Gavlord K.Finch INVENTOR

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Transfer Hydrogenations and Kinetic Resolutions Van Dirk Klomp

transferhydrogenations and kineticresolutions DirkKlomp transferhydrogenationsandkineticresolutions DirkKlomp Uitnodiging voorhetbijwonenvande openbareverdedigingvan hetproefschriften destellingenop maandag 13maart2006 13.00uur endedaaraan voorafgaandetoelichting voorniet-chemiciom 12.30uur indeSenaatszaalvande TechnischeUniversiteitDelft Mekelweg5teDelft Naafloopvande plechtigheidbentuookvan hartewelkomopdereceptie inhetzelfdegebouw. DirkKlomp Esdoornlaan32 1521EBWormerveer 075-6223403 [email protected] Stellingen behorende bij het proefschrift transfer hydrogenations and kinetic resolutions van Dirk Klomp 1- De door Kao et al. gebruikte structuurbepalende verbinding fructose voor de synthese van de mesoporeuze silica SBA-1 bepaalt niet de structuur van het materiaal. H.-M. Kao, C.-C. Ting, A. S. T. Chiang, C.-C. Teng, C.-H. Chen, Chem. Commun. 2005 ,1058-1060. 2- Het door Kim et al. gesuggereerde mechanisme voor de deactivering van het enzym α-CT in de hydrolyse van β-lactonen, waarbij het lacton opent op de 4-positie, is zeer onwaarschijnlijk. D. H. Kim, J. Park, S. J. Chung, J. D. Park, N.-K. Park, J. H. Han, Bioorg. Med. Chem. 2002 , 10 , 2553-2560. 3- Psychologisch gezien betekent de omschakeling door wetenschappelijke tijdschriften van papieren versies naar elektronische, een verlies aan kennis voor de wetenschapper. 4- Omdat de aarde langzamer gaat draaien is soms de toevoeging van schrikkelsecondes noodzakelijk. Wetenschappers die deze secondes pas willen toevoegen op het moment dat ze zijn opgespaard tot een schrikkeluur, omdat de toevoegingen storingen kunnen veroorzaken in elektronische apparatuur, hebben de menselijke factor uit het oog verloren. 5- In de weekeindes waarin een nieuw boek over Harry Potter uitkomt, is het aantal kinderen dat op de eerstehulpafdeling van het ziekenhuis belandt bijna half zo groot als in andere weekeindes. Gwilym et al. hebben de afname over de lange termijn waarschijnlijk onderschat. -

Synthesis, Hydrogenation, and Hydrodeoxygenation of Biomass-Derived Furans for Diesel Fuel

Synthesis, Hydrogenation, and Hydrodeoxygenation of Biomass-Derived Furans for Diesel Fuel By Ying Lin Louie A dissertation submitted in partial satisfaction of the requirements for the degree of Doctor of Philosophy in Chemical Engineering in the Graduate Division of the University of California, Berkeley Committee in charge: Professor Alexis T. Bell, Chair Professor Alexander Katz Professor F. Dean Toste Summer 2017 Synthesis, Hydrogenation, and Hydrodeoxygenation of Biomass-Derived Furans for Diesel Fuel © 2017 Ying Lin Louie All rights reserved Abstract Synthesis, Hydrogenation, and Hydrodeoxygenation of Biomass-Derived Furans for Diesel Fuel by Ying Lin Louie Doctor of Philosophy in Chemical Engineering University of California, Berkeley Professor Alexis T. Bell, Chair Hydrogenation and hydrodeoxygenation (HDO) processes are critical for the chemical conversion of lignocellulosic biomass into liquid transportation fuels such as gasoline, jet, and diesel. Hydro-treatment processes can remove undesired functionalities and reduce the oxygen content in biomass-derived oxygenates to produce candidates suitable for fuel blends. In this study, the liquid phase hydrogenation and hydrogenolysis of several model substrates including, 2,5-dimethylfuran (DMF), 5-methylfurfural (5-MF), bis(5-methylfuran-2-yl)methane (BMFM), and 5-(2-(5-methylfuran-2-yl)vinyl)furan-2-aldehyde (MFVFAL), were investigated over noble metal catalysts (Pd, Pt, Ru) at moderate conditions (353 – 473 K, 0.55 – 5.1 MPa). Understanding the mechanism and kinetics by which undesired functionalities found in these substrates, such as aromatic furans, unsaturated C=C bonds, and C=O bonds, are removed during hydrogenation will allow for the design of efficient catalysts and processes to improve the hydroupgrading reactions of biomass-derived fuels. -

The Evans-Tishchenko Reaction: Scope and Applications

Edinburgh Research Explorer The Evans-Tishchenko Reaction: Scope and Applications Citation for published version: Ralston, KJ & Hulme, AN 2012, 'The Evans-Tishchenko Reaction: Scope and Applications', Synthesis: Journal of Synthetic Organic Chemistry, vol. 44, no. 15, SS-2012-M0312-SR, pp. 2310–2324. https://doi.org/10.1055/s-0032-1316544 Digital Object Identifier (DOI): 10.1055/s-0032-1316544 Link: Link to publication record in Edinburgh Research Explorer Document Version: Peer reviewed version Published In: Synthesis: Journal of Synthetic Organic Chemistry Publisher Rights Statement: Copyright © 2012 Georg Thieme Verlag Stuttgart & New York. All rights reserved. General rights Copyright for the publications made accessible via the Edinburgh Research Explorer is retained by the author(s) and / or other copyright owners and it is a condition of accessing these publications that users recognise and abide by the legal requirements associated with these rights. Take down policy The University of Edinburgh has made every reasonable effort to ensure that Edinburgh Research Explorer content complies with UK legislation. If you believe that the public display of this file breaches copyright please contact [email protected] providing details, and we will remove access to the work immediately and investigate your claim. Download date: 07. Oct. 2021 This document is the Accepted Version of a published article that appeared in final form in Synthesis, copyright © Georg Thieme Verlag Stuttgart · New York. To access the final edited and published work see http://dx.doi.org/10.1055/s-0032-1316544 Cite as: Ralston, K. J., & Hulme, A. N. (2012). The Evans-Tishchenko Reaction: Scope and Applications. -

Organic Chemistry Reactions

Organic Chemistry Reactions 1 Birch Reduction Birch Reduction The Birch Reduction offers access to substituted 1,4-cyclohexadienes. Mechanism of Birch Reduction I) The question of why the 1,3-diene is not formed, even though it would be more stable through conjugation, can be rationalized with a simple mnemonic. When viewed in valence bond terms, electron-electron repulsions in the radical anion will preferentially have the nonbonding electrons separated as much as possible, in a 1,4-relationship This question can also be answered by considering the mesomeric structures of the dienyl carbanion: II) The numbers, which stand for the number of bonds, can be averaged and compared with the 1,3- and the 1,4-diene. The structure on the left is the average of all mesomers depicted above followed by 1,3 and 1,4-diene: III) The difference between the dienyl carbanion and 1,3-diene in absolute numbers is 2, and between the dienyl carbanion and 1,4-diene is 4/3. The comparison with the least change in electron distribution will be preferred. Reactions of arenes with +I- and +M-substituents lead to the products with the most highly substituted double bonds: IV) The effect of electron-withdrawing substituents on the Birch Reduction varies. For , the reaction of benzoic acid leads to 2,5- cyclohexadienecarboxylic acid, which can be rationalized on the basis of the carboxylic acid stabilizing an adjacent anion: V) Alkene double bonds are only reduced if they are conjugated with the arene, and occasionally isolated terminal alkenes will be reduced. 2 Aldol Condensation Aldol Condensation In some cases, the adducts obtained from the Aldol Addition can easily be converted (in situ) to ,-unsaturated carbonyl compounds, either thermally or under acidic or basic catalysis. -

Regioselective Biocatalytic Self-Sufficient Tishchenko-Type

ChemComm View Article Online COMMUNICATION View Journal | View Issue Regioselective biocatalytic self-sufficient Tishchenko-type reaction via formal Cite this: Chem. Commun., 2020, 56,6340 intramolecular hydride transfer† Received 9th April 2020, a a a a Accepted 28th April 2020 Erika Tassano, Kemal Merusic, Isa Buljubasic, Olivia Laggner, a b a Tamara Reiter, Andreas Vogel and Me´lanie Hall * DOI: 10.1039/d0cc02509g rsc.li/chemcomm A self-sufficient nicotinamide-dependent intramolecular bio-Tishchenko- Recently, we established a biocatalytic variant of the (inter- type reaction was developed. The reaction is catalyzed by alcohol molecular) Cannizzaro reaction, which could be further developed dehydrogenases and proceeds through formal intramolecular into a parallel interconnected dynamic asymmetric disproportio- hydride transfer on dialdehydes to deliver lactones. Regioselectivity nation of a-substituted aldehydes. The system relies on the con- 0 0 Creative Commons Attribution-NonCommercial 3.0 Unported Licence. on [1,1 -biphenyl]-2,2 -dicarbaldehyde substrates could be controlled current oxidative and reductive activity of nicotinamide-dependent via the electronic properties of the substituents. Preparative scale alcohol dehydrogenases (ADHs) to perform the dismutation of synthesis provided access to substituted dibenzo[c,e]oxepin-5(7H)-ones. aldehydes with high enantioselectivity in a redox-neutral fashion.11,12 The latter feature renders the system appealing from a sustainability The Claisen–Tishchenko reaction is a disproportionation reaction pointofview,sinceonlycatalyticamounts of cofactor are necessary, that leads to the formation of esters through dimerization of in addition to the biocatalyst. Since two products are generated, an aldehydes.1 Due to the variety of protocols available, it is a additional purification step is necessary, or alternatively, convergent synthetically relevant transformation2 and one of the major processes toward a single product must be designed. -

Chemistry Topic: Aldehyde Ketones and Carboxylic Acid No

Class: 12 Subject: chemistry Topic: Aldehyde ketones and carboxylic acid No. of Questions: 25 1. Directions: The following question has four choices out of which ONLY ONE is correct. The Cannizzaro reaction is not given by: a. trimethylacetaldehyde b. acetaldehyde c. benzaldehyde d. formaldehyde Sol.(b)For aldehydes with a hydrogen atom alpha to the carbonyl, i.e. R2CHCHO, the preferred reaction is an aldol condensation, originating from deprotonation of this hydrogen. This reaction restricts the scope of the Cannizzaro reaction. 2. Benzene reacts with CH3COCl in the presence of anhydrous AlCl3 to give a. C6H5CH3 b. C6H5Cl c. C6H5O2Cl askIITians d. C6H5COCH3 Sol.(d)Benzene reacts with CH3COCl in the presence of anhydrous AlCl3 to give C6H5COCH3. 3. Benzaldehyde reacts with ammonia to form a. benzaldehyde ammonia b. hydrobenzamide c. urotropine d. ammonium chloride Sol.(b)Benzaldehyde reacts with ammonia to form hydrobenzamide 4. Formaldehyde on reaction with ammonia forms urotropine whose formula is a. (CH2)6 N4 b. (CH2)4 N6 c. (CH2)3 N4 d. (CH3)6 N4 Sol.(a)Formaldehyde on reaction with ammonia forms urotropine whose formula is (CH2)6 N4. 5. What is the increasing order of the rate of HCN addition to compounds A – D? A. HCHO B. CH3COCH3 C. PhCOCH3 D. PhCOPh askIITians a. C < D < B < A b. A < B < C < D c. D < B < C < A d. D < C < B < A Sol.(d)reater is the positivity of carbon in carbonyl group, higher is the reactivity towards nucleophilic addition (i.e HCN addition) 6. Under Wolf-Kishner reduction conditions, the conversion which may be brought about is a. -

Tishchenko Reaction

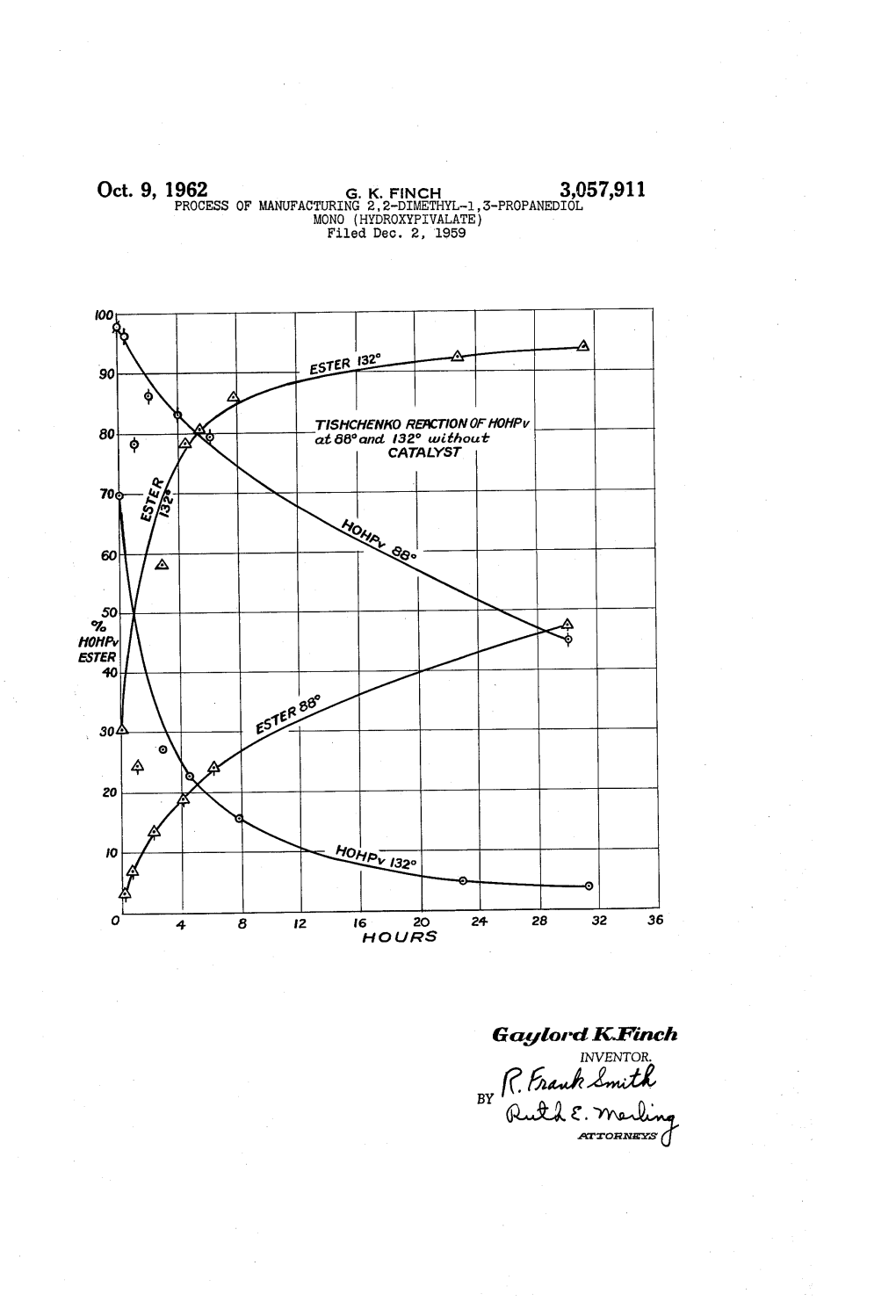

Tishchenko reaction The Tishchenko reaction is an organic chemical reaction that involves disproportionation of an aldehyde in the presence of an alkoxide. The reaction is named after Russian organic chemist Vyacheslav Tishchenko, who discovered that aluminium alkoxides are effective catalysts for the reaction.[1][2] [3] In the related Cannizzaro reaction, the base is sodium hydroxide and then the oxidation product is a carboxylic acid and the reduction product is an alcohol. Contents History Examples Further reading Related topics References History The reaction involving benzaldehyde was discovered by Claisen using sodium benzylate as base.[1] The reaction produces benzyl benzoate.[4] Enolizable aldehydes are not amenable to Claisen's conditions. Vyacheslav Tishchenko discovered that aluminium alkoxides allowed the conversion of enolizable aldehydes to esters. Examples The Tishchenko reaction of acetaldehyde gives the commercially important solvent ethyl acetate. The reaction is catalyzed by aluminium alkoxides.[5] The Tishchenko reaction is used to obtain isobutyl isobutyrate, a specialty solvent.[6] Hydroxypivalic acid neopentyl glycol ester is produced by a Tishchenko reaction from hydroxypivaldehyde in the presence of a basic catalyst (e.g., aluminium oxide).[7] The Tishchenko reaction of paraformaldehyde in the presence of aluminum methylate or magnesium methylate forms methyl formate.[8] Paraformaldehyde reacts with boric acid to form methyl formate.[9] The key step in the reaction mechanism for this reaction is a 1,3-hydride shift in the hemiacetal intermediate formed from two successive nucleophilic addition reactions, the first one from the catalyst. The hydride shift regenerates the alkoxide catalyst. Further reading V. E. Tishchenko | title= О действии алкоголятов алюминия на альдегиды. -

Cis-Trans Enantiomerism, Fulvene Cycloadditions And

View metadata, citation and similar papers at core.ac.uk brought to you by CORE provided by Electronic Theses and Dissertations at Indian Institute of Science SYNOPSIS ‘Topics in Synthetic Methodology: from Heterocycles to Hydride Transfers’ This thesis, largely describing diverse studies in organic synthesis, is divided into three parts. Part I, titled ‘Heterocycles’, describes in two chapters studies directed towards elaborating certain thiazole and oxazole derivatives as useful synthons. Part II, titled ‘Hydride transfers’, describes in two chapters synthetic and some mechanistic studies involving the Cannizzaro and Tishchenko reactions, apart from work with chirally-modified alumino and borohydride reagents. Finally, Part III, titled ‘Miscellaneous studies’, describes structural studies on cyclic carbonates. PART I. HETEROCYCLES O O S O DCC, 10min. (i) (ii) R OH S S Ph N N S H DCM, rt N N O Ph Ph Ph 1 I 2 (68-81%) (i) 5 mol % Pb(OAc)2Ph(OH)2 (ii) RCHO, DCM, rt, 20min. R = Et, n-Pr, i-Pr, i-Bu, n-Hexyl, Ph, PhCH=CH-, 4-MeO-C6H4- Scheme I Chapter 1. The Erlenmeyer synthesis with a thioazlactone and its applications. This chapter describes the synthesis and reactivity of 2-phenylthiazolin-5-one (1). This was generated in situ from N-(thiobenzoyl)glycine and N,N’-dicyclohexylcarbodiimide in CH2Cl2/r.t., and condensed with various aldehydes (Scheme I). The reaction occurred rapidly at room temperatures to furnish the corresponding 4-alkylidene or arylidene products (2) in excellent yields (68-81%). i The reaction was catalysed by basic lead acetate, and was equally successful with both aliphatic and aromatic aldehydes. -

Thesis Rests with Its Author

University of Bath PHD Catalytic electronic activation: The addition of nucleophiles to an allylic alcohol Black, Phillip James Award date: 2002 Awarding institution: University of Bath Link to publication Alternative formats If you require this document in an alternative format, please contact: [email protected] General rights Copyright and moral rights for the publications made accessible in the public portal are retained by the authors and/or other copyright owners and it is a condition of accessing publications that users recognise and abide by the legal requirements associated with these rights. • Users may download and print one copy of any publication from the public portal for the purpose of private study or research. • You may not further distribute the material or use it for any profit-making activity or commercial gain • You may freely distribute the URL identifying the publication in the public portal ? Take down policy If you believe that this document breaches copyright please contact us providing details, and we will remove access to the work immediately and investigate your claim. Download date: 08. Oct. 2021 Catalytic Electronic Activation: The Addition of Nucleophiles to an Allylic Alcohol submitted by Phillip James Black for the degree of PhD of the University of Bath 2002 COPYRIGHT Attention is drawn to the fact that copyright of this thesis rests with its author. This copy of the thesis has been supplied on condition that anyone who consults it is understood to recognise that its copyright rests with its author and that no quotation from the thesis and no information derived from it may be published without the prior written consent of the author. -

The Winding Road from Oppenauer to Sustainable Catalytic Oxidations of Alcohols

The winding road from Oppenauer to sustainable catalytic oxidations of alcohols Citation for published version (APA): Meijer, R. H. (2002). The winding road from Oppenauer to sustainable catalytic oxidations of alcohols. Technische Universiteit Eindhoven. https://doi.org/10.6100/IR557870 DOI: 10.6100/IR557870 Document status and date: Published: 01/01/2002 Document Version: Publisher’s PDF, also known as Version of Record (includes final page, issue and volume numbers) Please check the document version of this publication: • A submitted manuscript is the version of the article upon submission and before peer-review. There can be important differences between the submitted version and the official published version of record. People interested in the research are advised to contact the author for the final version of the publication, or visit the DOI to the publisher's website. • The final author version and the galley proof are versions of the publication after peer review. • The final published version features the final layout of the paper including the volume, issue and page numbers. Link to publication General rights Copyright and moral rights for the publications made accessible in the public portal are retained by the authors and/or other copyright owners and it is a condition of accessing publications that users recognise and abide by the legal requirements associated with these rights. • Users may download and print one copy of any publication from the public portal for the purpose of private study or research. • You may not further distribute the material or use it for any profit-making activity or commercial gain • You may freely distribute the URL identifying the publication in the public portal. -

Unravelling the Reaction Mechanism for the Claisen–Tishchenko Condensation Catalysed by Mn(I)-PNN Complexes: a DFT Study

Unravelling the reaction mechanism for the Claisen–Tishchenko condensation catalysed by Mn(I)-PNN complexes: a DFT study Item Type Article Authors Azofra, Luis Miguel; Cavallo, Luigi Citation Azofra LM, Cavallo L (2019) Unravelling the reaction mechanism for the Claisen–Tishchenko condensation catalysed by Mn(I)-PNN complexes: a DFT study. Theoretical Chemistry Accounts 138. Available: http://dx.doi.org/10.1007/s00214-019-2449-7. Eprint version Post-print DOI 10.1007/s00214-019-2449-7 Publisher Springer Nature Journal Theoretical Chemistry Accounts Rights Archived with thanks to Theoretical Chemistry Accounts Download date 24/09/2021 18:36:07 Link to Item http://hdl.handle.net/10754/652462 LETTER – Theor. Chem. Acc. – TCAC-D-19-00076 Unravelling the reaction mechanism for the Claisen–Tishchenko condensation catalysed by Mn(I)-PNN complexes: A DFT study Luis Miguel Azofraa,b,* and Luigi Cavalloc,* aCIDIA-FEAM (Unidad Asociada al Consejo Superior de Investigaciones Científicas, CSIC, avalada por el Instituto de Ciencia de Materiales de Sevilla, Universidad de Sevilla), Instituto de Estudios Ambientales y Recursos Naturales (i-UNAT), Universidad de Las Palmas de Gran Canaria (ULPGC), Campus de Tafira, 35017, Las Palmas de Gran Canaria, Spain bDepartamento de Química, Universidad de Las Palmas de Gran Canaria (ULPGC), Campus de Tafira, 35017, Las Palmas de Gran Canaria, Spain cKAUST Catalysis Center (KCC), King Abdullah University of Science and Technology (KAUST), Thuwal 23955-6900, Saudi Arabia *E-mails: [email protected], [email protected] TCA Special issue of the ESPA 2018 Conference (Dedicated to Prof. Dr. Otilia Mó and Prof. Dr. Manuel Yáñez on occasion of their 70th birthdays) KEYWORDS: manganese complexes PNN ligands homogeneous catalysis esters DFT ABSTRACT: In this work, we study the potential catalytic role of previously identified Mn(I)- PNN complexes in the Claisen–Tishchenko reaction. -

Zinc Oxide-Catalyzed Dehydrogenation of Primary Alcohols Into Carboxylic Acids

Downloaded from orbit.dtu.dk on: Sep 26, 2021 Zinc Oxide-Catalyzed Dehydrogenation of Primary Alcohols into Carboxylic Acids Monda, Fabrizio; Madsen, Robert Published in: Chemistry: A European Journal Link to article, DOI: 10.1002/chem.201804402 Publication date: 2018 Document Version Peer reviewed version Link back to DTU Orbit Citation (APA): Monda, F., & Madsen, R. (2018). Zinc Oxide-Catalyzed Dehydrogenation of Primary Alcohols into Carboxylic Acids. Chemistry: A European Journal, 24(67), 17832-17837. https://doi.org/10.1002/chem.201804402 General rights Copyright and moral rights for the publications made accessible in the public portal are retained by the authors and/or other copyright owners and it is a condition of accessing publications that users recognise and abide by the legal requirements associated with these rights. Users may download and print one copy of any publication from the public portal for the purpose of private study or research. You may not further distribute the material or use it for any profit-making activity or commercial gain You may freely distribute the URL identifying the publication in the public portal If you believe that this document breaches copyright please contact us providing details, and we will remove access to the work immediately and investigate your claim. FULL PAPER Zinc Oxide-Catalyzed Dehydrogenation of Primary Alcohols into Carboxylic Acids Fabrizio Monda and Robert Madsen*[a] Abstract: Zinc oxide has been developed as a catalyst for the formation of zinc(II) hydrides[7] which are known to be able to dehydrogenation of primary alcohols into carboxylic acids and reduce C=O and C=N bonds.