USOO6541695B1 (12) United States Patent (10) Patent No.: US 6,541,695 B1 MOwles (45) Date of Patent: *Apr. 1, 2003

(54) HIGH EFFICIENCY SOLAR T.A. Mowles, Master's Thesis, Lawrence Berkely Lab, Univ PHOTOVOLTAC CELLS PRODUCED WITH of Cal. (LBL 7661). NEXPENSIVE MATERALS BY PROCESSES T.A. Mowles, Ph. D. Thesis, Matls Science Dept, Univ of SUTABLE FOR LARGE VOLUME CA, Berkeley (Nov. 1981). PRODUCTION M.E. Fleet et al., Acta Cryst., vol. C40, pp 1778-1779 (1984). (76) Inventor: Thomas Mowles, 2727 Midtown Ct., M.E. Fleet et al., J. Mater. Res., vol. 1, No. 1, Jan./Feb. 1986, #23, Palo Alto, CA (US) 94.304 pp. 187-192. R.S. Berg et al, Solid State Comm., vol. 46, No. 2, pp (*) Notice: Subject to any disclaimer, the term of this 101-104 (1983). patent is extended or adjusted under 35 V. Samuel et al., J. Mater. Res., vol. 4, No. 1, Jan/Feb. 1989, U.S.C. 154(b) by 0 days. pp. 185-188. V.A. Demis et al, Cryst. Res. Technol. vol. 24, No. 6, pp This patent is Subject to a terminal dis 585-590 (1989). claimer. Ch. Kloc et al., J. Crystal Growth, vol. 106, pp 635-642 (1990). (21) Appl. No.: 07/947,863 S. Fletchter etal, Mat. Res. Bull, vol. 22, pp 543–549 (1987). T. Gibinski et al, Kristall und Technite, vol. 9, No. 2, (1974), (22) Filed: Sep. 21, 1992 pp. 161-163. (51) Int. Cl." ...... H01L 31/06; H01L 31/0392 H. Von Kanel et al., Hydrogen Energy Progress V, pp (52) U.S. Cl...... 136/252; 136/265; 257/431; 969-980 (Date Unknown). 257/613; 437/5 * cited by examiner (58) Field of Search ...... 136/252,265; Primary Examiner Aaron Weisstuch 257/431, 613 (74) Attorney, Agent, or Firm John A Frazzini (56) References Cited (57) ABSTRACT U.S. PATENT DOCUMENTS A thin film, photovoltaic, Solar energy conversion device comprising: a thin-film, photovoltaic layer; a transparent 3,230,044 A 1/1966 Hegyi ...... 423/299 electrical conducting layer in contact with said photovoltaic 4,692.203 A * 9/1987 Betz et al...... 117/109 layer; a back electrical conducting layer in contact with Said OTHER PUBLICATIONS photovoltaic layer, fabricated on a Suitable Substrate; Said photovoltaic layer being of a material Selected from the class K. Ito et al., Jpn.J. Appl. Phys., vol. 20 (1981), Supplement consisting of monoclinic Zinc diphosphide (also referred to 20–2, pp. 109-112.* as beta Zinc diphosphide and indicated by B-ZnP), copper A. Catalano, Thin Solid Films, vol. 83, pp L141-L145 diphosphide (CuP); magnesium tetraphosphide (MgP); (1981).* gamma-iron tetraphosphide (Y-FeP) and mixed crystals J. Lang, J. Electrochem. Soc., vol. 130, No. 3, pp 725-727 formed from these four materials. A thin film fabrication (1983). process is presented that produces high efficiency, low-cost T. Suda, J. Crystal Growth, vol. 99, pp 625-629 (1990). photovoltaic layers of the above-indicated class. M. Rubenstein et al., J. Appl. PhyS., vol. 41, No. 4, pp1777–1786 (1970). 47 Claims, 16 Drawing Sheets

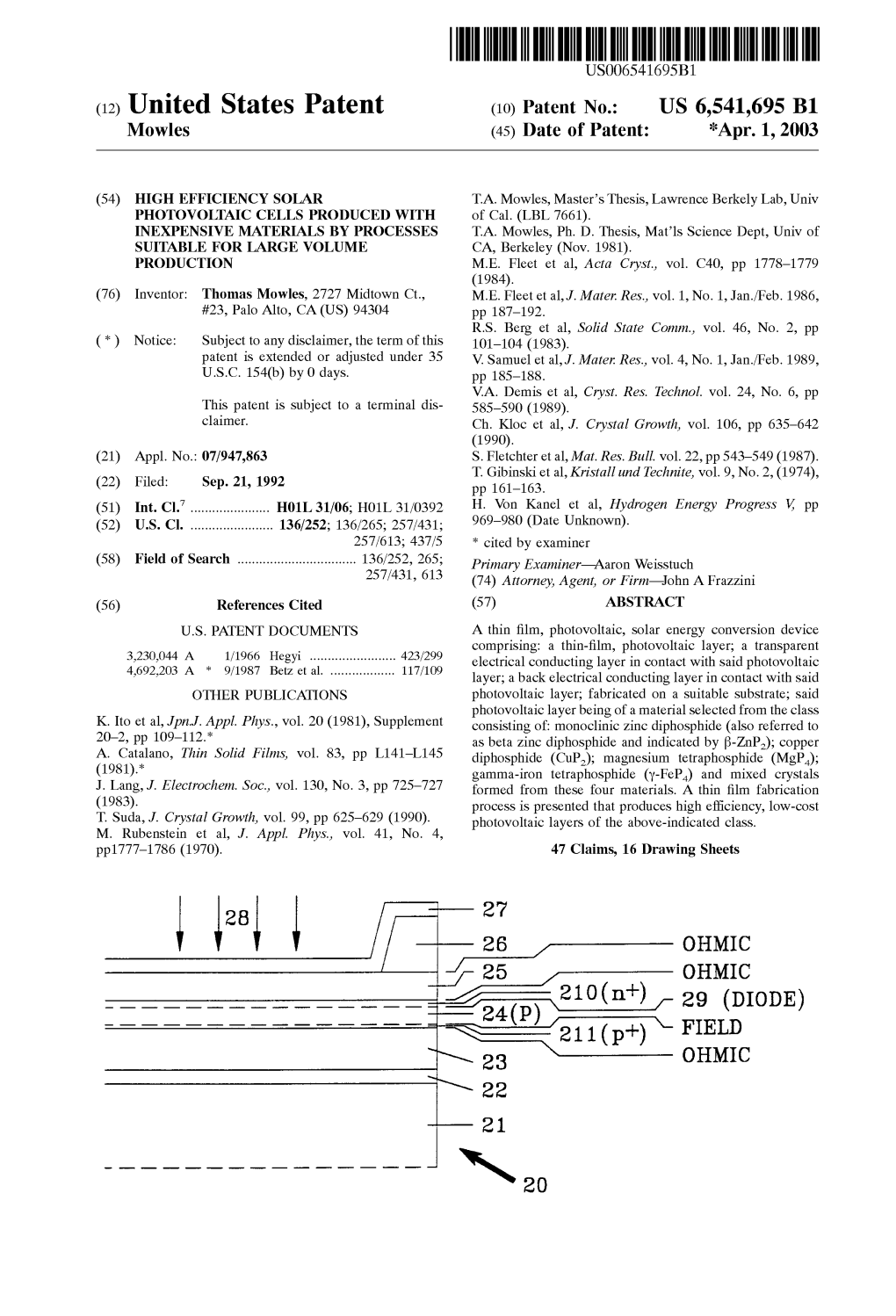

28 27 2 - OEMI E24(p))2–21 210 on (nt) K- 29 (DIODE)E FIELD OHMIC U.S. Patent Apr. 1, 2003 Sheet 1 of 16 US 6,541,695 B1

?V0(INV8(A9)

EFFICIENCY

U.S. Patent Apr. 1, 2003 Sheet 4 of 16 US 6,541,695 B1

(GIOIOICI)62

OIWHO OIWHO CITTHIÆ OIWHO OIWHO

Iaddoo WOJ?JOJE XOd[UIZJOd’I? ULInu?ULIn?V U.S. Patent Apr. 1, 2003 Sheet S of 16 US 6,541,695 B1

OIWHO OIWHO (GIGIOICI)62 CITIGII,H |OIWHO |OIWHO (I2?Inõ?¢I

(+d)[12S 02 \£2| ———————————– `N

U.S. Patent Apr. 1, 2003 Sheet 7 of 16 US 6,541,695 B1

OIWHO (±(IOICI)63-??'?

(d)72 OIWHO92 U.S. Patent Apr. 1, 2003 Sheet 8 of 16 US 6,541,695 B1

62(GIGIOICI) 9_InáH?2

OIWHO OIWHO U.S. Patent Apr. 1, 2003 Sheet 9 of 16 US 6,541,695 B1

In???aHa

U.S. Patent Apr. 1, 2003 Sheet 11 of 16 US 6,541,695 B1

??9.In?fa 2-FgºHOLOnqNOOIW?Sto(+u)2-T)?(d)?ä–62(qqord) 2.? OIWHO93 U.S. Patent Apr. 1, 2003 Sheet 12 of 16 US 6,541,695 B1

ZINC PHOSPHIDE PHASE BOUNIDARIES

ZnP2 -- Zn3P2

1. Melting 37 Point OS znp/ 3 NO - 1 Mt. W.() '" (pP4 = 1) 10 Point % N N %.% N

2 1 0. 32 2. 31 % V 3 () 1 O -- pPA = 5 Atrn %% H 8 9 1(f/T (K )1 Figure 3 U.S. Patent Apr. 1, 2003 Sheet 13 of 16 US 6,541,695 B1 ZINC DIPHOSPHIDE PHASE BOUNDARIES

log pP (Atm) Figure 4 U.S. Patent Apr. 1, 2003 Sheet 14 of 16 US 6,541,695 B1 ZnP2 DECOMPOSITION PRESSURE

1 OOO ATM ------

100 ------

1.0 ------rm------/ A = Alikhanyan B = Shantsovoi

0.1 ------600 700 800 900 TEMPERATURE (C) Figure 5 U.S. Patent Apr. 1, 2003 Sheet 15 of 16 US 6,541,695 B1

N AZZZZZZZZZZÒØ 9€)Jin?I„HIo?onpu?oo?e?ptreg??quaredstre.II.Jo U.S. Patent Apr. 1, 2003 Sheet 16 of 16 US 6,541,695 B1

WHITE PHOSPHORUS WAPOR PRESSURE 1000 ATM --- r ------

S O) st 100 -- r f Vapor A. r A. 10 7- - - D A. O Ph A) O

AI 1.0 - / arm------, ------b) O -