

6 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B”

SECTION III SPECIFICATIONS

(2) EACH LC EXCAVATOR 36,000 – 37,500 lb CLASS Item 1-Page 1 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

I. GENERAL INFORMATION:

Bid hydraulic excavator must be new, unused current production track mounted model. (gray market models not accepted) Shall be bid with standard equipment whether called for or not in these specifications, except where these specifications call for a substitute feature or item in lieu of manufacturers standard. The bid unit shall operate on state owned forest road maintenance projects with high service demands and expectations.

NOTE TO BIDDER: Bid excavators shall be of the LC 16 metric ton size. One shall be placed at Sedro Woolly, Wa and the other at Forks, Wa. Servicing and warranty work shall be completed at these locations and/or within region boundaries.

All references to these specifications shall be addressed in a PRE-CONSTRUCTION after bid award.

NOTE: All items marked as “EXCEED” or DEVIATES” must be explained in detail. Failure to do so may result in bid rejection.

II. WEIGHT:

The advertised operating weight of base LC excavator, including all standard equipment, lubricants, coolant, full fuel tank and operator must be a minimum 36, 000 and maximum 37,500 lbs.

Following Specifications Shall be Standard Equipment on Bid Excavator With the Exception of Requested Options.

7 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 1-Page 2 of 13

DESCRIPTION MEETS EXCEEDS DEVIATES

III. ENGINE:

Engine shall be water cooled, four (4) or (6) cylinder, turbo charged, direct injection diesel, low emission (meeting EPA, and Tier 2 emissions regulations), air to air after- cooled, with low operating dynamic noise level X (Tier 3 of 102 db. compliant)

110hp@2150 Minimum SAE flywheel HP 110 @ 2200 RPM. rpm

Engine displacement shall not be less than 239 cu. in. 305 cu. in.

A two (2) stage dry type air cleaner shall be used with electronic service indicator.

Engine speed shall be electronic with a control dial in operators cab controlling engine speed (throttle). Shall be featured with auto deceleration only

Shall have engine oil sampling port for easy sampling access while engine is running.

Engine exhaust stack shall be curved towards the rear of the machine. Exhaust shall be a low noise type meeting in-cab requirements and USFS requirements for use in forest environments.

Engine oil, and fuel filters shall be placed in a remote area for ground level service. Spin-on oil and fuel filters are required. Engine service at 500 hr inter

Engine Turbo shall have a heat shield.

Engine compartment shall have side by side or swing out radiator, and oil cooler for ease of maintenance. Shall have independent removable dust-proof radiator net.

IV. ELECTRICAL:

Shall have DT type electrical connectors.

Electrical system shall be 24 volt. 8 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 3-Page 1 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

Shall have a Equipment Management Monitoring System. Monitoring engine functions ,maintenance intervals with capabilities of adjusting and presetting hydraulic working pressure and flows.

Shall have a color or easy to read monitor.

Shall have a on-board malfunction display with screen error code fault and component display.

Shall have on-board machine maintenance alert.

Shall have on-board trouble diagnostic data memory.

Shall have on-board operation data display mode. (record up to a minimum of 30 monitored faults)

50 Amp Shall have minimum 35 amp alternator.

Shall have automatic bi-level air-conditioner.

Automatic engine warm-up system.

Am/Fm Radio with (2) flush mounted speakers.

OPTION # 1: Quick release mounted (removable) CB Radio with external individual speaker. (12V converter shall be standard equipment) Antenna shall be mounted behind the cab with flexible base. (placement of radio, speaker and antenna shall be pre-approved by DNR) State Installed Price: $_658.00 ___

Back up alarm with shut-off.

OPTION # 2: “Working Time Hour Meter” in addition to the OEM Hour Meter or Service Meter which records total engine hours. The machine shall be equipped with a hour meter which records actual operation (working time) of the machine. The working meter or recorder shall begin to 9 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 4-Page 1 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES operate for a defined period of time (defined period of time shall be field adjusted from approximately 20 seconds to 15 minutes), as long as one of 3 pre-selected work essential functions are activated. The meter shall stop if one of the essential functions has been de- activated. “Working Essential Functions are: 1. Activation of swing circuit. 2. Activation of travel circuit. 3. Pressure exceeding 60% of expected hydraulic pressure at rated power. Working Time Hour Meter shall not be functional when the engine is not running and the key off. The hour meter installation shall be weather proof and all elements sealed (security) preventing tampering or disconnecting the meter system. (If bid machine’s computer has this capability, state which working function(s)are being recorded. Recorded information must be obtainable from onboard monitor screen). (System and location must be pre-approved by DNR) State Installed Price: $ __ 1,325.00______

V. STEERING/TRAVEL SYSTEM: Travel speed shall be low and high speeds. Steering control shall be with (2) levers with pedals. Travel motors shall be 2 x axial piston with park and service brake hydraulic lock. Travel method shall be hydrostatic Drawbar Pull shall be a minimum of 33,500 lbs.

VI. SWING SYSTEM: Drive method shall be hydrostatic Shall have swing reduction planetary gear. Holding brake/swing brake shall be wet multiple- disc brake. Service brake shall be hydraulically locked.

10 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 1-Page 5 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES Swing motor shall have access tube(s) for oil check and oil add. Swing speed shall be a minimum of 10.2 R

VII. HYDRAULIC SYSTEM(S): We have open-centered, negative flow control system Shall be equipped with load sensing and pressure compensating valves hydraulic system. State Type of System: ______ Boom and Arm holding valves shall be part of the main control valve O-Ring face hydraulic fitting are preferred Hydraulic pumps shall be variable displacement piston type with (2) sets of pistons and separate oil ports with high pressure hydraulic screens/filters to insure against pump(s) failure from contamination. Minimum pump flow shall be 40 gpm per pump and 80 gpm in combination with minimum implement circuit pressure of 4,980 psi.. State GPM and Circuit Implement Pressure: ______ Shall have a minimum of 4 working modes (automatic adjusting or manual): (1) Active mode (2) Economy Mode (3) Lifting Mode (4) Attachment Operation. Shall have one standard auxiliary hydraulic service valve for hydraulic thumb with ability of regulating speed of function with easy adjustment by an operator. Shall have engine and hydraulic oil sample port(s) for ease of sampling while machine is running. OPTION # 3 : Additional Auxiliary Hydraulic Circuit: Shall install a auxiliary hydraulic circuit for a Helac TT-10 Powertilt attachment. Service valve shall have the capacity to regulate the speed of function with easy adjustment by a operator. All metal hydraulic tubing and hoses shall be mounted on top of the main boom and arm. Plumbing shall be secured by brackets with insulators. . State installed price: $ _ 5,411.00 __ Option #3A: Hydraulics to power thumb. $_5,371.00__

11 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 1-Page 6 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

Hex-nut couplers shall serve as the connections points between arm power tilt tubing and power tilt hoses.

Shall have removable screen/filter system in hydraulic tank to insure filtration of hydraulic oil. State type of hydraulic filtration system with micron absolute count on filter(s).

NOTE: All additional auxiliary hydraulic circuits shall be installed by base machine vendor. No exceptions.

VIII. Structure Design / Undercarriage:

Boom and arm shall be built to withstand severe side stress and down pressure. (DNR uses a 60” ditching bucket under a TT-10 Helac Powertilt).

Chain, track shoes, top and bottom track rollers, idlers, travel motors and final drives shall be the same as equipped on a 20 ton LC class excavator

Boom foot and boom tip shall be cast or fabricated metal. Front linkage joints use a bushing with a sintered inner-layer and is self- Bucket shall have grease intervals of 100 hrs, stick and lubricating with 1,000 hr. grease intervals, bucket pin joints use a mesh boom joint(s) shall have grease intervals of 500 hrs. bearing with 100 hr. grease intervals State Grease Intervals: Bucket 100 hrs. Stick and boom, 1,000 hours

Shall have a minimum of 44 manufactured triple grouser 24” shoes. (cut to meet specifications shall not be accepted) State # of grousers:_44______

2 carrier 7 bottom rollers-single Shall be equipped per side with 7 bottom and 2 carrier rollers flange sealed rollers with alternating flanges. Shall be equipped with front, center and rear track guides.

12 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B”

13 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 1-Page 7 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

Counter weight shall be a minimum of 6,200 lbs. State counter weight amount: 6,640 lbs.

Track link with strut shall be sealed pins and bushings

OPTION # 4: Shall have cover for undercarriage hydraulic swivel compartment made from the same dimension steel as main under frame. All bolt heads on cover shall be recessed. State Installed Price $315.00

OPTION # 5: Tow eyes front and rear: Forged lashing rings (1” diameter material) shall be welded to the rear and front (2 ea) of the car body angled for cross chaining. Location to be pre-approved by DNR. State Installed Price: $527.00

IX. CAB:

Cab shall be pressurized with access to cab and A/C filter compartment at ground level.

Front operators window shall be one touch release power assist type.

Viscous cab damper mounts shall be of the rubber silicon oil type.

Cab shall not have right side operator cab middle support pillar for better right side visibility.

The operators seat shall be a soft deluxe suspension multi- positioning cloth covered seat with retractable seat-belts. Shall contain the pilot controls with independent positioning.

OPTION #6: Shall be equipped with ergonomically designed SAE pilot control handles. The handles shall be Sure Grip “C” series side by side button w/o trigger. Function control as follows: Left top handle left function button power tilt swing left --- right function button swing right. Right top handle left function button close thumb --- right function button open thumb. State Installed Price: $1,130.00

14 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 1-Page 8 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

OPTION: # 7 Shall have cab sun visor. State Installed Price: $205.00

OPTION: # 8 Horn shall be mounted on right side floor. Location pre-approved by DNR. Horn switch shall be a one touch and release with rubber sealed body. State Installed Price $125.00

OPTION: # 9 Swing motor/gear compartment shall be covered so debris will not accumulate. Swing gear oil check and fill shall be made easily assessable to operator(s) and maintenance personnel. Pre-approved by DNR. State Installed Price if Cover is Additional. $742.00

X. PERFORMANCE SPECIFICATIONS:

Minimum Arm length 8’ 6” --- maximum arm Length 8’ 7” State Length 8’6”

Minimum boom length 16’ 9” State Length. 16’9”

Minimum lifting capacity at 20’ reaches from swing center, over the side, at ground level 5,100 lbs. State lbs 5,900 lbs..

Transport width shall be 8” 6”.

Minimum track length 13’. State Length 13’

Minimum track on the ground 10’ 5”. State Length 10’5”

Bucket digging force SAE rating shall be a minimum of 22,250 lbs. State Force in lbs: 22,250 lbs.

Arm crowd force shall be a minimum of 17, 080 lbs State Force in lbs: 17,080 lbs.

15 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” DESCRIPTION MEETS EXCEEDS DEVIATES

Digging depth minimum of 19’10”. State depth: 19’10”

16 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 1-Page 9 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

XI. OTHER SPECIFICATIONS:

Paint to be manufacturers standard colors.

One set of replacement filters shall be furnished with each machine.

Vendor shall supply the following sets of Manuals: Operators manual: 2 ea Parts Manuals: 2 ea Shop Manuals: 2 ea

Successful bidder shall be required to provide training covering the base machine and all attachments before machine leaves vendors premises. Another training after the machine has been in the field scheduled by DNR. Training shall cover operation, maintenance, service (vendor support), and warranty.

XII. PARTS, SERVICE & WARRANTY

Factory authorized service and support shall not be not more than 2 hrs from Sedro Woolly, Wa and not more than 4 hours from Forks, Wa. State Distance to these locations: Sedro Woolly Miles 8-10 Time 15 min. Forks Miles 54 Time 1 hr. 16 min.

Machine downtime impacts job production. It is vitally important normal wear parts, service and warranty be available not more than 24 hours after ordered by DNR The majority of remaining hard parts should be available within 48 hours of order. Failure to comply shall be documented and will be used in evaluation future bid awards. Attach a statement indicating parts availability and delivery times your organization will normally meet

.

17 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 1-Page 10 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

XIII. ATTACHMENTS OPTIONS:

OPTION #1: Helac Model TT-10 Powertilt. Attachment shall be fully operation at time of delivery. State installed price : $8,485.00

OPTION #2: Progressive Hydraulic Link Thumb matched in length with attached power tilt and bucket combination if required. (hydraulic circuit is bid separately Pg 5 of 13 Option # 3) State installed price $8,288.00

OPTION #3: Heavy Duty 36” General Purpose Bucket . Bucket shall be built to withstand sever down/side pressure from operational positioning of powertilt while digging. Bucket capacity shall be a minimum of (1)cu. yd. heaping with 5 teeth Option #3 Bucket Specifications as follows: Bucket shell , side plates and top plate: 5/16”

Hardox 400 BHN material or equal.

Side Wear Plates: 1/4” thick covering bottom 1/3 of side plates to be Hardox 500 BHN or equal.

Leading Edges: ¾” x 5 “ wide covering full height shall be Hardox 500 BHN or equal.

Cutting Edge : 1” x 10” shall be Hardox 400 BHN or equal

Wear Plates : 1/4” x 3” Hardox 500 BHN or equal covering the outside bottom of bucket shell beginning at rear of cutting edge continuing up through bucket radius with 1” spacing between ea

18 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 1-Page 11 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

Reinforcing: Outside bottom shell edges shall be wrapped with Hardox 500 BHN or equal

Reinforcing: Inside bottom and top shell edges shall be reinforced with gussets using Hardox 400 BHN or equal.

Radius: Bucket radius shall be continuous from top through the cutting edge. (4 degree radius on bottom)

Bucket Lugging: Shall have replaceable press fit bushings. Lugging shall be as short as possible without limiting the bucket from it’s arch swing of 70 degrees right and left. Lugging shall have gussets to provide strength from side-load -- out sides of each lug.

Bucket Pins: (2) ea. Shall be greasable with starting end chamfered for ease of starting when changing attachments

Lifting Hook: Rear of bucket shall have a lifting hook, with safety clasp, capable of machine’s maximum lifting capacity at 10 feet.

Teeth: Bucket shall be supplied with one additional set of replaceable teeth including all attaching hardware.

State option #3 installed bucket price with “ALL” bucket specifications indicated above : $8,488.00

OPTION: #4: Heavy Duty General Purpose: Standard manufactured bucket without increased BHN material. All dimensions and bucket specifications shall remain as stated in “ Option #3 Bucket Specification” Pg 10 & 11 of 13 State Option #4 installed price $4,371.00

OPTION: #5 Auto Lube System: “Groeneveld” Auto Lube System with 4 liter grease canister with controller placed inside a existing compartment or mounted inside compartment door only by machine vendor’s approval. All grease point lines on Arm, Thumb, Bucket Link Pins and Arm Pins shall have super steel pipe (3/8 OD x 1/8 ID) or equal.

19 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 1-Page 12 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

Excavators work in a forest environment, all grease lines and fittings shall be routed and installed for maximum protection. State installed price: $7,626.00

XIV. BASE WARRANTY: Shall have no less than a standard full warranty of 12 months or 1500 engine hours. State standard warranty: 12 mo./1,500 hr. Full Machine Warranty NOTE: The warranty shall be honored by all dealers in Washington and boarding states. In event that warranty work is required, the vendor shall be responsible for all costs incurred ie: travel cost, machine transported to vendor facilities (if needed), and at DNR’s decision a replacement of like kind machine transported to same job site.

XV. WARRANTY OPTIONS:

State All Warranty Options with Prices starting from end of standard warranty period extending through 7 years 7,000 hours. State all variations and combinations ( years and hour increments – with components) of warranty options (i.e. full machine, power-train, hydraulics, undercarriage, boom, stick, etc) NOTE: Cost of extended warranty shall be used to determine lowest responsive bid IF this option is chosen

XVI. ADDITIONAL OPTION EQUIPMENT:

OPTION A: List all options (non-standard equipment offered by machine manufacturer), with associated pricing

OPTION C: Helac Power grip 60” ditching bucket with radiuses of 4 – 6 – 32.5 degrees beginning from top through bottom to cutting edge. Bucket capacity shall be 1 cu yd heaping. State Price: $14,261.00

OPTION D : Helac Power grip 36” GP bucket with 4 degree bottom radius. 1 cu yd heaping. State Price: $ 14,261.00

NOTE: Radius include the power grip lip on all power grip buckets.

20 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 1-Page 13 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

OPTION E: Standard 60” ditching bucket with radiuses of 4 – 6 – 32.5 degrees beginning from top of bucket through foreword edge of cutting edge. Capacity shall be 1 cu yd heaping. Reinforcing and wear plates shall be included at purchaser’s request and approval. State Standard Bucket Price: $5,281.00

State Price of Heavy Duty Bucket with reinforcing and wear material described on Option #4 Pg 11 of 13: $11,529.00

If any additional option attachment(s) shall be accepted as part of this bid, structural design and specifications shall be presented by purchaser (ie. DNR) at PRE-Construction meeting.

OPTION F: ONE YEAR FULL SERVICE State service options with price per service for one year. This would include all regular manufacturer recommended hour service intervals with estimated 1,200 yearly machine hours. Location is described on Pg 1 of 13 Under: “NOTE TO BIDDER” State Price for One Year Full Service: $2,500.00

OPTION G: BODY SIDE GUARD Lower side body guards shall be fabricated to a width not extending past the outside of track pads (total width of body with guarding 8’6”). Guarding designed from square or rectangle tubing with ¼” wall. Guard to be one continuous piece front to rear, extending past the beginning of counter-weight, blended with closed ends. Guarding attached to the lowest portion of the windshield and body, a formed standing platform10” deep and windshield width with ends to be blended with operator side guarding with closed ends. State installed price: $3,053.00

INSPECTIONS: By the Department of Natural Resources (DNR) may be periodic throughout manufacturing and before delivery/acceptance. Inspections shall be made by a DNR representative from the DNR Engineering Forest Roads Section. Contact representative, DON ROLLER, (360) 701-4398 or (360) 902-1176 for specification interpretation and compliance issues/concerns.

21 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” (1) EACH LC EXCAVATOR – ZERO TAIL SWING 30,800 --- 32,500 lb CLASS Item 2-Page 1 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

I. GENERAL INFORMATION:

Bid hydraulic excavator must be new, unused current production track mounted model. (gray market models not accepted) Shall be bid with standard equipment whether called for or not in these specifications, except where these specifications call for a substitute feature or item in lieu of manufacturers standard. The bid unit shall operate on state owned forest road maintenance projects with high service demands and expectations.

NOTE TO BIDDER:

Bid excavators shall be of the LC 13.8 metric ton size. One shall be placed at Forks, Wa. Servicing and warranty work shall be completed at this location and/or within region boundary.

All references to these specifications shall be addressed in a PRE– CONSTRUCTION meeting after bid award.

NOTE: All items marked as “EXCEED” or DEVIATES” must be explained in detail. Failure to do so may result in bid rejection.

II. WEIGHT:

The advertised operating weight of base LC excavator, including all standard equipment, lubricants, coolant, full fuel tank and operator must be a minimum 30, 800 and maximum 32,500 lbs.

Following Specifications Shall be Standard Equipment on Bid Excavator With the Exception of Requested Options

22 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 2-Page 2 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

III. ENGINE:

Engine shall be water cooled, four cycle, 4 cylinder, turbo 4 cyl-Turbo Charged, charged, direct injection diesel, low emission (meeting Tier 2, No ATAAC, EPA, and Tier 2 emissions regulations), air to air after- 103db cooled, with low operating dynamic noise level of 102 db 90hp@1950rpm Minimum SAE flywheel HP 90 @ 2200 RPM. 259 cu. in. Engine displacement shall not be less than 239 cu. in.

2-stage air cleaner, A two (2) stage dry type air cleaner shall be used with mechanical indicator electronic service indicator. Control dial-Auto Deceleration with Engine speed shall be electronic with a control dial in one-touch low idle operators cab controlling engine speed (throttle). Shall for added convenience be featured with auto deceleration only

Shall have engine and hydraulic oil sampling port for easy sampling access while engine is running.

Engine exhaust stack shall be curved towards the rear of the machine. Exhaust shall be a low noise type meeting in-cab requirements and USFS requirements for use in forest environments

Engine oil, and fuel filters shall be placed in a remote area for easy access for ground level service. Spin-on oil and fuel filters are required. Engine service at 500 hr intervals.

Engine Turbo shall have a heat shield.

Engine compartment shall be separated from the hydraulic compartment for fire prevention. Engine and Swing out oil oil radiators shall have a independent removable dust- cooler proof net.

IV. ELECTRICAL:

Shall have DT type electrical connectors.

Electrical system shall be 24 volt.

23 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 2-Page 3 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES Shall have a Equipment Management Monitoring System. Monitoring engine functions, maintenance intervals with capabilities of adjusting and presetting hydraulic working pressures and flows..

Shall have a on-board color and easy to read monitor.

Shall have on-board malfunction display with screen error code fault and component display

Shall have on-board trouble diagnostic data memory.

Shall have on-board operation data display mode. (record up to 30 monitored faults)

50 amp Shall have minimum 35 amp alternator.

Shall have automatic bi-level air-conditioner.

Automatic engine warm-up system.

Am/Fm Radio with (2) flush mounted speakers.

OPTION # 1: Quick release mounted (removable) CB Radio with external individual speaker. (12V converter shall be standard equipment) Antenna shall be mounted behind the cab with flexible base.(placement of radio, speaker and antenna shall be pre-approved by DNR) State Installed Price: $662.00

Back up alarm with automatic temporary shut-off.

24 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” DESCRIPTION MEETS EXCEEDS DEVIATES

OPTION # 2: “Working Time Hour Meter” in addition to the OEM Hour Meter or Service Meter which records total engine hours. The machine shall be equipped with a hour meter which records actual operation (working time) of the machine. The working meter or recorder shall be begin to operate for a defined period of time (defined period of time shall be field adjusted from approximately 20 seconds to 15 minutes), as long as one of 3 pre-selected work essential functions are activated. The meter shall stop if one of the essential functions has been de-activated

25 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 2-Page 4 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES “Working Essential Functions are: 4. Activation of swing circuit. 5. Activation of travel circuit. 6. Pressure exceeding 60% of expected pressure at rated power. Working Time Hour Meter shall not be functional when the engine is not running and the key off. The hour meter installation shall be weather proof and all elements sealed (security) preventing tampering or disconnection the meter system. (If bid machine’s computer has this capability, state which working function(s) are being recorded. Recorded information must be obtainable from onboard monitor screen). (System and location must be pre-approved by DNR) State Installed Price: $1,325.00 OPTION # 3: Brush cutter electrical hydraulic circuit safety switch shall be dash mounted with activation light and flip cover. Operating electrical switch shall be floor mounted rubber sealed one touch on and off. Pre- approved location. State Installed Price: Not Available from NC Machinery

V. STEERING/TRAVEL SYSTEM:

Two speed travel speeds.

Steering control shall be with (2) levers with pedals. Travel motors shall be 2 x axial piston with park and service brake hydraulic lock.

Travel method shall be hydrostatic 24,730 lbs. Drawbar Pull shall be a minimum of 24,700 lbs.

VI. SWING SYSTEM:

Drive method shall be hydrostatic.

Shall have swing reduction planetary gear. Holding brake/swing brake shall be mechanical disc brake.

Service brake shall be hydraulically locked.

26 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 2-Page 5 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

Swing motor shall have access tube(s) for oil check and add. 12.6 rpm Swing speed shall be a minimum of 11 RPM.

VII. HYDRAULIC SYSTEM(S): Shall be equipped with load sensing and pressure compensating valve(s) hydraulic system. State Type of System: Open Center, Negative flow control system Boom and Arm holding valves shall be part of the main Anti-drift valves are part of the main control valve valve

O-Ring face hydraulic fitting are preferred.

Hydraulic pumps shall be variable displacement piston type. With (2) sets of pistons and separate oil ports with high pressure hydraulic screens/filters to insure against pump(s) failure from contamination.

Minimum pump flow shall be 67 gpm in combination with implement circuit pressure @ a min. of 4,300 psi. State GPM & Circuit Implement Pressure: 67gpm@4,340psi

Shall have a minimum of 3 working modes (automatic or manual) (1) Active mode (2) Economy Mode (3) Breaker Operation.

Shall have one standard auxiliary hydraulic service valve for hydraulic thumb with ability of regulating speed of function with easy adjustment by an operator.

Shall have engine and hydraulic oil sample port(s) for ease of sampling while machine is running.

27 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 2-Page 6 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

OPTION # 4 : Auxiliary Hydraulic Circuit: Installed auxiliary hydraulic circuit for a Helac PT-9 Powertilt attachment. Service valve shall have the capacity to regulate the speed of function with easy adjustment by a operator. All metal hydraulic tubing and hoses shall be mounted on top of the main boom and arm. Plumbing shall be secured by brackets with insulators. . State installed price: $5,411.00 Hex-nut couplers shall serve as the connections points between arm power tilt tubing and power tilt hoses. OPTION # 5: Auxiliary Hydraulic Circuit . Installed Includes Thumb Hyd. auxiliary hydraulic circuit for the operation of a ProMac *No option #3 as stated CMP 36 Series –2 brushcutter. Minimum 28 gpm) oil flow on page 10 of 13 for and a minimum of 4,000 psi is required. Installation shall be thumb circuit. to ProMac’s manufacturing specifications (hydraulic circuitry, valving and operation.) Performance and productivity of machine and brushing head is critical. Performance shall include the simultaneous productive movement of brusher operation, boom, stick, and swing. Travel shall simultaneous while brusher head is in operation. DNR shall test simultaneous critical operational performances before machine is accepted. of machine with brusher in cutting operation shall be at DNR’s approval. Additional specifications: (1) Boom mounted plumbing shall be secured to the top of theboom not extending over the outer edges. (2) Arm plumbing shall be mounted on the sides with ¼” channel bolt on coverings. Bolted covering over couplers shall be a separate piece for easy access. (3) Quick couplers between arm and brush cutter shall be of the hex-nut type on all hydraulic circuit connection points. Steel caps shall be supplied for coupler openings when brush cutter is detached. (4) Protection covering for brush cutter hoses shall be a boot type. (5) Protective steel fabricated cover over brusher hydraulic motor. State complete hydraulic circuit installed price: Not Available from NC Machinery Shall have removable screen/filter system in hydraulic tank to Removable suction screen in tank. Main insure filtration of hydraulic oil. State type of hydraulic return, pilot oil, drain oil filtration system with micron absolute count on filter(s). filters are 10 micron

All additional auxiliary hydraulic circuit(s) shall be installed by the base machine vendor . No exceptions

28 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 2-Page 7 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

VIII. Structure Design / Undercarriage: Boom and arm shall be built to withstand severe side stress and down pressure. (DNR uses a 60” ditching bucket under a PT-9 Helac Powertilt). Boom foot and boom tip shall be casted or fabricated metal

Bucket shall have grease intervals of 100 hrs, stick and boom joint(s) shall have grease intervals of 500 hrs. State Grease Intervals. Bucket 100 hrs; Stick and Boom 1,000 hrs.

Shall have a minimum of 46 manufactured triple grouser 24” shoes. (cut to meet specifications shall not be accepted) State # of grousers: 46

Shall be equipped with a minimum of 7 bottom and 2 carrier sealed rollers with alternating flanges. State number of carrier and bottom rollers: #7 bottom/2 carrier

Shall be equipped with front, center and rear track Front, center guides guides.

Counter weight shall be a minimum of 7,280 lbs. State counter weight amount: 7,280.00 lbs.

Track link with strut shall be sealed pins and bushings

OPTION: # 6 Cover for undercarriage hydraulic swivel compartment made from the same dimension steel as main under frame. All bolt heads on cover shall be recessed. State Installed Price: $340.00 OPTION # 7: Tow eyes front and rear: Forged lashing rings (1” diameter material) shall be welded to the rear and front (2 ea) of the car body angled for cross chaining. Location to be pre-approved by DNR. State Installed Price: $527.00

29 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 2-Page 8 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

IX. CAB:

Filter is inside cab Cab shall be pressurized with access to cab and A/C filter under seat compartment at ground level. Rear window is fixed Rear operator’s window shall slide open.

Viscous cab damper mounts shall be of the rubber silicon oil type.

Cab shall not have right side operator cab middle support pillar for better right side visibility.

The operators seat shall be a soft deluxe suspension multi- positioning cloth covered seat with seatbelt retractors. Shall contain the pilot controls with independent positioning.

OPTION # 8: Shall be equipped with ergonomically designed SAE pilot control handles. The handles shall be Sure Grip “C” series side by side button w/o trigger. Function control as follows: Left top handle left function button powertilt swing left --- right function button swing right. Right top handle left function button close thumb --- right function button open thumb. State Installed Price: $1,130.00

OPTION # 9: Installed cab sun visor. State Installed Price: $205.00

OPTION # 10: Horn shall be mounted on side floor. Location pre-approved by DNR. Horn switch shall be a one touch and release with rubber sealed body. State Installed Price: $146.00

X. PERFORMANCE SPECIFICATIONS: Maximum Arm length 6’ 11”. State Length 6’10”

Minimum boom length 15’ 1” State Length.15’1”

Minimum lifting capacity at 20’ reaches from swing center, over the side, at ground level 3,850 lbs. State lbs 3,860 lbs.

Transport width shall be 8” 6”.

30 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 2-Page 9 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

Minimum track length 12’ 4”. State Length 12’4”

Minimum track on the ground 9’ 11”. State Length 9’11”

Bucket digging force SAE rating shall be a minimum of 19,800 lbs. State Force in lbs: 18,800 lbs.

Arm crowd force shall be a minimum of 16,000 lbs State Force in lbs: 16,640 lbs.

Digging depth minimum of 16’8”. State depth: 16’9”

Minimum implement swing radius 6’ 6” State radius: 6’6”

Minimum tail swing radius 4’ 10” State radius: 4’10”

XI. OTHER SPECIFICATIONS: Paint to be manufacturer’s standard colors

One set of replacement filters shall be furnished with each machine.

Vendor shall supply the following sets of Manuals: Operators manual: 2 ea Parts Manuals: 2 ea Shop Manuals: 2 ea

Successful bidder shall be required to provide training covering the base machine and all attachments before machine leaves vendors premises. Another training after the machine has been in the field scheduled by DNR. Training shall cover operation, maintenance, service (vendor support), and warranty.

XII. PARTS, SERVICE & WARRANTY Factory authorized service and support shall not be not more than 4 hours from Forks, WA. State Distance to this location: Forks Miles 54 Time1 hr. 16 min.

31 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 2-Page 10 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

Machine downtime impacts job production. It is vitally important normal wear parts, service and warranty be available not more than 24 hours after ordered by DNR The majority of remaining hard parts should be available within 48 hours of order. Failure to comply shall be documented and will be used in evaluation future bid awards. Attach a statement indicating parts availability and delivery times your organization will normally meet.

XIII. ATTACHMENTS OPTIONS: OPTION #1: Helac Model PT-9 Powertilt. Attachment shall be fully operation at time of delivery. State installed price: $ 6,711.00

OPTION #2: Pro Mac 36 CMP Series – 2 Pro Mac Brush cutter with single front door opening, modified pusher pad thumb bracket – Part #8003-8011, drive flex coupler and (2) ea greasable chamfered pins. State installed price: Not Available from NC Machinery

OPTION #3: Windshield Protective Covering Lexan windshield protection mounted to protect the windshield from breaking and operator protection. Mounting shall be swing away or mounted for easy cleaning of outside windshield. Lexan breaking strength to be determined by machine vendor. State installed price: $1,865.00

OPTION #4: Progressive hydraulic link thumb matched in length with attached powertilt and bucket combination. (hydraulic circuit is bid separately Pg 5 of 13 Option #3) State installed price: $8,130.00 OPTION #5: Heavy Duty 36” General Purpose Bucket. Bucket to withstand sever down/side pressure from operational positioning of power tilt while digging. Bucket capacity shall be a minimum of (.88)cu. yd. heaping with 5 teeth.

32 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 2-Page 11 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES Option #5 Bucket Specifications as follows: Radius: Bucket radius shall be continuous from top through the cutting edge. (4 degree radius on bottom) Bucket Lugging: Shall be have replaceable pressed bushings. Lugging shall be as short as possible without limiting the bucket from it’s arch swing of 70 degrees right and left. Lugging shall have gussets to provide strength from side-load both sides of each lug. Wear Points : Bottom of bucket, leading edges, outside bottom shell edges, side wear plates shall all be reinforces with A 400 or equal steel. Shall install inside top and bottom reinforcing gussets. Bucket Pin: (1) ea Shall be greasable and chamfered for ease of starting when changing attachments. Lifting Hook: Rear of bucket shall have a lifting hook with safety clasp capable of machine’s maximum lifting capacity at 10 feet. Teeth: Bucket shall be supplied with one additional set of replaceable teeth including all attaching hardware. State installed price with “ALL” bucket specifications indicated above: $12,138.00 OPTION # 6: Auto Lube System: System shall be a twin “Groeneveld” Auto Lube System with 4 liter grease canister with controller placed inside a existing compartment or mounted inside compartment door only on machine vendor’s approval. All grease points on Arm, Thumb, Bucket Link Pins and Arm Pins shall have super steel pipe (3/8” OD x 1/8” ID) or equal. Bid machine shall work as a Brusher 90% of working hours. All grease lines and fittings shall be routed and installed for maximum protection. State installed price: $ 7,620.00

33 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 2-Page 12 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

XIV. BASE WARRANTY: Shall have no less than a standard full warranty of 12 months or 1500 engine hours. State standard warranty: 12 mo. / 1500 hr Full Machine Warranty

NOTE: The warranty shall be honored by all dealers in Washington and boarding states. In event that warranty work is required, the vendor shall be responsible for all costs incurred ie: travel cost, machine transported to vendor facilities (if needed), and at DNR’s decision a replacement of like kind machine transported to same job site.

XV. WARRANTY OPTIONS: List All Warranty Options with Prices starting from the end of standard warranty period extending through 7 years / 7,000 hours. State all variations and combinations (year and hour increments – with components) of warranty options (ie. full machine, power-train, hydraulics, undercarriage, boom, stick, etc. NOTE: Cost of extended warranty shall be used to determine lowest responsive bid IF this option is chosen.

XVI. ADDITIONAL OPTION EQUIPMENT:

OPTION A: “List” all options (non-standard equipment offered by machine manufacturer), with associated pricing”.

OPTION B: Helac Power grip 48” ditching bucket with radiuses of 4 – 6 – 32.5 degrees beginning from top through bottom to cutting edge. Bucket capacity shall be .88 cu yd heaping. State Price: $13,803

OPTION C: Helac Power grip 36” GP bucket with 4 degree bottom radius .88 cu yd heaping State Price: $12,138.00

OPTION D: Standard 48” ditching bucket with radiuses of 4 – 6 – 32.5 degrees beginning from top through bottom to cutting edge. Bucket capacity shall be 1 cu yd heaping. State Price: $ 4,758.00

NOTE: Radius includes the power grip lip on the power grip buckets If optional attachment(s) shall be accepted as part of this bid, structural design specifications shall be presented by purchaser (ie. DNR).

OPTION E: ONE YEAR FULL SERVICE State service options with price per service for one year. This would include all regular manufacturer recommend hour service intervals with estimated 1,200 yearly machine hours. Location is described on Pg 1 of 13 Under: “NOTE TO BIDDER”. State Price for One year Full Service: $ 2,546.00 34 Current Contract Information Change Notice No. 6 Contract No. Contract No. 14203 Attachment “B” Item 2-Page 13 of 13 DESCRIPTION MEETS EXCEEDS DEVIATES

OPTION F: BODY SIDE GUARD Lower side body guards shall be fabricated to a width not extending past the outside of track pads (total width of body with guarding is 8’ 6”). Guarding designed from square or rectangle tubing with ¼” wall. Guard to be one continuous piece front and rear, extending past the beginning of counter weight, blended with closed ends. Guarding attached to the lowest portion of the windshield and body, a formed standing platform 10” deep and windshield width with ends to be blended with operator side guarding with closed ends. State Installed Price: $ 3,053.00

INSPECTIONS: By the Department of Natural Resources (DNR) may be periodic throughout manufacturing and before delivery/acceptance. Inspections shall be made by a DNR representative from the DNR Engineering Forest Roads Section. Contact representative, DON ROLLER, (360) 701-4398 or (360) 902-1176 for specifications interpretation and compliance issues/concerns.

35 Current Contract Information Change Notice No. 6 Contract No. 14203 Page 32

PERFORMANCE REPORT FOR PURCHASING & CONTRACT ADMINISTRATION

To OSP Customers: Please take a moment to let us know how our services have measured up to your expectations on this contract. Please copy this form locally as needed and forward to the Office of State Procurement Purchasing Manager. For any comments marked unacceptable, please explain in remarks block.

Procurement services provided: Excellent Good Acceptable Unacceptable Timeliness of contract actions Professionalism and courtesy of staff Services provided met customer needs Knowledge of procurement rules and regulations Responsiveness/problem resolution Timely and effective communications

Comments:

Agency: Prepared by: 085c850859eeffaff03b3d94ee81c312.do Contract No.: c Title: Contract Title: Date: Phone:

Send to:

Purchasing Manager Office of State Procurement PO Box 41017 Olympia, Washington 98504-1017

36 Current Contract Information Change Notice No. 6 Contract No. 14203 Page 37

PERFORMANCE REPORT FOR CONTRACTOR PRODUCT/SERVICE

Complete this form to report problems with suppliers or to report unsatisfactory product or services. You are also encouraged to report superior performance. Agency personnel should contact suppliers in an effort to resolve problems themselves prior to completion and submission of this report.

Contract number and title: 085c850859eeffaff03b3d94ee81c312.doc

Supplier’s name: Supplier’s representative:

PRODUCT/SERVICE

Contract item quality higher than required Damaged goods delivered Contract item quality lower than required. Item delivered does not meet P.O./contract specifications Other: SUPPLIER/CONTRACTOR PERFORMANCE

Late delivery Slow response to problems and problem resolution Incorrect invoice pricing. Superior performance Other: CONTRACT PROVISIONS

Terms and conditions inadequate Additional items or services are required. Specifications need to be revised Minimum order too high. Other:

Briefly describe situation:

Agency Name: Delivery Location: Prepared By: Phone Number: Date: Supervisor:

Address: Email:

Send To:

NAME STATE PROCUREMENT OFFICER OFFICE OF STATE PROCUREMENT PO BOX 41017 OLYMPIA WA 98504-1017

37