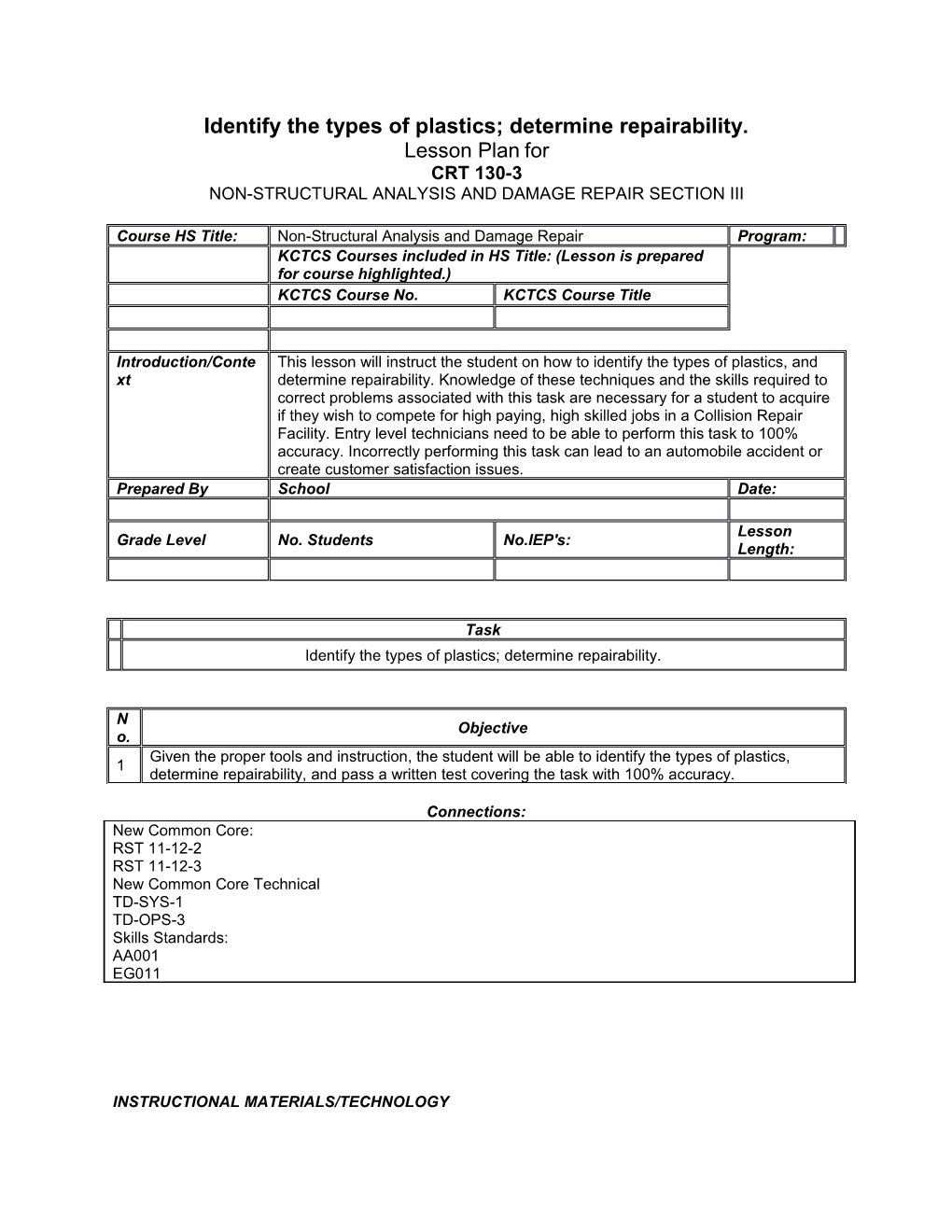

Identify the types of plastics; determine repairability. Lesson Plan for CRT 130-3 NON-STRUCTURAL ANALYSIS AND DAMAGE REPAIR SECTION III

Course HS Title: Non-Structural Analysis and Damage Repair Program: KCTCS Courses included in HS Title: (Lesson is prepared for course highlighted.) KCTCS Course No. KCTCS Course Title

Introduction/Conte This lesson will instruct the student on how to identify the types of plastics, and xt determine repairability. Knowledge of these techniques and the skills required to correct problems associated with this task are necessary for a student to acquire if they wish to compete for high paying, high skilled jobs in a Collision Repair Facility. Entry level technicians need to be able to perform this task to 100% accuracy. Incorrectly performing this task can lead to an automobile accident or create customer satisfaction issues. Prepared By School Date:

Lesson Grade Level No. Students No.IEP's: Length:

Task Identify the types of plastics; determine repairability.

N Objective o. Given the proper tools and instruction, the student will be able to identify the types of plastics, 1 determine repairability, and pass a written test covering the task with 100% accuracy.

Connections: New Common Core: RST 11-12-2 RST 11-12-3 New Common Core Technical TD-SYS-1 TD-OPS-3 Skills Standards: AA001 EG011

INSTRUCTIONAL MATERIALS/TECHNOLOGY Teacher Designed Materials and Other Handouts

Textbooks and Workbooks Autho Editio Publishe Page Title/ISBN No. r n r s Variou ASE Test Prep Non Structural Analysis and Damage Repair Third Delmar 34-35 s

Equipment Quantity Item Source As Needed Plastic Welder Various

Content/Presentation/Demonstration Outline Teach students that there are two general types of plastics are used in automotive construction: thermoplastics and thermosetting plastics. Explain that Thermoplastics can be repeatedly softened and reshaped by heating, with no change in their chemical makeup. They soften when heated and harden when cooled. Thermoplastics are also weldable with a plastic welder. Tell students that Thermosetting plastics undergo a chemical change by the action of heating, a catalyst, or ultraviolet light. They are hardened into a permanent shape that cannot be altered by reapplying heat or catalysts. Let them know that Thermosets are not weldable but can be repaired with flexible part repair materials. Inform students that composite plastics, or hybrids, are blends of different plastics and other ingredients designed to achieve specific performance characteristics. Instruct students that a good example of the change in unibody vehicles centers around the use of fiber- reinforced composite plastic panels, commonly known as sheet-molded compounds (SMC). Tell them that the reason for using an SMC is simple: It is light, corrosion proof, dent resistant, and relatively easy to repair compared to the more traditional materials. Let students know that the use of SMC and other fiber-reinforced plastics (FRP) is not new, and that they have been used in various applications on automobiles for years. The use of large external body panels of reinforced plastic is not unusual either. Tell students that what is new is that, unlike the external panels on earlier vehicles, these panels now are bonded to a metal space-frame using structural adhesives, thus adding overall structural rigidity to the vehicle. Instruct students that there are several ways to identify an unknown plastic. One way is by international symbols, or ISO codes, which are molded into plastic parts. Many manufacturers are using these symbols. Let them know that the symbol or abbreviation is formed in an oval on the back of the part. Tell them that one problem is that they will usually have to remove the part to read the symbol. If the body part is not identified by a symbol, the body repair manual will give information about plastic types used on the vehicle. Let them know that body manuals often name the types of plastic used in a particular application. Another way to identify plastics is the burn test, but it is no longer recommended for identifying plastics. Explain that the burn test involves using a flame and the resulting smoke to determine the type of plastic. The reason it is no longer recommended is, first, an open flame in a collision repair shop creates a potential fire hazard, Secondly, it is environmentally unsound. Finally, tell them the burn test is not always reliable, Many parts are now being manufactured from composite plastics that use more than one ingredient. A burn test is of no help in such cases. Instruct students that a reliable means of identifying an unknown plastic is to make a trial-and-error weld on a hidden or damaged area of the part. Tell them to try several different filler rods until one sticks. Let them know that most suppliers offer only a few types of plastic filler rods. The range of possibilities is not that great and the rods are color coded. Tell them that once they find a rod that works, the base material is identified.

Applications/Practice 1 Refer to content

Evaluation and feedback Prior to Testing or Lab Work Objective 1. / Formative assessment / Instructor will observe students as they practice the procedure to assure correct procedure and safety practices are being followed. A checklist will be utilized to chart 1 student progress on the task. Questioning techniques will be utilized as necessary to demonstrate student comprehension / Adaptations and/or accommodations for special needs students will be added if required.

STUDENT ASSESSMENT: (Assess student progress with performance criteria.) Objective 1 / Summative assessment / written test questions on stated objective / adaptation and / or 1 accommodations for special needs students will be added if required

IMPACT--Reflection/Analysis of Teaching and Learning: (How did students’ progress in relation to the state objectives? Was the instruction successful? Analyze samples of student work particularly that which is unsatisfactory, for the purpose of planning further instruction.)

REFINEMENT--Lesson Extension and Follow-up: (To be filled in as the lesson is modified during initial planning and/or during the teaching learning process.)