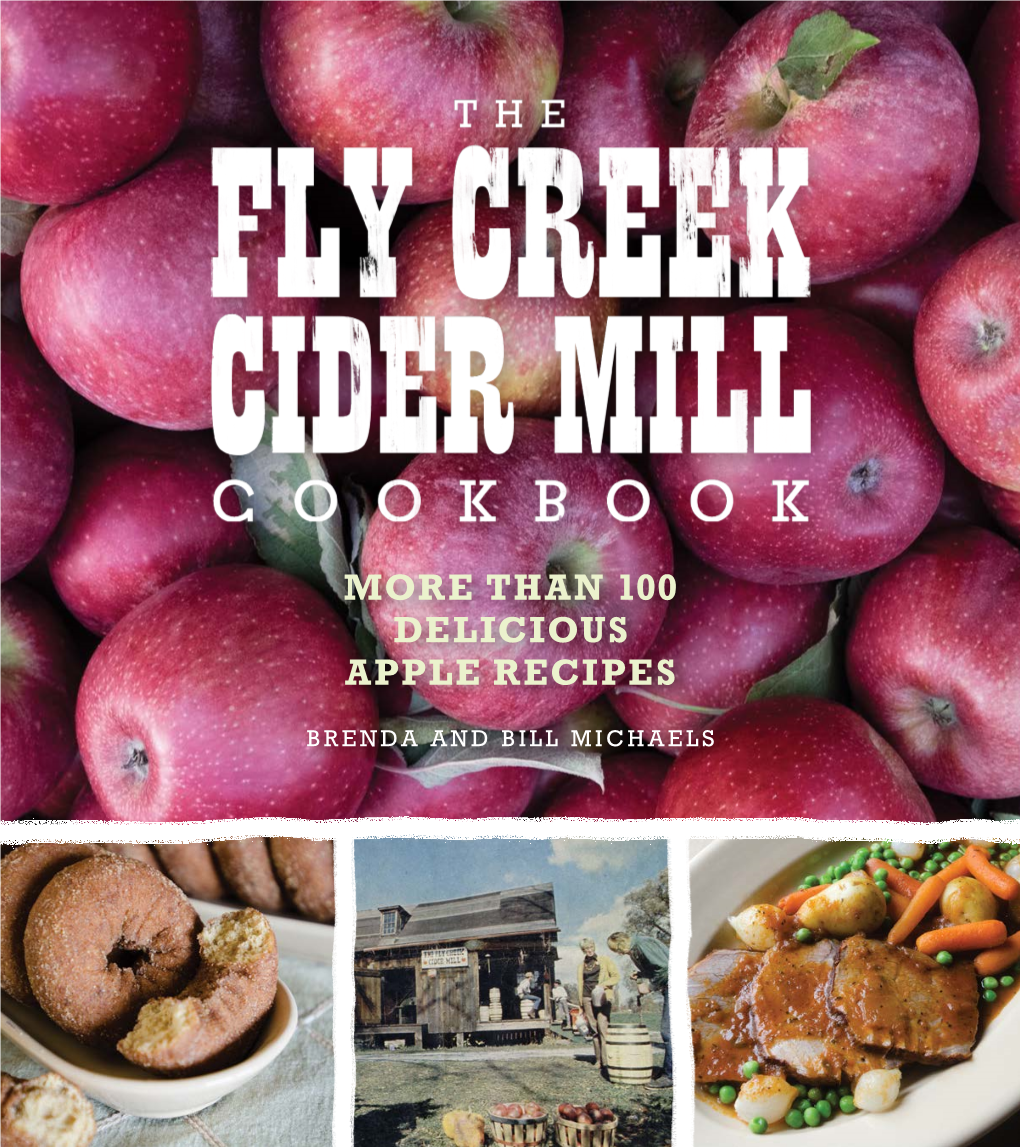

More Than 100 Delicious Apple Recipes

Total Page:16

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Ice Cider Product Development – Effects of Concentration, Yeast Strains and Processing Conditions on Biochemical and Sensory Quality Traits

Faculty of Natural Resources and Agricultural Sciences Department of Food Science Ice cider product development – Effects of concentration, yeast strains and processing conditions on biochemical and sensory quality traits Lisa Åkerman Master Program – Food – Innovation and Market Independent Project in Food Science • Master Thesis • 30 hec • Advanced A2E Publikation/Sveriges lantbruksuniversitet, Institutionen för livsmedelsvetenskap, no 433 Uppsala, 2016 1 Ice cider product development – -Effects of concentration, yeast strains and processing conditions on biochemical and sensory quality traits Lisa Åkerman Supervisor: Supervisor: Kimmo Rumpunen, Researcher, Department of Plant Breeding, Balsgård, Kristianstad Examiner: Examiner: Jana Pickova, Professor, Department of Food Science, SLU, Uppsala Credits: 30 hec Level: Advanced A2E Course title: Independent Project in Food Science Course code: EX0396 Program/education: Master’s Programme Food – Innovation and Market Place of publication: Uppsala Year of publication: 2016 Title of series: Publikation/Sveriges lantbruksuniversitet, Institutionen för livsmedelsvetenskap Serie no: 433 Online publication: http://stud.epsilon.slu.se Keywords: ice cider, apple, fermentation, cryoconcentration, yeast Sveriges lantbruksuniversitet Swedish University of Agricultural Sciences Faculty of Natural Resources and Agricultural Sciences Department of Food Science 2 Abstract Ice cider is produced by fermenting apple juice that has been concentrated by freezing (cryoconcentration or cryoextraction). Ice cider is more a sweet wine than a cider, with an intense apple flavour and sweetness, and acidity to balance the flavours. It originates from Canada, where specifications includes a pre-fermentation sugar content of not less than 30 °Brix, and a finished product with a residual sugar content of not less than 130 g/l, containing 7-13 % alcohol. This project aims to investigate and document some of the aspects of ice cider production process for Swedish conditions. -

Alternative Fermentations

the best of ® ALTERNATIVE FERMENTATIONS Please note all file contents are Copyright © 2021 Battenkill Communications, Inc. All Rights Reserved. This file is for the buyer’s personal use only. It’s unlawful to share or distribute this file to others in any way including e-mailing it, posting it online, or sharing printed copies with others. MAKING MEAD BY BRAD SMITH ead, which is a fermented beverage made from honey, is one of the oldest alcoholic M beverages. Vessels found in China dating back to 7000 B.C. have organic compounds consistent with fermented honey and rice. Mead was the revered “nectar of the gods” in ancient Greece and the “drink of kings” throughout history, though it has faded to obscurity in modern times. For homebrewers, mead is a great addition to complement your other fermented offerings. Many of your guests may have never tasted a good quality mead or melomel (fruit mead), but almost everyone enjoys this sweet beverage. Using some modern methods, mead is also relatively easy and quick to make, and you can use equipment you already have on hand for homebrewing. MODERN MEADMAKING TECHNIQUES When I started homebrewing back in 1987, the fermentation of mead was a very slow process, taking 12 to 18 Photo by Charles A. Parker/Images Plus Parker/Images A. Charles by Photo months for a mead to fully ferment and age. Honey has antibacterial it highlights the flavor of the honey country may have additional variants. properties and is poor in nutrients, varietal itself. In the US, a lot of honey production particularly nitrogen, resulting in a The variety of honey and strength is still done by small, independent very slow fermentation. -

The Story of Cider

The Story of Cider By Paul Dunseath ©1992, 1996 For all of its many benefits, both to our health and peace of mind, wine has at least one major deficiency: the same alcohol which preserves it and gives wine its balance and life in a glass makes it impractical to drink in large quantities on hot summer days. To be sure, "summer coolers" or mixes of wine and ginger ale or fruit juice, are enjoyed by many people, but these drinks are both wasteful of wine and relatively expensive. A foaming glass of cold cider is both cheaper and, to our mind, more satisfying. History records that there were extensive vineyards in Britain until the 12th century when Gascony in France was acquired as part of the dowry in the marriage of Eleanor of Aquitaine to Henry II. At that time the ordinary wine of Bordeaux, known as "clairette", enjoyed an excellent reputation and good quality. Tariff-free imports of clairette virtually wiped out the small domestic English wine industry, and few remnants of it remain today. Clairette, of course, has come down to us as the generic British term "Claret", and both its reputation and its quality remain superior. Not all the British wine producers were troubled by the influx of Bordeaux wines, since many of them were also cider producers. (The Domesday Book regarded cider orchards as being vineyards). The beverage that many people regard as being in effect the "vin ordinaire" of Britain, cider, was unchallenged, and is produced to this day over a large area of Southern England (particularly Somerset, Devon, Sussex and Kent). -

Calvados & Other Fruit Spirits

CALVADOS & OTHER FRUIT SPIRITS There are a lot of different types of fruit based spirits all over the world, most are not particularly famous or consumed other than in the producing country itself, except for the Calvados which goes worldwide. France is the producer of this apple brandy that we call Calvados which will be the primary focus of this section. You might also have come across applejack from North America or other versions of fruit spirits based on cherries, raspberries, pears, plums etc. In short you can base a fruit spirit (brandy) on any kind of fruit and most have been tried and many have very, very old traditions within their country of origin. Calvados Calvados is a fruit spirit produced in northern France where grapes are having a hard time to grow but apples and pears thrive. Calvados is an apple distillate (sometimes with a small addition of pear) and is regulated in French law. In contrast to Cognac and Armagnac which only has one appellation each, Calvados actually has three "Appellation d'origine controlee"; AOC Calvados, AOC Calvados Pays d'Auge and AOC Calvados Domfrontais. Let's break it down below. AOC Calvados Either pot still or copper double-column stills are allowed to be used. Must be aged for at least two years on oak. Accounts for around 70% of the total production of Calvados. AOC Calvados Pays d'Auge Pot stills are to be used exclusively. The fermentation process must be at least 6 weeks contributing to its complex flavour. Must be aged for at least two years on oak. -

The 9Th Annual Great Lakes International Cider & Perry

The 9th Annual Great Lakes International Cider & Perry Competition March 23, 2014 St. Johns, Michigan Results Analysis Eric West Competition Registrar GLINTCAP 2014 Medalists A-Z Noncommercial Division Alan Pearlstein - Michigan Apple Anti-Freeze New England Cider Silver Commerce Township Table Cider Common Cider Silver Andrew Rademacher - Michigan Tin Man Hard Cider Specialty Cider & Perry Bronze Andrew Schaefer - Michigan Rome Crab Common Cider Silver Spy Turley Common Cider Silver Crab Common Cider Bronze Bill Grogan - Wisconsin Northern Dragon Wood Aged Cider & Perry Bronze C. Thomas - Pennsylvania Gilbert + Hale Common Cider Bronze Charlie Nichols - Michigan Black Moon Raspberry Mead Other Fruit Melomel Bronze Char Squared Raspberry Hard Apple Cider Fruit Cider Bronze Staghorn Moon Spiced Hard Apple Cider Specialty Cider & Perry Bronze Charlie Nichols & Joanne Charron - Michigan Staghorn Moon Raspberry Hard Apple Cider Fruit Cider Bronze Chris McGowan - Massachusetts Applewine Applewine Bronze Cherry Cider Specialty Cider & Perry Bronze Rum Barrel Cider New England Cider Bronze Christopher Gottschalk - Michigan Leo Hard Cider Specialty Cider & Perry Bronze Claude Jolicoeur - Quebec Cidre de Glace Intensified (Ice Cider) Silver Colin Post - Minnesota Deer Lake - SM Common Cider Silver Deer Lake - Lalvin Common Cider Bronze Deer Lake - WL/Wy Mix Common Cider Bronze Great Lakes Cider & Perry Association Page 2 www.greatlakescider.com GLINTCAP 2014 Medalists A-Z Noncommercial Division David Catherman & Jeff Biegert - Colorado Red Hawk -

INTRODUCTION to CIDER Dan Daugherty Co-Founder & Cidermaker, St

IN-CIDER SERIES™: INTRODUCTION TO CIDER Dan Daugherty co-founder & cidermaker, St. Vrain Cidery Overview ■ Introductions ■ Topics For This Session: 1. What is Cider? • A Brief History of Apples and Cider 2. Cidermaking Approaches • Cider Styles • Tastings (Interspersed) 3. Upcoming Sessions WHAT IS CIDER? The Short Answer: Fermented Apple Juice Cider Terms You May Have Heard: The Basics ■ “Cider” Is (for purposes of this presentation): ■ The fermented juice of apples and/or pears – Fermented pears can be either “cider” or “perry” – “Cider” can also include juice made from concentrate – Additional ingredients may be included (co-fermented or added later) ■ An often confusing term in the U.S. ■ “Hard Cider” is: ■ A U.S. term for fermented cider – A product of Prohibition and U.S. tax laws – Not a term you hear much outside of the U.S. when referencing fermented apple juice (it’s generally called “cider”) A Growing Market ■ At a 15% annual growth rate, cider will be equivalent to 2% of the beer market in 2020 (from a Cidercon 2016 presentation) ■ About 30 million cases $1 billion in cider sales in 2015 (source) ■ Cider is still very small relative to the beer market, but growing fast… Craft Beer Volume (source: Brewers Association) ■ Cider 2015: – $1 billion – 30 million cases (approx. 70 million gallons) The Basic Process ■ Basic Cidermaking Process: 1. Grow apples 2. Harvest apples 3. Grind apples 4. Press apples into juice 5. Ferment juice (naturally or with cultivated yeast) 6. Maturation – barrels, tanks, totes, etc 7. Packaging – bottles, -

Hard Cider Production: Sanitation, Fermentation, & Stabilization

HARD CIDER PRODUCTION: SANITATION, FERMENTATION, & STABILIZATION By: Denise Gardner, Extension Enologist January 2015 Why Sanitation is Important… • “Garbage-in equals garbage-out” • Enhances your opportunity to minimize quality (and spoilage) problems • Allows the cider maker more time to focus on stylistic decisions and creating a good quality cider • Most problems that occur in hard cider production can be easily prevented with good sanitation practices Cleaning vs. Sanitizing • Cleaning – [physical] removal of mineral and organic material or debris from equipment surfaces • Sanitizing – reduction of microorganisms through such means as addition of chemicals or heat (i.e. steam) (Sterilizing – killing 100% of all viable microorganisms, associated spores, and viruses is rarely achieved in commercial processes) Fugelsang & Edwards, 2007 Cleaning vs. Sanitizing • Overall Considerations: 1) Clean – Rinse – Sanitize 2) Cleaning equipment does not imply that the equipment has been sanitized 3) Improperly cleaned equipment cannot subsequently be sanitized 4) Must always clean equipment before sanitizing (increases the efficiency of the sanitization step) Fugelsang & Edwards, 2007 FDA Approved No-Rinse Sanitizers • Sanitizers – an agent that reduces viable cell populations to acceptable lower numbers; used in sanitizing steps – List of FDA Approved No-Rinse Sanitizers 1) Chlorine (Cl) 2) Chlorine Dioxide (ClO2) 3) Iodophors 4) QUATS 5) Peroxyacetic Acid FDA Approved No-Rinse Sanitizers • Sanitizers – an agent that reduces viable cell populations -

Handling of Apple Transport Techniques and Efficiency Vibration, Damage and Bruising Texture, Firmness and Quality

Centre of Excellence AGROPHYSICS for Applied Physics in Sustainable Agriculture Handling of Apple transport techniques and efficiency vibration, damage and bruising texture, firmness and quality Bohdan Dobrzañski, jr. Jacek Rabcewicz Rafa³ Rybczyñski B. Dobrzañski Institute of Agrophysics Polish Academy of Sciences Centre of Excellence AGROPHYSICS for Applied Physics in Sustainable Agriculture Handling of Apple transport techniques and efficiency vibration, damage and bruising texture, firmness and quality Bohdan Dobrzañski, jr. Jacek Rabcewicz Rafa³ Rybczyñski B. Dobrzañski Institute of Agrophysics Polish Academy of Sciences PUBLISHED BY: B. DOBRZAŃSKI INSTITUTE OF AGROPHYSICS OF POLISH ACADEMY OF SCIENCES ACTIVITIES OF WP9 IN THE CENTRE OF EXCELLENCE AGROPHYSICS CONTRACT NO: QLAM-2001-00428 CENTRE OF EXCELLENCE FOR APPLIED PHYSICS IN SUSTAINABLE AGRICULTURE WITH THE th ACRONYM AGROPHYSICS IS FOUNDED UNDER 5 EU FRAMEWORK FOR RESEARCH, TECHNOLOGICAL DEVELOPMENT AND DEMONSTRATION ACTIVITIES GENERAL SUPERVISOR OF THE CENTRE: PROF. DR. RYSZARD T. WALCZAK, MEMBER OF POLISH ACADEMY OF SCIENCES PROJECT COORDINATOR: DR. ENG. ANDRZEJ STĘPNIEWSKI WP9: PHYSICAL METHODS OF EVALUATION OF FRUIT AND VEGETABLE QUALITY LEADER OF WP9: PROF. DR. ENG. BOHDAN DOBRZAŃSKI, JR. REVIEWED BY PROF. DR. ENG. JÓZEF KOWALCZUK TRANSLATED (EXCEPT CHAPTERS: 1, 2, 6-9) BY M.SC. TOMASZ BYLICA THE RESULTS OF STUDY PRESENTED IN THE MONOGRAPH ARE SUPPORTED BY: THE STATE COMMITTEE FOR SCIENTIFIC RESEARCH UNDER GRANT NO. 5 P06F 012 19 AND ORDERED PROJECT NO. PBZ-51-02 RESEARCH INSTITUTE OF POMOLOGY AND FLORICULTURE B. DOBRZAŃSKI INSTITUTE OF AGROPHYSICS OF POLISH ACADEMY OF SCIENCES ©Copyright by BOHDAN DOBRZAŃSKI INSTITUTE OF AGROPHYSICS OF POLISH ACADEMY OF SCIENCES LUBLIN 2006 ISBN 83-89969-55-6 ST 1 EDITION - ISBN 83-89969-55-6 (IN ENGLISH) 180 COPIES, PRINTED SHEETS (16.8) PRINTED ON ACID-FREE PAPER IN POLAND BY: ALF-GRAF, UL. -

Cocktail Recipes Cocktail Recipes Cocktail Recipes Cocktail Recipes

STARLIGHT STARLIGHT STARLIGHT STARLIGHT DISTILLERY DISTILLERY DISTILLERY DISTILLERY EST. 2001 EST. 2001 EST. 2001 EST. 2001 Cocktail Recipes Cocktail Recipes Cocktail Recipes Cocktail Recipes The Orchard Mule* The Orchard Mule* The Orchard Mule* The Orchard Mule* 1 ½ oz Starlight Distillery Vodka 1 ½ oz Starlight Distillery Vodka 1 ½ oz Starlight Distillery Vodka 1 ½ oz Starlight Distillery Vodka 1 ½ oz House-made Ginger Beer 1 ½ oz House-made Ginger Beer 1 ½ oz House-made Ginger Beer 1 ½ oz House-made Ginger Beer Top with Huber Apple Cider Top with Huber Apple Cider Top with Huber Apple Cider Top with Huber Apple Cider Garnish with a slice of apple. Garnish with a slice of apple. Garnish with a slice of apple. Garnish with a slice of apple. Hawaiian Star* Hawaiian Star* Hawaiian Star* Hawaiian Star* 1 ½ oz Pineapple Infused 1 ½ oz Pineapple Infused 1 ½ oz Pineapple Infused 1 ½ oz Pineapple Infused Starlight Distillery Vodka Starlight Distillery Vodka Starlight Distillery Vodka Starlight Distillery Vodka (Soak fresh pineapple slices in (Soak fresh pineapple slices in (Soak fresh pineapple slices in (Soak fresh pineapple slices in Starlight Distillery Vodka) Starlight Distillery Vodka) Starlight Distillery Vodka) Starlight Distillery Vodka) Top with Sprite and Top with Sprite and Top with Sprite and Top with Sprite and Garnish with an Orange Slice. Garnish with an Orange Slice. Garnish with an Orange Slice. Garnish with an Orange Slice. Bee’s Knees* Bee’s Knees* Bee’s Knees* Bee’s Knees* 1¼ part Starlight Distillery “1843” Gin 1¼ part Starlight Distillery “1843” Gin 1¼ part Starlight Distillery “1843” Gin 1¼ part Starlight Distillery “1843” Gin ¾ part Lemon Juice ¾ part Lemon Juice ¾ part Lemon Juice ¾ part Lemon Juice 1¼ part Honey Syrup 1¼ part Honey Syrup 1¼ part Honey Syrup 1¼ part Honey Syrup Garnish with a lemon twist. -

Catalog 2020.Pdf

Copyright © 2020 - Happy Valley Ranch, Inc. 2020 Catalog Safe, Pure, Delicious Apple Cider From Your Own Yard Thank you for giving us the opportunity to present to you our famous Happy Valley Ranch Cider and Wine Presses. We have been building these presses for over 40 years and they have withstood the test of time. Don’t settle for a cheap knock-off that will be here today and gone tomorrow. Cider making is fun for the entire family. Sparkling, clear fresh pressed apple cider is delicious and very good for you. Some credit it with great therapeutic value but the taste alone convinces our family. When you compare the cost to store bought juices a great deal of money can be saved and you don’t have to worry about what chemicals and preservatives that might have been used. Cider making in America dates back as far as the Pilgrims in the 1600’s and our equipment is designed after the OLD FASHIONED presses used in that period. It is still the most efficient and easiest to operate press on the market today. Even a child can easily turn the Grinder Wheel. Your family and friends will enjoy getting together for an afternoon of old time cider making. This fruit harvest season get in on the fun and excitement of tasting fresh made apple cider. Please take our catalog and go through it page by page. You’ll see that our presses are built solid with heavy cast Iron and steel parts. The Acme threaded screw is 50% larger around than any other model and the heavy CAST IRON upper cross-arm with the treads turned into it is essential for strength and will last for years. -

Your List for Epcot's Food & Wine Festival Here

Africa Hops and Barley • Spicy Kenyan Vegan • New England Lobster Roll: Warm Lobster with Fresh Herb Corn and White Beans with Pigeon Peas, Quinoa & Ancient Grains Medley and Kachumbari Slaw (Plant-based) Mayonnaise and Griddled Roll • Piri Piri Skewered Shrimp with Citrus-scented Couscous • Southern Seafood Boil: Shrimp, Mussels, Crawfish, Potatoes, • Tusker Lager Corn, and Andouille Sausage • Jam Jar Sweet Shiraz • Freshly Baked Carrot Cake and Cream Cheese Icing • North Coast Bewing Co. Blue Star Wheat Appleseed Orchard • 3 Daughters Brewing A Wake Coffee Blonde Ale • Heavy Seas AmeriCannon APA • Charcuterie and Cheese Plate featuring Burton’s Maplewood Farm Applejack Brandy Barrel Aged Maple Syrup • Angry Orchard Rosé Hard Cider • Caramel-Apple Popcorn • Mer Soleil Reserve Chardonnay • Frozen Apple Pie (non-alcoholic) • Broadside Cabernet Sauvignon • Short’s Brewing Co. Mule Beer • Heavy Seas Brewery TropiCannon Citrus IPA • Parish Brewing Co. Ghost in the Machine Double IPA Islands of the Caribbean • 3 Daughters Raspberry Lemonade Dry Hard Cider • Ropa Vieja Empanada with Tomato Aïoli • Short’s Brewing Company Starcut Ciders Mosa Hard Cider • Jerk-spiced Chicken with Roasted Sweet Plantain Salad and Mango Chutney Yogurt • Ciderboys Banana Bliss Hard Cider • Flancocho: Passion Fruit Cake with Coconut Flan • Apple Blossom Sky: Fanta® Apple, Ginger Beer, Floodwall Apple Brandy, Burton’s Maplewood Farm Applejack • Red Stripe Lager Brandy Barrel Aged Syrup and Mini Marshmallows • Opici Family White Sangria • Frozen Mojito Brazil • Crispy -

From Sawdust and Cider to Wine a Book Review and Comments from Reida: September Is the Harvest Month on Our Farm

From Sawdust and Cider to Wine A book review and comments from Reida: September is the harvest month on our farm. Most days see me picking and canning or drying some goodies from the garden and orchard. It is also the month when we spread the summer's aged manure and bedding on the hill pasture before the rains come and the hill becomes too slippery for the “powerwagon.” Finally there is wood to bring down from the slash piles on clearcuts behind our land, cords of it to saw and split and fit into the woodshed for our winter's heat. Most of the hard work is done now, and soon it will be time to make apple juice and butcher turkeys and lambs. All this sounds like real farming, but let me assure you, it is just play compared to the daily work routines of the people who lived on farms a century or even a half a century ago. The history of Eugene and its environs is fascinating. I think we all long to know more of what the land looked like in the past, how it was used, how people lived, how they worked, and what they did for enjoyment. We are so fortunate to live in a recently settled part of America where the stories of the pioneer past are still alive in the memories of the grandchildren and the great grandchildren of the early settlers. Many families have invaluable collections of letters, and some of the earliest houses survive. So much has been preserved, but so much is on the verge of being lost as the old-timers pass on.