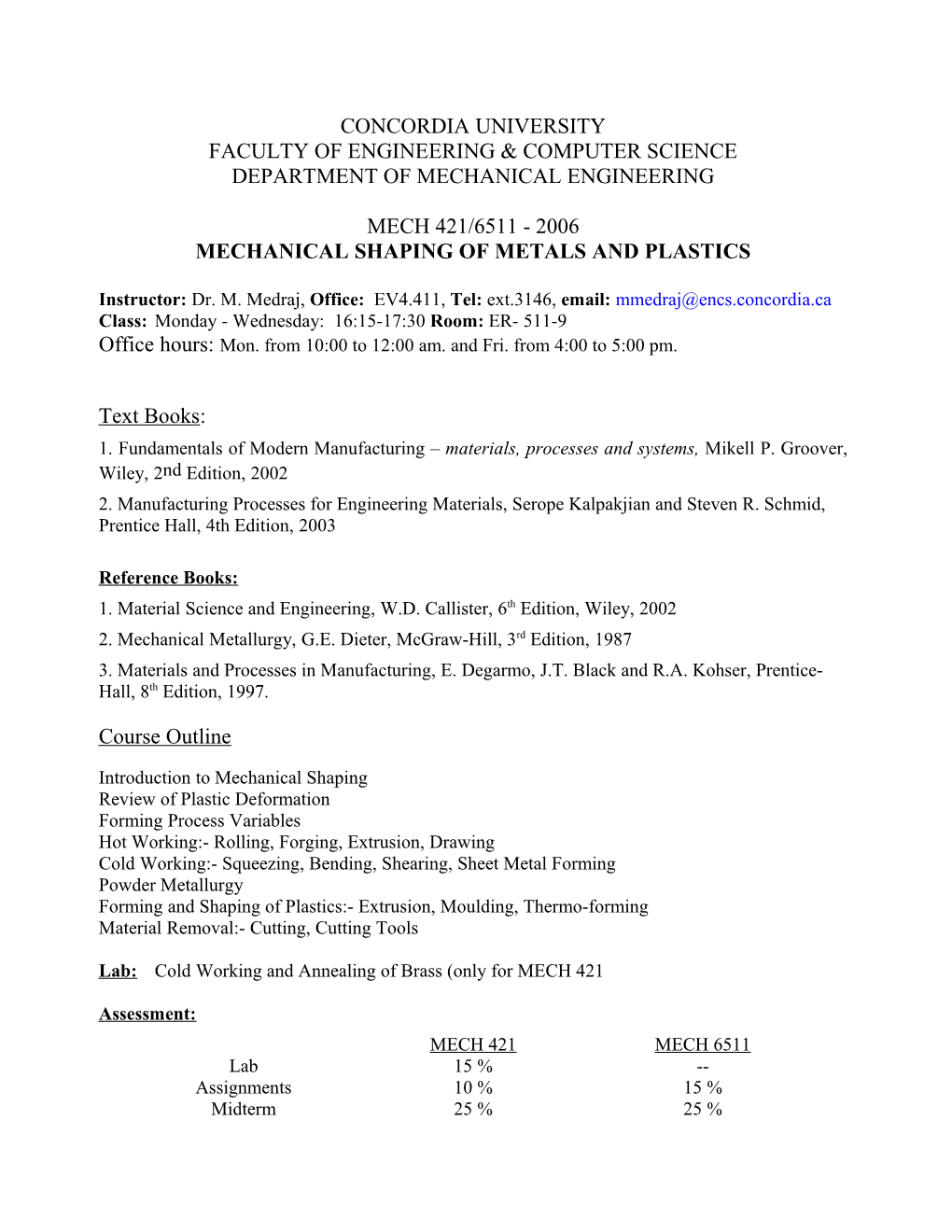

CONCORDIA UNIVERSITY FACULTY OF ENGINEERING & COMPUTER SCIENCE DEPARTMENT OF MECHANICAL ENGINEERING

MECH 421/6511 - 2006 MECHANICAL SHAPING OF METALS AND PLASTICS

Instructor: Dr. M. Medraj, Office: EV4.411, Tel: ext.3146, email: [email protected] Class: Monday - Wednesday: 16:15-17:30 Room: ER- 511-9 Office hours: Mon. from 10:00 to 12:00 am. and Fri. from 4:00 to 5:00 pm.

Text Books: 1. Fundamentals of Modern Manufacturing – materials, processes and systems, Mikell P. Groover, Wiley, 2nd Edition, 2002 2. Manufacturing Processes for Engineering Materials, Serope Kalpakjian and Steven R. Schmid, Prentice Hall, 4th Edition, 2003

Reference Books: 1. Material Science and Engineering, W.D. Callister, 6th Edition, Wiley, 2002 2. Mechanical Metallurgy, G.E. Dieter, McGraw-Hill, 3rd Edition, 1987 3. Materials and Processes in Manufacturing, E. Degarmo, J.T. Black and R.A. Kohser, Prentice- Hall, 8th Edition, 1997.

Course Outline

Introduction to Mechanical Shaping Review of Plastic Deformation Forming Process Variables Hot Working:- Rolling, Forging, Extrusion, Drawing Cold Working:- Squeezing, Bending, Shearing, Sheet Metal Forming Powder Metallurgy Forming and Shaping of Plastics:- Extrusion, Moulding, Thermo-forming Material Removal:- Cutting, Cutting Tools

Lab: Cold Working and Annealing of Brass (only for MECH 421

Assessment: MECH 421 MECH 6511 Lab 15 % -- Assignments 10 % 15 % Midterm 25 % 25 % Final 50 % 60 % MECH 421/6511

Learning Outcomes:

This is a course aimed at Mechanical Engineering Students who will need to know how components (whether big or small, simple or complex) are made and the effect that this shaping has on the properties of the material. A car door, a wing spar, a cell phone casing are all made from materials and must all be shaped in some way. How this shaping is carried out affects many factors; the cost, the complexity available, the mechanical properties such as strength and ductility and other less obvious properties such as corrosion resistance and toughness. Any engineer who is designing components need to know not just how to make things but the effect that this has on the final product.

By the end of this course, you should have: an understanding of the main processes by which metals and plastics can be formed; an understanding of the effect these processes have on material properties.

This course should be seen as part of the whole process of Design and Production in that the shaping of a component will influence the designs possible, the mechanics of the system, the ease of manufacture and finally the performance of the product. Note: This course does not cover welding and casting of metals as these topics are covered in Mech 423.

Laboratory: (only for MECH 421 students)

There is a laboratory component to this course, namely; the cold working and annealing of brass. The aim of this lab is to illustrate the effects of cold working processes such as rolling on the mechanical properties of metals and then how these effects may or may not be reversed.