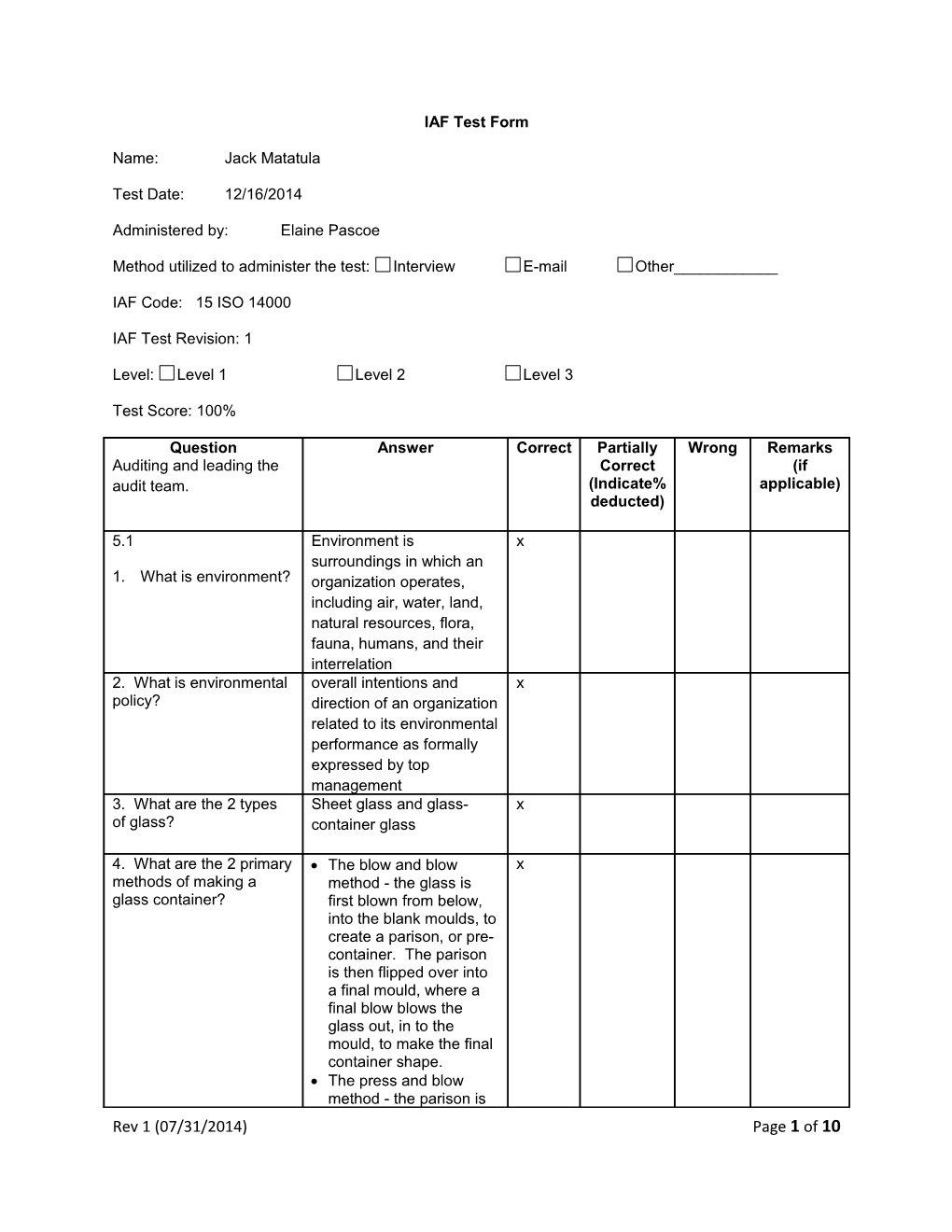

IAF Test Form

Name: Jack Matatula

Test Date: 12/16/2014

Administered by: Elaine Pascoe

Method utilized to administer the test: Interview E-mail Other______

IAF Code: 15 ISO 14000

IAF Test Revision: 1

Level: Level 1 Level 2 Level 3

Test Score: 100%

Question Answer Correct Partially Wrong Remarks Auditing and leading the Correct (if audit team. (Indicate% applicable) deducted)

5.1 Environment is x surroundings in which an 1. What is environment? organization operates, including air, water, land, natural resources, flora, fauna, humans, and their interrelation 2. What is environmental overall intentions and x policy? direction of an organization related to its environmental performance as formally expressed by top management 3. What are the 2 types Sheet glass and glass- x of glass? container glass

4. What are the 2 primary The blow and blow x methods of making a method - the glass is glass container? first blown from below, into the blank moulds, to create a parison, or pre- container. The parison is then flipped over into a final mould, where a final blow blows the glass out, in to the mould, to make the final container shape. The press and blow method - the parison is Rev 1 (07/31/2014) Page 1 of 10 formed with a metal plunger, which pushes the glass out, into the blank mould. The process then continues as before, with the parison being transferred to the mould, and the glass being blown out into the mould. 5. What is Annealing? A process of slowly cooling x glass to relieve internal stresses after it was formed. The process may be carried out in a temperature-controlled kiln known as a Lehr. Glass which has not been annealed is liable to crack or shatter when subjected to a relatively small temperature change or mechanical shock. Annealing glass is critical to its durability. If glass is not annealed, it will retain many of the thermal stresses caused by quenching and significantly decrease the overall strength of the glass. 6. What are the Raw materials x manufacturing steps for preparation - The ceramic tiles? ceramic process starts by selecting the raw materials required for the body composition, which are mainly clays, feldspars, sands, carbonates and kaolins. After a first mixing of the body components, the mixture is usually dry milled (hammer or pendulum mills) or wet milled (continuous or batch ball mills). During the mizing staged, the water and raw materials making up the body composition are closely mixed to a

Rev 1 (07/31/2014) Page 2 of 10 consistent paste that is readily mouldable by extrusion. Pressing and drying of the green body - Dry pressing (at 5-7% moisture content) with hydraulic presses is the most common tile forming method. Forming takes place by mechanically compressing the paste in the die and is one of the most cost-efficient forming methods for making ceramic ware with a regular geometry. Tile forming by extrusion processes basically consists of putting the plastic body through a die that produces a constant tile cross section. After forming, the tile body is dried to reduce the moisture content (0.2-0.5 %) to appropriately low levels for the firing and eventual glazing stages. Firing, with or without glazing - Unglazed products are fired after the drying stage. Similarly, in the case of glazed twice-fire products, the green bodies are fired after drying. Glazing involves applying one or more coats of glaze with a total thickness of 75-500 microns onto the tile proper surface by different methods. Glazing is done to provide the fired product with a series of technical and esthetical properties such as impermeability,

Rev 1 (07/31/2014) Page 3 of 10 cleanability, gloss, colour, surface texture, and chemical and mechanical resistance. Additional treatments - In some cases, particularly in porcelain tiles, the fired tile surface is polished to produce a shiny unglazed homogeneous tile. Sorting and packing - The ceramic tile manufacturing process ends with sorting and packing. Sorting is done by automatic systems with mechanical equipment and tile surface inspection. The result is a controlled product with regard to dimensional regularity, surface appearance and mechanical and chemical characteristics. 7. What are the main Thermal cycle x variables to be considered (temperature-time) and kiln in the firing stage? atmosphere

Raw Materials x 8. What are the steps to Management – This manufacture clay roof includes extraction of tiles? clay Preparation of Clay - The clay is prepared and made workable in a second step by grinding, mixing, wetting and cleaning to remove foreign materials such as stones. Additives (e.g. sawdust) are then added before further production. Shaping - This step involves the actual shaping of the roof tile, where either the prepared clay is pressed through dies by extruders or pressed Rev 1 (07/31/2014) Page 4 of 10 into forms and made into pressed tiles. Drying - The drying process prepares the brick for firing by removing the moisture from the soft "green" brick. Colouring - After the drying process the clay roof tile, except it remains natural red, is either engobed or glazed. Engobed clay roofing tiles have matt, matt-glossy or glossy surfaces. Engobes are applied as clay- containing slips by dipping, pouring over, centrifugal casting or spraying on the still unfired clay tile. Glazed tiles are covered with a very hard continuous glass layer that closed all pores and makes the tile extremely water- resistant. at the same time this glass layer gives the tile its special shiny look. Firing - For Clay roof tiles that are produced with a ceramic surface (engobe or glaze), this is burned in during firing process. The firing of the tiles at a temperature of 900 to 1200°C in a tunnel kiln is the final part of the production process. After this step, the finished product is available for use. After firing, brick products are nonflammable and fire- safe for ever. Packaging 10. What are the basic Percussion tools for x tools used for stone hitting - such as mallets, carving? axes, adzes, bouchards and toothed hammers. Tools for rough shaping Rev 1 (07/31/2014) Page 5 of 10 of stone, to form a block the size needed for the carving. These include feathers and wedges and pitching tools. Chisels for cutting - such as lettering chisels, points, pitching tools, and claw chisels. Chisels in turn may by hand held and hammered or pneumatic powered. Abrasives for erosion - such as carborundum blocks, drills, saws, grinding and cutting wheels, water erosion machinery and dressing tools such as French and English drags. 5.2 An environmental indicator x is a parameter, or a value 11. What is an derived from parameters, environmental indicator? that points to, provides information about and/or describes the state of the environment, and has a significance extending beyond that directly associated with any given parametric value 5.3 Check the personnel x competence who 14. How do you assess conduct monitoring and equipment used for measurement monitoring and measuring Check the availability of environmental aspect? documentation, i.e. documented procedure or instruction The equipment used have maintenance program and calibrated 12. How do you assess Check the maintenance x maintenance program and program whether its calibrate equipment for planned regularly measuring environmental Check the calibration aspect? status Check the calibration certificate Check maintenance record, etc 5.4 Check whether they x have an objective and 13. What will you assess program how to control Rev 1 (07/31/2014) Page 6 of 10 as an auditor if there is those significant aspect any significant aspect and and impact impact? Check whether the organization have a program to reduce the risk of aspect? Check that the operational control in place Check whether they determine the criteria and follow 5.5 No, it does not. The x company have to identify 14. Does the company environmental aspect and have to identify all evaluate the impact for environmental aspects and impact? How do you those can control and assess that? influence. How to assess: There is mechanism for identifying of environmental aspect and impact The personnel who conduct identifying environmental aspect and impact has been received proper training Check that the environmental aspect and impact have been done for all process, activity and product that can control and influence 5.6 Check whether they set x program for 15. What will you ask to environmental the auditee to prove that performance environmental evaluation? performance evaluation Check document and has been conducted? record of monitoring achievement and progress? Check whether performance achieve? 5.7 As the name implies, these x audits are intended to 16. How do you assess review the the legal and other site's/company's legal requirements that are applicable for Non- compliance status for non- Metallic Mineral metallic products business. business? Compliance audits Rev 1 (07/31/2014) Page 7 of 10 generally begin with non- metallic products the applicable compliance requirements against which the operations will be assessed. This tends to include federal regulations, state regulations, permits and local ordinances/codes. In some cases, it may also include requirements within legal settlements. Compliance audits may be multimedia or programmatic. Multimedia audits involve identifying and auditing all environmental media (air, water, waste, etc.) that apply to the operation/ company. Programmatic audits (which may also be called thematic or media- specific) are limited in scope to pre-identified regulatory areas, such as air.

Audits are also focused on operational aspects of a company/site, rather than the contamination status of the real property. Assessments, studies, etc. that involve property contamination/ remediation are typically not considered an environmental audit. 5.8 Check whether the x organization has establish 17. How do you assess and maintain procedure to the emergency condition identify potential for and that has been identified by respond to accidents and the company? emergency situations?

5.9 Check whether identify x aspect and impact 18. How do you assess evaluation are operational control for available? Rev 1 (07/31/2014) Page 8 of 10 identified significant Control in place, i.e. environmental aspects? documented procedure, maintenance of equipment. Evaluation of effectiveness of its control Check whether the organization establish and maintain documented procedures to cover situations where their absence could lead to deviations from the environmental policy and the objectives and targets? Check whether the organization stipulating operating criteria in the procedures? Check whether the organization establish and maintain procedures related to the identifiable significant environmental aspects of goods and services used by the organization and communicating relevant procedures and requirements to suppliers and contractors? 5.10 Check whether identify x aspect and impact 19. How do you assess evaluation are factors related to site available? It includes during environmental related site surrounding aspect and impact area of the organization premises? assessment? Is significant aspect and impact identified? Is it control by establish objective and program to control significant aspect and impact? Control in place, i.e. documented procedure, etc. 20. How do you assess Check whether identify x operational control aspect and impact relating to this matter? evaluation are available? Control in place, i.e. Rev 1 (07/31/2014) Page 9 of 10 documented procedure, maintenance of equipment. Evaluation of effectiveness of its control Check whether the organization establish and maintain documented procedures to cover situations where their absence could lead to deviations from the environmental policy and the objectives and targets? Check whether the organization stipulating operating criteria in the procedures?

Rev 1 (07/31/2014) Page 10 of 10