Reference & Information AWG Cable Description

American Wire Gauge

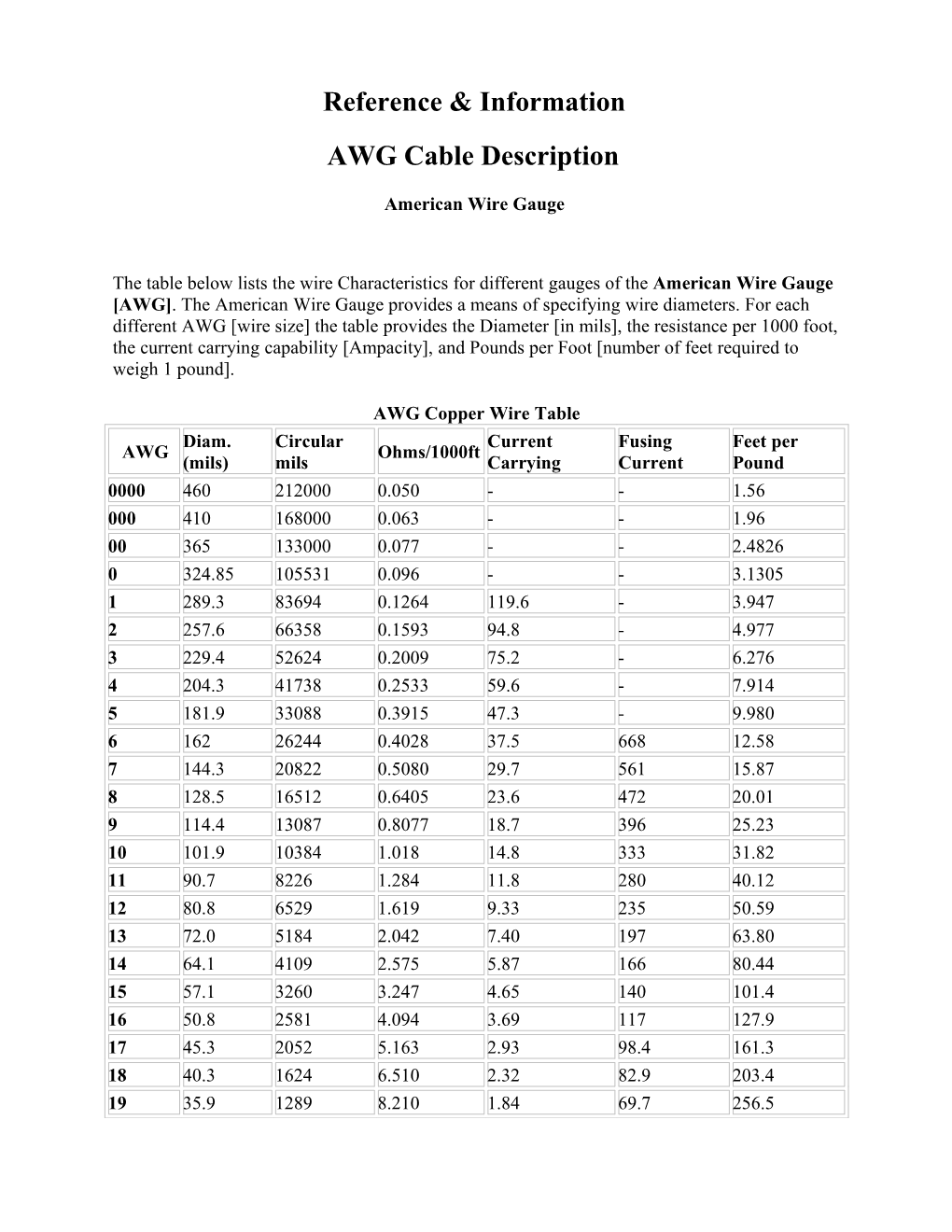

The table below lists the wire Characteristics for different gauges of the American Wire Gauge [AWG]. The American Wire Gauge provides a means of specifying wire diameters. For each different AWG [wire size] the table provides the Diameter [in mils], the resistance per 1000 foot, the current carrying capability [Ampacity], and Pounds per Foot [number of feet required to weigh 1 pound].

AWG Copper Wire Table Diam. Circular Current Fusing Feet per AWG Ohms/1000ft (mils) mils Carrying Current Pound 0000 460 212000 0.050 - - 1.56 000 410 168000 0.063 - - 1.96 00 365 133000 0.077 - - 2.4826 0 324.85 105531 0.096 - - 3.1305 1 289.3 83694 0.1264 119.6 - 3.947 2 257.6 66358 0.1593 94.8 - 4.977 3 229.4 52624 0.2009 75.2 - 6.276 4 204.3 41738 0.2533 59.6 - 7.914 5 181.9 33088 0.3915 47.3 - 9.980 6 162 26244 0.4028 37.5 668 12.58 7 144.3 20822 0.5080 29.7 561 15.87 8 128.5 16512 0.6405 23.6 472 20.01 9 114.4 13087 0.8077 18.7 396 25.23 10 101.9 10384 1.018 14.8 333 31.82 11 90.7 8226 1.284 11.8 280 40.12 12 80.8 6529 1.619 9.33 235 50.59 13 72.0 5184 2.042 7.40 197 63.80 14 64.1 4109 2.575 5.87 166 80.44 15 57.1 3260 3.247 4.65 140 101.4 16 50.8 2581 4.094 3.69 117 127.9 17 45.3 2052 5.163 2.93 98.4 161.3 18 40.3 1624 6.510 2.32 82.9 203.4 19 35.9 1289 8.210 1.84 69.7 256.5 20 32.0 1024 10.35 1.46 58.4 323.4 Diam. Circular Current Fusing Feet per Ohms/1000ft AWG (mils) mils Carrying Current Pound 21 28.5 812 13.05 1.16 - 407.8 22 25.3 640 16.46 .918 41.2 514.12 23 22.6 511 20.76 .728 - 648.4 24 20.1 404 26.17 .577 29.2 817.7 25 17.9 320 33.0 .458 - 1031 26 15.9 253 41.62 .363 20.5 1300 27 14.2 202 52.48 .288 - 1639 28 12.6 159 66.17 .228 14.4 2067 29 11.3 128 83.44 .181 - 2607 30 10.0 100 105.2 .144 10.2 3287 31 8.9 79 132.7 .114 - 4145 32 8.0 64 167.3 .090 - 5227 33 7.1 50.125 211.0 .072 - 6591 34 6.3 39.75 266.0 .057 5.12 8310 35 5.6 31.5 335 .045 4.28 10480 36 5.0 25.0 423 .036 3.62 13210 37 4.45 19.83 533 .028 - 16660 38 3.97 15.7 673 .022 2.5 21010 39 3.5 12.47 848 .018 - 26500 40 3.14 9.89 1070 .014 1.77 33410 41 2.8 7.842 - - 1.52 - 42 2.494 6.219 - - 1.28 - 43 2.221 4.932 - - 1.060 - 44 1.978 3.911 - - 0.916 - 45 1.761 3.102 - - - - 46 1.568 2.460 - - - - 47 1.397 1.951 - - - - 48 1.244 1.547 - - - - 49 1.107 1.227 - - - - 50 0.986 0.973 - - - -

Table of Bare Copper Wire General Notes:

The wire size is different between the American Wire Gage [AWG] and the British standard. The table above only lists the AWG standard.

AWG [American Wire Gauge] may also be called the Brown and Sharpe (B&S) Wire Gauge. [note]

The Birmingham Wire Gauge [BWG] is used for steel armor wire. [other wire gauge standards] Watch for round-off errors, as many numbers were rounded. Use the table as a guide. [Equivalent Cross-Sections of Wire]

The weight [pound per foot] does not include wire insulation. The weight of the wire is critical in some applications. More data [AWG Table for 25C - 65C]

Circular mils is the diameter squared in mils. [Table of AWG sizes in metric] The editor has never seen the American Wire Gauge [AWG]

Current Notes:

The current shown per wire size listed above is based on 1 amp/ 700 Circular mils, other tables provide different current per wire size, and different current for open air ~ check your local electrical code for the correct current capacity [Ampacity]. The 1 amp/ 700 Circular mils seems to be the most conservative, other sites provide/allow for 1 amp per 200 or 300 Circular mil. For shot wire lengths use 1A/200 Circular mil, for longer wire runs use 300 Circular mil, and for very long wire runs use the table above, 1 amp / 700 Circular mil.

The current rating is listed based on permissible voltage drop and not conductor heating.

The ability of a wire to carry a given amount of current is affected by a number of additional factors, which are not accounted for in the AWG table above. The ambient temperature of the surrounding air, wire insulation, and number of other wires bundled together [provided below].

Ampacity relates to the ability of the conductor to carry current [amps] before the cable over heats. I understand there are hundreds of Ampacity tables for many different conditions. The numbers above are but one example. Ampacity Tables for many conditions:

IEEE Standard 835, IEEE Standard Power Cable Ampacity Tables IEEE Standard 848, Procedure for the Determination of the Ampacity Derating of Fire Protected Cables

ICEA P-54-440, NEMA Pub. No. WC 51 - Ampacities of Cables in Open-Top Trays.

The National Electrical Code [NEC] requires their own cable sizing for premises wiring. Refer to the NEC rules to determine building wiring, as this page relates to electronic equipment wiring. For reference, the ampacity of copper wire at 30 0C for common wire sizes

14 AWG may carry a maximum of 20 Amps in free air, or 15 Amps as part of a 3 conductor cable.

12 AWG may carry a maximum of 25 Amps in free air, or 20 Amps as part of a 3 conductor cable.

10 AWG may carry a maximum of 40 Amps in free air, or 30 Amps as part of a 3 conductor cable.

8 AWG may carry a maximum of 70 Amps in free air, or 50 Amps as part of a 3 conductor cable.

The wire fusing [melting] current is based on the material the wire is made of, the diameter of the wire and the melting point of the material. The wire fusing current of a wire is provided in tables as constant current or as [a larger] current for some given amount of time.

I found this formula used on a few different sites [un-verified]; I=Ad (3/2) @ d is in inches, A is a constant: A = 10,244 for Copper. A = 7,585 for Aluminum.

I have listed a number of values for fusing current in the table above, for selected AWG sizes.

Aluminum wire properties are listed under on the Aluminum electrical Wire page

Cable manufacturers will provide different numbers based on the insulation used for the wire. Use the table below to off-set the conservative current carrying numbers in the table above, and the fusing current. The table below lists copper wire with a Teflon [TFE] insulation. Teflon insulation has a higher operation temperature range then other insulators, for example PVC. The table below is based on data derived from MIL-STD-975, using 70 0C as the operating temperature. To derate based on number of wires in a bundle: IBW = ISW x (29 - #wire) / 28 @ [1 to 15 Bundled wires] IBW = ISW x (0.5) @ [more then 15 Bundled wires] ISW = Single wire IBW = Bundled wires To derate by temperature use; derate by 80% at 150 0C, 70% at 135 0C, or 50% at 105 0C (per MIL-STD-975)

Copper Wire TFE Insulated AWG Current Carrying AWG Current Carrying 00 169 0 147 2 108 4 81 6 60 8 44 10 33 12 25 14 19 16 13 18 9.2 20 6.5 22 4.5 24 3.3 26 2.5 28 1.8 30 1.3 - -

Refer to the How to Derate Components page for derating wire with other then Teflon insulation

I have seen one other Military Specification [MIL-STD-xx] for copper wire current capability. That standard [I did not note the standard number] listed AWG 18 [for example] as 10 amps with TFE insulation. That indicates that this additional military specification uses the same data listed in the table above, but may be listed for 25 0C, and not 70 0C as the table uses. So this table above has already been derated for 70 0C.