WORKPLACE SAFETY INSPECTION SCHEDULE

WORKPLACE

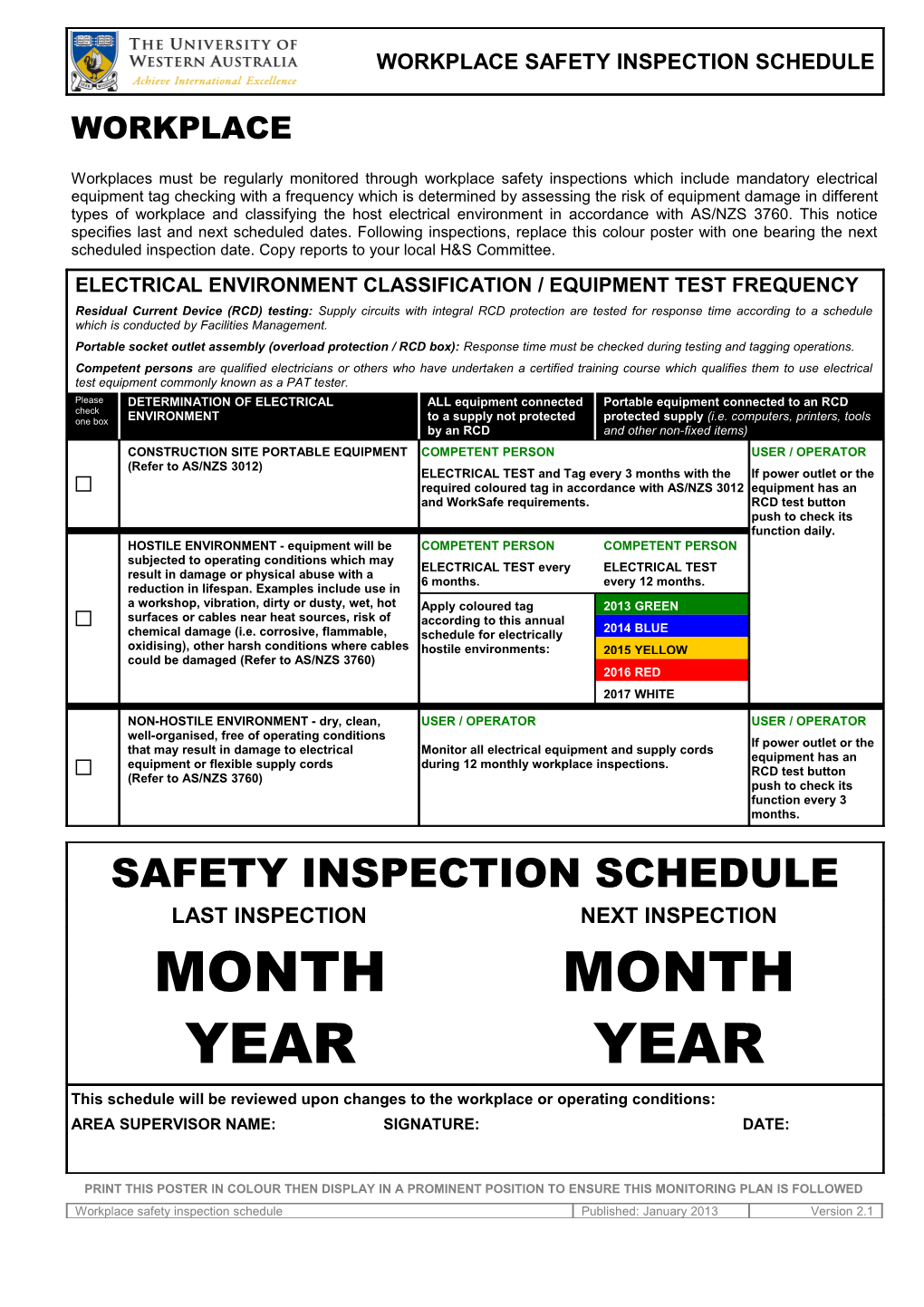

Workplaces must be regularly monitored through workplace safety inspections which include mandatory electrical equipment tag checking with a frequency which is determined by assessing the risk of equipment damage in different types of workplace and classifying the host electrical environment in accordance with AS/NZS 3760. This notice specifies last and next scheduled dates. Following inspections, replace this colour poster with one bearing the next scheduled inspection date. Copy reports to your local H&S Committee. ELECTRICAL ENVIRONMENT CLASSIFICATION / EQUIPMENT TEST FREQUENCY Residual Current Device (RCD) testing: Supply circuits with integral RCD protection are tested for response time according to a schedule which is conducted by Facilities Management. Portable socket outlet assembly (overload protection / RCD box): Response time must be checked during testing and tagging operations. Competent persons are qualified electricians or others who have undertaken a certified training course which qualifies them to use electrical test equipment commonly known as a PAT tester. Please DETERMINATION OF ELECTRICAL ALL equipment connected Portable equipment connected to an RCD check one box ENVIRONMENT to a supply not protected protected supply (i.e. computers, printers, tools by an RCD and other non-fixed items) CONSTRUCTION SITE PORTABLE EQUIPMENT COMPETENT PERSON USER / OPERATOR (Refer to AS/NZS 3012) ELECTRICAL TEST and Tag every 3 months with the If power outlet or the required coloured tag in accordance with AS/NZS 3012 equipment has an and WorkSafe requirements. RCD test button push to check its function daily. HOSTILE ENVIRONMENT - equipment will be COMPETENT PERSON COMPETENT PERSON subjected to operating conditions which may ELECTRICAL TEST every ELECTRICAL TEST result in damage or physical abuse with a 6 months. every 12 months. reduction in lifespan. Examples include use in a workshop, vibration, dirty or dusty, wet, hot Apply coloured tag 2013 GREEN surfaces or cables near heat sources, risk of according to this annual 2014 BLUE chemical damage (i.e. corrosive, flammable, schedule for electrically oxidising), other harsh conditions where cables hostile environments: 2015 YELLOW could be damaged (Refer to AS/NZS 3760) 2016 RED 2017 WHITE

NON-HOSTILE ENVIRONMENT - dry, clean, USER / OPERATOR USER / OPERATOR well-organised, free of operating conditions If power outlet or the that may result in damage to electrical Monitor all electrical equipment and supply cords equipment has an equipment or flexible supply cords during 12 monthly workplace inspections. RCD test button (Refer to AS/NZS 3760) push to check its function every 3 months. SAFETY INSPECTION SCHEDULE LAST INSPECTION NEXT INSPECTION MONTH MONTH YEAR YEAR This schedule will be reviewed upon changes to the workplace or operating conditions: AREA SUPERVISOR NAME: SIGNATURE: DATE:

PRINT THIS POSTER IN COLOUR THEN DISPLAY IN A PROMINENT POSITION TO ENSURE THIS MONITORING PLAN IS FOLLOWED Workplace safety inspection schedule Published: January 2013 Version 2.1