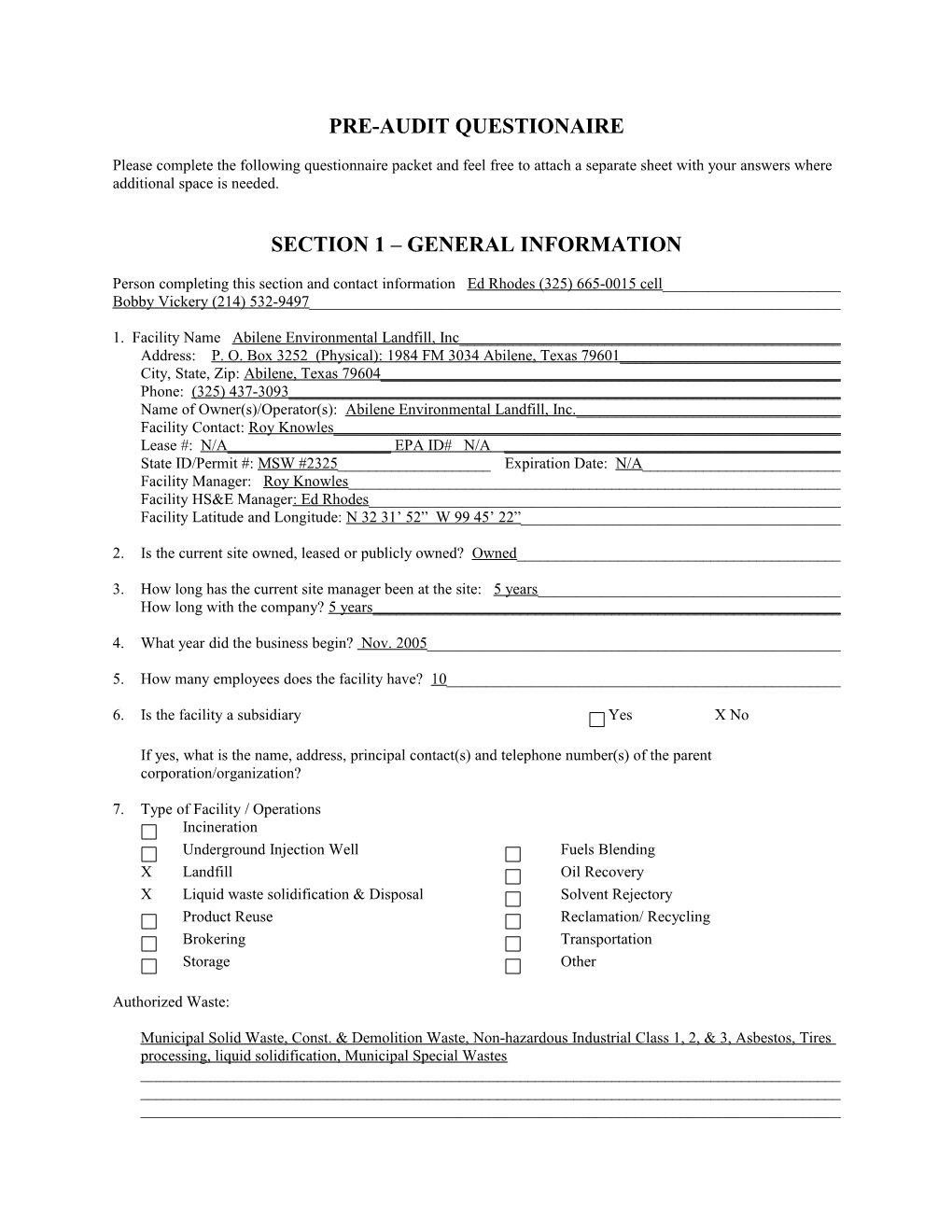

PRE-AUDIT QUESTIONAIRE

Please complete the following questionnaire packet and feel free to attach a separate sheet with your answers where additional space is needed.

SECTION 1 – GENERAL INFORMATION

Person completing this section and contact information Ed Rhodes (325) 665-0015 cell______Bobby Vickery (214) 532-9497______

1. Facility Name Abilene Environmental Landfill, Inc ______Address: P. O. Box 3252 (Physical): 1984 FM 3034 Abilene, Texas 79601 ______City, State, Zip: Abilene, Texas 79604 ______Phone: (325) 437-3093 ______Name of Owner(s)/Operator(s): Abilene Environmental Landfill, Inc. ______Facility Contact: Roy Knowles ______Lease #: N/A ______EPA ID# N/A ______State ID/Permit #: MSW #2325______Expiration Date: N/A______Facility Manager: Roy Knowles______Facility HS&E Manager: Ed Rhodes______Facility Latitude and Longitude: N 32 31’ 52” W 99 45’ 22”______

2. Is the current site owned, leased or publicly owned? Owned______

3. How long has the current site manager been at the site: 5 years______How long with the company? 5 years ______

4. What year did the business begin? Nov. 2005______

5. How many employees does the facility have? 10______

6. Is the facility a subsidiary Yes X No

If yes, what is the name, address, principal contact(s) and telephone number(s) of the parent corporation/organization?

7. Type of Facility / Operations Incineration Underground Injection Well Fuels Blending X Landfill Oil Recovery X Liquid waste solidification & Disposal Solvent Rejectory Product Reuse Reclamation/ Recycling Brokering Transportation Storage Other

Authorized Waste:

Municipal Solid Waste, Const. & Demolition Waste, Non-hazardous Industrial Class 1, 2, & 3, Asbestos, Tires processing, liquid solidification, Municipal Special Wastes ______What is the total size, in acres, of the current site? 242.62 acres ______

9. Describe historical uses of the property. Include past owners, dates, and operations. Owner #1: Agricultural – Farm & Ranch land______Owner #2; ______Owner #3: ______Owner #4______

10. Which form of management does the firm operate?

X Corporation Proprietorship Limited Partnership Municipality Other Partnership Other______

11. What is the firm’s policy on indemnification by the parent corporation for acts of individual sites subsidiaries? Mutual Indemnification by both disposal facility and generator______

12. Is there any pending litigation against the facility? Yes X No If yes, what would be potential financial impact to the facility?______

13. Is the facility currently involved in any Superfund related activities? Yes X No If yes, please describe______

14. Indicate the type of financial assurance mechanism for liability insurance and closure (and post closure if applicable).

Not applicable; no financial assurance required______Trust fund______Corporate guarantee______Surety bond______X Letter of credit See attached Copy of Current LC______Insurance______None or Unknown______

15. If a publicly held company, what is the current bong rating and year? N/A______Standard and Poors______Moody’s______

16. Please attach a copy of the documentation to the Environmental Protection Agency or the State as evidence of satisfying the financial assurance mechanism (if applicable). See attached

17. Please provide copy of facilities current license. See Attached

18. Has the site had any general liability or environmental impairment insurance * in effect for the past three years? See Attached Certificate of Insurance X Yes No

If yes, specify type (such as general liability, environmental impairment, pollution liability See Attached copy of certificate of Insurance ______

* May also be known as gradual or seepage If pollution liability, identify the sites of coverage) See Attached copy of certificate of Insurance______

19. Have any insurance policies been terminated, cancelled, or refused renewal by any of the insurance carriers? Yes X No

20. Have any claims been made against the policy? Yes X No If yes, please attach a copy of the details and describe the potential financial impact from the claims.

21. Did any insurance carrier leave an independent engineering/risk assessment designed to look for potential liabilities performed before issuing any of the insurance policies listed above? No If yes, attached a copy of the potential liability findings.

22. What is the facilities closure cost estimate? See Attached Closure & Post Closure Info______

23. Provide a copy of the State’s or governing bodies approval of the closure and post-closure costs if applicable.

24. What is the facilities post-closure cost estimate? See Attached Closure & Post Closure Info______

25. Provide a copy of the State’s or governing bodies approval of the closure and post-closure costs if required by regulation.

26. If the facility has initiated corrective actions, what is the cost estimate? No______

27. Does the facility hold any financial instruments for corrective action? Yes X No If so, obtain a copy.

28. Has facility booked any environmental reserves on the company’s current balance sheet? Yes X No If yes, obtain amount and purpose:______

29. Does the site accept hazardous waste? Yes X No If yes, what wastes area accepted:______30. Does the site generate hazardous waste? Yes X No

31. For all facility permits, enter the permit name or agency and ID or permit number. Please attach pertinent information from each permit.

Discharge or Waste Type Permit / Agency Identification Number Air Operating TCEQ 2823

Wastewater N/A

Solid Waste TCEQ 2325

Hazardous Waste (RCRA) N/A

Special Waste TCEQ 2325 Industrial Waste SWR TCEQ 87859 Storm Water TCEQ TPDES TXR05U184

Other Waste (Specify)

Other Waste (Specify)

32. Provide names and telephone numbers of the environmental regulatory offices, if applicable, that are jurisdictional for the authorized waste.

Agency Contact Telephone No. TCEQ, Region 3 Ron Dennis 325-698-6126

33. Does the facility have the following plans and/or documents in place? SPCC and/or a Facility Response Plant? X Yes No Not Applicable Expiration date/other 2011______

Closure/Post-Closure Plan? X Yes No Not Applicable Expiration date/other: N/A______

Contingency/Emergency Response Plan? X Yes No Not Applicable Expiration date/other: N/A______

Waste Analysis Plan? X Yes No Not Applicable Expiration date/other: N/A______

Health and Safety Plan? X Yes No Not Applicable Expiration date/other: N/A______

Hazard Communication Plan? X Yes No Not Applicable Expiration date other: N/A______

Inspection Program? X Yes No Not Applicable Expiration date/other: N/A______

Training Program? X Yes No Not Applicable Expiration date/other: N/A______

Other Plans? X Yes No Not Applicable Expiration date/other: N/A as required by permit______

34. Has your facility received a regulatory inspection within the last five years? X Yes No If yes, please provide a copy of reports or correspondence from the last two years of regulatory inspection.

35. Please attach copies of any Notice of Violation (NOV) correspondence for the last two years? Yes X No

36. Is the site under enforcement for regulatory violations? Yes X No If yes, explain.______

______

37. Has the facility received any fines in the last two years? Yes X No

38. What was the total amount of all fine(s) in the last two years? N/A______

39. Have industrial solid or hazardous wastes ever been disposed of in a land-based unit at your facility? Yes X No

40. If the site has any inactive land-based units that are or may be designated as Solid Waste Management Units (SWMU’s) or RCRA Units, have they all been closed? Select the most representative answer. X Not applicable, no land based units ever existed at the site No, one or more units are still inactive Closure is n progress for one or more units All units have been certified clean closed with all waste removed

41. Are any SWMU’s being addressed under corrective action within a one-half mile radius of any drinking water wells? Yes X No

42. Is your facility engaged in post-closure ground water monitoring? Yes X No If yes, explain______

43. Please attach a site map showing facility boundaries and total acreage, with applicable treatment, storage, disposal and processing facilities, wastewater discharge points, monitoring wells, water wells and fire protection equipment labeled. See Attached Drawing

44. Please provide a process flow diagram of all operations that take place at this facility. The diagram need not break down individual processes, but should indicate (with arrows as appropriate): a. influent and effluent streams –N/A b. Process throughputs, actual and design –N/A ____c. All waste streams and their dispositions (if shipped off-site, facility shipped to and ultimate fate of the waste). N/A d. The nature of the waste stream (i.e. hazardous and non-hazardous) – See attached waste acceptance description. e. All air pollution devices – N/A f. Wastewater treatment system – N/A

45. Does this facility plan to discontinue use of any of the above processes? Yes X No If so, how will this affect maximum facility capacity?______

. Does this facility have any approved expansion projects awaiting or undergoing construction? XYes No

If yes, please describe Future cell construction for additional airspace______

47. What is the current operating volume and projected site life for ongoing operations? + - 350 cubic yards of MSW & Industrial waste per Day. Approx remaining site life is + - 36 years______

. Are there any additional neighbors within a quarter mile of the current site boundary? X Yes No Unknown

49. How far from the site is the nearest water body (flowing stream, river, lake, bay or ocean)? On or adjacent to the site Within 500 feet of the site Between 500 and 1300 feet (1/4 mile) from site Between 1/4 and 1/2 mile of the site Between 1//2 and 1 mile X Greater than 1 mile

50. Is the site located on or adjacent to wetlands? Yes X No Unknown

51. Is the site outside the 100-year flood plain? X Yes No Unknown

52. What is the depth to groundwater below this location? No aquifer exist under the site, see attached Hydrology Statement.______Identify the basis of your answer: X On-site wells are Dry Wells on adjacent property Shallow aquifer Give Name:______Other (Specify)______

53. Has groundwater been monitored or tested X Yes___ No

54. Has the site ever been filled to build elevation, improve drainage, or level the surface? Yes X No Unknown Was the fill analyzed? Yes No _For materials containing metals residues _For materials containing petrochemical constituents _For other constituents (Specify) ______

55. Describe the site and/or how access is controlled. Site has main entrance, with gates, that is locked when not in use. Site has 10 foot mesh wire fence around perimeter______

56. Does facility have perimeter fencing? X Yes No Does facility have signs? X Yes No Describe the information contained on the signs: Allowable wastes, prohibited wastes, operating hours, contact information, speed limits, type of facility, permit number, emergency numbers, TCEQ information______

57. Is there a preventative maintenance program in place? For equipment X Yes No Have tank integrity tests been performed N/A Yes No

. List the types of industries and businesses that send wastes to your facility for treatment and or disposal;_____ Non-hazardous generators, Industrial process waste , manufacturing companies, oil & gas drilling and producing Compines. ______

59. Which of the following best characterize your facilities waste receipt procedure? (Check all that apply) X Written waste procedures are followed X Documentation accompanies all incoming waste loads Documentation accompanies only certain types of waste loads

0. For the most recent year available, what type of estimated total amount of liquid and/or solid wastes are treated or disposed of at the facility?

VOLUME (units) TREATMENT DISPOSAL AREA PROCESS MSW Tons : 47,655 disposal MSW Cell Class 1 Non-haz.Tons: 4420 disposal Ind. cell Liquids Tons: 6979 solidification Ind. cell

61. Does the facility have onsite laboratories? Yes X No If yes, are they accredited? Yes No

62. What analyses are required for each load of waste accepted? Depends on waste and how it is generated. Usually TCLP Metals, organics ,& inorganics Lab Test, TPH or generator Knowledge statement with MSDS Sheets for unused product.______

63. Are daily and annual records maintained? X Yes No (Please attach an example of each) See Copies of Daily, Qtrly and annual Reports

64. What happens if a contaminated load is discovered after its arrival at the facility? Describe what happens to rejected incoming waste load. Truck is pulled to the side and waste profile is researched; attempt to correct any deficiencies; if cannot be corrected, load is rejected. Rejected loads are documented and returned to generator. ______

65. Please list the waste or product residues generated at the facility. Include all wastewater streams and solid wastes and materials that are recycled, reclaimed or blended (e.g., paint, oil, sandblasting sand, sludge, solvents, acids, caustics, pesticides, etc.) List the waste disposition method and name of offsite facilities receiving wastes, if any.

WASTE/PRODUCT DISPOSAL METHOD DISPOSAL FACILITY RESIDUE N/A

66. Describe how companies are selected to handle your residue(s), are audits conducted?______N/A ______

67. Describe tests, if any, and frequency performed on wastewater and/or runoff discharged N/A______

68. Describe the storage facilities. (Check all that apply)- N/A Piles X Surface Impoundmounts Drums Above Ground Tanks Below Ground Tanks Other Containers

69. List types of permitted storage volumes and tank capacities; N/A

LOCATION CAPACITY (tons/day) TYPE Liquids Processing pit 35000 gals Industrial and MSW Liquids Liquids storage pit 2,500,000 gals Industrial and MSW Liquids

70. Check all that apply to storage areas: N/A X Diked Covered X Secondary Containment Enclosed Other 71. Please describe storage area inspection procedures, if applicable; Visual Inspection are done on a daily bases. ______

72. Does the facility have satellite operations (also referred to as transfer facilities)? Yes X No If yes, list the site addresses for satellites that store Pioneer Natural Resources USA, Inc. generated waste.

SATELLITE CAPACITY (Tons/day) ACREAGE (Per Site) LOCATION

73. If drums are stored outdoors, or if you have any waste piles outdoors, have provisions been made for run- on /run-off controls? Yes No If yes, please describe; N/A______

74. Describe the nature, quality and date of any spills or releases of hazardous constituents that have occurred over the last five years at the facility (if applicable). N/A

SUBSTANCE DATE AMOUNT (gals) CORRECTIVE ACTION SECTION II - INCINERATION

Conducted Onsite X Not Conducted Onsite

75. What wastes and phases (i.e. solids, liquids, sludges) are permitted for incineration:______

76. What of incineration and auxiliary equipment is in place?______

77. What is the combustion temperatures and combustions times in the primary and chambers:______

78. What is the combustion/destruction efficiency?______

79. What feed loading procedures are used?______

What are the automatic feed shut-off provisions?______

80. What type of auxiliary fuel and system are in place?______

81. What controls/operational functions are monitored?______

82. What emergency shut down provisions are in place?______

83. What air emissions controls are in place?______

84. Obtain emission testing and trial burn data. Does it indicate proper destruction efficiencies and emissions levels? Yes No SECTION III - WATER TREATMENT

Conducted Onsite X Not Conducted Onsite

85. Is wastewater sent to a POTW? Yes No If yes, what is the name and location of the POTW?______

What permit is held by the facility for discharge into the POTW?______

What is the rough capacity taken by the POTW from the facility in regards to total volume taken by the POTW?______

86. Is the discharge monitored? Yes No If yes, by whom (the POTW or the facility?______

87. Is the wastewater sent offsite for disposal (other than POTW)? Yes No If yes, what facility and location?______

88. Describe the treatment process: ______

89. What air emissions controls and monitoring are conducted for treatment process?______

90. What are the discharge limits, average discharge and latest sampling results.?______

Were any limits or constituents exceeded in the past? Yes No If yes, describe: ______SECTION IV - UNDERGROUND INJECTION WELLS

Conducted Onsite X Not Conducted Onsite

91. Does the facility hold a permit for UIC of wastes: Yes No

92. Has a no migration petition been completed? Yes No If yes, are there any special provisions within the petition? Yes No

93. What wastes are injected?______

94. What depth and strata are the waste being injected?______

95. What is the permitted pressure at the well head?______Was the annulus reading at the well head within the permit conditions? Yes No

96. Are there special loading and unloading provisions in the permit? Yes No

97. Are there special construction provisions for sumps, loading areas, tanking, or pump equipment in the permit? Yes No SECTION V - LANDFILL / LANDFARM

X Conducted Onsite Not Conducted Onsite

98. What are the landfill liner design details 3 foot compacted clay liner, 60 HDPE liner, geonet drainage layer, 2 foot protective layer______

99. Describe the leachate collection and monitoring systems; Leachate lines are drained to sumps that are collected and remove by pumps. Depth of leachate is monitored on a weekly basis.______

How is the leachate managed or disposed of? Leachate is collected and solidified and disposed of on-site______

100. What leak detection systems are in place? Groundwaster monitoring wells are placed around perimeter of facility. Gas detection probes are installed around perimeter______

What is the Action Leakage Rate (ALR)? N/A______Has it even been reached? Yes No If yes, what were the causes:______

101. Is there a methane gas collection and control system in place? Yes X No Not Applicable If yes, describe the system:______

102. What storm water run-off and run-in-control measures are in place: Berms are in place for run-off and run –on controls. Waste is covered with soil or an approved alternate daily cover (ADC) on a daily basis ______

103. What is the current life expectancy of the landfill? 36 plus years______Is there room for expansion? Yes xNo If yes, does the facility plan to expand in the future: Yes No If yes, what is the new life expectancy?______

104. What are the capping and closure requirements? 3 foot clay laver, HDPE cover, 18 inches soil, 6 inches of soil for vegetative cover______

105. What cell operational, segregation, and placement procedures are in place? Facility has an approved fill sequence plan in place______106. What type of interior access roads are in place and what is their condition? Access roads are all weather roads mostly asphalt______

107. What on-site pretreatment and solidification facilities are in place? No pre-treatment – liquids are solidified in a specified area______

What types of wastes are pretreated/solidified? Liquids are solidified to past paint filter before disposal__ What materials are used for solidification// pretreatment? On-site soil______SECTION VI - PRODUCT RESUSE/RECYCLING

Conducted Onsite X Not Conducted Onsite

108. What materials are reused or recycled at the facility?______

Is this material exempt under RCRA? Yes No If yes, please provide the regulatory citation and special provisions:______

109. Provide a brief process description:______

110. What air emissions controls and monitoring are conducted for the reuse or recycling process?______

111. Is wastewater generated from the reuse or recycling process? Yes No If yes, how is it managed and disposed?______SECTION VII - OILS/SOLVENT RECOVERY/FUELS BLENDING

Conducted Onsite X Not Conducted Onsite

112. If a fuel blending facility, does the facility have the proper RCRA permitting and documentation in place? Fuels blending is not exempt from RCRA regulation . Yes__ No

113. What operation processes are conducted specific to recovery/blending?______

114. Is a preventative maintenance program and inspection procedures in place for the equipment involved in such activities? Yes No

115. Are the fuels incinerated onsite? Yes No If yes, is a BIF used? Yes No SECTION VIII – TRANSPORTATION

X Conducted Onsite Not Conducted Onsite

116. How are the wastes transported to the facility? Mark all that apply X Generator X Facility vehicles X Transporter vehicles List names of third party transporter companies. Traid Transporters, Ashland Chemical, Coal City Cobb, Disposal Solutions, KCI Trucking______

______

117. If you use company-owned trucks to transport incoming materials are you registered? X Yes No If yes, provide registration/permit numbers. ______

118. What type of transportation is provided (i.e. commercial, private, etc.)? Commerical______

119. Is the facility licensed for transportation in other states or countries? Yes No If yes, what states/countries?______

120. What type and number of vehicles does the facility operate? Vehicle Type Quantity End Dump trailers 2 Walking Floor 1

121. Describe vehicle maintenance and safety procedures: DOT inspections______Review inspection checklists

122. Are vehicles cleaned and/or maintained onsite? Yes X No If yes, describe cleaning and/or maintenance procedures:______How is wash water managed and disposed?______If no, where are vehicles maintained and or cleaned?______

122. What training and/or certificate are required and provided for drivers?______

123. What equipment is provided for spills and leaks? What procedures are in place?______SECTION IX - BROKERING

Conducted Onsite X Not Conducted Onsite

124. What wastes are brokered by the facility?______

125. Are brokered wastes sampled at the facility? Yes No

126. What name are the brokered wastes manifested/shipped under?______

127. What offsite disposal facilities are used for brokering?______

Are they selected by the generator or the facility?______Are audits conducted on these facilities? Yes No SECTION X - MANAGEMENT/HEALTH AND SAFETY

X Conducted Onsite Not Conducted Onsite

128. How long has the current site manager been at the site? 5 years (Roy Knowles has 28 years of solid waste experience ______How long with the company? 5 years______

129. Are there dedicated EH&S positions X Yes No If yes, who fills this role? Ed Rhodes / Bobby Vickery______

130. What type of environmental, health and safety, and site-specific training is providing to employees? Weekly safety meetings, waste screening training, MSW licensed supervisors on-site______

131. What type of safety and emergency equipment is provided at the facility? Hard hats, ear/eye protection gloves, booms and pads______

132. Has workplace monitoring been performed? X Yes No If yes, what were the results? Satisfactory______

133. Have there been any fires, explosions, or other safety incidents in the last five years? Yes X No If yes, explain?______

134. Does the facility have a written Health and Safety Plan? X Yes No If yes, what does it include? Training requirements, emergency contacts, emergency planning______

135. Provide a copy of the facility’s last two OSHA 300 Logs. How many recordable injuries were there? See OSHA 300 Log Attached______How many lost time injuries were there?______How many man-hours were worked in each of the years reviewed?______SECTION XI – SITE INSPECTION CHECKLIST

General housekeeping Excellent good fair poor Comments: ______

Odor Control: Strong detectable faint none detectable Comments: ______Visible Emissions: Significant minimal nonexistent

Facilities cooperation with regulatory agencies (may require contacting regulatory agencies and reviewing any facility correspondence): Operations and response generally well above and beyond requirements Meet requirements, reactive mode Generally not meeting requirements No information

Facilities cooperation with the public (may require contacting local public officials, such as health department and reviewing any facility correspondence): Operations and response generally well above and beyond requirements Meet requirements, proactive mode Meet requirements, reactive mode Generally not meeting requirements No information

Has there been any public complaints about the facility: None Sporadic Frequent (give details)

Facility EHS compliance history (check those that apply): Information not available Excellent: well regarded by regulatory agencies, many good management practices, no fines, no violations Good: no fines, no violations Fair, no fines, minor violations Poor: minor fines, violations Bad: major fines and violations

Waste Management Equipment condition / housekeeping:

Waste manifest record-keeping (random sample of files) – check for: Manifest document number Generator’s name, mailing address, telephone number, EPA ID number Transporter’s name and EPA ID number “decribed and labeled properly” certification LDR certification forms attached when necessary Signature of generator facility representative and date Signature of transporter representative and date Signature of authorized facility representative and date Copy returned to generator within 30 days Copy retained for at least 3 years

Is containment for incompatible materials separated?

Describe container conditions (e.g., labeled, corrosion, leaking, dented):

Is the base of storage area(s) sufficiently impervious to hazardous materials and accumulated precipitation?

Evidence of spills or leaks?