OPTIMIZATION OF LAYERED SHIELDS WITH A GIVEN AREAL DENSITY

G. Ben-Dor, A. Dubinsky and T. Elperin The Pearlstone Center for Aeronautical Engineering Studies, Department of Mechanical Engineering, Ben-Gurion University of the Negev, P.O.Box 653, Beer-Sheva, 84105, Israel Tel: 972-7-6477078; Fax: 972-7-6472813

Abstract. Using approximate model for impactor-armor interaction it is showed that the maximum (minimum) ballistic limit velocity for a multi-layered shield with a given surface density for a conical-nosed impactor is achieved when a shield is manufactured from the material which is characterized by a maximum (minimum) ratio of a distortion pressure to density.

1. Introduction. Literature on analytical investigation of problems associated with optimization of multi-layered shields against a high speed sub-ordnance impact is very limited (see, Aptukov et al. (1992), Ben-Dor et al. (1998), Hetherington (1992), Wang and Lu (1996) and references therein). A model which may be used in further investigations and some illustrative results on above subject are presented in this Note.

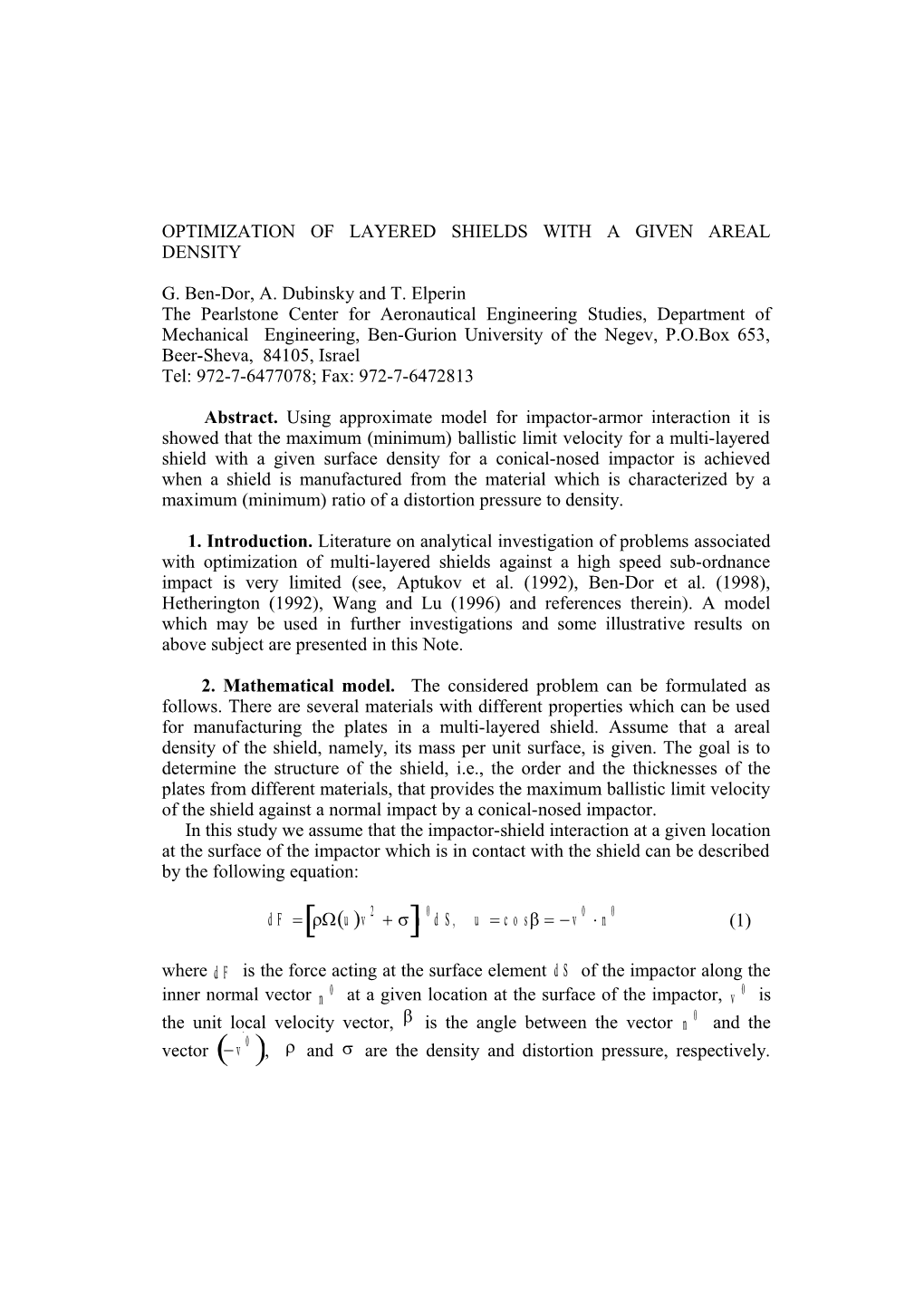

2. Mathematical model. The considered problem can be formulated as follows. There are several materials with different properties which can be used for manufacturing the plates in a multi-layered shield. Assume that a areal density of the shield, namely, its mass per unit surface, is given. The goal is to determine the structure of the shield, i.e., the order and the thicknesses of the plates from different materials, that provides the maximum ballistic limit velocity of the shield against a normal impact by a conical-nosed impactor. In this study we assume that the impactor-shield interaction at a given location at the surface of the impactor which is in contact with the shield can be described by the following equation: d F u v 2 n0 d S , u c o s v0 n0 (1) where d F is the force acting at the surface element d S of the impactor along the 0 0 inner normal vector n at a given location at the surface of the impactor, v is 0 the unit local velocity vector, is the angle between the vector n and the vector v0 , and are the density and distortion pressure, respectively. Equation (1) with constant parameters , together with an equation u u 2 comprise the most widely used phenomenological models for describing interactions of impactors with homogenous shields manufactured from ductile and some other materials (for details, see, e.g., Bunimovich and Dubinsky (1995); Recht (1990)). In the case of a multi-layered armor the values of these parameters are determined by the properties of the material of that plate which is in contact with the impactor. It is assumed that the adjacent plates do not interact to one another, and several adjacent plates made from the same material and a single plate with the same total thickness and the same material are equivalent. For a shield consisting of any N plates the notations are shown in Fig. 1. The coordinate h is defined as the distance of the nose of the impactor from the front surface of the armor, and the coordinate is associated with the target. The plate with the number i is located between the sections i and i 1 i i i 1 , . . . , N where 1 0 , N 1 b , b and i are the thickness of the shield and of the i -th plate, respectively. x

0 x 0 1 1 2 2 i r i+1 L i i

=b N N+1 x 2

h 0 0 Fig. 1. Coordinates and notations.

We assume that the shape of the impactor is such that the total force acting on it is directed along the h -axis. Only the nose of the impactor with the length L interacts with the shield, and the impactor may have also a cylindrical part. The equation of the lateral surface of conical nose part of the impactor can be represented as r R 0 x where R 0 is the characteristic size of the base of the impactor, x x L , is the function determining the cross-sectional contour of the impactor, 0 1 , 0 2 . The part of the lateral surface of the impactor between the cross-sections x x 1 and x x 2 (see Fig. 1) interacts with some plate of the shield where

0 i f 0 h b h i f 0 h 1 x 1 ( h ) , x 2 ( h ) (2) h b i f b h b + 1 1 i f 1 h b + 1 and x1 x 1 L , x 2 x 2 L , h h L , b b L .

The total force which acts on the impactor is determined by integrating the local force over the impactor-target contact surface taking into account that the parameters and are the functions of the coordinate L . Solving the equation of motion of the impactor along the h -axis yields the following formula for the ballistic limit velocity v which is defined as the initial velocity of the impactor required for its nose to emerge from the armor with a zero velocity:

b 1 h 2 v f h e x p f H d H d h (3) 0 0 where

x 2 h x 2 h f c x h x d x , f c x h x d x x 1 h x 1 h (4) 2 2 1 2 c c , c , c 2 d 2 d K c M 0 0

2 R d u u , 0 , , 2 2 2 L d 1

a a i i f i i i , a , , i i L , i i L , i 1 , . . . , N ,

V and are volume and density of the impactor, respectively, a parameter K M takes into account the contribution of the cylindrical part of the impactor to its mass and volume (for an impactor without a cylindrical part K M 1 ), i and i are the density and distortion pressure of i -th plate, respectively (for details see Ben-Dor et al. (1997)) The surface density of the shield P is given, i.e. the following condition must be valid: N i i P , P P L (5) i 1 with non-negative i . Note that since the goal is to determine the optimum order of the plates we must use a subscript i instead i where i is the number of the material that applies for the plate with the number i in the armor. However we use a simplified notations as will become clear bellow.

3. Solution of the problem. Let us introduce the following function

0 i f h 0 x 0 h h i f 0 h 1 (6) 1 i f h 1

Functions f and f can be represented in the following form a , :

x h n 0 i f a h c a a i x d x (7) i 1 x0 h 1 i and Eq. (3) can be rewritten as follows:

N N v 2 c F c F c F i i i i i i (8) i 1 i 1 i i where i is any number between 1 and N , x 0 H i b 1 d h h 1 i F h d h, i h e x p c i d H X d X , i h d h i 0 0 x 0 H i 1 (9)

N i h h , i i i 1 i F Rewrite expression for i using integration by parts:

b 1 b 1 1 d i h h b 1 d h F h d h h h d h i h d h h 0 i d h h 0 i 0 i N (10) e x p c B 1 F i i 1 i i where B can be transformed changing the order of integration:

x H N b 1 0 i 1 N X i i N B i d H X d X Xd X i d H 0 . 5 i i 0 . 5 P (11) i 1 i 1 i 1 0 x 0 H i 1 0 X i

Equations (10) and (11) allow to rewrite Eq. (8) as follows:

N v 2 c e x p 0 . 5 c P 1 c F i i i i (12) i 1 i i

The first in Eqs. (9) can be transformed as follows: x h b 1 0 i 1 x i 1 F i c i h d h x d x c i x d x h d h 0 x h 0 x 0 i 1 i (13) 1 i c i x d x h x i d h 0 0

Equation (13) shows that F i 0 if i 0 and F i 0 if i 0 . Assume for simplicity that all i are different. Let i i m a x is such that m a x i m a x i . Then all i i 0 and Eq. (12) implies that maximum v is 1 i N . . . . . . attained when 1 i m a x 1 i m a x 1 N . Thus, the shield with the maximum ballistic limit velocity must consist of one or several adjacent plates (these cases are equivalent in our model) manufactured from the material with maximum value of parameter , regardless of the shape of conical-nosed b P impactor. The thickness of the optimum shield is i m a x . Similarly, the shield with the minimum ballistic limit velocity consists of one or several adjacent plates manufactured from the material with the minimum value of parameter . The ballistic limits of different shields with a given surface density vary in the range between these two limiting values. Published experimental data on ballistic penetration by conical impactors into multi-layered targets are quite scarce. Radin and Goldsmith (1988) studied the ballistic limit velocities for 60-grad conical-nosed projectile penetrating into adjacent layered targets composed of different materials (2024-0 aluminum and Lexan). In particular, the latter study shows the ballistic limit as a function of a surface density for the targets of different structure. These data comply with the above theoretical findings.

REFERENCES

Aptukov, V. N., Murzakaev, A. V. and Fonarev, A.V. (1992) Applied Theory of Penetration [Prikladnaja Teorija Pronikanija], Moscow, Nauka. In Russian. Ben-Dor, G., Dubinsky, A. and Elperin, T. (1997) Optimal 3D impactors penetrating into layered targets. Theoretical and Applied Fracture Mechanics, 27, 161-166. Ben-Dor, G., Dubinsky, A. and Elperin, T. (1998) Analysis of ballistic properties of layered targets using cavity expansion model. International Journal of Fracture. In press. Bunimovich, A. I. and Dubinsky, A. (1995) Mathematical Models and Methods of Localized Interaction Theory. World Sci. Publ. Hetherington, J.G. (1992) The optimization of two-component composite armors. International Journal of Impact Engineering, 12, 229-259. Radin, J. and Goldsmith, W. (1988) Normal projectile penetration and perforation of layered targets. International Journal of Impact Engineering, 7, 229-259. Recht, R. F. (1990) High velocity impact dynamics: Analytical modeling of plate penetration dynamics. In High Velocity Impact Dynamics, Chap. 7, 443-513, ed. Zukas, J. A., New York, Wiley Interscience Publ. Wang, B. and Lu, G. (1996) On the optimization of two-component plates against ballistic impact. Journal of Materials Processing Technology, 57, 141-145.