District Profile Kohat [2009]

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Pakistan National Nutrition Cluster Preparedness and Response Plan

National Nutrition Cluster 3 July 2013 Pakistan National Nutrition Cluster Preparedness and Response Plan The National Nutrition Cluster Preparedness and Response Plan is a common framework to guide the actions of all partners in the nutrition sector in the event of a disaster. It does not replace the need for planning by individual agencies in relation to their mandate and responsibilities within clusters, but provides focus and coherence to the various levels of planning that are required to respond effectively. It is envisioned that the Preparedness and Response Plan is a flexible and dynamic document that will be updated based on lessons learnt in future emergency responses. Each Provincial Nutrition Cluster will develop a Provincial Nutrition Cluster Preparedness and Response Plan, in cooperation with the Provincial Disaster Management Authority (PDMA) and the Department of Health (DoH). The Provincial Plans are stand-alone documents, however are linked and consistent with the National Plan. 1. Background The 2011 Pakistan National Nutrition Survey confirmed that Pakistan’s population still suffers from high rates of malnutrition and that the situation has not improved for several decades. Two out of every five (44 percent) of children under five are stunted, 32 percent are underweight and 15 percent suffer from acute malnutrition.1 Maternal malnutrition is also a significant problem; 15 percent of women of reproductive age have chronic energy deficiency. Women and children in Pakistan also suffer from some of the world’s highest levels of vitamin and mineral deficiencies. The malnutrition rates are very high by global standards and are much higher than Pakistan’s level of economic development should warrant. -

WHO Emergency Humanitarian Program Situation Report

WHO Emergency Humanitarian Program Situation Report Khyber Pakhtunkhwa and FATA Week 17 Date: April 22-28, 2012 1. Situation around IDP hosting districts A: Situation in “Jalozai” IDP camp, Nowshera district WHO shares updates on the disease situation on the newly influx of IDPs of Jalozai IDP camp with health cluster partners on district, provincial and national levels. WHO along with health cluster partners, UNICEF and provincial health authorities lead the emergency health response for the newly displaced IDPs in Jalozai camp and living in host communities in District Nowshera. Till 28th April, 2012, total IDPs population in KPK and FATA are 148,593families with 689007 individuals. Out of 148,593 families 41745 families are residing in host communities. 6215 families are residing in Jalozai IDP camp. In total Jalozai camp host 11,350 families with 53 970 individuals. This includes the new influx for Khyber and old caseload of Khyber and Bajaur Agencies. A total of 39 families with 173 individuals were registered on 28th April, 2012. Out of which 35 families with 156 individuals opted to live outside the camp and 4 families with 17 individuals elected to reside in Jalozai CAMP. Elsewhere in KP and FATA return has continued with more than 1000 families returning to South Waziristan. A total of 8 alerts including 6 measles and 2 AFP were reported and responded in this week. There were 6,704 consultations provided through health care provider, including acute respiratory infection (19% or 1,271 cases), acute diarrhoea (9.3% or 621 cases), skin infection (2% or 114) and suspected malaria (1% or 39 cases). -

KT15D00002-Repair Approach Street Dispensary Mirahmad Khel 220,000 220,000 220,000 220,000

District Project Description BE 2017-18 Final Budget Releases Expenditure KOHAT KT15D00002-Repair approach street dispensary MirAhmad khel 220,000 220,000 220,000 220,000 KOHAT KT15D00003-Const of Toilets, waiting shed andother 740,000 740,000 740,000 740,000 repair/maintenance of BHU Sherkot KOHAT KT15D00004-Pipe Line at BHU LandiKachai, Repair ofroof of RHC 649,000 649,000 649,000 649,000 UstarZai, Repair Work at RHC Usterzai. KOHAT KT15D00005-Maj; repair, w/s and elect, BHU KhaddarKhel 423,892 423,892 423,892 423,892 KOHAT KT15D00006-R&(M) works, const of waiting shed andG/Lat 04 No. 740,000 740,000 740,000 740,000 at RHC Lachi Bala KOHAT KT15D00007-R&(M) at BHU Ali Kach 740,000 740,000 740,000 740,000 KOHAT KT15D00008-Elect, W/S, Sanitary and building repairBHU Dolli 596,291 596,291 596,291 596,291 Banda KOHAT KT15D00009-Prov; of health related equipments andhygienic kits in 740,000 740,000 740,000 - civil hospital Shakardara Urban. Dev; works at civilHospital Shakardara. KOHAT KT15D00010-Solarization at BHU Gabari in U/CShakardara Rural-II. 740,000 740,000 740,000 - KOHAT KT15D00011-Major Repair of buildings and w/s of BHUGabari 740,000 740,000 740,000 740,000 KOHAT KT15D00012-Const;/repair works and S/F of Hand Pumpat BHU 488,122 488,122 488,122 488,122 Surgul KOHAT KT15D00013-Pavement of Dispensary street at U/CUrban III 507,090 507,090 507,090 507,000 KOHAT KT15D00014-Purchase of Hygienic kits,Purchase ofHematology 3,981,535 3,981,535 3,981,535 1,204,000 analyzer, for LMH Kohat, Purchase of Spray Pumps andInsecticides KOHAT KT15D00015-Const: -

IVAP Analysis Report April 2015

IVAP Analysis Report April 2015 IVAP is proudly funded by ECHO and DFID Background to KP/FATA Complex Emeregency The Federally Administered Tribal Areas (FATA) is a semi-autonomous tribal region in northwestern Pakistan. It borders Afghanistan as well as Pakistan’s Khyber Pakhtunkhwa and Baluchistan provinces. More than 5 million people have been registered with the government and/or UNHCR as an internally displaced person (IDP) at some point since 2008 due to violent clashes in the country’s northwest region made up of FATA and Khyber Pakhtunkhwa (KP) province. The 2014 military operations in North Waziristan and Khyber Agencies aggravated the situation, leading to the displacement of a further 233,000 families (approximately 1.4 million people). According to latest estimates from the UNHCR (2014), there are currently 1.6 million registered IDPs in KP/FATA. The vast majority of IDPs in KP/FATA chose to live in host communities (97%) rather than in camps for cultural reasons, including the privacy of females and difficult living conditions in the camps. The rest, who often have no other option, live in IDP camps (3%) (WFP). OCHA and other sources put the proportion of displaced families living outside of camps at 90% (OCHA, 18 June 2014; NYT, 20 June 2014; Al-Jazeera, 26 June 2014; IDMC, 12 June 2013, p.6). Displacement is difficult in Pakistan, which is ranked 146th on the list of 186 countries covered by the Human Development Index (UNDP, 24 July 2014, p.159). An estimated one fifth of its population are poor across the country, while in the KP/FATA a staggering one third of the population are poor (FDMA/UNDP, 2012, p.5; HDR, 2013, p.18; HPG, May 2013, p.21; UNDP, 27 October 2011). -

Checklist of Butterfly Fauna of Kohat, Khyber Pakhtunkhwa, Pakistan

Arthropods, 2012, 1(3):112-117 Article Checklist of butterfly fauna of Kohat, Khyber Pakhtunkhwa, Pakistan Farzana Perveen, Ayaz Ahmad Department of Zoology, Hazara University, Garden Campus, Mansehra-21300, Pakistan E-mail: [email protected] Received 26 February 2012; Accepted 2 April 2012; Published online 5 September 2012 IAEES Abstract The butterflies play dual role, firstly as the pollinator, carries pollen from one flower to another and secondly their larvae act as the pest, injurious to various crops. Their 21 species were identified belonging to 3 different families from Kohat, Pakistan during September-December 2008. The reported families Namphalidae covered 33%, Papilionidae 10%, and Pieridae 57% biodiversity of butterflies of Kohat. In Namphalidae included: species belonging to subfamily Nymphalinae, Indian fritillary, Argynnis hyperbius Linnaeus; common castor, Ariadne merione (Cramer); painted lady, Cynthia cardui (Linnaeus); peacock pansy, Junonia almanac Linnaeus; blue pansy, J. orithya Linnaeus; common leopard, Phalantha phalantha (Drury); specie belonging to subfamily Satyrinae, white edged rock brown, Hipparchia parisatis (Kollar). In Papilionidae included: subfamily Papilioninae, lime butterfly, Papilio demoleus Linnaeus and common mormon, Pa. polytes Linnaeus. In Pieridae included: subfamily Coliaclinae, dark clouded yellow, Colias croceus (Geoffroy); subfamily Coliadinae, lemon emigrant, Catopsilia pomona Fabricius; little orange tip, C. etrida Boisduval; blue spot arab, Colotis protractus Butler; common grass yellow, Eumera hecab (Linnaeus); common brimstone, Gonepteryx rhamni (Linnaeus); yellow orange tip, Ixias pyrene Linnaeus; subfamily Pierinae, pioneer white butterfly, Belenoi aurota Bingham; Murree green-veined white, Pieris ajaka Moore; large cabbage white, P. brassicae Linnaeus; green-veined white, P. napi (Linnaeus); small cabbage white, P. rapae Linnaeus. The wingspan of collected butterflies, minimum was 25 mm of C. -

June 10- 16 , 2012

WHO Emergency Humanitarian Program Situation Report Khyber Pakhtunkhwa and FATA Week 24 Date: June 10- 16 , 2012 1. Situation around IDP hosting districts A: Situation in “Jalozai” IDP camp, Nowshera district WHO along with health cluster partners, UNICEF and provincial health authorities lead the emergency health response for the displaced IDPs in Jalozai camp and IDPs living in host communities of district Nowshera. Population: Till 17th June, 2012 total IDPs families living in camp and off camp are 66,847 with 309,165 individuals. Jalozai IDP camp hosts 11,867 families with 57,531 individuals. 55,122 families are living in off camp with 252,269 individuals. Alerts and Consultations: WHO received and responded one alert of suspected Measles. There were 3,171 consultations provided through health care provider, including acute respiratory infection (17% or 539 cases), acute diarrhea (8% or 241 cases), skin infection (1.5% or 47 cases) and suspected malaria (3.2% or 103 cases). Coordination: Health & WASH cluster meetings take place once a week on every Wednesday in Jalozai attended by partners from health (Merlin, CAMP, CERD, FATA Health, GiZ, AGEG, IR, CTC, UNICEF), WASH, Nutrition, Food and CCM clusters working in the camp where issues are discussed and decisions are taken on the spot to address any loop holes in the health response for containment and control of disease outbreaks in the camp. The twenty eighth Camp Health Cluster meeting of Jalozai IDP Camp was held on Wednesday, June, 13th, 2012, in J-3 Health Post of Merlin. The meeting was jointly chaired by DHS FATA and WHO. -

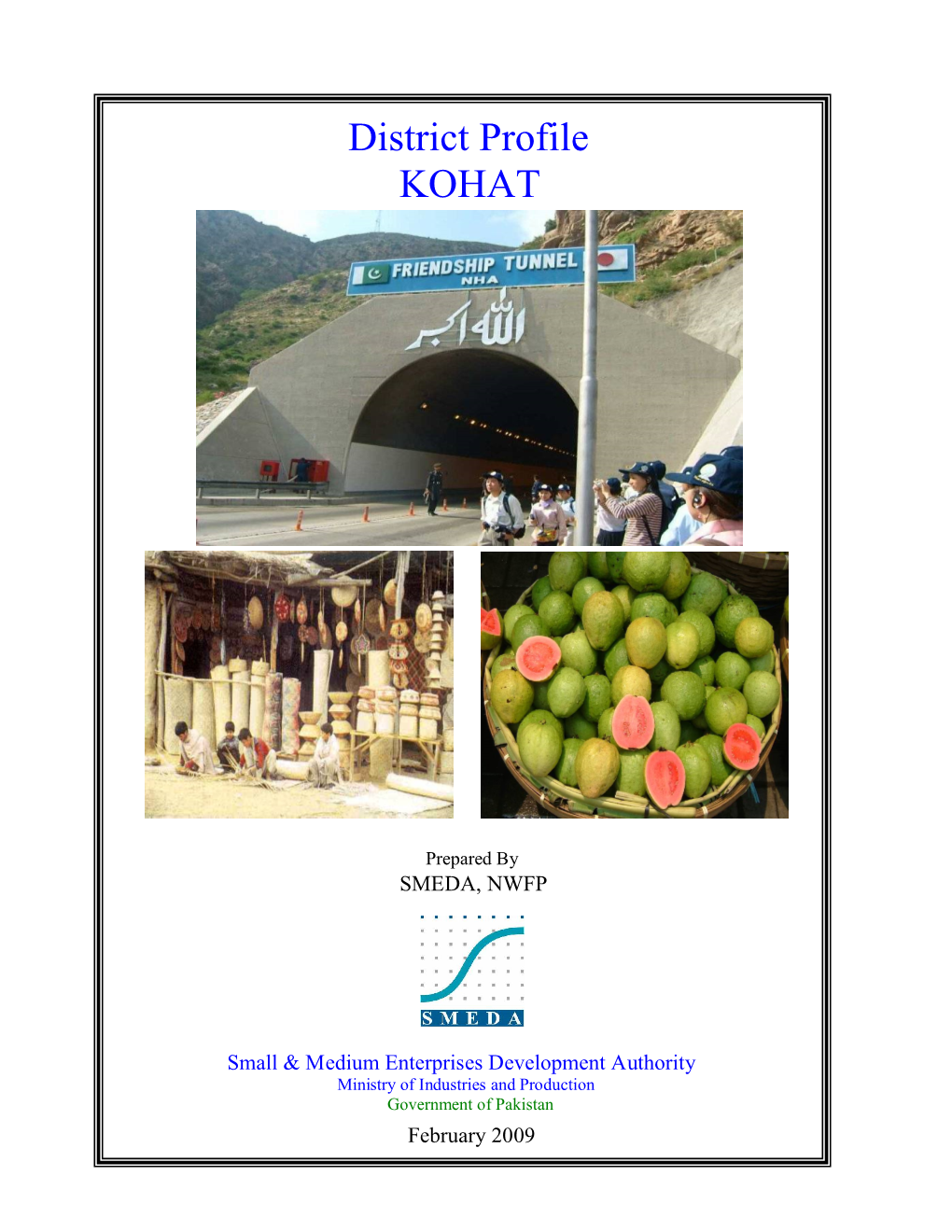

Production Constraints of Guava in District Kohat

Sarhad J. Agric. Vol.24, No.3, 2008 PRODUCTION CONSTRAINTS OF GUAVA IN DISTRICT KOHAT Urooba Pervaiz*, Ayesha Khan*, Rukhsana Javed** and Jehan Zeb*** ABSTRACT This article is based on primary data collected during Nov-Dec 2005 and the universe of the study was district Kohat, being a famous area for Guava cultivation. 50 respondents were randomly selected from five villages and interviewed. It was found that water shortage seriously hampered the yield of guava in project area. The serious bottlenecks were insignificant use of chemical fertilizer as reported by less than 17% of the total respondents, this was followed by defective marketing system and fear of risk taking 15.23%, lack of marketing information 9.52%, lack of processing and preservation industry 34.32%, lack of credit facilities 50.00%, time constraint 29.82%, costly labor 36.84% and carrying out traditional practices regarding post harvest techniques. Situation was further aggravated by the non-availability, ineffective and expensive nature of insecticides and pesticides. The study also revealed that the sample respondents’ access to the extension services was considerably low 92%. The study suggested post harvest recommended practices, training of field staff, institutional credit facilities and encouragement of preservation and processing industry. Key words : Guava, Extension services, Water shortage INTRODUCTION Guava ( Psidium guajava L.) belongs to the However, the yield of guava is quite low, 8.1 Myrtaceae family; it has more than 80 genera and tones/ha; considerably less than the potential yield of 3000 species dispersed throughout the tropics and 25 tones/ha (Anka, 2003). subtropics, mostly in the America, Asia and Australia (Nakasone and Paull, 1998).Guava tolerates a wide Guava is grown in all the districts of Punjab where range of climates, provided they are frost-free climate and soil are suitable for this crop. -

Union Council Level

Southern K.P. Districts- Union Council Level Sher Kot Urban-4 Chorlaki Usterzai Bahadar Kot 2 Muhammad Zai Urban-3 Urban-1 Nusrat Khel Urban-2 Urban-5 Kech Banda Raisan Togh Bala Urban-6 Khan Bari Darband Ganjiano Shah Pur Kalli Bahadar Kot 1 Billitang Gumbat Sur Gul Naryab Kharmatu Khushal Garh Kahi Kotki Jarma Tora Warai Hangu Togh Serai Darsamand Dhoda Doaba HA N G U Kohat Lachi Rural Mandoori Thall Rural Muhammad Khawja Lachi Urban KO H A T Sudal Thall Urban Karbogha Dallan Gurguri Teri Jatta Ismail Khil Banda Daud Shah Empty Shakardara Urban Shakardara Nari Panos Bahadur Khel Sabir Abad Mittha Khel Karak Karak Rehmat Abad KA R A K Esak Chuntra Latambar Ghundai Mir.k.khel Chukara Dabli Aral Hathi Khel Warana Lalozai Sikandar Dand Shaho Khel Bala Kha Amandi Umar Khan 1 Asperka Wazir Ahmad Abad Chagarmash Kheli Mu Nizam Darma Khel Baloch Amandi Umar Shahbaz Azmat Khel 1 Khan 2 Hinjal Takhat Nasrati Khawaja Karab Kalli Baka Khel Muhammad Khan WazirMad Mandan Shahbaz Azmat Khel 2 Thatti Nasrati Mitta Killa Khel Masti Khel Khel Jhando Khel Jehangiri Mandew Mira Khel B A NN U Mandan Shaamshi Khel Nurar Bharat Zargar Mama Khel Azim Killa Bannu Khojary Bannu Ghoriwala Lewan Dardariz Sharawah Kaki Landidak Nar Jafar Khan Mama Khel. Jani Khel Lalozai Sikandar Khel Bala Kha Mash Masti Khani Dand Shaho Asperka Wazir Tikhtee Khel. Marmandi Azeem. Amandi Umar Khan 1 Ghundi Khan Khel. Chagarmash Kheli Mu Kot Kashmir Nizam Darma Khel Baloch Landiwah Kachi Kamar Muhammad Khan Wazir Shahbaz Azmat Khel 1 Baist Khel Amandi Umar Khan 2 Bakhmal Ahmaed Zai LA K K I Hinjal Dharka Soliman Khel Shahbaz Azmat Khel 2 MA R W A T Khawaja Mad Mandan Jhando Khel Tajazai Baka Khel Mitta Khel Killa Khel Masti Khel Pahar Khel Thal Behram Khel Mira Khel Kharu Khel Pacca Lakki Marwat Bego Khel. -

PAKISTAN: Khyber Pakhtunkhwa

PAKISTAN: Khyber Pakhtunkhwa T A J I K I S T A N ± Zhuil ! Lasht ! Moghlang Nekhcherdim Chitral ! ! Morich ! Nichagh ! Muligram ! Druh ! Rayan ! Brep ! Zundrangram ! Garam Chashma Chapalli ! Mastuj ! Drasan !Bandok ! Arkari Sanoghar Nawasin ! ! Ghari ! Lon Afsik Besti ! ! ! Nichagh ! Dung Harchin ! Gushten Beshgram ! ! Laspur Imirdin ! ! Mogh Maroi ! ! Darband ! Koghozi Chitral ! Serki Singur ! ! Goki Chitral Shahi ! P.A.K !!! Nekratok ! ! Kuru Atchiku Paspat ! ! ! Brumboret ! Tar ! Kalam Gabrial ! Drosh Banda-i- ! Kalam Sazin ! ! Dong Kalkot Utrot ! Mirkhani ! Halil ! ! ! Lamutai Harianai ! Dammer Babuzai Nissar ! Sur Dassu ! Biar Swat Banda ! Biaso ! Dassu !! Gujar !! Banda Arandu ! Chodgram Chochun ! Dir ! Kohistan ! Ayagai Upper ! Bahrain Dir Pattan Dadabund Dir Banda ! Bahrain ! ! ! !! Ushiri ! ! Chachargah Chutiatan Daber ! ! ! Baiaul Barawal KHYBER Patan Bandai ! ! Kwana Matta ! Gidar Fazildin-Ki-Basti Nachkara Sebujni PAKHTUNKHWA ! ! A F G H A N I S T A N ! ! Khandak Palas Shenkhor ! ! Matta Bara ! Saral ! Aligram ! Domela Baihk ! Khararai Drush ! ! ! Wari Khel Rambakai Barwa ! Domel ! ! Alpuri ! Burawai Dardial Khwazakhela ! ! Samar ! Khal Bar Shang ! Kaga Bagh ! !Alamganj Kotka!i!! Alpuri ! ! Salarzai Lower ! ! Pokal ! ! Alai ! Batagram Dadai Tehsil Dir Kab!al Charbagh Shangla ! ! Mamund !Mian ! Bisham Kili !! Galoch ! ! Aspanr !Dandai Balakot ! Khalozai ! ! Alagram Chiksar ! ! ! ! Khongi Saidu Sharif!! Mongora ! Lari ! ! ! ! Khar Utman ! ! Nawagai Anangurai ! ! ! Khel ! Tim!ergara !!! Jatkol Panjnadi Bar ! Khar !Babuzai ! ! -

R Functional 2 332101 BHU Barh Kohat

DISTRICT KOHAT BASIC HEALTH UNIT S.No ID No Institute Name Tehsil Class Beds Locality Status 1 332099 BHU Ali Kach Lachi 1 - R Functional 2 332101 BHU Barh Kohat 1 - R Functional 3 332100 BHU Bazid Khel Kohat 1 - R Functional 4 332023 BHU Dhoda Kohat 1 - R Functional 5 332024 BHU Gabari Lachi 1 - R Functional 6 332026 BHU Kachai Kohat 1 - R Functional 7 332027 BHU Khaddar Khel Lachi 1 - R Functional 8 332028 BHU Marai Payan Kohat 1 - R Functional 9 332029 BHU Mohammad Zai Kohat 1 - R Functional 10 332030 BHU Nakband Kohat 1 - R Functional 11 332031 BHU Pershai Kohat 1 - R Functional 12 332033 BHU Shawaki Lachi 1 - R Functional 13 332035 BHU Suleman Talab Kohat 1 - R Functional 14 332036 BHU Sumari Payan Lachi 1 - R Functional 15 332037 BHU Togh Bala Kohat 1 - R Functional 16 332038 BHU Toolang Kohat 1 - R Functional 17 332039 BHU Ziarat Shaikh Aladad Kohat 1 - R Functional 18 332041 BHU Duli Banda Lachi 1 - R Functional 19 332042 BHU Kamal Khel Kohat 1 - R Functional 20 332045 BHU Sher Kot Kohat 1 - R Functional DISPENSARY 1 332050 Civil Dispy. Bezadi chikar kot Kohat 1 - U Functional 2 332052 Civil Dispy. Dartappi Lachi 1 - R Functional 3 332053 Civil DispY: Garhi mawaz khan Kohat 1 - R Functional 4 332054 Civil Dispy: Jangle khel kohat Kohat 1 - U Functional 5 332055 Civil Dispy: Kharmatoo Kohat 1 - R Functional 6 332056 Civil Dispy: Shadi khel Kohat 1 - R Functional 7 332057 Civil Dispy: Shadi pur Kohat 1 - R Functional 8 332064 Urban Dispy: Mir ahmad khel Kohat 1 - U Functional 9 332065 Urban Dispy: Lachi Lachi 1 - U Functional 10 -

ERF Update Pakistan

ERF Update Pakistan A quarterly bulletin of the Pakistan Emergency Response Fund Issue 11 | July – September 2014 ERF Update Photo: Photo: Photo credit: PEACE Photo credit: SHED Photo credit: EHSAR SRSP Muslim Aid ERF supports NWA response Funding The new contribution from the Swedish International Cooperation Development Agency Status (USD) (SIDA) in August 2014 enabled the Pakistan Emergency Response Fund (ERF) to fund response activities to displaced persons from North Waziristan Agency (NWA). $3.8 million ERF allocated US$3.5 million to 26 projects in Bannu, DI Khan, Karrak and Lakki Marwat. Contribution in 2014 Cluster Allocated Fund (US$) Project Location Education $725,000 5 projects in Bannu $3 million Carried over from 2013 Food Security $500,000 3 projects in Lakki Marwat and Karrak Health $775,000 7 projects in DI Khan and Bannu $6.5 million Nutrition $670,000 5 projects in Bannu and Lakki Marwat Allocated in 2014 Protection $700,000 5 projects in Bannu WASH $130,000 1 project in Bannu $58 million Contributions since 2010 Through education projects, 165 temporary learning centres (TLCs) will be operational and 8 existing government schools will be strengthened in 36 union councils1 (UCs) in Bannu, covering approximately 18,000 students with equal enrolment of girls and boys. $55.7 million School supply kits will be provided to the TLCs and supported schools and teachers will Allocated since 2010 be trained in Education in Emergency. Students will receive student packages and provided with psychosocial support. Livestock support under food security projects will target 1,830 livestock-owning families in Inside this 9 UCs in Lakki Marwat and 600 families in 5 UCs in Karrak. -

Afridi Tribe

Program for Culture and Conflict Studies AFRIDI TRIBE The Program for Culture & Conflict Studies Naval Postgraduate School Monterey, CA Material contained herein is made available for the purpose of peer review and discussion and does not necessarily reflect the views of the Department of the Navy or the Department of Defense. PRIMARY LOCATION Khyber Agency, Peshawar District MAJOR TOWNS The headquarters for the Political Agent is in Peshawar, but Assistant Political Agents may be found in Bara, Jamrud, and Landi Kotal. There is also a government presence (Customs house) at Torkham on the Durand Line. TERRAIN AND CLIMATE TERRAIN FATA is situated between the latitudes of 31° and 35° North, and the longitudes of 69° 15' and 71° 50' East, stretching for maximum length of approximately 450 kilometers and spanning more than 250 kilometers at its widest point. Spread over a reported area of 27,220 square kilometers, it is bounded on the north by the district of Lower Dir in the NWFP, and on the east by the NWFP districts of Bannu, Charsadda, Dera Ismail Khan, Karak, Kohat, Lakki Marwat, Malakand, Nowshera and Peshawar. On the south-east, FATA joins the district of Dera Ghazi Khan in the Punjab province, while the Musa Khel and Zhob districts of Balochistan are situated to the south. To the west lies Afghanistan. The central region covers the Khyber, Kurram and Orakzai agencies, and the FRs of Kohat and Peshawar. Here, the Safid Koh Mountains rise from the Terimangal pass and stretch eastward, reaching an elevation of 3,600 meters. The Sikaram, at 4,760 meters, is the tallest peak in this range.