Design Review

April 17, 2009 Team Members: Snehapriya Rao Edward Budriss Edward Wolf Alex Scarangella Anna Cheung

Faculty Guide: Dr. Margaret Bailey Table of Contents

ANSYS Models...... 3

Cooling Loop Calculations & Specifications...... 9

Installation/ Test Cell...... 12

Final List of Sensors...... 17

Sensor Installation...... 18

Test Plan – Usability Testing...... 22

Prior to First Run...... 23

Miscellaneous Room Preparations...... 25

During First Run...... 25

Removal and Re-install of Parts...... 27

Vibrations Lab...... 28

Thermo Fluids Lab...... 30

Safety Document...... 32

Bill of Materials...... 41

Scope of Supply...... 42 ANSYS Models

Test Cell The test cell and surrounding rooms were modeled using SolidWorks. Dimensions of the test cell and surrounding rooms were calculated using an AutoCAD file of building 9, provided by Facilities Management. This model was then imported into ANSYS to perform structural and modal analysis. The model was constrained at the top of the walls as well as basement walls. Using the built in ANSYS material list, the building was defined to be construction grade concrete. The weight of the compressor was then applied over the footprint of the skid on which it sits. The mesh was refined several times in the areas of concern to make sure the model was accurately capturing true deformation and stress values. After two iterations both stress and deformation plateau at values shown. Results as followed:

Figure 1: Deformation due to static load of compressor (top view) (MAX = .00402in) Initial testing of the static load showed that there was a larger then acceptable stress and deflection in the supporting surface. Working with our senior design team’s PE it was recommended that two I-beams be inserted under the final location of the compressor.

Figure 2: Excerpt from PE report I-beams were then modeled in solid works to the specifications laid out in the PE’s report. The material was defined as structural steel and imported into ANSYS. The I-beams were constrained as shown above and static loading simulations were recompiled.

Figure 3: Deformation due to static load of compressor with I-beams under skid extremes

With the addition of the two I-beams the deflection of the floor decreased dramatically to below one thousandth of an inch. To determine if there could be any improvements by moving the I-beams more centrally towards the highest deflection and stress areas, the ANSYS models were rerun with the beams moving inwardly in steps of one-foot increments. Results as follows:

Figure 4: Deformation due to static load of compressor, I-beams inboard 1 foot Figure 5: Deformation due to static load of compressor, I-beams inboard 2 feet

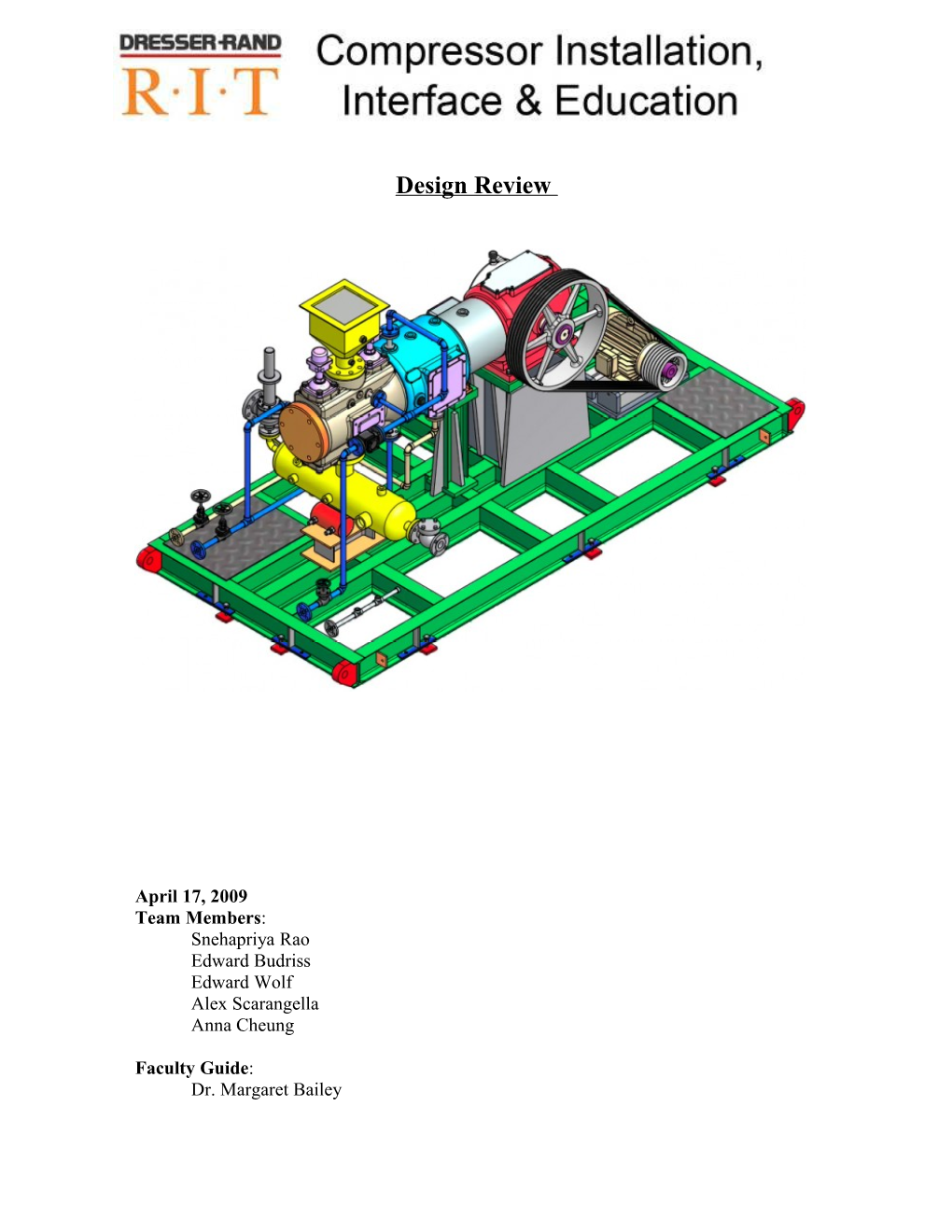

Figure 6: Deformation due to static load of compressor, I-beams inboard 3 feet Compressor Skid Using the documents provided by Dresser Rand, the skid was modeled in SolidWorks and then imported into ANSYS. The skid was constructed from the material IS 2062. The skid’s I-beams are of the type ISBM 150. For purposes of analysis, the skid was constrained at each of its mounting locations, ten in total. The forces due to reciprocation were then applied to the model at compressor mounting locations. The mesh was refined several times in the areas of concern to ensure the model was accurately capturing true deformation and stress values. It was refined again after three iterations; all plateau values are stated. Results as followed:

Figure 7: Total deformation of skid due to moment created by primary forces (MAX=.0054464 inch) Figure 8: Stress due to forces generated from compressor.

Yield strength for material of skid (IS 2062) is 36,259psi providing a factor of safety present in the skid of 4.56. Cooling Loop Calculations & Specifications Some of the heat of compression is transferred through the cylinder wall into four water jacket channels. Each of these channels are identical. For the theoretical analysis of this transfer, these channels were approximated as being round. The exact dimensions of theses channels and other relevant geometries are unknown so approximate values were used and may be changed as more precise information becomes available. The following is a list of assumed dimensions and other parameters.

delta t in compressor 116.6667 K Cyl. wall thickness 0.5 inch jacket width 2 inch circum 21.9911 inch number of jackets 2 # K steel 43 W/m*K K water 0.58 W/m*K Water flow 150 GPH Density of water 999.8395 kg/m^3 assumed hydraulic D 1.1284 in Mass flow rate 0.1577 kg/s Viscosity of water 0.0003 Pa*s Cp water 4181.3 KJ/Kg-K Relevant Parameters

Heat transfer (conduction + convection)

Nu .023Re 0.8 Pr .4 Heating fluid in round channel

m˙ D Re H Reynolds number equation A

Heat transfer coefficient Results: Re 5560.1048 # prandtl number water 7.0000 # nusselt number 49.6402 # h forced convection 57.5826 BTU/ft^2*hr*F Q 234.2986 W Q*4 channels 937.1943 3198.6441 W BTU/Hr delta t of water 8.731621881 oF

From these results we are able to find a heat exchanger that will be able to handle the required thermal load. The following components are suggested to make up the cooling system.

Pump: Shurflo Industrial Pump — 198 GPH, 115 Volt, 1/2in., Model# 2088-594-154 http://www.northerntool.com/webapp/wcs/stores/servlet/product_6970_200249074_20024 9074 Heat exchanger: Brazed Flat Plate Heat Exchanger, Model LA14-10 3/4 NPT inch connection - 8 long by 3 1/4 wide by 2 1/4 inches http://www.houseneeds.com/shop/HeatingProducts/HydronicHeating/heatexchangers/misc heatexchangers/heatexchangerbuyage.asp

Coolant Tank: 5 Gallon Flat Bottom Poly Storage Tank, 22" L x 10" W x 8" H http://www.plastic-mart.com/class.php?item=2465

Heater: Screw Plug Immersion Heater, 400W, 5/8" diameter, 1/2 NPT Model # EMH-060-120V http://www.omega.com/ppt/pptsc.asp?ref=EMH_Heater&Nav=heaf01 Installation/ Test Cell

Needs and Specifications:

Need Specification Units Range List of end arrival date and schedule on room 1 Timeline preparation activities. List n/a Safety is ensured number throughout the installation Injuries due to installation are minimized and of 2 processes. none of the parties involved are liable. injuries 0 Ample amount of room space available to operate Provide expected room layout of the test cell 3 machine. and the final compressor destination. List n/a Consider the effects the machine will have to Reduce impact from sound its surroundings and evaluate efforts that can 4 and vibrations. be taken during installation to minimize. List n/a Accessibility of the machine Select the proper compressor position within for maintenance and use in the room that gives ample room to service the 5 future projects. machine safely. Binary Yes List current capabilities RIT and the senior design teams have for servicing the machine. These include tools, methods of lifting RIT maintenance equipment, mechanical and electrical capabilities to provide supplies, storage space for parts, and safety 6 adequate service. equipment. List n/a

Provide sufficient support Account for the weight and other forces 7500- 7 for compressor operation. exerted by the compressor. lbs 10000

Timeline: Incorporated into Senior Design II Timeline and Installation Procedure

Safety: Use of Rigging Company that has substantial experience moving heavy equipment.

Space: Layout of room with clear path ways around machine for maintenance and operation in Test Cell. Ensured obstructions such as overhead lights, exhaust systems, and doors are not threats.

Vibrations: Vibration dampening is not necessary due to the configuration of the compressor and the building. Current Test Cell has sufficient acoustic capabilities.

Accessibility: Position of compressor was selected to allow for sufficient maintenance space on each side of the machine and room for Auxiliary Unit installation. Maintenance: Tools will be ordered to service machine as well as proper storage space for parts and materials. Lifting requirements are suitable with current shop supplies for parts that may need to be removed. Electrical and mechanical supplies necessary were verified and are accessible to machine. Proper safety equipment and placement of clearly visible signs have been planned for.

Structural: Analysis of floor was performed to determine effects of static load. Structural consultants have been used to verify analysis. I-beam reinforcement is required.

Installation Procedure: - Formula Team and other projects has vacated room: o Engine Dyno will be removed from the back 4 feet of the room by beginning of 1st week of fall quarter to allow for housekeeping in room. o All tools and other supplies not pertaining to compressor will be removed o Need to have clear access to floor and surrounding walls of test cell.

- Senior Design Team will prepare for the compressor’s arrival: o Manage the logistics of the contracted work . Work with general contractor to locate ideal placement of I-beams . Install I-beams

Figure 1: Basement view of Test Cell, Reinforcement and Mounting Detail Provided by Structural Engineer o Order and purchase all items for the installation, interface, and education materials needed . Storage racks . Tools . Safety Equipment . Mounting hardware and plates . Sensors . DAQ and mounting equipment

o Provide necessary information to Boulter: . Schedule and route for transportation. . Materials necessary for install. . Structural concerns and requirements. Provide structural engineer’s analysis and suggestions.

Willis Boulter Cell Phone: 585-261-3102 Boulter Industrial Contractors, Inc. 610 Salt Road Webster, NY 14580 Phone: (585) 265-3260 Fax: (585) 265-0605 E-mail: [email protected]

o Prepare the room for compressor: . Clean up and create a sustainable work environment. . Ensure unrestricted access to all areas of the room and input supplies. . Mark and drill the required holes needed for mount installation when compressor is placed in final position. . Identify and mark the location of the control panel and emergency stop. . Room must be vacated of all materials to give sufficient room to rigging company. . Ensure that path to the room is clear of any obstructions.

- Preparations by Boulter for relocation: o Transport machine from Dresser-Rand to Boulter Rigging Company . Provide sufficient time for Boulter to define needs for transportation. . Verify that the correct equipment is used and available. o Transport machine from Boulter Rigging Company to RIT machine shop loading bay. o Upon arrival to RIT: . Unload from truck with fork lift.

. Fork lift will place machine on skates in new addition of shop. Use bar stock to find C.O.G and secure firmly. o Use skates to transport machine across the machine shop . Use no less than 4 carts to ensure sufficient load distribution . Locate the carts underneath machine with proper access. o Place machine in final location with mounts over bolt holes in floor. . Place machine as precisely as possible with limited loads being seen by floor.

Figure 2: Building 09 Transport Route

- 45 feet of transportation across floor with basement underneath. - Loading bay area has foundation and can use fork lift up to the entrance to the old machine shop. - Load of the compressor must be applied over 60ft2 to prevent damaging of structure Figure 3: Top View of Test Cell with Components and Locations

- After Installation o Coordinate with FMS to manage the logistics for the completion of contracted work . Electrical hookups . Ventilation . Chilled water loop o Install and hook up cooling system . Coolant tank, heat exchanger, heater, valves and piping o Assemble and install storage rack and work bench in test cell . Placement of these items should follow the Test Cell Layout. . Upon completion, these items will be used for storage of equipment. o Place computer, DAQ, tools, spare parts, etc. in proper locations o Provide all safety material in the test cell. . Post signs and stickers . Place necessary safety equipment in the room (see safety document) o Install and hook up sensors and data acquisition unit . See sensor document for specifications and locations. Final List of Sensors

Resonant Measurement Sensor Type Qty Sensitivity Frequency Range Overload Limit Inter bore pressure transducer 1 0.75% 8.333 50 - 70 PSI 100 PSI PCB 102A21 50 mV/psi ≥ 250 kHz up to 1 kpsi 1 kpsi Inlet air pressure 1 0.75% 8.333 0 - 70 PSI 17 PSIA PCB 101A05 50 mV/psi ≥ 250 kHz uo to 1 kpsi 1 kpsi Outlet air pressure 1 0.75% 8.333 0 - 70 PSI 60 PSIA PCB 102A21 50 mV/psi ≥ 250 kHz up to 1 kpsi 1 kpsi Inlet air temperature 1 0.25% 8.333 50-120 °F 100 °F Omega RTD-805 NA NA up to 450 °F 450 °F Outlet air temperature 1 0.25% 8.333 0-350 °F 330 °F Omega RTD-805 NA NA up to 450 °F 450 °F Air flow meter 1 8.333 0 - 50 ACFM 50 ACFM Omega FTB-936 NA NA 4 to 60 ACFM 60 ACFM Inlet water flow rate and temp 1 0.25% 8.333 0 - 100 °F 100 °F Omega FV101 ±2% FS NA 35 to 210°F 210°F Outlet water flow rate and temp 1 0.25% 8.333 0 - 100 °F 100 °F Omega FV101 ±2% FS NA 35 to 210°F 210°F Accelerometer 3 8.333 PCB 623C00 10 mV/g 40kHz ± 4905 m/s² 49,050 m/s² Velocity 2 8.333 PCB VO622A11 100 mV/in/sec20 kHz ± 50 in/sec 49,050 m/s² pk Oil Pressure 1 0.75% 8.333 0 - 70 PSI PCB 101A05 50 mV/psi ≥ 250 kHz uo to 1 kpsi 1 kpsi Oil Temperature 1 0.25% 8.333 Omega PR-12 NA NA NA NA Tank air pressure 1 0.75% 8.333 0 - 70 PSI 60 PSIA PCB 102A21 50 mV/psi ≥ 250 kHz up to 1 kpsi 1 kpsi Tank air temperature 1 0.25% 8.333 0-350 °F 330 °F Omega RTD-NPT-72-E-DUAL-MTP NA NA up to 450°F 450°F

Output Operational Connection Sensor Type Input Voltage Voltage Temperature Type Inter bore pressure transducer 12VDC 0-12VDC 0-375 °F PCB 102A21 18 to 27 VDC 3 to 8 VDC -65 to +325 °F 10-32 Coaxial Jack Inlet air pressure 12VDC 0-12VDC 0-150 °F PCB 101A05 20 to 30 VDC 8 to 14 VDC -100 to +275 °F 10-32 Coaxial Jack Outlet air pressure 12VDC 0-12VDC 0-375 °F PCB 102A21 18 to 27 VDC 3 to 8 VDC -65 to +325 °F 10-32 Coaxial Jack Inlet air temperature 12VDC 0-12VDC 35-120 °F Omega RTD-805 NA NA up to 450 °F Custom Outlet air temperature 12VDC 0-12VDC 0-375 °F Omega RTD-805 NA NA up to 450 °F Custom Air flow meter 12VDC 0-12VDC 35-120 °F Omega FTB-936 NA 30 mV p-p sine -450 to 450°F Custom Inlet water flow rate and temp 12VDC 0-12VDC 35-120 °F Omega FV101 24VDC 4 to 20 mA 35 to 210°F Custom Outlet water flow rate and temp 12VDC 0-12VDC 35-120 °F Omega FV101 24VDC 4 to 20 mA 35 to 210°F Custom Accelerometer 12VDC 0-12VDC 35-120 °F PCB 623C00 18 to 28 VDC 8-12VDC -65 to +250 °F 2-Pin MIL-C-5015 Velocity 12VDC 0-12VDC 35-120 °F PCB VO622A11 18 to 28 VDC 8-12VDC -65 to +250 °F MIL-C-5015 Oil Pressure 12VDC 0-12VDC 35-120 °F PCB 101A05 20 to 30 VDC 8 to 14 VDC -100 to +275 °F 10-32 Coaxial Jack Oil Temperature 12VDC 0-12VDC 35-120 °F Omega PR-12 NA NA NA Custom Tank air pressure 12VDC 0-12VDC 0-375 °F PCB 102A21 18 to 27 VDC 3 to 8 VDC -65 to +325 °F 10-32 Coaxial Jack Tank air temperature 12VDC 0-12VDC 0-375 °F Omega RTD-NPT-72-E-DUAL-MTP NA NA NA Custom Sensor Installation There are numerous sensors that will be installed onto the compressor. The scope of this project is to allow for flexibility in the location and configuration of all sensors. As laboratory experiments evolve, it may become necessary to add or move additional sensors to different locations. The following information is manufacturers’ preferred installation methods for the sensors to be used in the DAQ system.

Source: http://www.pcb.com/techsupport/tech_accel.php

Adhesive Mount Adhesive mounting bases are recommended to prevent an adhesive from damaging the sensor base or clogging the mounting threads. Below is a table of PCB’s suggested mounting adhesives. Magnetic Mount Magnetic mounts are to be used for temporary sensors on a magnetic surface. A thin layer of silicone grease should be applied between the sensor and magnetic base, as well as between the magnetic base and the structure.

Stud Mounting This type of installation is to be used for the permanent installation of sensors. First, grind or machine on the test object a smooth, flat area at least the size of the sensor base, according to the manufacturer's specifications. Then, prepare a tapped hole in accordance with the supplied installation drawing, ensuring that the hole is perpendicular to the mounting surface. Install accelerometers with the mounting stud and make certain that the stud does not bottom in either the mounting surface or accelerometer base. A thread- locking compound may be applied to the threads of the mounting stud to guard against loosening.

Screw Mounting Like a stud mount installation, screw mount installations are to be used on thin-walled surfaces. A cap screw passing through a hole of sufficient diameter is an acceptable means for securing the accelerometer to the structure. A thin layer of silicone grease at the mounting interface ensures high-frequency transmissibility. Test Plan – Usability Testing

6-8 student test subjects, with 2nd to 3rd year engineering/computer abilities. 1-2 faculty test subjects. 5-10 minute overview of the project and compressor.

Tasks to be completed by each test subject: o Start up Compressor Interface o Turn program on o View Graphs Screen and see if they can easily interpret information on the screen o Turn program off o Close out Compressor Interface o Access excel file

Assessment Factors: o Thought process of subject as they are performing actions o Frequency of help requests o Number of errors made in execution of instructions (ie Laboratory) o Time to complete task o Intuitiveness/Navigation/Aesthetics/comments

Other situations to test: Run program with the previous data file open while the new instance is set to save to the same file name Run program with previous data file open while the new instance is set to save to a different file name Prior to First Run

E-Stop

1) Ensure power is connected to the control unit by using a voltmeter to check power supply to the control unit. 2) Press the E-Stop button located in the front of the room. 3) Ensure that the control unit has lost power. 4) Reset the circuit breaker. 5) Press the E-Stop button located in the back of the room. 6) Ensure that the control unit has lost power. 7) Reset the circuit breaker. 8) Press the E-Stop button located outside of the room. 9) Check that the control unit has lost power. 10) Reset the circuit breaker.

Lock-Out Tag-Out for Control Panel

1) Pull down the power lever to shut down the main circuit breakers. 2) Use the lock-out tag-out lock to ensure the lock-out lever is restricted from moving. 3) Turn on the control panel. 4) Use a multi-meter to check that the control panel is not receiving power. 5) Turn off the control panel. 6) Un-lock the lock-out lever. 7) Pull the power lever up to return power to the main circuit breakers.

Measure and Adjust Machine Level

1) Check that the compressor is fully installed on the vibe-prevention mounts. 2) Place a level on the base of the compressor. 3) Check that the compressor is level. If it is leveled, no further adjustments are necessary. 4) If it is not, determine the appropriate mount for adjustment. 5) Lift the compressor off of the adjustable mount. 6) Use a wrench to adjust the mount. 7) Return the compressor into the mount. 8) Check that the compressor is level. If it is leveled, no further adjustments are necessary. 9) If it is not level, repeat steps 5-8.

Vibration Trip-Switch

1) Mount the Vibe Trip-Switch to the Vibration Shaker in 09-2100 “Vibrations Lab”. 2) Use LabVIEW to create a customized adjustment program. 3) Adjust the shaker to the desired vibration levels. 4) Connect a multi-meter to the Vibe Trip-Switch to test for an open or closed circuit. 5) Turn on the Vibration Shaker. 6) As Vibration Shaker escalates, ensure the Vibe Trip-Switch trips at desired vibration level. 7) Disconnect the apparatus.

Air Flow Results 1) Obtain the test results for the air circulation from Dave Hathaway. 2) Ensure that the room air will be fully circulated at least every 15 minutes.

Gravity Inlet 1) Open the gravity inlet valve. 2) Close the room doors. 3) Use a barometer to measure the air pressure in the room (baseline). 4) Turn on the exhaust fan. 5) Continue measuring and recording the air pressure every minute for 10 minutes. 6) If the air pressure levels remain constant, then the gravity inlet valve is sufficient. 7) If the air pressure levels decline, then the gravity inlet valve is not supplying enough air. Miscellaneous Room Preparations

1) Use a simple lamp, or any other safe electronic device, to test the room’s wall outlets. 2) Use a laptop and spare Ethernet cable to test the internet connectivity of the CAT-5 connection outlet located in the front of the room.

During First Run E-Stops 1) Start the compressor. 2) Press the E-Stop button located in the front of the room. 3) Ensure that the compressor has lost power. 4) Reset the circuit breaker. 5) Start the compressor. 6) Press the E-Stop button located in the back of the room. 7) Ensure that the compressor has lost power. 8) Reset the circuit breaker. 9) Start the compressor 10) Press the E-Stop button located outside of the room. 11) Check that the compressor has lost power. 12) Reset the circuit breaker.

Visual Safety and Maintenance Checks 1) Refer to the official “Maintenance Manual” for important details and tests that should be conducted during the first time the compressor is run after installation. 2) Record all noticeable areas of moving parts that are potential safety hazards or pinch points. 3) Record any unexpected noises that occur. Lock-Out Tag-Out for Compressor 1) Pull down the power lever to shut down the main circuit breakers. 2) Use the lock-out tag-out lock to ensure the lock-out lever is restricted from moving. 3) Turn on the compressor. 4) Use a multi-meter to check that the compressor is not receiving power. 5) Turn off the compressor. 6) Un-lock the lock-out lever. 7) Pull the power lever up to return power to the main circuit breakers.

Room Sound Levels 1) Obtain a Sound Level Meter from the Ergonomics Lab in the IE Department. 2) Record a sound measurement at a distance of 1m from the compressor. 3) Record a sound measurement at a distance of 1m from room 09-2329 with opened doors. 4) Record a sound measurement at a distance of 10m from room 09-2329 with closed doors. 5) Ensure all readings are within the safety requirements.

Room Temperature 1) Obtain a type K thermocouple attachment and a multi-meter from John Wellin or a Thermo-fluids lab. 2) Obtain a temperature reading from 10m outside of room 09-2329 as a baseline ambient temperature value. 3) Stand in the center of the front half of room 09-2329, and record the ambient temperature value every minute for 12 minutes (to provide 3 cycles of the air exhaust system). 4) Stand in the center of the back half of room 09-2329, and record the ambient temperature value every minute for 12 minutes (to provide 3 cycles of the air exhaust system). Vibrations 1) Move outside the Test Cell (09-2329), shutting the door on way out. 2) Face the door to the Test Cell (one meter away from center) and make observations on any vibrations felt. 3) If vibrations can be felt through floor (step 4), move back from Test Cell one meter at a time until vibrations are no longer felt. 4) Repeat step 3 for all directions (right and left) and record values to create circle of influence. 5) Make final observations about effects from vibrations of the compressor.

Removal and Re-install of Parts Lock-Out Tag-Out for Compressor 1) Pull down the power lever to shut down the main circuit breakers. 2) Use the lock-out tag-out lock to ensure the lock-out lever is restricted from moving. 3) Turn on the compressor. 4) Use a multi-meter to check that the compressor is not receiving power. 5) Turn off the compressor. 6) Conduct any necessary part removals and re-installs. 7) Un-lock the lock-out lever. 8) Pull the power lever up to return power to the main circuit breakers.

Lifting Capabilities 1) Bring the lift crane into the test cell room with the compressor. 2) Ensure that the lift crane can fully access the compressor. 3) Check that manual lifting is possible for any areas that are not accessible by the lift crane. Vibrations Lab

Investigation: Damping provided by Skid

This investigation looks at how much damping the skid is providing to the singe cylinder system. ANSYS was used to develop a theoretical model of the skid and the forces applied to it. Using the documents provided by Dresser Rand, the skid was modeled in SolidWorks and then imported into ANSYS. The skid was constructed from the material IS 2062. The skid’s I beams are of the type ISBM 150. For purposes of analysis, the skid was constrained at each of its mounting locations, 10 in total. The forces due to reciprocation were then applied to the model at compressor mounting locations. The max deformation was found to be 0054464 inch. Assignment

Before starting the compressor, make yourself aware of all startup procedures and take all the necessary safety precautions. Before recording any data, be sure to run the compressor for a minimum of 5 minutes to ensure that the compressor has had time to reach steady state. Using the Labview interface, locate the vibration tab and begin logging accelerometer data by pressing “Log Data” and saving the values in a .txt file format. The log data feature will automatically log data for a limited amount of time due to the large number of samples per second.

Create a formal report section comparing experimental data with theoretical predictions, following the guidelines and specific topics below. Create a theoretical model using vibration analysis Calculate the maximum deflection on the compressor Then using the data logged from the accelerometer attached to the skid measure the deflection on the skid. Compare the theoretical and experimental data. Include the ANSYS analysis. Thermo Fluids Lab

Investigation: Compressor P-V Diagrams

This investigation explores the concepts of adiabatic compression in a Dresser-Rand single piston, double acting, reciprocating compressor. Utilizing a high sample rate pressure transducer located in the bore of the cylinder and a crank position sensor, we are able to generate real-time plots of Pressure vs. Volume. This can be compared with the theoretical Pressure vs. Volume diagram. Assuming adiabatic compression and negligible pressure drop through the valves, a theoretical P-V diagram can be generated.

Assignment

Before starting the compressor, make yourself aware of all startup procedures and take all the necessary safety precautions. Before recording any data, be sure to run the compressor for a minimum of 5 minutes to ensure that the compressor has had time to reach steady state. Using the Labview interface, locate the thermal fluids lab 1 tab and begin logging pressure and volume data by pressing “Log Data” and saving the values in a .txt file format. The log data feature will automatically log data for a limited amount of time due to the large number of samples per second. These values can be imported into excel and plotted to create the experimental p-v diagram.

Create a formal report section comparing experimental data with theoretical predictions, following the guidelines and specific topics below. Fully documented calculations for theoretical values. We will assume that the air entering the cylinder is at atmospheric pressure when the piston is at bottom dead center. Compute enough values to produce a nice smooth curve. When performing calculations, make sure that valve opening pressure is identical to the experimental outlet pressure. The pressure in the cylinder should also be constant after the valve is opened. Be sure to incorporate the clearance volume in your calculations. State all assumptions. Generate one chart with both theoretical and experimental plots. Discuss the general agreement between the measured pressure curve, and the theoretical predictions. Do they agree within the experimental errors? If not, what else might account for the discrepancies (other than simple human error)? Compute average error in pressure over one cycle. Were our assumptions valid? Explain. Safety Document Observe All Hazard and Warning Labels

PERSONAL PROTECTITIVE EQUIPMENT

Always Wear the Appropriate Safety Gear

Steel toe shoes

Safety glasses or goggles

Gloves

Hard hat

Ear protection TORQUING SAFETY POINTS These Are Unsafe Tool Uses! Never torque any fasteners or flanges on a unit that is running or pressurized Use correct torquing procedures Use correct size / range torque wrench Do not use cheater bars or pipes on wrenches Use thick wall sockets, no chrome sockets Make sure you have good support to back up hydraulic wrenches and torque multipliers LIFTING SAFETY Use Your Legs, Spare Your Back

Know the weight of the item you are lifting Bend at the knees (not your waist) and lift using your legs Ask a co-worker to help with the load Use a crane, hoist, fork truck etc. if in doubt

Proper Crane and Sling Use

Inspect all lifting straps and chains for cuts or other damage before using Verify lifting capacity of cranes or chain falls Check lifting eye bolts for bent or damaged thread section

Use Proper Swivel Eye Bolts LOCKOUT, TAG-OUT ELECTRICAL POWER

Before performing any work on the unit ensure that the electrical power has been de-energized and locked out at the breaker panel to prevent accidental electrical shock or start up of the unit Normal Daily Operating Procedures

• Check the oil level

• Check discharge pressure is zero

• Turn on the cooling water

• Start the compressor unloaded

• Select the compressor load: 50% or 100%

• Do this within 10 minutes to prevent overheating

• Compressor discharge pressure will rise to the setting of the backpressure valve (typically around 35 psi).

Normal Operation Depressurize Before Valve Cover Removal

Be careful where you place your hands and finger when tightening the piston rod jam-nut with hammer wrench Typical Reciprocating Compressor Cylinder Assembly

Cylinder Pinch-Points

Running Gear Pinch-Points Pinch-Point Electric Motor Drive Belts Pressurized Valve Cover

Hot Discharge Temperatures: Compressor Cylinder & Discharge Bottle Electric Motor Shock Hazard

Bill of Materials

Part Subsystem Part Number Vendor Description

1 Installation NA Boulter Rigging Corp. Transportation and Placement of Compressor 2 Installation NA Professional Engineer Structural Consultant (Building) 3 Installation NA Contractor I-beam Construction Electrical Hookup 4 Installation NA Contractor (Main Power and Shut offs) 5 Installation NA Contractor Chilled Water Piping 6 Installation NA Contractor Ventilation Modifications 7 Installation LA14-10 HouseNeeds.com Heat Exchanger Installation 2088-594-154 Northern Tool and Equipment Shurflo Industrial Pump Installation SP0005-RT PlasticMart.com Coolant Tank Installation EMH-060-120V Omega Screw Plug Immersion Heater 8 Installation 90322A215 McMaster 36" Fully Threaded Grade 8 Rod 9 Installation 90322A220 McMaster 72" Fully Threaded Grade 8 Rod 10 Installation 6544K22 McMaster 6" x 6" x 1/4" Steel Plate 11 Installation 93827A245 McMaster Nuts 12 Installation 90073A237 McMaster Spring Lock Washers 1/2" CLICKER TORQUE WRENCH (10- 13 Room Setup 239-6VGA Harbor Freight 150 ft-lbs) 3/8" CLICKER TORQUE WRENCH (0-80 14 Room Setup 807-9VGA Harbor Freight ft-lbs) Split Leather Palm Patch Work Gloves (6 15 Safety 41632-3VGA Harbor Freight pairs) MAXLite® Low Pressure Uncorded Ear 16 Safety 117-1456 Northern Safety co. Plugs 17 Safety TBD TBD Vibration Monitoring Switch 18 Safety TBD TBD Pressure Monitoring Switch 19 Safety TBD TBD Overheating Monitoring Switch 20 Safety E22ASB106 Eaton E-Stop Switches 21 Safety 190-3040 Northern Safety co. Lock-out Tag-out 22 Interface National Instruments Data Acquistion 23 Interface TBD TBD Data Acquistion Mounting Brackets 24 Learning Tool 80893 PCB Piezotronics Mounting pads for Sensor 25 Learning Tool 075A06 PCB Piezotronics Adhesive for Sensor 26 Learning Tool 102A21 PCB Piezotronics Inlet Bore Pressure Transducer 27 Learning Tool 101A05 PCB Piezotronics Inlet Air Pressure sensor 28 Learning Tool 102A21 PCB Piezotronics Outlet Pressure sensors 29 Learning Tool 102A21 PCB Piezotronics Tank Air Pressure 30 Learning Tool RTD-NPT-72-E-DUAL-MTP Omega Tank Air Temperature 31 Learning Tool RTD-805 Omega Inlet Air Temperature sensor 32 Learning Tool RTD-805 Omega Outlet Air Temperature 33 Learning Tool FTB-936 Omega Air Flow meter 34 Learning Tool FV101 Omega Water Temperature sensor (inlet and outlet) 35 Learning Tool FV101 Magnatrol Water Flow Rate sensor 36 Learning Tool TBD PCB Piezotronics Motor Torque sensor 37 Learning Tool 623C00 PCB Piezotronics Accelorameter 38 Learning Tool 101A05 PCB Piezotronics Oil Pressure Sensor 39 Learning Tool VO622A11 PCB Piezotronics Velometer 40 Learning Tool PR-12 Omega Oil Temperature sensor Scope of Supply A scope of supply list was created based off the hazard analysis findings. With the ability to customize portions of the compressor, the scope of supply will communicate RIT’s specific needs to Dresser Rand.

- Relief Valve repositioned - Kill Switches: Incorporate into control panel o Kill switch activated by vibration o Kill switch activated by pressure o Kill switch activated by over heating

- E-stop o Incorporate into control panel

- Bore Holes o Need placement o Characteristics o Number

- Weld Handles to access panels

- Piston access panels made of Lexan

- 5 gallon tank