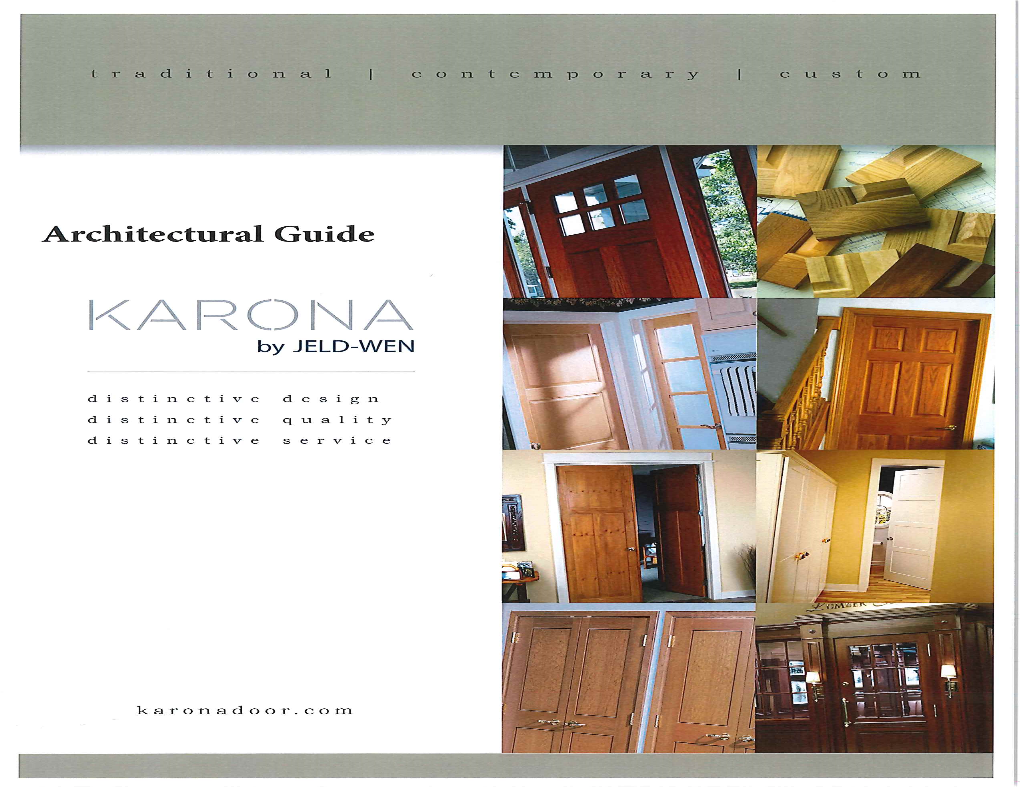

Karona Architectural Guide

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Fall 2019 Lovell’S Shook Industry by Catherine Stone

Yesterday’s News Published quarterly by the Lovell Historical Society Volume 26, Number 4 Fall 2019 Lovell’s Shook Industry By Catherine Stone Hauling apples in barrels made in Lovell The early settlers of Lovell were an industrious had flat headings or ends. They primarily made casks, lot - clearing land, cultivating fields, and harvesting barrels, buckets, vats, firkins, and troughs. timber. In the process, small farms made many of By the 1830s, barrel making was an important their daily necessities, including wooden containers. industry in Lovell. The business was called the shook These containers were used for storage and to transport industry because of the way the wood was bundled goods. This was before the advent of plastics, stainless together for transport. The staves and headings were steel, and corrugated cardboard. formed into barrels or boxes and then dismantled. Making wooden containers was not just a result of Next, they would bundle them together into a kit for necessity. It also became a source of cash money. The shipping. In the process of bundling the wood, they people making the containers as a profession were would shake the material. Shook bundles took up less called coopers. They would make wooden, staved space for shipping. vessels, held together with wooden or metal hoops that Charlotte Hobbs (1879-1968), one of Lovell’s (continued on page 3) From the President This summer was extremely busy and very enjoyable. We hosted two events—our Summer Fair and our biennial House Tour—and were fortunate to have the assistance of a great summer intern, Jonathan Fall Harvest Festival Griggs. -

Cordless Jigsaw MANUAL INSTRUCTION (Model CL180JS)

Cordless Jigsaw INSTRUCTION MANUAL (Model CL180JS) PART NO. 912236 - 05-20-04 Copyright © 2004 Delta Machinery To learn more about DELTA MACHINERY ESPAÑOL: PÁGINA 15 visit our website at: www.deltamachinery.com. For Parts, Service, Warranty or other Assistance, please call 1-800-223-7278 (In Canada call 1-800-463-3582). SAFETY GUIDELINES - DEFINITIONS This manual contains information that is important for you to know and under- stand. This information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the symbols below. Please read the manual and pay attention to these sections. indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. indicates a potentially hazardous situation which, if not avoided,could result in death or serious injury. indicates a potentially hazardous situation which, if not avoided,may result in minor or moderate injury. used without the safety alert symbol indicates potentially hazardous situation which, if not avoided, may result in property damage. Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known (to the State of California) to cause cancer, birth defects or other repro- ductive harm. Some example of these chemicals are: ● lead from lead-based paints ● crystalline silica from bricks and cement and other masonry products ● arsenic and chromium from chemically-treated lumber Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, always wear MSHA/NIOSH approved, properly fitting face mask or respirator when using such tools. -

Historic Douglas-Fir Colonization and Land Use

HISTORIC DOUGLAS-FIR COLONIZATION AND LAND USE PRACTICES AT PRESERVATION SITES NEAR EUGENE, OR by WADE MARTIN A THESIS Presented to the Department of Environmental Science and the Robert D. Clark Honors College in partial fulfillment of the requirements for the degree of Bachelor of Science June 2015 Acknowledgements I would like to thank Professor Daniel Gavin for his insight in so many different disciplines of study that advised the completion of this project. Thank you to the members of my defense panel, Professors Margaret Boulay and Casey Shoop, for the positive reinforcement and valuable diversity of perspective offered to this project. I would like to extend an equally important acknowledgement to the members of the Nature Conservancy Willamette Valley Field Office for providing access to information integral to my studies on the Eugene area conservation sites as well as permission to extract specimen from the Willow Creek, Coburg Ridge, and Willamette Confluence preserves. Without your help, this project would not have been possible. Thank you to Professors Mark Carey, Kevin Hatfield, and Jennifer O’Neal for aiding my research on Kalapuya culture; and my honors advisor Ocean Howell for his assistance along the way. Thank you to my father for enduring the coring sessions, my mother and grandparents for keeping my morale up, my brother for his keen and polished eye for revision, and all of my friends for making these four years unforgettable. iii Table of Contents Introduction 1 Historic Willamette Valley Vegetation Cover 2 Indigenous -

Workmate Sawbuck by Tinkerjim on August 20, 2013

Food Living Outside Play Technology Workshop Workmate Sawbuck by TinkerJim on August 20, 2013 Table of Contents Workmate Sawbuck . 1 Intro: Workmate Sawbuck . 2 Step 1: . 2 Step 2: . 2 Step 3: . 3 Step 4: . 3 Step 5: . 4 Step 6: . 4 Related Instructables . 5 Advertisements . 5 http://www.instructables.com/id/Workmate-Sawbuck/ Author:TinkerJim Emeritus Professor of Mathematics. Intro: Workmate Sawbuck With two simple wooden crosspieces, a Workmate becomes a solid and stable sawbuck. Step 1: The jaws of the Workmate clamp and hold the sawbuck vee pieces securely. Step 2: These photos show in detail how the Workmate jaws hold the sawbuck pieces. They are gripped from above and below in a wedging manner and 'alternate' in such a way that great lateral stability is realized. http://www.instructables.com/id/Workmate-Sawbuck/ Step 3: The vees shown here were made from 13" lengths of good 2x4. They are actually "X" shapes with two short legs, the latter being long enough for the Workmate jaws to grip from below as shown in the previous step. The short legs on the prototype shown here are about 1-1/2" long. The angle between the legs is about 85° which is the largest angle our Workmate jaws would accommodate. Four 3" deck screws hold each crosspiece together - two from one side and two from the other. A tight clearance hole was drilled through the 'top' piece to preclude splitting which would adversely affect rigidity. Also, waterproof glue was used to ensure absolute rigidity (but mostly because this tinkerer likes to use glue !). -

Reconsidering the Process for Bow-Stave Removal from Juniper Trees in the Great Basin

Journal of California and Great Basin Anthropology | Vol. 37, No. 2 (2017) | pp. 125–131 Reconsidering the Process for Bow-Stave Removal from Juniper Trees in the Great Basin CONSTANCE I. MILLAR USDA Forest Service, Pacific Southwest Research Station 800 Buchanan St., Albany, CA, 94710, USA KEVIN T. SMITH USDA Forest Service, Northern Research Station 271 Mast Road, Durham, NH, 03824, USA In 1988, Wilke described juniper trees in the Great Basin from which bow staves had been removed, and suggested the method that had likely been employed to do so. Based upon our own knowledge of tree growth and responses to wounding, we question certain of his assumptions, and offer modifications to Wilke’s proposal as to how prospective staves might have been removed. Further research and experimentation is encouraged. N A CLASSIC PAPER ON GREAT BASIN ARCHEOLOGY, question that the scarred trees were used for bow-stave IWilke (1988) integrated information from ethnography, extraction, nor do we question other aspects developed by knowledge of indigenous practices of tool fabrication and Wilke (1988) about stave harvesting methods. use, and extensive field observations of trees that had been anthropogenically wounded to propose a process by which prospective bow staves were removed from SUMMARY OF WILKE’S (1988) KEY trees. Based on our knowledge of tree growth and wound OBSERVATIONS AND PROCESSES response, and our own field observations of scarred trees FOR BOW-STAVE REMOVAL (CIM: December 2016, Long Valley, California and Little Based on extensive observation of intentionally scarred Whisky Flat, Nevada), we question several premises trees in the western Great Basin, Wilke (1988) described that underlie Wilke’s (1988) proposed mechanism. -

Specification Considerations for Architectural Wood Doors

CONTINUING EDUCATION SPECIFICATION CONSIDERATIONS FOR Presented by: ARCHITECTURAL WOOD DOORS LEARNING OBJECTIVES Upon completion of this course the student will be able to: 1. Identify components of an architectural wood door. 2. Increase awareness of wood door assembly and construction. 3. Provide a better understanding of industry standards and new door technology. 4. Review how to specify doors to meet project requirements. CONTINUING EDUCATION CREDIT: 1 LU COURSE NUMBER: ARjuly2016.3 Use the learning objectives above to focus your study as you read this article. To earn credit and obtain a certificate of completion, visit http://go.hw.net/AR716Course3 and complete the quiz for free as you read this article. If you are new to Hanley Wood University, create a free learner account; returning users log in as usual. ENDLESS CREATIVE POTENTIAL WITH All doors consist of a core, stiles, rails, and face ARCHITECTURAL WOOD DOORS materials. Crossbanding and backers may be applied, depending on the construction process. Architectural wood doors command attention with their distinctive elegance. Whether you’re The core is the innermost layer or section in envisioning something understated or wildly component construction. Core types include exotic, extensive wood veneer options, as well particleboard, structural composite lumber as a variety of factory and custom finishes will (SCL), staved lumber, agrifiber, and fire resistant open your eyes to endless creative possibilities. composite. Stiles are the upright or vertical But, taking all design and performance pieces of the core assembly of a wood flush All doors consist of a core, stiles, rails, and face materials. options into consideration when specifying the Crossbanding and backers may be applied, depending on the door, while rails are the top and bottom edge construction process. -

30" Fence and Rail System

INSTRUCTIONS 30" Fence and Rail System (Model 36-648) SHOWN ASSEMBLED TO MODEL 36-649 PART NO. 912859 - 10-20-03 Copyright © 2003 Delta Machinery To learn more about DELTA MACHINERY visit our website at: www.deltamachinery.com. For Parts, Service, Warranty or other Assistance, please call 1-800-223-7278 (In Canada call 1-800-463-3582). SAFETY GUIDELINES - DEFINITIONS This manual contains information that is important for you to know and understand. This information relates to protect- ing YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the symbols to the right. Please read the manual and pay attention to these sections. Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury. Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. Used without the safety alert symbol indicates potentially hazardous situation which, if not avoided, may result in property damage. INTRODUCTION The Delta Model 36-648 30" Fence and Rail System can be assembled to the Delta Model 36-649 10" Professional Table Saw. The Model 36-648 is a heavy duty fence that has a rip capacity of 30" to the right side of the blade. NOTICE: THE MANUAL COVER PHOTO ILLUSTRATES THE CURRENT PRODUCTION MODEL. ALL OTHER ILLUSTRATIONS ARE REPRESENTATIVE ONLY AND MAY NOT DEPICT THE ACTUAL COLOR, LABELING OR ACCESSORIES AND MAY BE INTENDED TO ILLUSTRATE TECHNIQUE ONLY. CARTON CONTENTS 1 2 3 4 5 6 8 9 10 7 Fig. -

Timberline™ Blades Part No

GENE ALTERNATE TOP BEVE 12" 1" ARBOR 60 Teeth TOOL NO. 300-600 MAX 4800 R.P.M. This blade i o Timberline™ Blades Part No. Blade Dia. Page No. Machine types 120-300 4-3/8"/4-1/2" 5, 9 Circular Saws, Worm Drives, Trim Saws Jepson®, 8211 Makita®, 4100RH Makita®, 4200NH Panasonic®, EY3502FQMKW-12Volt Porter-Cable®, 314, 9314 135-300 5-3/8"/5-1/2" 5, 9 Circular Saws, Worm Drives, Trim Saws Black&Decker®, CS144-14.4Volt DeWalt®, DW930K-12Volt DeWalt®, DW935K-14Volt DeWalt®, DW936K/936-18Volt Grizzly®, G8598-18Volt Makita®, 5005BA Panasonic®, EY3503FQWKW-12Volt Panasonic®, EY3531FQWKW-15.6Volt Ryobi®, R10730K2-18Volt Skil®, HD5510 150-200 6" 5 Circular Saws, Worm Drives, Trim Saws 150-400 Porter Cable®, 345 SAW BOSS® Porter Cable®, 9845 SAW BOSS® -19.2Volt 165-240 6-1/2" 5, 9 Circular Saws, Worm Drives, Trim Saws 165-400 DeWalt®, DW007K-24Volt, DW939K-18Volt Hitachi®, C6DC-18Volt Makita®, 5620DWA-18Volt, 5621DWD-18Volt, 5026DWD-18Volt, 5630DWA-14.4Volt Milwaukee®, 6310-20-18Volt, 6310-22-18Volt Skil®, HD5825, HD5525, 5125 Talon®, TJ759000-18Volt 175-24, 175-40, 175-60 7-1/4" 4, 6, 7, 9 Circular Saws, Worm Drives, Cordless Saws 185-180, 185-240,185-36 11, 13 Black&Decker®, 2683, 2684, 2694, 2700, 2701 185-140, 185-505, 190-240 Bosch®, 1655, 1657, 1658, 1655K, 1658K DeWalt®, DW359/359K, DW362/362K, DW369CSK, DW364, DW378G, DW368K 72524, 72540 Grizzly®, G9906 Hitachi®, C7BD, C7S Jepson®, 8207, 8218 Makita®, 5007NB/K, 5037NB/K/A, 5057KB, 5007NHK/NLK, 5007FK/FAK, 5740NB, 5177B, 5277B BLS712SFK-24Volt, BSS730SHK-24Volt, LS0711Z Milwaukee®, 6368, 6365-6, -

Pedestal Table Router Jig Makes Easy Work of Shaping Round and Curved Parts

Pedestal Table Router jig makes easy work of shaping round and curved parts BY JOHN ZEITOUN love flipping through books of an- tique furniture and looking over I pieces at garage sales, and I jump at the challenge of reproducing an an- tique in my shop. Such was the case when a client showed me a picture of a 160-year-old French Regency pedes- tal table from the book The Furniture of Old Ontario (Macmillan, 1973) and asked if I could make it for him. The picture didn’t explain construc- tion techniques, but using generally accepted proportions, as well as con- sidering the space it was to occupy, I was able to reproduce the table. Ac- cording to the book, the original table had a hardwood base with bird’s-eye maple veneer and a pine tabletop. But I chose to make mine out of walnut. Work from the bottom up The table offers a few challenges. For one, each piece either is curved or has a compound angle. I was able to simplify the construction process by breaking it down into small steps and by using a few jigs. Prepare a trammel jig— The curved parts that make up the triangular base of the table are shaped using a router mounted to a large trammel device. The workpieces first are cut to rough size on the bandsaw and then are screwed to the base of the trammel jig (see p. 62), where a router is used to cut the inside and outside edges of each piece. Before shaping the walnut, use the jig to make a particleboard template. -

Creating Woodturnings That Incorporate Slanted Staves This Article Is About Creating Woodturnings Incorporating Slanted Stave Elements

Creating Woodturnings that incorporate Slanted Staves This article is about creating woodturnings incorporating slanted stave elements. Since this is an extension of the segmented vessel process let’s start by comparing three methods of creating segmented vessels used by turners to create pieces of art using multiple pieces of wood in combination. There other forms of the segmented art, but the three we’ll discuss are: 1. Rings of staves 2. Rings of segments 3. Slanted stave rings Rings of Simple staves – those with straight sides – are a simple construction in which the key to success is to accurately make the two key elements – angle and width of the stave – close into a stave ring with no gap. The angle is derived by a simple formula dividing 360° by the number of staves. Then for convenience to divide that by 2 to set your saw’s bevel angle for two cuts. Hence, a stave construction of 8 staves would require dividing 360 by 8 to get 45° and then dividing that by 2 to get two equal cuts of 22.5°. Once you know what you’re accomplishing you can use the short form of this to divide 180° by the number of staves. The width of the stave can be roughly determined by dividing the circumference by the number of staves in the ring. For example: A ring of 8 staves with a circumference of 24” would seem to require 8 staves of 3” width. Actually due to the geometry of the ring and the flat cut staves, if you were to follow the above formula the finished circumference of your ring would be less than 24” – in fact close to 22 ¾”. -

Ruin, Resistance and Renewal in a Qom Community of Northern Argentina

University of Pennsylvania ScholarlyCommons Publicly Accessible Penn Dissertations 2015 Fighting With Wine: Ruin, Resistance and Renewal in a Qom Community of Northern Argentina Christopher A. Golias University of Pennsylvania, [email protected] Follow this and additional works at: https://repository.upenn.edu/edissertations Part of the Indigenous Studies Commons, Latin American Languages and Societies Commons, Latin American Studies Commons, and the Social and Cultural Anthropology Commons Recommended Citation Golias, Christopher A., "Fighting With Wine: Ruin, Resistance and Renewal in a Qom Community of Northern Argentina" (2015). Publicly Accessible Penn Dissertations. 1741. https://repository.upenn.edu/edissertations/1741 This paper is posted at ScholarlyCommons. https://repository.upenn.edu/edissertations/1741 For more information, please contact [email protected]. Fighting With Wine: Ruin, Resistance and Renewal in a Qom Community of Northern Argentina Abstract This study examines public binge drinking among the Qom (Toba) ex-foragers of Formosa, northern Argentina. Based upon 15 months of ethnographic fieldwork in a peri-urban Qom barrio (Lot 84), this analysis relates binge drinking to Qom ethnohistory, community life, and interactions with the Argentine state. The public, performative nature of Qom binge drinking is explored; intoxication is shown to convey in sometimes violent public spectacle the pathos of their socioeconomic marginality, reinforce non- indigenous Argentines’ entrenched perceptions of violent “Indians”, and paradoxically provide the Qom with vehicle for continued colonial resistance. Many Qom view drinking problems as rooted in Lot 84’s close proximity to the city (Formosa) relative to more rural Qom villages. Thus they reference a continuum of health that runs from urban, non-indigenous spaces to the rural bush country where foods—including home-brewed alcohol—are healthful rather than harmful. -

10 Contractor's

10" Contractor’s Saw INSTRUCTION MANUAL (Models 36-441B, 36-451X) NOTE: Shown with UniRip® Fence System PART NO. 422-19-651-0058 - 03-22-04 Copyright © 2004 Delta Machinery To learn more about DELTA MACHINERY visit our website at: www.deltamachinery.com. For Parts, Service, Warranty or other Assistance, please call 1-800-223-7278 (In Canada call 1-800-463-3582). SAFETY GUIDELINES - DEFINITIONS This manual contains information that is important for you to know and understand. This information relates to protect- ing YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the symbols below. Please read the manual and pay attention to these sections. Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury. Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. Used without the safety alert symbol indicates potentially hazardous situation which, if not avoided, may result in property damage. SOME DUST CREATED BY POWER SANDING, SAWING, GRINDING, DRILLING, AND OTHER CONSTRUCTION ACTIVITIES contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are: · lead from lead-based paints, · crystalline silica from bricks and cement and other masonry products, and · arsenic and chromium from chemically-treated lumber. Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, always wear MSHA/NIOSH approved, properly fitting face mask or respirator when using such tools.