Chapter 8 Constrained Optimization

Total Page:16

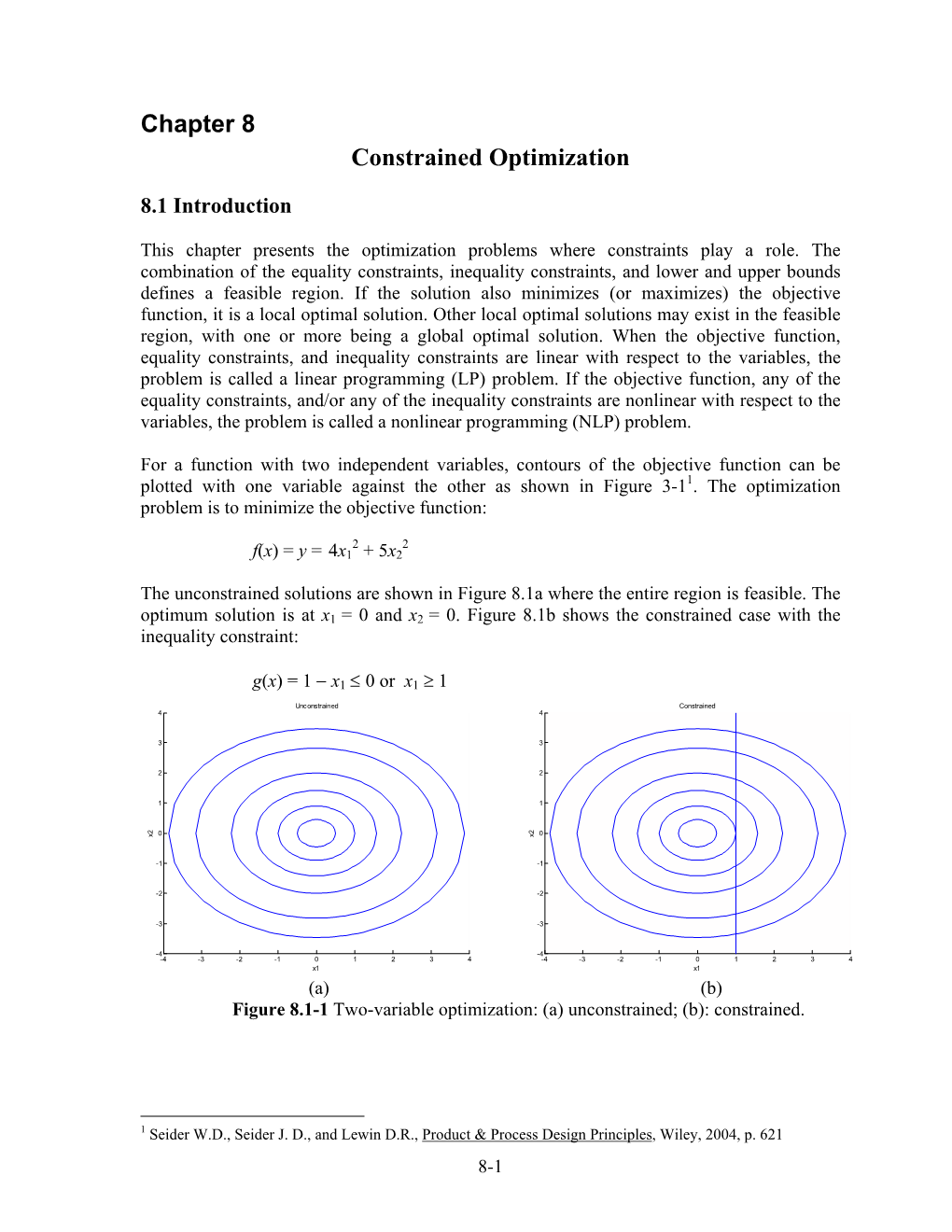

File Type:pdf, Size:1020Kb

Load more

Recommended publications

-

Lecture 3 1 Geometry of Linear Programs

ORIE 6300 Mathematical Programming I September 2, 2014 Lecture 3 Lecturer: David P. Williamson Scribe: Divya Singhvi Last time we discussed how to take dual of an LP in two different ways. Today we will talk about the geometry of linear programs. 1 Geometry of Linear Programs First we need some definitions. Definition 1 A set S ⊆ <n is convex if 8x; y 2 S, λx + (1 − λ)y 2 S, 8λ 2 [0; 1]. Figure 1: Examples of convex and non convex sets Given a set of inequalities we define the feasible region as P = fx 2 <n : Ax ≤ bg. We say that P is a polyhedron. Which points on this figure can have the optimal value? Our intuition from last time is that Figure 2: Example of a polyhedron. \Circled" corners are feasible and \squared" are non feasible optimal solutions to linear programming problems occur at \corners" of the feasible region. What we'd like to do now is to consider formal definitions of the \corners" of the feasible region. 3-1 One idea is that a point in the polyhedron is a corner if there is some objective function that is minimized there uniquely. Definition 2 x 2 P is a vertex of P if 9c 2 <n with cT x < cT y; 8y 6= x; y 2 P . Another idea is that a point x 2 P is a corner if there are no small perturbations of x that are in P . Definition 3 Let P be a convex set in <n. Then x 2 P is an extreme point of P if x cannot be written as λy + (1 − λ)z for y; z 2 P , y; z 6= x, 0 ≤ λ ≤ 1. -

Extreme Points and Basic Solutions

EXTREME POINTS AND BASIC SOLUTIONS: In Linear Programming, the feasible region in Rn is defined by P := {x ∈ Rn | Ax = b, x ≥ 0}. The set P , as we have seen, is a convex subset of Rn. It is called a convex polytope. The term convex polyhedron refers to convex polytope which is bounded. Polytopes in two dimensions are often called polygons. Recall that the vertices of a convex polytope are what we called extreme points of that set. Recall that extreme points of a convex set are those which cannot be represented as a proper convex combination of two other (distinct) points of the convex set. It may, or may not be the case that a convex set has any extreme points as shown by the example in R2 of the strip S := {(x, y) ∈ R2 | 0 ≤ x ≤ 1, y ∈ R}. On the other hand, the square defined by the inequalities |x| ≤ 1, |y| ≤ 1 has exactly four extreme points, while the unit disk described by the ineqality x2 + y2 ≤ 1 has infinitely many. These examples raise the question of finding conditions under which a convex set has extreme points. The answer in general vector spaces is answered by one of the “big theorems” called the Krein-Milman Theorem. However, as we will see presently, our study of the linear programming problem actually answers this question for convex polytopes without needing to call on that major result. The algebraic characterization of the vertices of the feasible polytope confirms the obser- vation that we made by following the steps of the Simplex Algorithm in our introductory example. -

The Feasible Region for Consecutive Patterns of Permutations Is a Cycle Polytope

Séminaire Lotharingien de Combinatoire XX (2020) Proceedings of the 32nd Conference on Formal Power Article #YY, 12 pp. Series and Algebraic Combinatorics (Ramat Gan) The feasible region for consecutive patterns of permutations is a cycle polytope Jacopo Borga∗1, and Raul Penaguiaoy 1 1Department of Mathematics, University of Zurich, Switzerland Abstract. We study proportions of consecutive occurrences of permutations of a given size. Specifically, the feasible limits of such proportions on large permutations form a region, called feasible region. We show that this feasible region is a polytope, more precisely the cycle polytope of a specific graph called overlap graph. This allows us to compute the dimension, vertices and faces of the polytope. Finally, we prove that the limits of classical occurrences and consecutive occurrences are independent, in some sense made precise in the extended abstract. As a consequence, the scaling limit of a sequence of permutations induces no constraints on the local limit and vice versa. Keywords: permutation patterns, cycle polytopes, overlap graphs. This is a shorter version of the preprint [11] that is currently submitted to a journal. Many proofs and details omitted here can be found in [11]. 1 Introduction 1.1 Motivations Despite not presenting any probabilistic result here, we give some motivations that come from the study of random permutations. This is a classical topic at the interface of combinatorics and discrete probability theory. There are two main approaches to it: the first concerns the study of statistics on permutations, and the second, more recent, looks arXiv:2003.12661v2 [math.CO] 30 Jun 2020 for the limits of permutations themselves. -

Linear Programming

Stanford University | CS261: Optimization Handout 5 Luca Trevisan January 18, 2011 Lecture 5 In which we introduce linear programming. 1 Linear Programming A linear program is an optimization problem in which we have a collection of variables, which can take real values, and we want to find an assignment of values to the variables that satisfies a given collection of linear inequalities and that maximizes or minimizes a given linear function. (The term programming in linear programming, is not used as in computer program- ming, but as in, e.g., tv programming, to mean planning.) For example, the following is a linear program. maximize x1 + x2 subject to x + 2x ≤ 1 1 2 (1) 2x1 + x2 ≤ 1 x1 ≥ 0 x2 ≥ 0 The linear function that we want to optimize (x1 + x2 in the above example) is called the objective function.A feasible solution is an assignment of values to the variables that satisfies the inequalities. The value that the objective function gives 1 to an assignment is called the cost of the assignment. For example, x1 := 3 and 1 2 x2 := 3 is a feasible solution, of cost 3 . Note that if x1; x2 are values that satisfy the inequalities, then, by summing the first two inequalities, we see that 3x1 + 3x2 ≤ 2 that is, 1 2 x + x ≤ 1 2 3 2 1 1 and so no feasible solution has cost higher than 3 , so the solution x1 := 3 , x2 := 3 is optimal. As we will see in the next lecture, this trick of summing inequalities to verify the optimality of a solution is part of the very general theory of duality of linear programming. -

Maxlik: Maximum Likelihood Estimation and Related Tools

Package ‘maxLik’ July 26, 2021 Version 1.5-2 Date 2021-07-26 Title Maximum Likelihood Estimation and Related Tools Depends R (>= 2.4.0), miscTools (>= 0.6-8), methods Imports sandwich, generics Suggests MASS, clue, dlm, plot3D, tibble, tinytest Description Functions for Maximum Likelihood (ML) estimation, non-linear optimization, and related tools. It includes a unified way to call different optimizers, and classes and methods to handle the results from the Maximum Likelihood viewpoint. It also includes a number of convenience tools for testing and developing your own models. License GPL (>= 2) ByteCompile yes NeedsCompilation no Author Ott Toomet [aut, cre], Arne Henningsen [aut], Spencer Graves [ctb], Yves Croissant [ctb], David Hugh-Jones [ctb], Luca Scrucca [ctb] Maintainer Ott Toomet <[email protected]> Repository CRAN Date/Publication 2021-07-26 17:30:02 UTC R topics documented: maxLik-package . .2 activePar . .4 AIC.maxLik . .5 bread.maxLik . .6 compareDerivatives . .7 1 2 maxLik-package condiNumber . .9 confint.maxLik . 11 fnSubset . 12 gradient . 13 hessian . 15 logLik.maxLik . 16 maxBFGS . 17 MaxControl-class . 21 maximType . 24 maxLik . 25 maxNR . 27 maxSGA . 33 maxValue . 38 nIter . 39 nObs.maxLik . 40 nParam.maxim . 41 numericGradient . 42 objectiveFn . 44 returnCode . 45 storedValues . 46 summary.maxim . 47 summary.maxLik . 49 sumt............................................. 50 tidy.maxLik . 52 vcov.maxLik . 54 Index 56 maxLik-package Maximum Likelihood Estimation Description This package contains a set of functions and tools for Maximum Likelihood (ML) estimation. The focus of the package is on non-linear optimization from the ML viewpoint, and it provides several convenience wrappers and tools, like BHHH algorithm, variance-covariance matrix and standard errors. -

Math 112 Review for Exam Ii (Ws 12 -18)

MATH 112 REVIEW FOR EXAM II (WS 12 -18) I. Derivative Rules • There will be a page or so of derivatives on the exam. You should know how to apply all the derivative rules. (WS 12 and 13) II. Functions of One Variable • Be able to find local optima, and to distinguish between local and global optima. • Be able to find the global maximum and minimum of a function y = f(x) on the interval from x = a to x = b, using the fact that optima may only occur where f(x) has a horizontal tangent line and at the endpoints of the interval. Step 1: Compute the derivative f’(x). Step 2: Find all critical points (values of x at which f’(x) = 0.) Step 3: Plug all the values of x from Step 2 that are in the interval from a to b and the endpoints of the interval into the function f(x). Step 4: Sketch a rough graph of f(x) and pick off the global max and min. • Understand the following application: Maximizing TR(q) starting with a demand curve. (WS 15) • Understand how to use the Second Derivative Test. (WS 16) If a is a critical point for f(x) (that is, f’(a) = 0), and the second derivative is: f ’’(a) > 0, then f(x) has a local min at x = a. f ’’(a) < 0, then f(x) has a local max at x = a. f ’’(a) = 0, then the test tells you nothing. IMPORTANT! For the Second Derivative Test to work, you must have f’(a) = 0 to start with! For example, if f ’’(a) > 0 but f ’(a) ≠ 0, then the graph of f(x) is concave up at x = a but f(x) does not have a local min there. -

The Feasible Region for Consecutive Patterns of Permutations Is a Cycle Polytope

Algebraic Combinatorics Draft The feasible region for consecutive patterns of permutations is a cycle polytope Jacopo Borga & Raul Penaguiao Abstract. We study proportions of consecutive occurrences of permutations of a given size. Specifically, the limit of such proportions on large permutations forms a region, called feasible region. We show that this feasible region is a polytope, more precisely the cycle polytope of a specific graph called overlap graph. This allows us to compute the dimension, vertices and faces of the polytope, and to determine the equations that define it. Finally we prove that the limit of classical occurrences and consecutive occurrences are in some sense independent. As a consequence, the scaling limit of a sequence of permutations induces no constraints on the local limit and vice versa. (1,0,0,0,0,0) 1 1 (0; 2 ; 2 ; 0; 0; 0) 1 1 1 1 (0; 0; 2 ; 2 ; 0; 0) (0; 2 ; 0; 2 ; 0; 0) 1 1 (0; 0; 0; 2 ; 2 ; 0) arXiv:1910.02233v2 [math.CO] 30 Jun 2020 Figure 1. The four-dimensional polytope P3 given by the six pat- terns of size three (see Eq. (2) for a precise definition). We highlight in light-blue one of the six three-dimensional facets of P3. This facet is a pyramid with square base. The polytope itself is a four-dimensional pyramid, whose base is the highlighted facet. This paper has been prepared using ALCO author class on 1st July 2020. Keywords. Permutation patterns, cycle polytopes, overlap graphs. Acknowledgements. This work was completed with the support of the SNF grants number 200021- 172536 and 200020-172515. -

Mathematical Modelling and Applications of Particle Swarm Optimization

Master’s Thesis Mathematical Modelling and Simulation Thesis no: 2010:8 Mathematical Modelling and Applications of Particle Swarm Optimization by Satyobroto Talukder Submitted to the School of Engineering at Blekinge Institute of Technology In partial fulfillment of the requirements for the degree of Master of Science February 2011 Contact Information: Author: Satyobroto Talukder E-mail: [email protected] University advisor: Prof. Elisabeth Rakus-Andersson Department of Mathematics and Science, BTH E-mail: [email protected] Phone: +46455385408 Co-supervisor: Efraim Laksman, BTH E-mail: [email protected] Phone: +46455385684 School of Engineering Internet : www.bth.se/com Blekinge Institute of Technology Phone : +46 455 38 50 00 SE – 371 79 Karlskrona Fax : +46 455 38 50 57 Sweden ii ABSTRACT Optimization is a mathematical technique that concerns the finding of maxima or minima of functions in some feasible region. There is no business or industry which is not involved in solving optimization problems. A variety of optimization techniques compete for the best solution. Particle Swarm Optimization (PSO) is a relatively new, modern, and powerful method of optimization that has been empirically shown to perform well on many of these optimization problems. It is widely used to find the global optimum solution in a complex search space. This thesis aims at providing a review and discussion of the most established results on PSO algorithm as well as exposing the most active research topics that can give initiative for future work and help the practitioner improve better result with little effort. This paper introduces a theoretical idea and detailed explanation of the PSO algorithm, the advantages and disadvantages, the effects and judicious selection of the various parameters. -

Lesson . Geometry and Algebra of “Corner Points”

SAh§þ Linear Programming Spring z§zË Uhan Lesson Ëþ.GeomeTry and Algebra of “Corner Points” §W arm up Example Ë. Consider The sysTem of equaTions hxË + xz − 6xh = Ë6 xË + þxz = Ë (∗) −zxË + ËËxh = −z ⎛ h Ë −6⎞ LeT A = ⎜ Ë þ § ⎟. We have ThaT deT(A) = Ç . ⎝−z § ËË ⎠ ● Does (∗) have a unique soluTion, no soluTions, or an inûniTe number of soluTions? ● Are The row vecTors of A linearly independent? How abouT The column vecTors of A? ● WhaT is The rank of A? Does A have full row rank? ËO verview xz ● Due To convexiTy, local opTimal soluTions of LPs are global opTimal soluTions þ ⇒ Improving search ûnds global opTimal soluTions of LPs ● _e simplex meThod: improving search among “corner points” of The h ↑ (Ë) feasible region of an LP z (z ) ↓ ● How can we describe “corner points” of The feasible region of an LP? Ë ● For LPs, is There always an opTimal soluTion ThaT is a “corner poinT”? xË Ë z h Ë z Polyhedra and exTreme points ● A polyhedron is a seT of vecTors x ThaT saTisfy a ûniTe collecTion of linear consTraints (equaliTies and inequaliTies) ○ Also referred To as a polyhedral seT ● In parTicular: ● Recall: The feasible region of an LP – a polyhedron – is a convex feasible region ● Given a convex feasible region S, a soluTion x ∈ S is an exTreme poinT if There does noT exisT Two disTincT soluTions y, z ∈ S such ThaT x is on The line segmenT joining y and z ○ i.e. There does noT exisT λ ∈ (§, Ë) such ThaT x = λy + (Ë − λ)z Example z. -

Geometry and Visualizations of Linear Programs (PDF)

15.053/8 February 12, 2013 Geometry and visualizations of linear programs © Wikipedia User: 4C. License CC BY-SA. This content is excluded from our Creative Commons license. For more information, see http://ocw.mit.edu/help/faq-fair-use/. 1 Quotes of the day “You don't understand anything until you learn it more than one way.” Marvin Minsky “One finds limits by pushing them.” Herbert Simon 2 Overview Views of linear programming – Geometry/Visualization – Algebra – Economic interpretations 3 What does the feasible region of an LP look like? Three 2-dimensional examples 4 Some 3-dimensional LPs Courtesy of Wolfram Research, Inc. Used with permission. Source: Weisstein, Eric W. "Convex Polyhedron." From MathWorld -- A Wolfram Web Resource. 5 Goal of this Lecture: visualizing LPs in 2 and 3 dimensions. What properties does the feasible region have? – convexity – corner points What properties does an optimal solution have? How can one find the optimal solution: – the “geometric method” – The simplex method Introduction to sensitivity analysis – What happens if the RHS changes? 6 A Two Variable Linear Program (a variant of the DTC example) objective z = 3x + 5y 2x + 3y 10 (1) Constraints x + 2y 6 (2) x + y 5 (3) x 4 (4) y 3 (5) x, y 0 (6) 7 Finding an optimal solution Introduce yourself to your partner Try to find an optimal solution to the linear program, without looking ahead. 8 Inequalities A single linear inequality determines a unique y half-plane 5 4 x + 2y 6 3 2 1 x 1 2 3 4 5 6 9 Graphing the Feasible Region y Graph the Constraints: 2x+ 3y 10 (1) 5 x 0 , y 0. -

B1 Optimization – Solutions

B1 Optimization – Solutions A. Zisserman, Michaelmas Term 2018 1. The Rosenbrock function is f(x; y) = 100(y − x2)2 + (1 − x)2 (a) Compute the gradient and Hessian of f(x; y). (b) Show that that f(x; y) has zero gradient at the point (1; 1). (c) By considering the Hessian matrix at (x; y) = (1; 1), show that this point is a mini- mum. (a) Gradient and Hessian 400x3 − 400xy + 2x − 2 1200x2 − 400y + 2 −400x rf = H = 200(y − x2) −400x 200 (b) gradient at the point (1; 1) 400x3 − 400xy + 2x − 2 0 rf = = 200(y − x2) 0 (b) Hessian at the point (1; 1) 1200x2 − 400y + 2 −400x 802 −400 H = = −400x 200 −400 200 Examine eigenvalues: • det is positive, so eigenvalues have same sign (thus not saddle point) • trace is positive, so eigenvalues are positive • Thus a minimum • λ1 = 1001:6006; λ2 = 0:39936077 1 2. In Newton type minimization schemes the update step is of the form δx = −H−1g where g = rf. By considering g.δx compare convergence of: (a) Newton, to (b) Gauss Newton for a general function f(x) (i.e. where H may not be positive definite). A note on positive definite matrices An n × n symmetric matrix M is positive definite if • x>Mx > 0 for all non-zero vectors x • All the eigen-values of M are positive In each case consider df = g:δx. This should be negative for convergence. (a) Newton g:δx = −g>H−1g Can be positive if H not positive definite. -

![An Augmented Lagrangian Method for Optimization Problems in Banach Spaces Arxiv:1807.04467V1 [Math.OC] 12 Jul 2018](https://docslib.b-cdn.net/cover/2033/an-augmented-lagrangian-method-for-optimization-problems-in-banach-spaces-arxiv-1807-04467v1-math-oc-12-jul-2018-2132033.webp)

An Augmented Lagrangian Method for Optimization Problems in Banach Spaces Arxiv:1807.04467V1 [Math.OC] 12 Jul 2018

An Augmented Lagrangian Method for Optimization Problems in Banach Spaces∗ Christian Kanzowy Daniel Stecky Daniel Wachsmuthy October 23, 2017 Abstract. We propose a variant of the classical augmented Lagrangian method for con- strained optimization problems in Banach spaces. Our theoretical framework does not require any convexity or second-order assumptions and allows the treatment of inequality constraints with infinite-dimensional image space. Moreover, we discuss the convergence properties of our algorithm with regard to feasibility, global optimality, and KKT conditions. Some numerical results are given to illustrate the practical viability of the method. Keywords. Constrained optimization, augmented Lagrangian method, Banach space, inequality constraints, global convergence. 1 Introduction Let X, Y be (real) Banach spaces and let f : X ! R, g : X ! Y be given mappings. The aim of this paper is to describe an augmented Lagrangian method for the solution of the constrained optimization problem min f(x) subject to (s.t.) g(x) ≤ 0: (P ) We assume that Y,! L2(Ω) densely for some measure space Ω, where the natural order on L2(Ω) induces the order on Y . A detailed description together with some remarks about this setting is given in Section 2. Augmented Lagrangian methods for the solution of optimization problems belong to the most famous and successful algorithms for the solution of finite-dimensional problems and are described in almost all text books on continuous optimization, see, e.g. [8, 29]. Their generalization to infinite-dimensional problems has received considerable attention throughout the last decades [6, 7, 16, 18, 20, 21, 22, 24, 25]. However, most existing arXiv:1807.04467v1 [math.OC] 12 Jul 2018 approaches either assume a very specific problem structure [6, 7], require strong convexity assumptions [18] or consider only the case where Y is finite-dimensional [20, 24].