FORMING BENCHMARK ─ FORMING OF A DOUBLE DOME (version: October 15, 2004) Benchmark Forum Website: http://www.gtwebsolutions.com/nwbenchmark/index.php Materials Testing Results Website: http://www.mech.northwestern.edu/ampl/benchmark/

The objective of this study is to benchmark the prediction capability of various software and users as applied to the forming of a double dome. This double-dome benchmark geometry is provided by Ford Motor Company (Dearborn, Michigan, U.S.A.) Measurements of fiber orientation, forming force, and final shape will be compared to predictions generated by process simulation models.

MATERIALS Commingled glass/polypropylene (PP) fabric materials have been provided by Saint-Gobain Vetrotex America, Inc. (Ft Worth, TX, U.S.A.). There are three fabrics used in this benchmark, i.e., balanced plain weave, balanced twill weave, and unbalanced twill weave. Rectangular blanks (540 mm x 380 mm) were cut from these fabrics for stamping. The fabric properties and their shear/tensile behaviors have been measured and tested by several groups. Results of material testing can be found at: http://www.mech.northwestern.edu/ampl/benchmark/ .

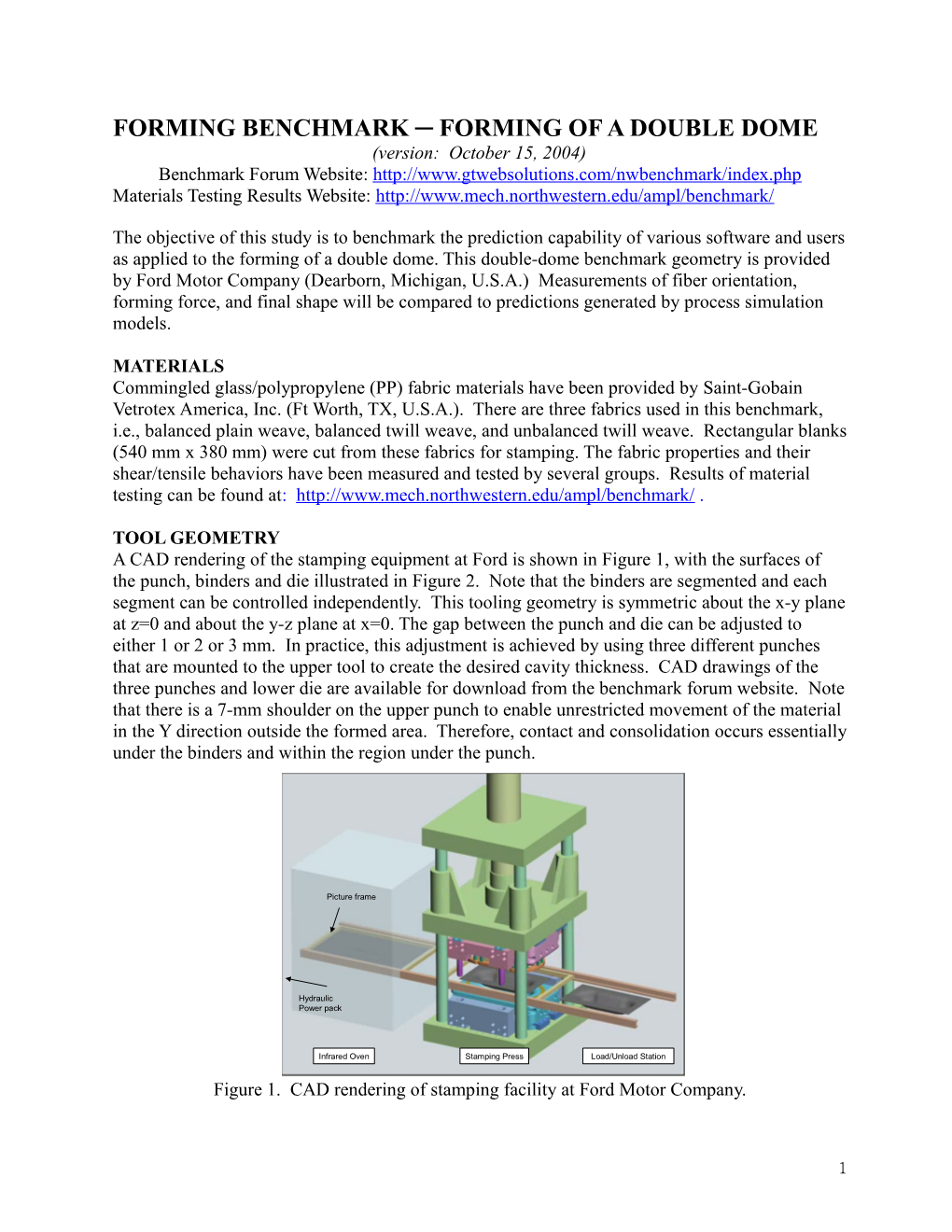

TOOL GEOMETRY A CAD rendering of the stamping equipment at Ford is shown in Figure 1, with the surfaces of the punch, binders and die illustrated in Figure 2. Note that the binders are segmented and each segment can be controlled independently. This tooling geometry is symmetric about the x-y plane at z=0 and about the y-z plane at x=0. The gap between the punch and die can be adjusted to either 1 or 2 or 3 mm. In practice, this adjustment is achieved by using three different punches that are mounted to the upper tool to create the desired cavity thickness. CAD drawings of the three punches and lower die are available for download from the benchmark forum website. Note that there is a 7-mm shoulder on the upper punch to enable unrestricted movement of the material in the Y direction outside the formed area. Therefore, contact and consolidation occurs essentially under the binders and within the region under the punch.

Picture frame

Hydraulic Power pack

Infrared Oven Stamping Press Load/Unload Station

Figure 1. CAD rendering of stamping facility at Ford Motor Company.

1 Upper punch

Binder segments

Material blank

Lower die

Figure 2. Surface rendering of stamping model.

PROCESS CONDITIONS

Heating Figure 3 shows the infrared heating station used in this benchmark exercise. There are 12 heating zones in this oven, six on the upper and six on the lower surfaces (Figure 3). Figure 4 shows the placement of the thermocouples, which were used to record temperatures on the blank from the preheat stage through the end of the forming stage. Sample temperature histories for one of the preheating trials are shown in Figure 5. A complete data set for these trials is available for download from the forum website.

Figure 3. Zone configuration of infrared oven used in benchmark study.

2 in in Table 1. oftheglass/PP used three stamp blanks to punch parameters and process The shown are weaves Forming Figure 5. Sample temperature histories for blank pre-heating trials ofthe trials 22-oz material. forblank pre-heating histories Figure temperature 5.Sample Pack Power Hydraulic

Temperature (C) 100 150 200 250 50 0 0 Figure 4. stamping study. forpre-heatingand locations Thermocouple Preheat Study:Double-Layer 22oz PP at 200C - Trial 1 TC 9, 12, 27 12, 9, TC 24 15, 6, TC 21 18, 3, TC 70 Heating 50 270 100 470 TC 8, 11, 26 11, 8, TC 23 14, 5, TC 20 17, 2 TC 540 Dwell 150 Tim e (s) e Tim TC 7, 10, 25 10, 7, TC 22 13, 4, TC 19 16, 1, TC 200 250 Mid Plane (where appropriate):19-27 TCs Bottom Surface: 10-18 TCs Top Surface:1-9 TCs 70 300 190 310

350 380 Press Stamping ) C ) ( 7 C ( 2 ) 6 C C 2 ) ( T 5 C C ( 2 ) T 4 C C ( 2 ) T 3 C C ( 2 T ) 2 C C 2 ) T ( 1 C C ( 2 T ) 0 C C 2 T ( ) C 9 C 1 T ( ) C 8 1 T C ) ( C 7 C 1 T ( ) C 6 1 T C ) ( C 5 C 1 T ( ) C 4 C 1 T ( ) C 3 C 1 T ( C ) 2 1 T ) C C ( 1 C 1 T ( ) C 0 1 T C ( ) C 9 T C ( C ) 8 T C ) C ( 7 T C ( C ) 6 T C ) C ( 5 T C ( ) C 4 C T ( ) C 3 T C ( C ) 2 T C C ( 1 T C T 3 Table 1. Process parameters used for benchmark study. Final cavity thickness 1, 2 or 3 mm Total punch displacement 183.9 mm Punch acceleration 111.1 mm/s2 Acceleration time 1500 ms Maximum punch velocity 166.6 mm/s Punch contacts fabric at y 113mm Deceleration -5555.55 mm/s2 Deceleration time 30 ms Mold Temperature 80 oC Binder force 300N/ segment (6 segments in total)

Figure 6 shows a sample calibration curve obtained for the binder force measurements for each of the six segments. Typical velocity and acceleration profiles for the punch are provided in Figure 7. Because the midplane of the fabric holder is just slightly above the surface on the die, it should be assumed that without sag, contact of the punch with the blank occurs at a displacement of 113mm.

350 Segment 1 Segment 2 300 Segment 3 Segment 4 Segment 5 250 Segment 6 )

N 200 (

e c

r 5 o 150

F 3 4 Top view of 100 binder segments

2 1 50 6 Hydraulics Load Station 0 0 500 1000 1500 2000 2500 3000 Time (ms) Figure 6. Binder force calibration measurements recorded prior to stamping trials.

4 200

180

160

) 140 m m (

120 t n e 100 m e c

a 80 l p s i 60 D

40

20

0 0 500 1000 1500 2000 Time (ms)

Figure 7. Punch displacement vs. time

FILES FOR SIMULATION

IGES Files: The provided surfaces are only the binder, die and punch surfaces. Three CAD files are available for the upper punch, one for each cavity thickness. A single CAD file is provided detailing the lower die and position of the binder segments. All data can be downloaded from the benchmark forum website: http://www.gtwebsolutions.com/nwbenchmark/index.php

Material Property Files: As noted from http://www.mech.northwestern.edu/ampl/benchmark/, material property variations have been reported by various groups. For the purpose of the first stage of the simulation benchmark, a set of material data has been collected to represent the shearing and tensile behavior of these three fabrics. This “standard material data set” is available on the benchmark forum website. Participants are required to use this standard set in reporting numerical findings for the benchmark activity. Extra efforts in utilizing all the knowledge obtained from the Phase I experimental benchmark (i.e., materials testing) are welcome, but not required.

TEST CASES FOR STAGE I OF THE SIMULATION BENCHMARK

For the first stage of the simulation benchmark, six cases are to be simulated, as indicated in Table

5 2. Note that participants in the simulation effort are not required to run all six cases, but are requested to obtain and report results in the order shown in Table 2.

Table 2. Test Cases for Stage I Simulation Effort Numbe Fabric Case Material r of Cavity Heating Set Binder Layers Point Temp 1 Balanced PW 2 1 mm 200oC Full (all 6) 2 Balanced PW 2 1 mm 200oC None 3 Balanced TW 1 1 mm 200oC Full (all 6) 4 Balanced TW 1 1 mm 200oC None 5 Unbalanced TW 1 1 mm 200oC Full (all 6) 6 Unbalanced TW 1 1 mm 200oC None

Plain Weave (PW) Twill Weave (TW)

BENCHMARK REPORT

All results are to be reported by filling in the Benchmark Report Template File Report.xls (available on the forum website) and emailed to Professor Julie Chen at [email protected].

When entering the data in the requested cells of the Excel spreadsheet, it is critical that the worksheets not be renamed and the cells not be relocated or otherwise altered since the Benchmark Analysis Committee will rely on this fixed format for efficient data analysis, graphing, and other processing. Furthermore, although the participants may want to create graphs of their results or do their own analysis in other cells of the Excel spreadsheet for their own purposes, these graphs or other additions to the spreadsheet must be deleted before submitting the file. It is recommended that participants use a separate copy of the spreadsheet file for their own analysis to avoid accidental modification of the Report File. Any files not following these instructions will be returned for correction.

The due date for benchmark submission is listed on the benchmark forum. The following information is requested for each material on the appropriate worksheet:

1. Blank draw-in (mm) after forming (see Figure 8). Report all values in positive numbers. Data values per test case: 12 (1 layer) or 24 (2 layers). 2. Punch force history (in N). Total punch force vs. punch displacement. Distributions/test case: 1. 3. Fiber positions after forming (see Figure 8). Report the final deformed position of those fibers marked in red in Fig. 8, starting from point A to point B. Exact coordinates from the CAD file are provided on the forum website. Distributions/test case: 4.

6 Dx1 Dx7 A Dz8 Dz7 Dz1

Dx6 Dx2

A B

Dx3 Dx5 Dz4 Dz3 B Dz5

7