Jumping Cracker Construction

Before you start – think safety, safety, safety! Ensure that you are wearing all relevant protective equipment (glasses, gloves etc). Consider other peoples safety – do not endanger anyone else. Ensure that you are familiar with everything that you are working with.

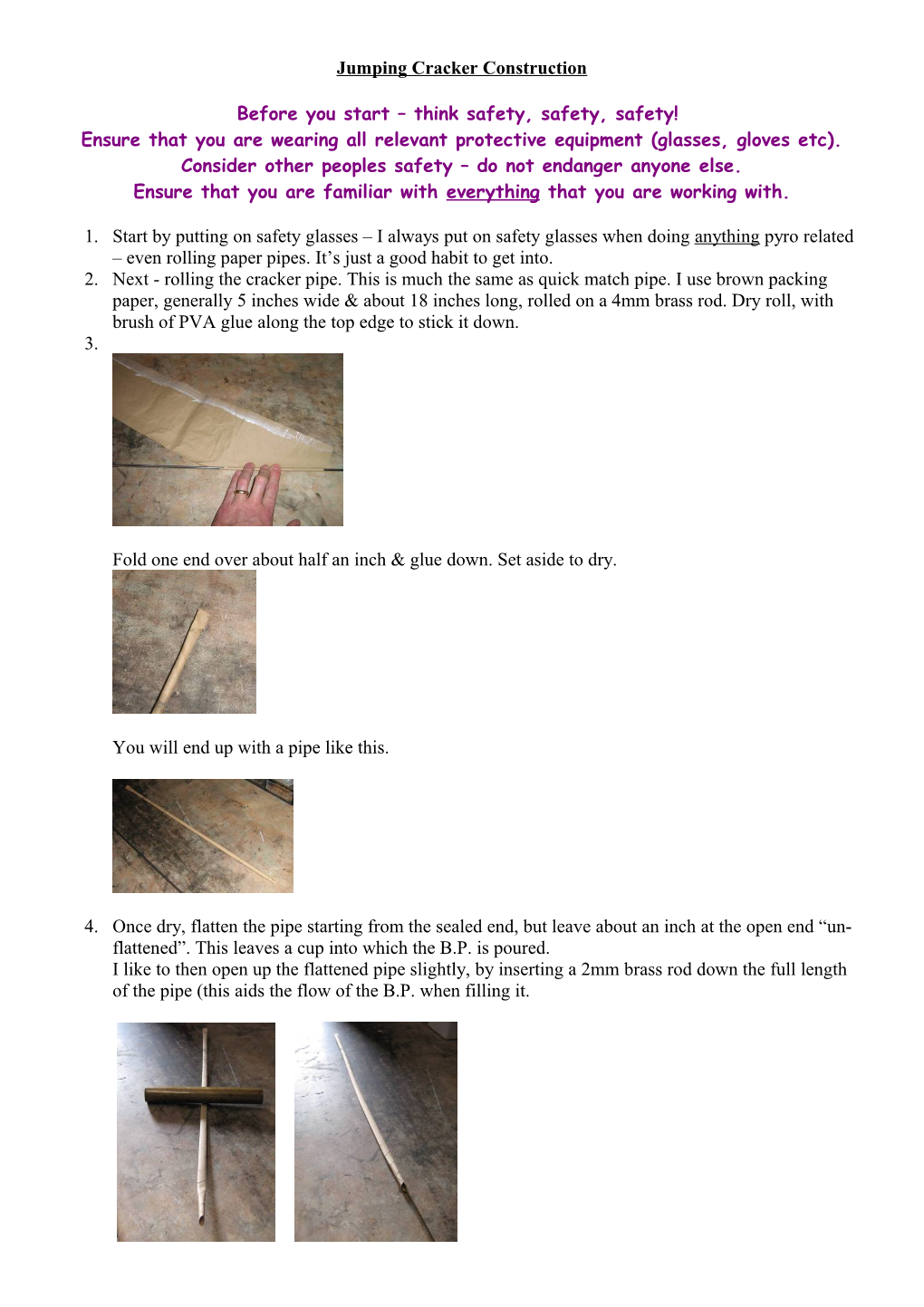

1. Start by putting on safety glasses – I always put on safety glasses when doing anything pyro related – even rolling paper pipes. It’s just a good habit to get into. 2. Next - rolling the cracker pipe. This is much the same as quick match pipe. I use brown packing paper, generally 5 inches wide & about 18 inches long, rolled on a 4mm brass rod. Dry roll, with brush of PVA glue along the top edge to stick it down. 3.

Fold one end over about half an inch & glue down. Set aside to dry.

You will end up with a pipe like this.

4. Once dry, flatten the pipe starting from the sealed end, but leave about an inch at the open end “un- flattened”. This leaves a cup into which the B.P. is poured. I like to then open up the flattened pipe slightly, by inserting a 2mm brass rod down the full length of the pipe (this aids the flow of the B.P. when filling it.

5. Next, pour in fine grain B.P. (fffg) using a small funnel. Tap the pipe to ensure that the B.P. forms a continuous trail to the bottom of the pipe.

6. Now the pipe & B.P. must be crushed. This is to reduce the B.P. to half grain & half powder (if it was all grain it would blow itself out, all powder it would not be quick enough to burst the pipe). Ideally a small slip roll could be used to crush the tube between its rollers, but I hammer the pipe flat, trying to ensure that I do not miss any section of the pipe. I wear nomex gloves for this.

7. The flattened pipe must now be dampened to make it flexible enough to be bent back & forth into its zig zag shape, without splitting. Lay the pipe on a damp cloth or towel. Spritz the pipe with a spray of water to further dampen it, then wrap it in the damp cloth. Leave for at least 30 mins to get thoroughly damp & flexible.

8. Now to bend the pipe into the zig zag shape using the special “jig”. The jig is a piece of wood with a slot cut out of it. The thickness of wood determines how wide the resulting cracker will be.

The cracker works by burning very quickly in the straight sections (acting like quick match) & bursting the pipe. When it gets to the bends, the powder is packed much tighter & so burns slower into the next straight section. This results in the BANG, pause BANG etc. Generally the longer the straight section the louder the bang – BUT, the longer the straight section, the more prone they are to blowing themselves out! I generally use a jig about ½ inch wide. Take the pipe & place the closed end into the special jig, with the open end towards you.

Now place the first wire or thin dowel on top of the pipe & bend the pipe back over it & back through the jig, away from you.

Place another dowel on top of the pipe & bend it over the top of it back towards you & so on until the pipe is used up. Keep the pipe taught at all times & compress the whole zig zag down when complete.

9. Lift the pipe, including the rods out of the jig. Let the dowels fall loose.

Now wrap the cracker tightly with cotton, twice along its length, then back & forth in & out of the folds to secure its shape. Leave to dry for a day or two.

10. When dry, cut the pipe flush, exposing the powder & wrap the end with blue touch paper.

11. Take to a suitable open space, light the touch paper, retire & enjoy!!