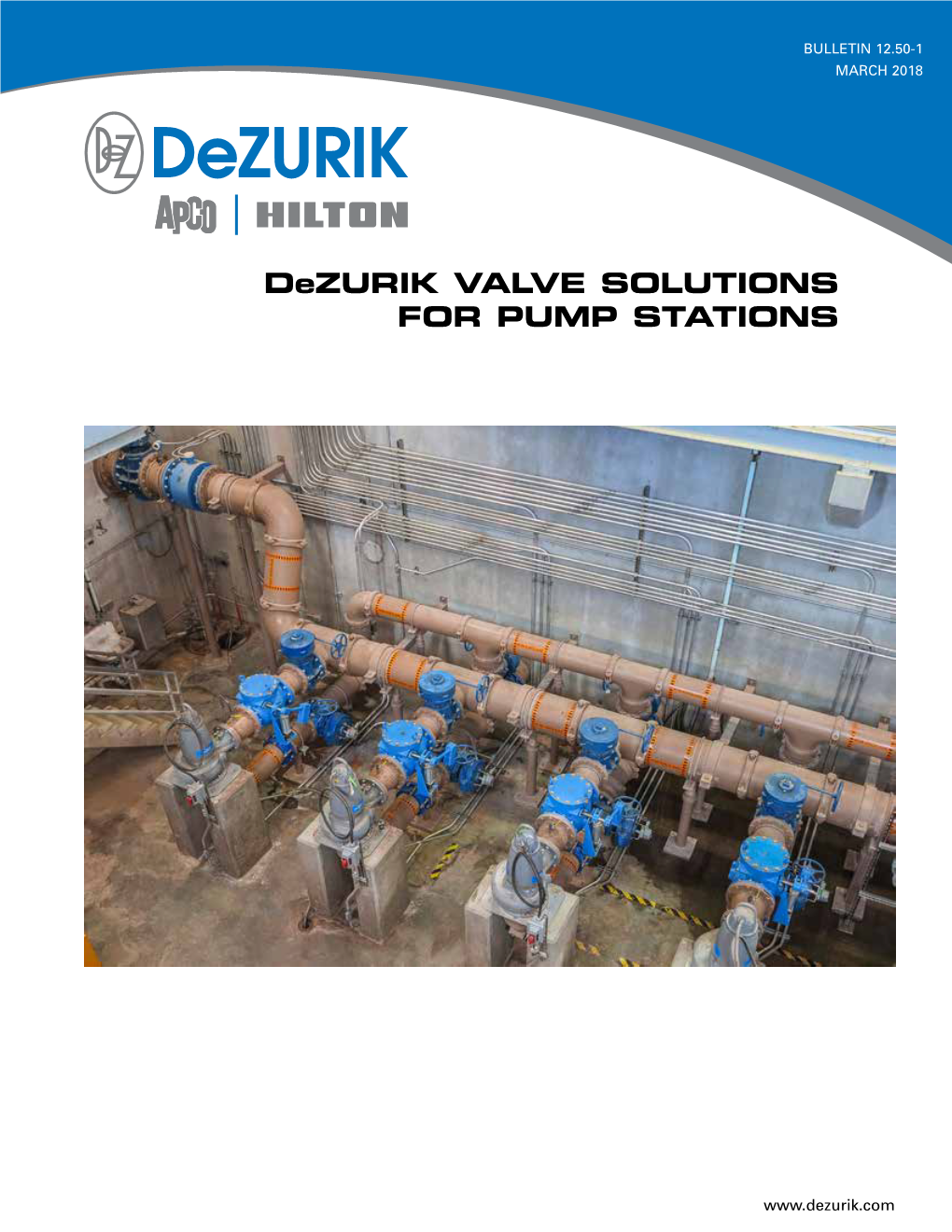

Dezurik VALVE SOLUTIONS for PUMP STATIONS

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Design and Selection of Check Valves

VM‐DSCV/WP White Paper Design and Selection of Check Valves Table of Contents Introduction. .. 2 Lift Check Valves. 3 Swing Check Valves . 4 Dashpot‐Assisted Check Valves . .. 6 Check Valve Selection Criteria. 7 Initial Costs. 7 Maintenance Costs. 8 Headloss . 10 Energy Costs. 11 Total Valve Costs . 12 Non Slam Characteristics. 13 Fluid Compatibility. 15 Selection Methodology. 15 Conclusion. 16 References. 17 Val‐Matic Valve & Mfg. Corp. • www.valmatic.com • [email protected] • PH: 630‐941‐7600 Copyright © 2018 Val‐Matic Valve & Mfg. Corp. Design and Selection of Check Valves INTRODUCTION An essential element in the design of water and wastewater pumping systems is the proper selection of the pump discharge check valve, whose purpose is to automatically open to allow forward flow and automatically return to the closed position to prevent reverse flow when the pump is not in operation. Another function that is often overlooked is the valve’s ability to minimize energy consumption. Patton estimated that water and wastewater plants in the United States consume 75 billion kW∙h of energy annually and nearly 80% of that energy is consumed for high service pumping costs to overcome the static head and friction losses. But just as important, the valve should protect the pumping system and piping from pressure surges caused by sudden closure. Every pump station designer has witnessed check valve slam, which is caused by the sudden stoppage of reverse flow through a closing check valve. To prevent slam, an automatic check valve must either close very quickly or close slowly by using oil dashpot devices. -

Forged Steel Valves

Edward Forged Steel Valves Experience In Motion Table of Contents Figure Number Index 5 Univalve® Stop-Check Valves Class 4500 55 Edward Valves Availability Chart 6 Univalve® Piston Check Valves Class 4500 56 Edward Description of Figure Number System 8 Hydraulic Stop Valves 57 Hydraulic Check Valves 58 Introduction Features and Descriptions of Edward PressurCombo Valves 59 PressurCombo Class 1690 60 High Performance for Critical Service 10 PressurCombo Class 2680 61 A History of Firsts 13 PressurCombo Class 4500 62 Miscellaneous Technical Data 14 Strainers Class 800 and Series 1500 63 Special Application Valves 15 Features and Descriptions of Features and Description of Edward Hermavalve® Hermetically-Sealed Valves 64 Edward Univalve® Globe Valves 16 Part Specification List For Edward Hermavalve® 66 Part Specification List for Edward Univalve® 17 Hermavalve® Hermetically-Sealed Valves 67 Edward Forged Steel Valves Feature Body-Guided Disks 18 Here’s How the Unique Stem-Disk Assembly is Made... 19 Features and Description of Accessories/Actuators Edward Bolted Bonnet Globe Valves 20 Accessories – Forged Steel 68 Part Specification List for Actuators – Forged Steel 69 Edward Bolted Bonnet Globe Valves 21 Required Information for Motor Actuators 70 Forged Steel Valves Reference Blow-Off Valves Class 300 22 Material Chemical Analysis (ASTM) for Edward Valves 72 Blow-Off Valves Class 400 & 600 24 ASME B16.34 – 2009 Pressure/Temperature Ratings 73 Blow-Off Valves Class 1500 & 2500 26 Continuous Blowdown Valves Class 1925 27 Technical Information -

Mueller Water Products, Inc. 2006 Annual Report

Mueller Water Products, Inc. 2006 Annual Report 1200 Abernathy Road, N.E. Suite 1200 STRONG PAST. STRONGER FUTURE. Atlanta, GA 30328 (770) 206-4200 2006 Annual Report LEADING BRANDS www.muellerwaterproducts.com INTERN AT I O N A L The 2006 Mueller Water Products, Inc. Annual Report saved the following trees water energy solid waste greenhouse gases resources by printing on 100% recycled fiber, 50% post-consumer waste, 30 6,557 14 1,434 2,424 and processed chlorine-free paper. fully grown gallons million BTUs pounds pounds Mueller Water Products, Inc. BOARD OF DIRECTORS OFFICERS SHAREHOLDER INFORMATION GREGORY E. HYLAND GREGORY E. HYLAND ANNUAL MEETING Chairman, President and Chief Executive Chairman, President and The annual meeting of stockholders Officer, Muellerater W Products, Inc. Chief Executive Officer of Mueller Water Products will be held March 22, 2007 at: DONALD N. BOYCE DALE B. SMITH Four Seasons Hotel Atlanta Retired Chairman and CEO, Chief Operating Officer, 75 14th Street IDEX Corporation Mueller Water Products, Inc. Atlanta, GA 30309 BUSINESS DESCRIPTION Chief Executive Officer, HOWARD L. CLARK, JR. Mueller Group CORPORATE OffICES Vice Chairman, Lehman Brothers, Inc. Mueller Water Products is a leading North American manufacturer and marketer of infrastructure Mueller Water Products, Inc. RAY TOROK JERRY W. KOLB 1200 Abernathy Road, N.E. and flow control products for use in water distribution networks and treatment facilities. Its broad President, U.S. Pipe Retired Vice Chairman, Suite 1200 product portfolio includes engineered valves, hydrants, ductile iron pipe and pipe fittings, which Deloitte & Touche LLP ThOMAS E. FISH Atlanta, GA 30328 are utilized by municipalities, as well as the commercial and residential construction, oil and gas, President, Anvil International (770) 206-4200 JOSEPH B. -

Control Valve Handbook

CONTROL VALVE HANDBOOK Fifth Edition Emerson Automation Solutions Flow Controls Marshalltown, Iowa 50158 USA Sorocaba, 18087 Brazil Cernay, 68700 France Dubai, United Arab Emirates Singapore 128461 Singapore Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user. The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without notice. Fisher is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners. © 2005, 2019 Fisher Controls International LLC. All rights reserved. D101881X012/ Sept19 Preface Control valves are an increasingly vital component of modern manufacturing around the world. Properly selected and maintained control valves increase efficiency, safety, profitability, and ecology. The Control Valve Handbook has been a primary reference since its first printing in 1965. This fifth edition presents vital information on control valve performance and the latest technologies. Chapter 1 offers an introduction to control valves, including definitions for common control valve and instrumentation terminology. -

Ball Butterfly Check Gate Globe Plug Valves Differences Applications Suitability

ADELAIDE • BRISBANE • PERTH VALVE TYPES There are a large variety of valves and valve configurations to suit all services and conditions; different uses (on/off, control), different fluids (liquid, gas etc; combustible, toxic, corrosive etc) different materials and different pressure and temperature conditions. Valves are for starting or stopping flow, regulating or throttling flow, preventing back flow or relieving and regulating pressure in fluid or gaseous handling applications. Common valve types include: Ball, Butterfly,Check, Diaphragm, Gate, Globe, Knife Gate, Parallel Slide, Pinch, Piston, Plug, Sluice, etc. The following types of valves are used in a variety of applications, these descriptions may provide a basic guideline in the selection of valves. BALL VALVES BUTTERFLY VALVES Because of their excellent operating The butterfly valve derives its name from the characteristics, ball valves are used for the wing-like action of the disc which operates at broadest spectrum of isolation applications and right angles to the flow. It’s main advantage is a are available in a wide range of sizes and seating surface which is not critical. It is materials and are available in full flow and full designed for flow isolation. The disc impinges through conduit. Advantages - quick acting, against a resilient liner to provide bubble straight through flow in either direction, low tightness with low operating torque. Compact pressure drop, bubble tight shut off & operating and with a simple construction, butterfly valves torque, easily actuated. Disadvantages - facilitate easy pipe arrangement. Due to disc, temperature limitations on seating material, long they have slightly reduced flow characteristics. “relative” face to face dimension. -

Ips-Full-Catalog.Pdf

ABOUT IPS Welcome to International Polymer Solutions Inc (IPS), a merger of two proud Southern California brand names providing more than a quarter-century of quality service to the marketplace. TEQCOM Industries and BECO Manufacturing now combine forces as IPS for the manufacture of High-Purity Fluid Handling Solutions for both standard and custom industrial applications. For use in semiconductor, solar, pharmaceutical, biomedical, life science, food processing, clean-room laboratory, chemical handling and other environments, IPS high-purity fluid handling and actuation products are ideal for applications requiring engineered performance. We work with PTFE, PFA, PVDF, PVC, PEEK, Polypropylene and other specialty polymer-based materials. We stock a standard line of high-purity products, including: • Solenoid Valves • Fittings • Pneumatic Valves • Filter Assemblies • Manual Valves • Process Tanks • Air Cylinders • Fluid Handling Products • Hand Spray Devices In addition, we are equipped to fabricate custom tanks, boxes, benches, cabinets and fluid-handling systems to fit your specific needs. With our extensive capability of in-house CNC Machining, Routing and Plastic Welding, we invite you to explore how IPS can deliver custom fabricated solutions to your specification. {2} Table of Contents Fittings and Connectors 4 PTFE Spray Guns (SG, RC, NITRO, EW, DG) 24 Miniature Solenoid Valves (M) 32 Sub miniature Solenoid Valves (S) 36 Miniature Pneumatic Diaphragm Valves (MTV) 38 HP Pneumatic Diaphragm Valves (HP) 42 Sub miniature Pneumatic Diaphragm -

Chemical Injection Quills

Distributed by: Chemical Injection Quills Chemical Injection Quills & Corporation Stops Injection quills are designed to ensure a uniform and rapid dispersal of injection chemicals into the center stream of a process pipeline. This With or without check valves. prevents corrosive liquids from clinging to the side of the pipe. Standard lengths of 2 3/4” for 4” pipes. Injection quills are available in a variety of materials and pressure ranges as Custom lengths to 36” (SP). shown in the chart below. Pressure and temperature are dependent on the material of construction and vary from 150 to 3000 psi and 100 °F (37 °C) Materials: PVC, Stainless Steel, C-20, and 500 °F (260 °C). Kynar. Chemical Injection Quills - with Built-in High Pressure Check Valve (QC) Installation Position Chemical Injection Quills - No Check Valves (QB) For lines smaller than 4” diameter, trim quill so chemical is released near center of line. Use as is for lines over 4” diameter or order special length that will disperse the chemical near the center of the pipe. Install with “Telltale” V-notch facing upstream so flow strikes angled face at end of quill for most rapid dispersal of injected chemical. QC-316-100-50FNPT For maintenance ease, installation of an isolation valve, rated above line Standard 2 3/4” Quills are designed for 4” pipes. operating pressure, immediately behind the quill is recommended. QC-316-100 Order Directly online at www.ChemWorld.com Distributed by: Corporation Stops Lever operated stop eliminates the need for a wrench. Protection chain prevents withdrawal before Corporation Stop is closed. -

Plug Valve Solutions for the Upstream Exploration and Production Pipelines Production Manifolds, Test Manifolds and Other Dirty Services

TECHNICAL ARTICLE Plug Valve Solutions for the Upstream Exploration and Production Pipelines Production manifolds, test manifolds and other dirty services Experience In Motion Experience In Motion Introduction highest level of efficiency in order to maximize return on investments and recognize the true total cost of In upstream exploration and production (E&P), uptime ownership. is critical, as every second of inactivity is an expense to O&G operators. Keeping the crude moving safely Many end users consider pressure-balanced plug to the process points without interruption is vital to valves as their preferred choice in these applications an efficient process, and valves play a crucial role in based on the valve’s intrinsic design advantage and ensuring just that. Operational inefficiencies resulting proven track record. from valve failures can result in millions of dollars in downtime and production losses. Production and Test Manifolds Offshore and onshore high-pressure piping systems Once a production site is identified, several wells are convey crude oil or natural gas from various wells to drilled and tested. Each successful well is connected the central processing facilities. These systems pose by flow lines to the production and test manifolds, difficult and challenging operational conditions for flow which are located in the main processing facility. control solutions. The environments are often punishing In these manifolds the well fluids are gathered into and demand a valve solution capable of performing separators for further processing. in severe operating conditions, while guaranteeing safe operation and reliable shutoff. The valves are also Valves play a crucial role in this process by controlling expected to have longer service life and provide the the flow through the various manifolds. -

Methods and Devices for the Prevention of Backflow and Back

Chapter Four Air Gap (2) The air gap may be easily Methods and Devices defeated in the event that the Air gaps are non-mechanical “2D” requirement was purposely backflow preventers that are or inadvertently compromised. for the Prevention of very effective devices to be used Excessive splash may be encoun- where either backsiphonage or tered in the event that higher Backflow and backpressure conditions may than anticipated pressures or exist. Their use is as old as flows occur. The splash may be a Back-Siphonage piping and plumbing itself, but cosmetic or true potential only relatively recently have hazard—the simple solution standards been issued that being to reduce the “2D” wide choice of devices standardize their design. In dimension by thrusting the Aexists that can be used to general, the air gap must be supply pipe into the receiving prevent backsiphonage and twice the supply pipe diameter funnel. By so doing, the air gap backpressure from adding but never less than one inch. is defeated. contaminated fluids or gases See Figure 12. into a potable water supply (3) At an air gap, we expose the system. Generally, the selection water to the surrounding air FIGURE 12. with its inherent bacteria, dust of the proper device to use is Air gap. based upon the degree of hazard particles, and other airborne posed by the cross-connection. pollutants or contaminants. In addition, the aspiration effect of Additional considerations are Diameter based upon piping size, location, “D” the flowing water can drag down and the potential need to surrounding pollutants into the periodically test the devices to “2D” reservoir or holding tank. -

Pocket Guide to Inspecting, Testing and Maintaining Fire Protection Equipment

1 Pocket Guide to Inspecting, Testing and Maintaining Fire Protection Equipment Fourth Edition Emergency Response Consultants Pocket Guide to Inspecting, Testing and Maintaining Fire Protection Equipment Fourth Edition Emergency Response Consultants This pocket guide is made available for informational purposes only in support of the insurance relationship between FM Global and its clients. This information does not change or supplement policy terms or conditions. No liability is assumed by or through the use of this information. The liability of FM Global is limited to that contained in its insurance policies. This pocket guide is produced in partnership with Emergency Response Consultants, a member of the FM Global Group. Emergency Response Consultants offers detailed hands-on training to site-level emergency response staff and management. Table of Contents 3 Introduction . 4 General Sprinkler System Layout . 5 Control Valves . 6 Post Indicator Valve (PIV) . 7 Wall-Mounted Post Indicator Valve (WPIV) . 11 Post Indicator Valve Assembly (PIVA) . 15 Indicating Butterfly Valve (IBV) . 18 Outside Screw and Yoke (OS&Y) Valve . 21 Curb Box or Roadway Valve . 24 Performing a Main Drain Test . 27 Common Valve Problems . 29 Hydrants . 30 Sprinklers and Piping . 34 Alarm Check Valves (Wet Valves) . 36 Check Valves . 40 Dry-Pipe Valves . 41 Performing a Flushing Investigation . 47 Fire Pumps – Diesel . 52 Fire Pumps – Electrical . 62 Pressure-Reducing Valves (PRVs) . 68 Pumper and Standpipe Connections . 70 Special Protection Systems . 72 Fire Alarm Systems . 74 Extinguishers . 77 Fire Doors . 79 Establishing an Inspection, Testing and Maintenance Program . 82 Maintenance of Fire Protection Equipment . 88 4 Introduction Prevention and readiness are the keys to property loss control . -

Submersible Pump Check Valves Installation Instructions Models 80VFD 2” Thru 8” Flomatic Corporation

Submersible Pump Check Valves Installation Instructions Models 80VFD 2” thru 8” Flomatic Corporation Operation: Flomatic 80VFD check valves are designed to prevent backflow, minimizing hydraulic shocks and give years of trouble-free operation without maintenance when installed properly and sized to the pumping application with regards to flow and maximum system pressures. The valve can be installed vertically or horizontally. Construction: The Flomatic 80VFD check valve body has been constructed to handle the rated system flow and pressures as stated, and in addition support the weight of the submersible pump, pipe and the water in the riser pipe. In addition, the valves have been uniquely designed to absorb some of the hydraulic water shocks associated with well water pumping when the check valve installation instructions are followed below. IMPORTANT INSTALLATION INSTRUCTIONS It is very important to install a check valve properly to help insure a trouble free water system. If the installation instructions are not followed or the valve is disassembled, warranty or any warranty claims will be void. On the back of this page is a diagram of a typical submersible valve installation (Fig. 1). A. Pipe Flow Velocities: Flomatic 80VFD is designed for both low and high flow conditions. For best service life a normal flow velocity range is 1 to 10 feet per second. B. System pressure: It is important to take the total system hydraulics into the calculation and not only the pump’s well setting when selecting valve type and model. In general, Flomatic 80VFD valve bodies are pressure rated 600 psi or 1,384 feet of static water column pressure. -

Design and Use of Check Valves

NIBCO INC. 1516 MIDDLEBURY ST. PHONE: 574.295.3000 WORLD HEADQUARTERS ELKHART, IN 46516-4740 FAX: 574.295.3307 USA WEB: www.nibco.com TECHNICAL BULLETIN Review Date: 01/18/2012 Original Date: 07/01/2003 Document ID: NTB-0703-02 Design and Use of Check Valves The simplicity of the check valve should not hide the importance of its function or its potential to cause problems. Check valves are installed to protect piping systems, equipment, and our health. Improperly installed check valves can result in costly repairs and system shutdowns. CHECK VALVE APPLICATION The check valve is an automatic shut-off valve. Under pressure and flow, the closure mechanism opens allowing the media to flow freely. When the flow and pressure stops, the closure mechanism returns automatically to the closed position, preventing the media from returning upstream. The most common installation is at the pump. A check valve may be installed on the suction side of the pump to maintain the pump's prime in the event of a pump shutdown. A check valve will be used commonly on the discharge of the pump to prevent backflow from the downstream system, when the pump shuts off. Check valves are used to prevent contaminated media in branches from flowing back into the main trunk line. The most common example is the use of backflow-prevention devices installed on any connection to a city water main. The backflow prevention device, a special form of check valve, prevents possibly contaminated water at a facility from flowing into the city water system when there is a sudden loss of water pressure in the main utility line.