Pave-IR.moba

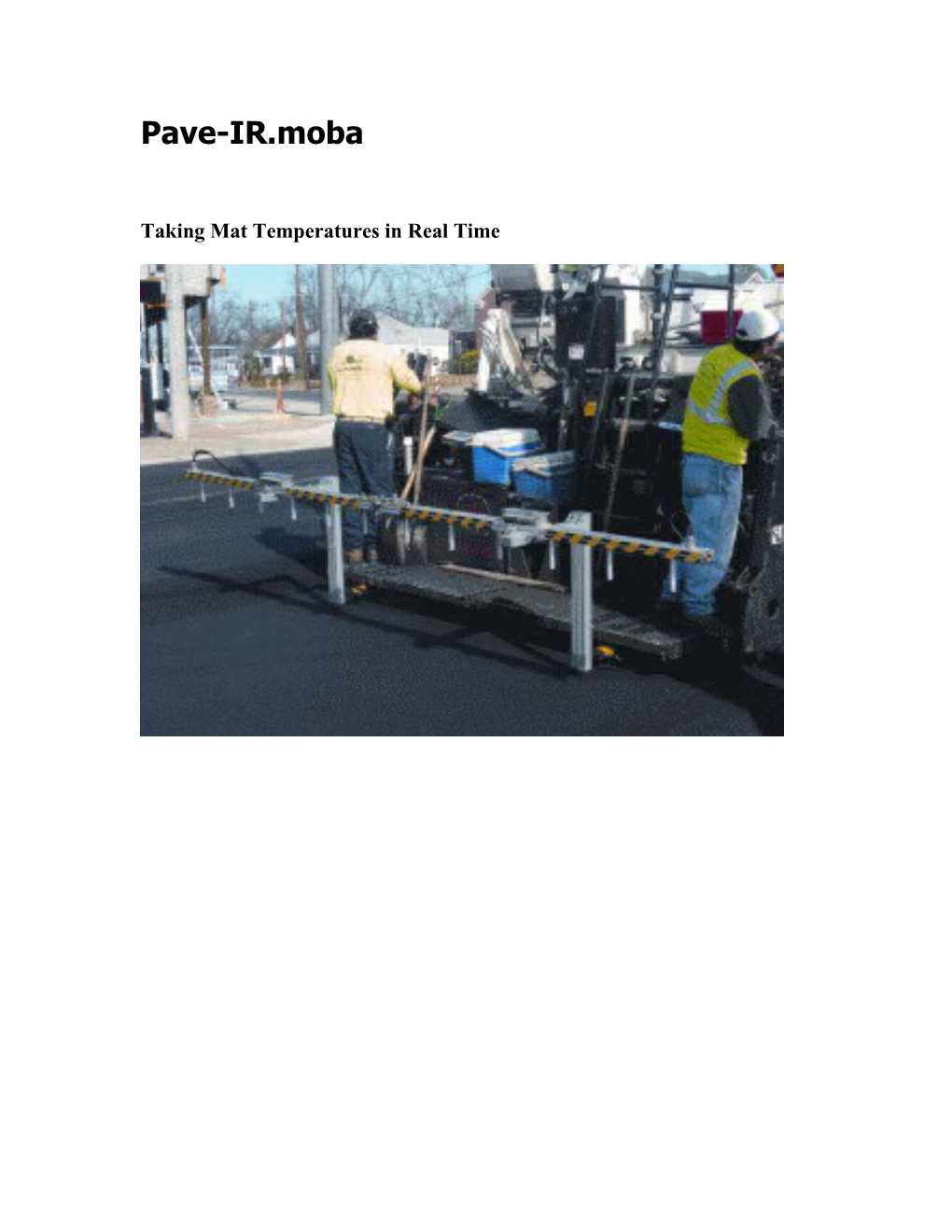

Taking Mat Temperatures in Real Time This Pave-IR bar has 12 infrared thermometers attached to take temperatures across the

mat. The MOBA system shows real-time mat temperature data as well as a detailed, color- coded thermal profile, foot by foot, of your asphalt mat.

The Pave-IR bar provides some beneficial feedback. "It's a management tool and a self- improvement tool for the crew," says Gene Smith, an owner of Smith & Co.

"This system forces you to do your job better - to place a better product on the road. We've got one of them, and we're thinking about buying another one," says David Morton, quality control manager with APAC's Texas Bitulithic Division in Dallas. "You can't hide from it." Morton is talking about the Pave-IR system from MOBA Corp. The system detects thermal segregation in the asphalt mat - in real time - and records a thermal profile.

Pave-IR's basic components are a bar mounted across the rear of a paver with 12 or more infrared thermometers attached, a computer, a distance encoder, and a GPS antenna. The infrared thermometers measure mat temperature at 2- to 6-inch intervals as the paver moves along. The computer records those temperatures and matches them to distance measurements taken by the distance encoder and attaches a GPS location to each of them.

In addition to displaying real-time mat temperature data on the computer screen for the operator or QC manager, the system can provide a detailed, color-coded thermal profile, foot by foot, of your asphalt mat. The profile is stored in a memory stick and can be printed out or emailed to the office for review. Reports can be performed to show tabular details of temperatures and paver stops. Thermal segregation is definitely visible by colors shown in the profile.

Spec'd in Texas

The Texas Department of Transportation thinks so highly of the system that TxDOT has written it into a specification that incentivizes contractors to use it. Early on, TxDOT was concerned that contractors would fear the system would be used to shut down their operations. Instead, TxDOT is encouraging the use of the system, and believes its use will spread nationwide

Texas specifications do not require contractors to use the Pave-IR system, but if they do, they can pave at temperatures down to 32° F. if they can show the absence of thermal segregation. Without the Pave-IR system, contractors typically have to wait for ambient temperatures of 50°, 60° or 70° before paving.

When not using the Pave-IR system, TxDOT required a density profile to be performed with either a nuclear gauge or an impedance gauge, says Dale Rand, Director of the Flexible Pavements Branch, Construction Division, TxDOT. Density profiles are required every time the paver stops - a minimum of once per sub-lot and anytime the inspector detects thermal segregation.

"Under our new specifications, the contractor (who has a Pave IR system) does not have to run any density profiles," says Rand. "Our standard specification says if they have severe thermal segregation, they automatically waive their production and placement bonus payments . Now, that does not happen if they use the Pave IR bar.

"So they don't risk automatically waiving their bonus for having segregation or failing a density profile," says Rand. "If a contractor using the Pave IR bar has recurring severe thermal segregation, he must take corrective action. If that fails, the state may suspend operations. (Texas defines moderate segregation as temperature differences of between 25° and 50°. Severe thermal segregation is for differences of more than 50°.) "If a contractor is not using the Pave-IR bar, and has severe segregation detected by an infrared temperature gun, they automatically waive bonuses," says Rand. "They have to run a density profile, and if that fails also, the pavement is subject to removal and replacement at the engineer's discretion." previous 1 2 3 4 5 next Click here for copyright permissions! Copyright 2010 Cygnus Business Media

Taking Mat Temperatures in Real Time

This Pave-IR bar has 12 infrared thermometers attached to take temperatures across the mat.

The MOBA system shows real-time mat temperature data as well as a detailed, color- coded thermal profile, foot by foot, of your asphalt mat.

"Opened up our eyes"

APAC's Morton says they used the system on three projects: one county road and two state jobs . One project was FM 1389 in Kaufman County, near Dallas. The contractor paved with a Cedarapids paver fed by a Roadtec Shuttle Buggy.

"Our temperatures were pretty good, but it opened up our eyes as to how many times the paver stopped," says Morton. "We had no idea we were stopping that much. The print-out showed us where the paver stopped and for how many minutes.

"It also showed us the screed heater's impact," says Morton. "At one point the paver was stopped for 20 minutes, and the screed heater was left on. So the profile showed us an over-heated area of the mat. The screed heater is supposed to cycle off and on. When you're moving it's not a problem but when you sit there it will overheat the mat."

Value of transfer vehicles

Rand, Morton, and other contractors say the Pave-IR bar definitely points up the value of using a material transfer vehicle to avoid temperature segregation. "On one job we used tandem trucks and no Shuttle Buggy," says Morton. "Every time the paver stopped to change trucks, the thermal profile would show a temperature variation. We have definitely seen that difference - but even with a Shuttle Buggy you can screw it up.

"We're using it as a training tool for ourselves," Morton continues. "Crews can slow the paver down. And they can try to space out trucks so that the paver does not stop. This system really slowed our crews down instead of running and gunning." previous 1 2 3 4 5 next Click here for copyright permissions! Copyright 2010 Cygnus Business Media

Morton says if he starts to see the paver waiting for asphalt because there aren't enough trucks, he can use the temperature profile to approach management and prove his case. "Now we have proof showing that we have issues," he says. "We usually email our results for each day to the office."

Another division of APAC in Texas, the Trotti & Thomson Division, used the Pave-IR system to help with resurfacing U.S. 96 in Jasper County. The company bought the system and began using it in December 2009.

The Jasper County project entailed placing a 1-inch lift of crack attenuating mixture (CAM) and a 1.5-inch lift of stone matrix asphalt (SMA). The paver was a Roadtec RP190 and the contractor used a Roadtec SB 2500 Shuttle Buggy as a transfer vehicle for the SMA only.

"Here's what we discovered with the first use of the Pave-IR bar," says Kal A. Kincaid, president of the Trotti & Thomson Division:

The material transfer vehicle greatly improved segregation profiles in the cold weather project. Plant production and trucking need to be balanced with the placing rate, as with all good paving operations. Trucks sitting in line to dump do cool off and contribute to thermal segregation problems, as shown with the Pave-IR bar in detail. If there is an overlap of a paver extension with the main screed, the dual screed heating action does overheat mix in the overlap area. That will be shown clearly on the profiles.

Colder weather

Kincaid said one reason he bought the Pave-IR bar was that it permitted crews to begin paving in colder weather. "We realized the enormous amount of detailed temperature readings available to us with this equipment," he said. "That information allowed us to develop some techniques to improve our paving practices. previous 1 2 3 4 5 next

"The CAM was placed without an MTV, but with the SMA we did use the transfer vehicle," says Kincaid. "With the CAM and no MTV we were able to see a higher degree of segregation; then we used the MTV and we could see that the temperatures were more uniform. "We have crews that have sound paving practices," says Kincaid. "A lot of our problems were worked out before we bought the Pave-IR bar, but it showed us how we could get better."

Gene Smith, an owner of Smith & Co., Conroe, TX, says he likes the real-time feedback of mat temperatures that the Pave-IR bar provides. "That's probably the single most important reason we bought it," he says. "Plus, the new Texas spec allows us to eliminate some of the QC work. Now we don't have to do reports with the hand-held infrared sensor.

"I think this device provides some beneficial feedback," Smith says. "Some people said our crew would resist it because it shows where they stopped. In our case that's not a problem. But if the paver stops you know where it stopped and why. It's a management tool and a self-improvement tool for the crew."

James Lano, sales manager for MOBA, says the company has been contacted by a number of contractors across North America who are interested in improving their paving operations this season. And MOBA is working on integrating a number of new quality control tools into the Pave-IR system. An example is a pre-compacted smoothness measurement.

"By providing asphalt contractors these types of tools, the benefits will include larger placement bonuses for the contractors and longer-lasting roads for the public," says Lano. previous 1 2 3 4 5

The Pave-IR bar provides some beneficial feedback. "It's a management tool and a self- improvement tool for the crew," says Gene Smith, an owner of Smith & Co. This Pave-IR bar has 12 infrared thermometers attached to take temperatures across the mat.

The MOBA system shows real-time mat temperature data as well as a detailed, color- coded thermal profile, foot by foot, of your asphalt mat.