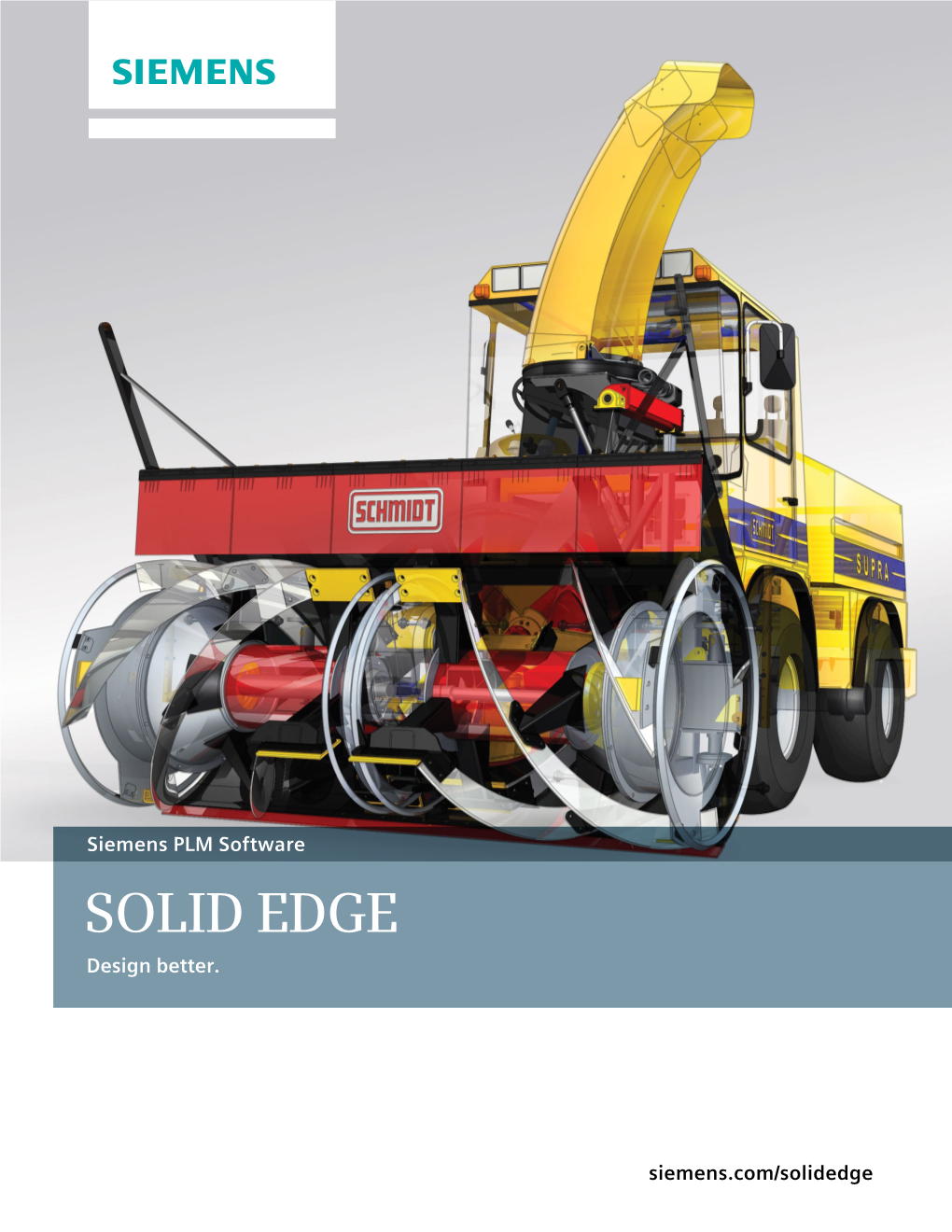

SOLID EDGE Design Better

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

3Dfindit.Com for Solid Edge Fact Sheet

3Dfindit.com for Solid Edge The all-new search engine crawls millions of 3D computer-aided design (CAD) mod- els from hundreds of manufacturer cata- logs worldwide, providing tool and 3D CAD content free of charge to Solid Edge® software users. 3Dfindit.com Enjoy access to millions of 3D CAD models offers millions of 2D and 3D CAD files at the click of a button verified by component manufacturers, which are available to all Solid Edge users with just a click of a button. Benefits Summary CAD files of requested parts are automat- • Millions of 3D CAD models in Streamline the process of finding 3D ically generated on the fly, ready to use native Solid Edge formats models using intelligent search functions in Solid Edge. This helps engineers easily through tight integration with a next- select and configure the components • Hundreds of manufacturer-verified dimension visual search engine for that match their needs. CAD catalogs mechanical, electrical and electronic • Intelligent CAD models with exten- engineering. 3Dfindit.com, powered by Hundreds of catalogs with intelligent sive metadata CADENAS, was developed to significantly CAD data reduce technical search times and 3Dfindit.com offers millions of 2D and 3D • Intuitive search methods for digital increase design efficiency. Searches can CAD files verified by component manu- components be performed using classifications, facturers. Depending on the catalog, the • Catalog content provided free of geometry, filters, sketches and digital parts are enriched with extensive charge much more. metadata such as kinematics information to test motion sequences, centers of mass, material, environmental protection standards, order numbers, etc. -

Solid Edge Overview

Solid Edge Siemens PLM Software www.siemens.com/solidedge Solid Edge® 벽 형상 반의 2D/3D CAD 으로 직접 모델링의 속도 및 유연성과 치수 반 설계의 정밀 제 을 결합하여 빠르고 유연 설계 경험을 제공합니다. Solid Edge 뛰난 부품 및 셈블리 모델링, 도면 작성, 투명 데터 관리 및 내 유 요 해석(FEA) 을 제공하여 점점 더 복잡해지 제품 설계를 간단하게 수행할 수 있도록 하 Velocity Series™ 폴리의 핵심 구성 요입니다. Solid Solid Edge 일반적인 계 Edge 직접 모델링의 속도 및 운데 유일하게 설계 유연성과 치수 반 설계의 관리 과 설계자들 매일 정밀 제 을 결합하여 하 CAD 도구를 결합 빠르고 유연 설계 입니다. Solid Edge의 경험을 제공합니다. 고객은 여러 지 확 Solid Edge는 PDM(Product Data 뛰난 부품 및 셈블리 Management) 솔루션을 모델링, 도면 작성, 투명 선택하여 설계를 생성하 데터 관리 및 내 즉 관리할 수 있습니다. 유 요 해석(FEA) 을 또 실적인<t-5> 협업 제공하여 점점 더 복잡해지 관리 도구를 통해 보다 제품 설계를 간단하게 수행할 효율적으로 설계 팀의 활을 수 있도록 하 Velocity Series 조정하고 잘못 폴리의 핵심 구성 의통으로 인 류를 요입니다. 줄일 수 있습니다. 업의 엔지니링 팀은 Solid 제품과 로세의 Edge 모델링 및 셈블리 복잡성 점차 제조 부문의 도구를 하여 단일 주요 관심로 떠르고 부품부터 수천 개의 구성 있으며, 전 세계 수천 개의 요를 하 조립품 업들은 Solid Edge를 르까지 광범위 제품을 하여 갈수록 증하 쉽게 개발할 수 있습니다. 복잡성 문제를 적극적으로 또 맞춤형 명령 및 해결해 나고 있습니다. 해당 구조 워크플로를 통해 업들은 Solid Edge의 모듈식 보다 빠르게 특정 업계의 통합 솔루션 제품군을 통해, 공통 을 설계할 수 먼저 CAD 업계의 혁신 있으며, 셈블리 모델 내 을 활하고 설계를 부품을 설계, 분석 및 성하여 류 없 제품으로 수정하여 부품의 정확 맞춤 진입할 수 있습니다. -

Solid Edge Requirements Management Also Offers Security Features Such As Take Control of Your Data, Including Role- and Credential-Based Authentica- Tion

Solid Edge Requirements product requirements, ID task tagging, interactive workflows and easy commu- nication with management and executives. Requirements Management Management administrators and project managers can provide specific permissions like commenting and approval rights to further manage project interactions. Solid Edge Requirements Management also offers security features such as Take control of your data, including role- and credential-based authentica- tion. These features provide strict your requirements access guidelines for an optimal project workflow. Solid Edge Requirements Management Benefits Summary is an add-on product for Solid Edge • Organize inputs for mechanical The ability to accurately record, main- Design. You must currently be running design tain and track key principles in the a Solid Edge base license to be eligible product design and manufacturing • Easily assess design and for adding Solid Edge Requirements process is crucial for meeting quality requirements changes Management. standards. Solid Edge Requirements • Demonstrate contract fulfillment Management provides a full array of Scalable for future needs traceability benefits to support project • Meet compliance and quality Solid Edge Requirements Management is managers from start to finish. With standards fully scalable to Polarion Requirements™ Solid Edge Requirements Management, software for managing complex soft- users can easily and instantly search ware systems and fully upgradable to and interact with work items and tasks. other Polarion products such as Polarion Requirements Management is seam- ALM™ and Polarion QA™. lessly integrated with Solid Edge, enabling you to work directly with your Extending value Solid Edge parts and assemblies while Solid Edge is a portfolio of affordable, simultaneously managing the project easy to deploy, maintain, and use requirements. -

Solid Edge 2D Drafting

Solid Edge 2D Drafting Solid Edge 2D Drafting provides excel- lent translation and editing of AutoCAD file formats and can replace AutoCAD Providing a high-value, robust and no-cost for many 2D machine design and layout 2D design solution applications. Solid Edge provides spe- cific online help resources for AutoCAD users, helping them to work in a mixed environment of Autodesk and Solid Benefits Summary Edge. This speeds their transition from • Save time and money with a Solid Edge® 2D Drafting software Autodesk mechanical design software high-value solution for 2D tasks delivers a production-proven set of to Solid Edge. capabilities for creating two-dimen- • Standardize on a single platform, sional (2D) documentation. It offers No matter where you are or where you reducing training and maintenance excellent drawing layout, diagramming, want to go, Solid Edge 2D Drafting will costs annotation and dimensioning controls. help you design better. This free appli- • Share native drawings with The 2D computer-aided design (CAD) is cation is available for download suppliers for design review or suited to a variety of tasks: laying out anywhere in the world. manufacture and optimizing schematics, streamlin- ing 2D drawing production and learning Design layout and optimization • Re-use 2D legacy data in 3D design how to design in a 3D CAD Some design tasks are better suited for • Make easy transition from 2D environment. 2D design, such as machinery or plant AutoCAD and other 2D products layout development. Layouts are often A free software offering, Solid Edge 2D the first step in outlining material • Use CAD solution with a fast Drafting, which is part of the routing through factories or machines. -

Solid Edge with Synchronous Technology Steering a New Course in 3D Design

Solid Edge with synchronous technology Steering a new course in 3D design • Learn from step-by-step examples • Watch video tutorials • Discover proven productivity tips siemens.com/solidedge Solid Edge with synchronous technology Steering a new course in 3D design Table of contents Prologue 1 Chapter 1: Introduction to synchronous technology 2-15 Chapter 2: Driving design intent without history 16-28 Chapter 3: Introduction to Solid Edge 29-41 Chapter 4: Creating geometry 42-58 Chapter 5: Selection and re-use 59-67 Chapter 6: Working with imported data 68-74 Chapter 7: Editing with synchronous technology 75-89 Chapter 8: Synchronous sheet metal 90-110 Chapter 9: Synchronous assemblies 111-127 Chapter 10: Synchronous, parametrics and associativity 128-139 Solid Edge with synchronous technology | Steering a new course in 3D design Prologue Synchronous technology was born out of the idea that merging the best ideas of direct edit techniques with the best ideas of history-based modeling would deliver unprecedented power and control in editing CAD geometry. For decades, history-based modeling has dominated the CAD world for reasons we will discuss more later. History-based methods have a lot of power, such as being dimension driven, highly automated, and feature-based, but come with a lot of less desirable baggage such as the need for pre-planning, inflexibility and the fact that it slows down as you add many features or many parts. Meanwhile, direct edit methods have also existed for a long time and have several advantages, but because of its associated weaknesses, it could never compete with history-based modeling. -

Solid Edge a Portfolio of Affordable, Easy-To-Use Software Solutions for Product Development

Siemens PLM Software Solid Edge A portfolio of affordable, easy-to-use software solutions for product development solidedge.siemens.com Disruption in product design and manufacturing Digitalization technologies are changing how products are designed and manufactured. Product design is becoming a cross-discipline collaboration, because product complexity is increasing exponentially and the complete design-to-manufacture process can now be fully digitalized. Such advances are improv- ing efficiency and effectiveness for all companies, enabling their success and growth. But for small and medium-sized businesses (SMBs) especially, digitalization can be a tremendous source of competitive advantage. SMBs have become synonymous with innova- tion and disruption, but often lack the infrastructure to bring products to market quickly. Digitalization provides the ability to connect people, devices and businesses to lower or remove that barrier. Since SMBs are more agile, they can more easily leverage digital transformation to leapfrog the big incumbents. Today’s startups and SMBs can be tomorrow’s large enterprises. Siemens PLM Software empowers SMBs with solutions that address their unique needs. The Solid Edge® software portfolio delivers value, flexibility and choice: a modular, end-to-end solution that begins with an exceptional electromechanical design experi- ence that is seamlessly integrated with market-leading applications for product optimization, data management, documenta- tion, and manufacturing. “ 46.2% of decision makers believe that technology levels the playing field for small businesses versus larger corporations.” Thriving in the Digital Economy IDC 2 Disruption in product design Digital transformation and manufacturing technology 48.3% of SMB manufacturers Image courtesy of Radio Bro believe their efforts around Selecting a technology platform is an digital transformation will be important decision, one that a company essential to their company’s can live or die by. -

New Math the Hidden Cost of Swapping CAD Kernels

New Math The Hidden Cost of Swapping CAD Kernels Schnitger Corporation Schnitger Corporation Page 2 of 11 When we first wrote about the costs of switching CAD kernels a decade ago, we profiled a company that had twenty years’ worth of legacy designs to refresh. They could either find copies of the old software (and the hardware to run it on) or convert the parts to a new format and use a modern CAD system to move the designs forward. Old CAD on old hardware was a non-starter, leaving migrating everything to a new CAD system. But what to convert to? They already used SolidWorks in part of their business and considered moving the legacy parts to that platform. One big problem: Many of SolidWorks’ newest features rely on Dassault Systèmes’ 3DEXPERIENCE platform. The traditional desktop SolidWorks is built on the Parasolid kernel, while the 3DEXPERIENCE platform uses the CGM kernel. This reliance on two kernels leads many users to worry that building parts in SolidWorks will eventually mean a wholesale conversion from Parasolid to CGM. If you migrate everything today, will you have to do it again in a few years? As you’ll see later, converting from one kernel to another can be tricky so, if there is an opportunity to avoid a kernel change, you should investigate this possibility. The company we wrote about decided that it couldn’t afford the risk, disruption, and uncertainty an unclear future might cause. They chose Siemens Solid Edge, which also uses the Parasolid kernel. Sticking with the same kernel simplified moving their Parasolid-based models from one CAD tool to another. -

PTC® Creo® Essentials Packages Powerful 3D CAD Solutions Optimized for Your Product Development Tasks

PTC Creo Essentials Packages PTC® CREO® ESSENTIALS PACKAGES Powerful 3D CAD solutions optimized for your product development tasks Product design firms and manufacturing companies are of your specific engineering design tasks and business under constant pressure to develop more products in less requirements as you grow. time, without sacrificing innovation or quality. No matter which package you choose, users will be able PTC’s 3D product design solution, PTC Creo, provides to take advantage of a powerful, intuitive, and comprehen- engineers with the right tools to achieve the highest qual- sive set of 3D CAD capabilities. ity designs in the fastest possible time. And since it is an integral part of PTC’s Product Develop- PTC delivers the most scalable range of 3D CAD product ment System, your 3D CAD solution will seamlessly development packages on the market today. Available connect to PTC’s other industry-leading solutions, including exclusively through PTC Value Added Resellers, the PTC PTC Windchill® for product data/product lifecycle Creo Essentials Packages are easy to use, competitively management (PDM/PLM) and PTC Mathcad® for priced and always upgradeable–to meet the varied needs engineering calculations. Page 1 of 7 PTC.com PTC Creo Essentials Packages PTC Creo Essentials Packages - At a Glance 3D Part & Assembly Design................................................................................... Automated 2D Drawing Creation & Update..................................................... Breakthrough multi-CAD data exchange -

Designing New Age Disruptive Engineering Solutions

Designing New Age Disruptive Engineering Solutions Corporate Profile I January 2020 Copyright © 2020 nCircle Tech Pvt. Ltd. All Rights Reserved. www.ncircletech.com Envision. Enhance. Endure. Since 2012, nCircle Tech has empowered passionate innovators in the AEC and Manufacturing industry to create impactful 3D engineering & construction solutions. Leveraging our domain expertise in CAD-BIM, we provide disruptive solutions that reduce time to market and meet business goals. Our team of dedicated engineers, partner ecosystem and industry veterans are on a mission to redefine how you design, collaborate and visualize. 50+ Customers | 150+ Solutions I 15+ Countries Copyright © 2020 nCircle Tech Pvt. Ltd. All Rights Reserved. www.ncircletech.com Collaboration Embrace the power of many Robust ecosystem including experts from leaders in CAD, PLM, ML/AI Experience Impact Founded in 2012 with collective 5 million lines of code team of 130+ technologists and developed & 1 million hours of subject matter experts testing delivered with 30x Across CAD-BIM Lifecycle ROI Leading To An World of nfinite Disruptions www.ncircletech.com Step Into A World Of nfinite Possibilities Differentiating nCircle Copyright © 2020 nCircle Tech Pvt. Ltd. All Rights Reserved. www.ncircletech.com Industry Footprint Made in India | For Global Standards AEC Manufacturing 3D Visualization Copyright © 2020 nCircle Tech Pvt. Ltd. All Rights Reserved. www.ncircletech.com www.ncircletech.com Embracing The Power of Many Industry Partnerships Copyright © 2020 nCircle Tech Pvt. -

Creo Elements/Pro 5.0 J-Link User's Guide

Parametric Technology Corporation Creo™ Elements/Pro™ 5.0 J-Link User’s Guide December 2011 Copyright © 2011 Parametric Technology Corporation and/or Its Subsidiary Companies. All Rights Reserved. User and training guides and related documentation from Parametric Technology Corporation and its subsidiary companies (collectively "PTC") are subject to the copyright laws of the United States and other countries and are provided under a license agreement that restricts copying, disclosure, and use of such documentation. PTC hereby grants to the licensed software user the right to make copies in printed form of this documentation if provided on software media, but only for internal/personal use and in accordance with the license agreement under which the applicable software is licensed. Any copy made shall include the PTC copyright notice and any other proprietary notice provided by PTC. Training materials may not be copied without the express written consent of PTC. This documentation may not be disclosed, transferred, modified, or reduced to any form, including electronic medi, or transmitted or made publicly available by any means without the prior written consent of PTC and no authorization is granted to make copies for such purposes. Information described herein is furnished for general information only, is subject to change without notice, and should not be construed as a warranty or commitment by PTC. PTC assumes no responsibility or liability for any errors or inaccuracies that may appear in this document. The software described in this document is provided under written license agreement, contains valuable trade secrets and proprietary information, and is protected by the copyright laws of the United States and other countries. -

Solid Edge 2D Drafting Fact Sheet

Velocity Series Solid Edge 2D Drafting Robust 2D design application – at no cost fact sheet Siemens PLM Software www.siemens.com/solidedge Solid Edge® 2D Drafting software delivers a production-proven set of capabilities for creating 2D documentation.This free application is available for download anywhere in the world. Solid Edge 2D Drafting offers excellent drawing layout, diagramming, annotation and dimensioning controls that automatically comply with a wide range of drafting standards – including ISO,ANSI, BSI, DIN, JIS and UNI.Visit www.solidedge.com/free2d to download your free software and learn more. Benefits Streamlined drawing creation Save time and money with a cost Solid Edge 2D Drafting demonstrates effective, high value solution for Siemens PLM Software’s commitment to 2D tasks helping companies control costs.Whether Continue to make use of 2D legacy data you are using 2D company wide or for specific 2D design processes, you will benefit Stop paying for upgrades and subscriptions from Solid Edge 2D Drafting. Solid Edge 2D Download regular updates for free Drafting capitalizes on 10 years of Standardize on a single platform, production-proven capabilities developed reducing training and maintenance for Solid Edge. costs Share native drawings with suppliers The innovative Microsoft Office 2007 style for design review or manufacture user interface includes a verticalized SmartStep that walks you through each command step, while providing quick access to all inputs so you are up and running faster and more productive when you Features become familiar with Solid Edge. Another helper is the new Ribbon that lists the most common Production proven 2D drafting operations on a “Home” tab for fast access to other commands. -

Solid Edge/CATIA Translator Fact Sheet

Siemens PLM Software Solid Edge/CATIA V4 translator Enabling more effective collaboration with suppliers and customers Benefits Summary ahead of the competition and provide data • Translate CATIA V4 data in Solid Edge® software includes the Solid in a timely, cost-effective manner. an efficient and effective Edge/CATIA V4 translator, which is a power- The Solid Edge/CATIA V4 translator provides manner ful migration tool that enables Solid Edge Solid Edge users with the ability to trans- users to reference CATIA V4 product design • Work with suppliers or late CATIA V4 data in an efficient and data that is provided by customers and customers in a more effective manner. Importing or exporting suppliers. By translating CATIA V4 data cohesive manner CATIA V4 model files with the Solid Edge/ from and to Solid Edge, companies can CATIA V4 translator allows design engi- • Create better designs, expect improved design communication, neers to work with suppliers or customers enhance communications, quality and productivity, as well as signifi- in a more cohesive manner. With the Solid increase customer cant cost savings. Whether it’s designing Edge/CATIA V4 translator, users can design satisfaction and deliver tooling or components for an assembly, it parts or assemblies in Solid Edge and then significant cost savings no longer matters if customers or suppliers translate data into the required CATIA V4 are using CATIA V4 data. Solid Edge Features format, or read in CATIA V4 data and provides the right tools to help you stay • Easily leverage the continue designs in Solid Edge. By using translator’s bidirectional the Solid Edge/CATIA V4 translator, compa- capabilities when handling nies achieve better designs, enhanced CATIA V4 files communication and increased customer satisfaction.