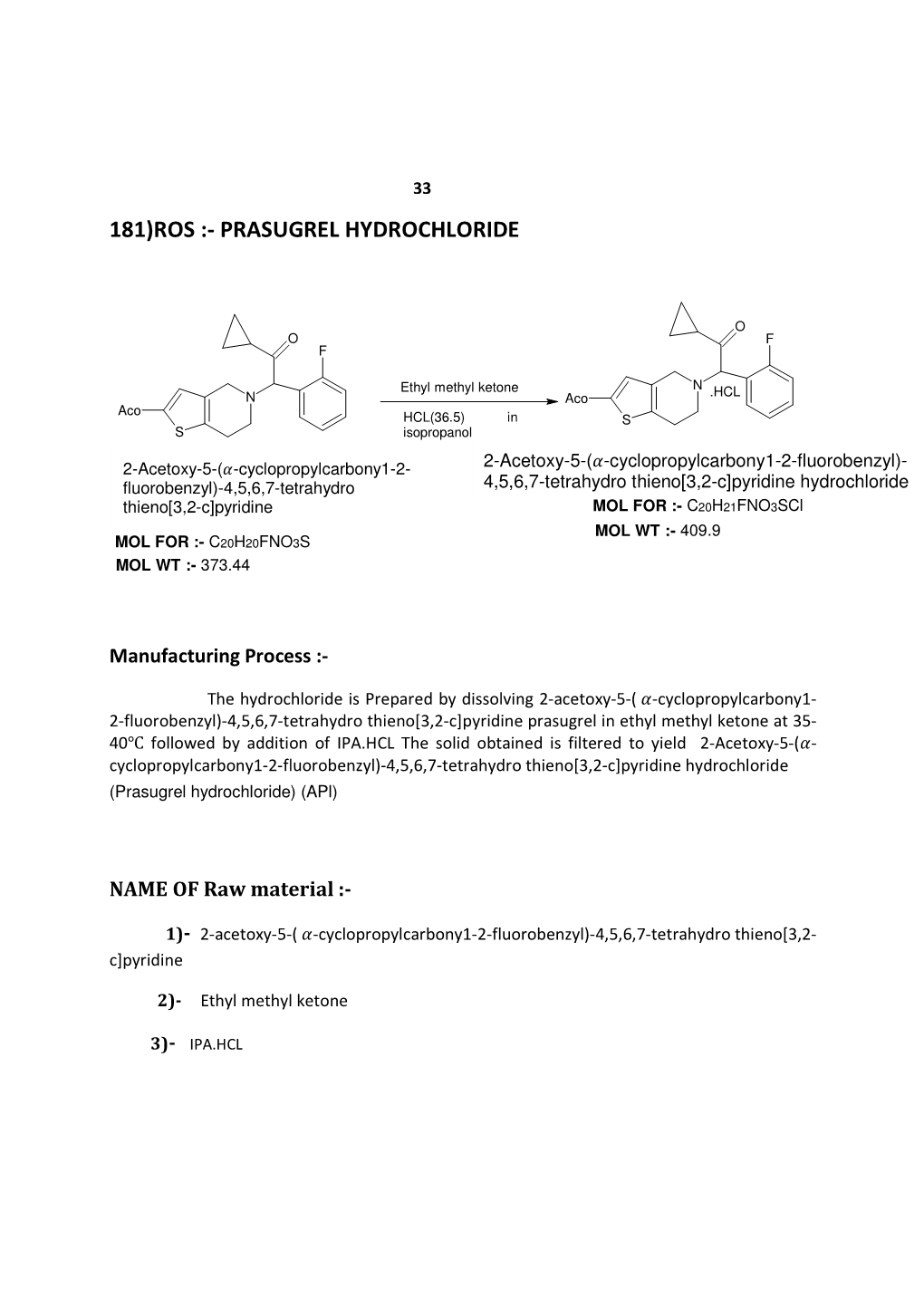

181)Ros :- Prasugrel Hydrochloride

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

2D Map of Proteins from Human Renal Stone Matrix and Evaluation of Their Effect on Oxalate Induced Renal Tubular Epithelial Cell Injury ______K.P

ORIGINAL Article Vol. 39 (1): 128-136, January - February, 2013 doi: 10.1590/S1677-5538.IBJU.2013.01.16 2D map of proteins from human renal stone matrix and evaluation of their effect on oxalate induced renal tubular epithelial cell injury _______________________________________________ K.P. Aggarwal, S. Tandon, S.K. Singh, C. Tandon Department of Biotechnology and Bioinformatics, Jaypee University of Information Technology (KPA, CT, ST), Waknaghat, Solan, HP and Department of Urology, Post Graduate Institute of Medical Education & Research (PGIMER) (SKS), Chandigarh-160012 India ABSTRACT ARTICLE INFO _________________________________________________________ ___________________ Purpose: Proteins constitute a major portion of the organic matrix of human calcium Key words: oxalate (CaOx) renal stones and the matrix is considered to be important in stone for- Urolithiasis; Calcium Oxalate; mation and growth. The present study evaluates the effect of these proteins on oxalate Madin Darby Canine Kidney injured renal epithelial cells accompanied by a 2D map of these proteins. Cells; Electrophoresis, Gel, Materials and Methods: Proteins were isolated from the matrix of kidney stones contai- Two-Dimensional ning CaOx as the major constituent using EGTA as a demineralizing agent. The effect of more than 3kDa proteins from matrix of human renal (calcium oxalate) CaOx stones Int Braz J Urol. 2013; 39: 128-36 was investigated on oxalate induced cell injury of MDCK renal tubular epithelial cells. A __________________ 2D map of >3kDa proteins was also generated followed by protein identification using MALDI-TOF MS. Submitted for publication: Results: The >3kDa proteins enhanced the injury caused by oxalate on MDCK cells. Also, August 14, 2012 the 2D map of proteins having MW more than 3kDa suggested the abundance of proteins __________________ in the matrix of renal stone. -

Plan Your Plate for Kidney Stones (Calcium Oxalate) High and Low Oxalate Foods

Lunch & Dinner Your diet plan will be customized based on your urine, blood tests and medical conditions when you are followed by a nutritionist Vegetables: Fruit: 1-2 svg 1 cup cooked or 2 cups raw 2 – 3 oz Lean Protein Starches & Grains: 1-2 svg 1 serving with each meal 3x/day Total fluid intake : 3L (quarts)/day Plan Your Plate For Kidney Stones (Calcium Oxalate) High and Low Oxalate Foods Foods Avoid Recommend Foods Avoid Recommend Draft beer Coffee Nuts** Bacon Ovaltine Beer (bottle) Peanuts, almonds, Mayonnaise Cocoa Carbonated soda pecans, cashews Salad dressing Distilled alcohol Chocolate**, Vegetable oils Lemonade Cocoa,** Butter, margarine Wine: red, rose, white Vegetable soup, Coconut Beverages Miscellaneous Buttermilk, Whole, low- Marmalade Jelly or preserves (made with allowed fat or skim milk fruits) Yogurt with allowed Lemon, lime juice fruits Salt, pepper Soy, almond and rice Soups with allowed ingredients, Sugar milk Beets**: tops, roots, Asparagus Currants, red Apple greens Broccoli Dewberries Apricots Collards Carrots Grapes, purple Cherries, red, sour Kale Corn: sweet, white Gooseberries Cranberry juice Leeks Cucumber, peeled Lemon peel** Grape juice Mustard greens Green peas, canned Lime peel** Orange, fruit and juice Okra Lettuce Orange peel** Peaches Parsley** Lima beans Rhubarb** Pears Sweet potato** Parsnips Pineapple, plum, purple Rutabagas Tomato, 1 small, juice Prunes Vegetables Fruits Spinach** Turnips Apple juice Swiss chard** Avocado Banana Watercress** Brussels sprouts Cherries, bing Cauliflower Mangos Cabbage Melons, cantaloupe, cassava honeydew, Mushrooms watermelon Onions Nectarines Peas, green Peaches White potato Pineapple juice Radish Plums, green or yellow Peanut butter Eggs Fruit cake Cornbread Tofu Cheese Soybean crackers** Sponge cake Meat and (if it is processed Beef, lamb or pork Wheat germ** Spaghetti, canned in tomato sauce Meat Starch with Ca, it is Poultry Rice Substitutes allowed in small Fish and shellfish Quinoa amount) Sardines All bread **: very high oxalate Adapted from the ChooseMyPlate.gov . -

Specialty Amphoterics Amphoteric Surfactants Are Known for Being Mild to the Skin and Hair

Specialty Amphoterics Amphoteric surfactants are known for being mild to the skin and hair. A special class of amphoterics — amphoacetates and amphopropionates — are exceptionally mild, making them great for applications where mildness matters: baby products, gentle cleansers for sensitive skin, or soothing and calming formulations. All of Stepan Company’s Specialty Amphoteric surfactants are: Biodegradable Naturally-derived from plant sources Exceptionally mild — milder than betaines1 Impart conditioning and softening effects to hair and skin AMPHOSOL® 1C Envision Performance • Best foaming profile and viscosity building of Stepan’s Specialty Amphoterics • Milder alternative to betaines without sacrificing performance • Minimally irritating to eyes, even at 16% active AMPHOSOL® 2C Envision Rinsability • Best suited for formulations where mildness and easy rinsing are desired • Non-irritating to eyes at 5% active and non-irritating to skin at 10% active • Application in gentle facial cleansers that won’t irritate the skin and baby washes with the possibility of “no tear” claims AMPHOSOL® 2CSF-AF Envision Salt-Free • Salt-free amphoteric surfactant — no residual sodium chloride or sodium sulfate • Best suited for mild personal care applications where salt or electrolyte levels are of concern • Stable and will foam in high electrolytic or alkaline systems • Free of residual methanol, making it an ideal choice for California Proposition 65-free formulations 1Based on Zein score The “Detox” Effect Chelation Values of Stepan AMPHOSOL Products Chelants, such as EDTA2, are known for their ability to “trap” heavy AMPHOSOLAMPHOSOL 2C 2C metals like iron and calcium. Two of Stepan’s Specialty Amphoteric surfactants demonstrate chelation AMPHOSOLAMPHOSOL 1C 1C abilities, a unique characteristic Tetrasoodium for surfactants. -

Towards On-Demand E. Coli-Based Cell-Free Protein Synthesis of Tissue Plasminogen Activator

Benchmark Towards On-Demand E. coli-Based Cell-Free Protein Synthesis of Tissue Plasminogen Activator Seung-Ook Yang 1, Gregory H. Nielsen 1, Kristen M. Wilding 1, Merideth A. Cooper 2, David W. Wood 2 and Bradley C. Bundy 1,* 1 Department of Chemical Engineering, Brigham Young University, Provo, UT 84602, USA; [email protected] (S.-O.Y.); [email protected] (G.H.N.); [email protected] (K.M.W.) 2 Department of Chemical and Biomolecular Engineering, Ohio State University, Columbus, OH 43210, USA; [email protected] (M.A.C.); [email protected] (D.W.W.) * Correspondence: [email protected] Received: 2 March 2019; Accepted: 18 April 2019; Published: 21 June 2019 Abstract: Stroke is the leading cause of death with over 5 million deaths worldwide each year. About 80% of strokes are ischemic strokes caused by blood clots. Tissue plasminogen activator (tPa) is the only FDA-approved drug to treat ischemic stroke with a wholesale price over $6000. tPa is now off patent although no biosimilar has been developed. The production of tPa is complicated by the 17 disulfide bonds that exist in correctly folded tPA. Here, we present an Escherichia coli-based cell-free protein synthesis platform for tPa expression and report conditions which resulted in the production of active tPa. While the activity is below that of commercially available tPa, this work demonstrates the potential of cell-free expression systems toward the production of future biosimilars. The E. coli-based cell-free system is increasingly becoming an attractive platform for low-cost biosimilar production due to recent developments which enable production from shelf-stable lyophilized reagents, the removal of endotoxins from the reagents to prevent the risk of endotoxic shock, and rapid on-demand production in hours. -

Role of Calcium Oxalate Monohydrate Crystal Interactions with Renal Epithelial Cells in the Pathogenesis of Nephrolithiasis: a Review

Scanning Microscopy Volume 10 Number 2 Article 19 2-6-1996 Role of Calcium Oxalate Monohydrate Crystal Interactions with Renal Epithelial Cells in the Pathogenesis of Nephrolithiasis: A Review John C. Lieske The University of Chicago Mary S. Hammes The University of Chicago F. Gary Toback The University of Chicago Follow this and additional works at: https://digitalcommons.usu.edu/microscopy Part of the Biology Commons Recommended Citation Lieske, John C.; Hammes, Mary S.; and Toback, F. Gary (1996) "Role of Calcium Oxalate Monohydrate Crystal Interactions with Renal Epithelial Cells in the Pathogenesis of Nephrolithiasis: A Review," Scanning Microscopy: Vol. 10 : No. 2 , Article 19. Available at: https://digitalcommons.usu.edu/microscopy/vol10/iss2/19 This Article is brought to you for free and open access by the Western Dairy Center at DigitalCommons@USU. It has been accepted for inclusion in Scanning Microscopy by an authorized administrator of DigitalCommons@USU. For more information, please contact [email protected]. Scanning Microscopy, Vol. 10, No. 2, 1996 (pages 519-534) 1051-6794/96$5. 00 +. 25 Scanning Microscopy International, Chicago (AMF O'Hare), IL 60666 USA ROLE OF CALCIUM OXALATE MONOHYDRATE CRYSTAL INTERACTIONS WITII RENAL EPITIIELIAL CELLS IN TIIE PATIIOGENESIS OF NEPHROLITIIIASIS: A REVIEW John C. Lieske, Mary S. Hammes and F. Gary Toback Department of Medicine The University of Chicago, Chicago, IL (Received for publication August 28, 1995 and in revised form February 6, 1996) Abstract Introduction Renal tubular fluid in the distal nephron is supersat Renal tubular fluid in the distal nephron is super urated with calcium and oxalate ions that nucleate to saturated with calcium and oxalate ions that nucleate to form crystals of calcium oxalate monohydrate (COM), form crystals of calcium oxalate (CaOx) monohydrate the most common crystal in renal stones. -

Comparative Stabilizing Effects of Some Anticoagulants on Fasting Blood Glucose of Diabetics and Non-Diabetics, Determined by Spectrophotometry (Glucose Oxidase)

Asian Journal of Medical Sciences 3(6): 234-236, 2011 ISSN: 2040-8773 © Maxwell Scientific Organization,2011 Submitted: September 21, 2011 Accepted: November 16, 2011 Published: December 25, 2011 Comparative Stabilizing Effects of Some Anticoagulants on Fasting Blood Glucose of Diabetics and Non-diabetics, Determined by Spectrophotometry (Glucose Oxidase) Nwangwu C.O. Spencer, Josiah J. Sunday, Omage K. Erifeta. O. Georgina, Asuk A. Agbor, Uhunmwangho S. Esosa and O. Jenevieve Department of Biochemistry, College of Basic Medical Sciences, Igbinedion University, Okada, Edo State, Nigeria Abstract: The comparative stabilizing effects of the anticoagulants; Fluoride oxalate, EDTA and Heparin on fasting blood glucose level were determined, using the spectrophotometry (glucose oxidase) method. Fasting blood samples were taken from ten (10) diabetic patients and ten (10) non-diabetic people, and the blood glucose levels determined at 30 min intervals for a maximum time of 2 h. Our results showed that the rate at which plasma glucose changes with time varies with specific anticoagulants. With Fluoride oxalate and Heparin, it increased by 1.77 and 6.67%, respectively, while with EDTA it decreased by 4.0%, within the first 30 minutes for non-diabetics. For diabetics, within the same period, with Fluoride oxalate and Heparin it increased by 1.9 and 3.7%, respectively, while with EDTA it decreased by 3.6%. Blood glucose levels were however shown to increase significantly (p<0.05) at 60 min (1 h) with the three anticoagulants in diabetics and non-diabetics. But at 120 min (2 h) plasma glucose in Fluoride oxalate, EDTA and Heparin decreased by 16.4, 17.5 and 8.5%, respectively for non-diabetics and by 10.6, 9.8 and 8.6%, respectively for diabetics. -

Review Article Vitamins K1 and K2: the Emerging Group of Vitamins Required for Human Health

Hindawi Journal of Nutrition and Metabolism Volume 2017, Article ID 6254836, 6 pages https://doi.org/10.1155/2017/6254836 Review Article Vitamins K1 and K2: The Emerging Group of Vitamins Required for Human Health Gerry Kurt Schwalfenberg DepartmentofFamilyMedicine,UniversityofAlberta,No.301,9509-156Street,Edmonton,AB,CanadaT5P4J5 Correspondence should be addressed to Gerry Kurt Schwalfenberg; [email protected] Received 30 January 2017; Accepted 10 May 2017; Published 18 June 2017 AcademicEditor:C.S.Johnston Copyright © 2017 Gerry Kurt Schwalfenberg. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. Objective. To review the evidence for the use of vitamin K supplementation in clinical conditions such as osteoporosis, vascular calcification, arthritis, cancer, renal calculi, diabetes, and warfarin therapy. Quality of Evidence. PubMed was searched for articles on vitamin K (K1 and K2) along with books and conference proceedings and health conditions listed above. Level I and II evidence supports the use of vitamins K1 and K2 in osteoporosis and Level II evidence supports vitamin K2 in prevention of coronary calcification and cardiovascular disease. Evidence is insufficient for use in diabetes, arthritis, renal calculi, andcancer. Main Message. Vitamin K2 may be a useful adjunct for the treatment of osteoporosis, along with vitamin D and calcium, rivaling bisphosphonate therapy without toxicity. It may also significantly reduce morbidity and mortality in cardiovascular health by reducing vascular calcification. Vitamin K2 appears promising in the areas of diabetes, cancer, and osteoarthritis. Vitamin K use in warfarin therapy issafeandmayimproveINRcontrol,althoughadosageadjustmentisrequired.Conclusion. -

Preventive Drug List for the Medical Plan of the Presbyterian Church (U.S.A.)

2021 Preventive Medications of the Medical Plan of the Presbyterian Church (U.S.A.) This list of commonly prescribed preventive medications is the preventive drug list for the Medical Plan of the Presbyterian Church (U.S.A.). Note that not all strengths and dosages of the medications listed below will be covered as preventive. Please check with Express Scripts at 800-344-3896 or the Board of Pensions at 800-773-7752 (800- PRESPLAN) if you have questions on coverage. You may also view benefit information materials at pensions.org/members or express-scripts.com. The amount you pay for medications will be determined by your medical option’s prescription coverage and formulary. ANTIPSYCHOTICS IMIPRAMINE Anti-Anginal Agents ARIPIPRAZOLE MIRTAZAPINE ISOSORBIDE DINITRATE COMPRO NEFAZODONE ISOSORBIDE MONONITRATE FLUPHENAZINE DECANOATE NORTRIPTYLINE ISOSORBIDE MONONITRATE ER HALOPERIDOL PAROXETINE NITROGLYCERIN LOXAPINE PHENELZINE SULFATE MOLINDONE HCL SERTRALINE Anticoagulants OLANZAPINE TRANYLCYPROMINE SULFATE ASPIRIN-DIPYRIDAMOLE ER OLANZAPINE-FLUOXETINE HCL TRAZODONE CILOSTAZOL PALIPERIDONE ER TRIMIPRAMINE MALEATE CLOPIDOGREL PROCHLORPERAZINE DIPYRIDAMOLE QUETIAPINE FUMARATE ASTHMA AND COPD ENOXAPARIN SODIUM RISPERIDONE ADVAIR HFA FONDAPARINUX SODIUM ZIPRASIDONE HCL ALBUTEROL NEB/SYRUP/TA B HEPARIN ALBUTEROL SULFATE HFA JANTOVEN ANTIDEPRESANTS FLOVENT DISKUS PRASUGREL AMITRIPTYLINE HCL FLOVENT HFA WARFARIN SODIUM AMOXAPINE FLUTICASONE-SALMETEROL BUPROPION IPRATROPIUM BROMIDE Cardiac Glycosides BUPROPION HCL ER IPRATROPIUM-ALBUTEROL DIGITEK -

Escitalopram Oxalate

HIGHLIGHTS OF PRESCRIBING INFORMATION --------------WARNINGS AND PRECAUTIONS------------ These highlights do not include all the information Clinical Worsening/Suicide Risk: Monitor for clinical needed to use Lexapro® safely and effectively. See full worsening, suicidality and unusual change in behavior, prescribing information for Lexapro®. especially, during the initial few months of therapy or at times of dose changes (5.1). Lexapro® (escitalopram oxalate) Tablets Serotonin Syndrome: Serotonin syndrome has been Lexapro® (escitalopram oxalate) Oral Solution reported with SSRIs and SNRIs, including Lexapro, both Initial U.S. Approval: 2002 when taken alone, but especially when co-administered WARNING: Suicidality and Antidepressant Drugs with other serotonergic agents (including triptans, See full prescribing information for complete boxed tricyclic antidepressants, fentanyl, lithium, tramadol, warning. tryptophan, buspirone, amphetamines, and St. John’s Increased risk of suicidal thinking and behavior in Wort). If such symptoms occur, discontinue Lexapro and children, adolescents and young adults taking initiate supportive treatment. If concomitant use of antidepressants for major depressive disorder (MDD) Lexapro with other serotonergic drugs is clinically and other psychiatric disorders. Lexapro is not warranted, patients should be made aware of a potential approved for use in pediatric patients less than 12 increased risk for serotonin syndrome, particularly during years of age (5.1). treatment initiation and dose increases (5.2). Discontinuation of Treatment with Lexapro: A gradual reduction in dose rather than abrupt cessation is -------------------RECENT MAJOR CHANGES---------------- recommended whenever possible (5.3). Warnings and Precautions (5.2) 1/2017 Seizures: Prescribe with care in patients with a history of seizure (5.4). --------------INDICATIONS AND USAGE------------------- Activation of Mania/Hypomania: Use cautiously in Lexapro® is a selective serotonin reuptake inhibitor (SSRI) patients with a history of mania (5.5). -

Appendix B - Product Name Sorted by Applicant

JUNE 2021 - APPROVED DRUG PRODUCT LIST B - 1 APPENDIX B - PRODUCT NAME SORTED BY APPLICANT ** 3 ** 3D IMAGING DRUG * 3D IMAGING DRUG DESIGN AND DEVELOPMENT LLC AMMONIA N 13, AMMONIA N-13 FLUDEOXYGLUCOSE F18, FLUDEOXYGLUCOSE F-18 SODIUM FLUORIDE F-18, SODIUM FLUORIDE F-18 3M * 3M CO PERIDEX, CHLORHEXIDINE GLUCONATE * 3M HEALTH CARE INC AVAGARD, ALCOHOL (OTC) DURAPREP, IODINE POVACRYLEX (OTC) 3M HEALTH CARE * 3M HEALTH CARE INFECTION PREVENTION DIV SOLUPREP, CHLORHEXIDINE GLUCONATE (OTC) ** 6 ** 60 DEGREES PHARMS * 60 DEGREES PHARMACEUTICALS LLC ARAKODA, TAFENOQUINE SUCCINATE ** A ** AAA USA INC * ADVANCED ACCELERATOR APPLICATIONS USA INC LUTATHERA, LUTETIUM DOTATATE LU-177 NETSPOT, GALLIUM DOTATATE GA-68 AAIPHARMA LLC * AAIPHARMA LLC AZASAN, AZATHIOPRINE ABBVIE * ABBVIE INC ANDROGEL, TESTOSTERONE CYCLOSPORINE, CYCLOSPORINE DEPAKOTE ER, DIVALPROEX SODIUM DEPAKOTE, DIVALPROEX SODIUM GENGRAF, CYCLOSPORINE K-TAB, POTASSIUM CHLORIDE KALETRA, LOPINAVIR NIASPAN, NIACIN NIMBEX PRESERVATIVE FREE, CISATRACURIUM BESYLATE NIMBEX, CISATRACURIUM BESYLATE NORVIR, RITONAVIR SYNTHROID, LEVOTHYROXINE SODIUM ** TARKA, TRANDOLAPRIL TRICOR, FENOFIBRATE TRILIPIX, CHOLINE FENOFIBRATE ULTANE, SEVOFLURANE ZEMPLAR, PARICALCITOL ABBVIE ENDOCRINE * ABBVIE ENDOCRINE INC LUPANETA PACK, LEUPROLIDE ACETATE ABBVIE ENDOCRINE INC * ABBVIE ENDOCRINE INC LUPRON DEPOT, LEUPROLIDE ACETATE LUPRON DEPOT-PED KIT, LEUPROLIDE ACETATE ABBVIE INC * ABBVIE INC DUOPA, CARBIDOPA MAVYRET, GLECAPREVIR NORVIR, RITONAVIR ORIAHNN (COPACKAGED), ELAGOLIX SODIUM,ESTRADIOL,NORETHINDRONE ACETATE -

Unusual Presentation of Oxalate Nephropathy Causing Acute

Case Report More Information *Address for Correspondence: Anas Diab, Department of Medicine, Section of Nephrology, Unusual presentation of oxalate 4th Floor, HSCN Room 4076A, Morgantown, WV 26506, USA, Tel: 304-293-2551; nephropathy causing acute kidney Fax: 304-293-7373; Email: [email protected] Submitted: 03 April 2020 injury: A case report Approved: 03 November 2020 Published: 04 November 2020 Anas Diab*, Michelle M Neuman, Kareem Diab and Daniel How to cite this article: Diab A, Neuman MM, Gordon Diab K, Gordon D. Unusual presentation of oxalate nephropathy causing acute kidney injury: Department of Medicine, Section of Nephrology, 4th Floor, HSCN Room 4076A, Morgantown, A case report. J Clini Nephrol. 2020; 4: 077-079. WV 26506, USA DOI: 10.29328/journal.jcn.1001063 Copyright: © 2020 Diab A, et al. This is an open access article distributed under the Creative Abstract Commons Attribution License, which permits unrestricted use, distribution, and reproduction Oxalate nephropathy due to Hyperoxaluria and elevated serum oxalate level is a well-known in any medium, provided the original work is cause for interstitial fi brosis, and ESRD. Conditions associated with high serum Oxalate, should properly cited. be considered as a possible contributing factor for a patient’s tubular injury. Keywords: Polyethylene glycol; Oxalate Well known cause for Hyperoxaluria including enteric Hyperoxaluria (due to gastric bypass, nephropathy; Acute kidney injury (AKI); chronic pancreatitis, small Bowel resection, or malabsorption, as well as depletion of enteric Hyperoxaluria; Kidney biopsy; End stage kidney oxalate-degrading bacteria [e.g., Oxalobacter). Other known causes of oxalate nephropathy disease include primary Hyperoxaluria, ethylene glycol intoxication, vitamin B6 defi ciency, excessive ingestion of vitamin C or dietary substances rich in oxalic acid, aspergillosis, prolonged renal failure and various drugs (e.g., Known medications to cause Oxalate Nephropathy are: Orlistat, Praxilene, COX-2 inhibitors). -

CDPHP Medicaid Select/HARP Clinical Formulary 2021

CDPHP Medicaid Select/HARP Clinical Formulary 2021 NON-DISCRIMINATION/MULTI-LANGUAGE INTERPRETER SERVICES: APPLIES TO MEMBERS/ENROLLEES ONLY Notice of Non-Discrimination Capital District Physicians’ Health Plan, Inc. (CDPHP®) complies with Federal civil rights laws. CDPHP does not exclude people or treat them differently because of race, color, national origin, age, disability, or sex. CDPHP provides the following: • Free aids and services to people with disabilities to help you communicate with us, such as: ○ Qualified sign language interpreters ○ Written information in other formats (large print, audio, accessible electronic formats, other formats) • Free language services to people whose first language is not English, such as: ○ Qualified interpreters ○ Information written in other languages If you need these services, call CDPHP at 1-800-388-2994. For TTY/TDD services, call 711. If you believe that CDPHP has not given you these services or treated you differently because of race, color, national origin, age, disability, or sex, you can file a grievance with CDPHP by: • Mail: CDPHP Civil Rights Coordinator, 500 Patroon Creek Blvd., Albany, New York 12206 • Phone: 1-844-391-4803 (for TTY/TDD services, call 711) • Fax: (518) 641-3401 • In person: 500 Patroon Creek Blvd., Albany, New York 12206 • Email: https://www.cdphp.com/customer-support/email-cdphp You can also file a civil rights complaint with the U.S. Department of Health and Human Services, Office for Civil Rights by: • Web: Office for Civil Rights Complaint Portal at https://ocrportal.hhs.gov/ocr/portal/lobby.jsf • Mail: U.S. Department of Health and Human Services, 200 Independence Avenue SW., Room 509F, HHH Building Washington, DC 20211 • Complaint forms are available at http://www.hhs.gov/ocr/office/file/index.html • Phone: 1-800-368-1019 (TTY/TDD 1-800-537-7697) Multi-language Interpreter Services ATTENTION: If you speak a non-English language, language assistance services, free of charge, are available to you.