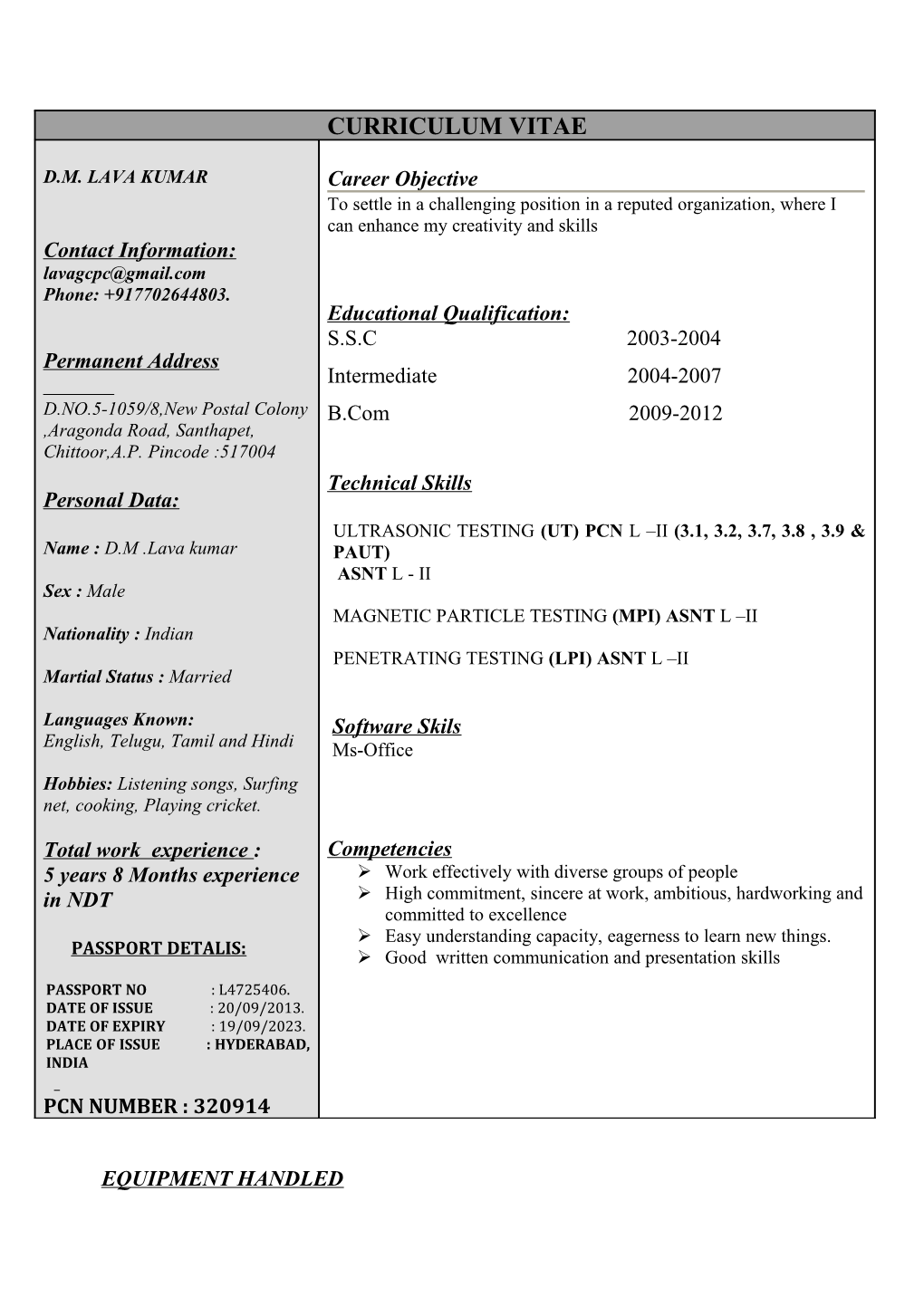

CURRICULUM VITAE

D.M. LAVA KUMAR Career Objective To settle in a challenging position in a reputed organization, where I can enhance my creativity and skills Contact Information: [email protected] Phone: +917702644803. Educational Qualification: S.S.C 2003-2004 Permanent Address Intermediate 2004-2007 D.NO.5-1059/8,New Postal Colony B.Com 2009-2012 ,Aragonda Road, Santhapet, Chittoor,A.P. Pincode :517004 Technical Skills Personal Data: ULTRASONIC TESTING (UT) PCN L –II (3.1, 3.2, 3.7, 3.8 , 3.9 & Name : D.M .Lava kumar PAUT) ASNT L - II Sex : Male MAGNETIC PARTICLE TESTING (MPI) ASNT L –II Nationality : Indian PENETRATING TESTING (LPI) ASNT L –II Martial Status : Married

Languages Known: Software Skils English, Telugu, Tamil and Hindi Ms-Office Hobbies: Listening songs, Surfing net, cooking, Playing cricket.

Total work experience : Competencies 5 years 8 Months experience Work effectively with diverse groups of people in NDT High commitment, sincere at work, ambitious, hardworking and committed to excellence Easy understanding capacity, eagerness to learn new things. PASSPORT DETALIS: Good written communication and presentation skills PASSPORT NO : L4725406. DATE OF ISSUE : 20/09/2013. DATE OF EXPIRY : 19/09/2023. PLACE OF ISSUE : HYDERABAD, INDIA

PCN NUMBER : 320914

EQUIPMENT HANDLED OMNI SCAN MX, MX2, USM PAUT & Conventional 36,OLYMPUS EPOCH 600,USM 1 Modosonic EECI Ultrasonic Testing 35,MODOSONIC Einstein II & TFT, DIGI SCAN

2 Magnetic particle Testing Yoke (all model) Magnaflux, Parker

Work Experience :

Name of organization : VIBRANT NDT SERVICES PVT Ltd, CHENNAI. Designation : NDT inspector (Phased Array) Duration : From January 2016 to Till Date

ROLES AND RESPONSIBILITIES :

Phased Array weld inspection of piping and plate weld joints. Phased Array weld scanning of Butt welds T structural Joints..

Lamination check on Raw materials. Give feed back to the client after finishing the job

Prepare reports and submit the documents to the client

Skilled in ASME Sec V, Sec VIII ASME B31.1 & b 31.3, AWS D 1.1 codes

Work Experience :

Name of organization : BETA INSPECTION SERVICES, Dubai UAE. Designation : NDT inspector (Phased Array) Duration : From August 2015 to January 2016 Project : VTTI oil storage construction Client : DNV-GL

ROLES AND RESPONSIBILITIES : Phased Array weld inspection on T Intersection joints, horizontal joints and vertical Butt joints. Phased Array weld inspection was carried out using DOPPLER scanner.

Lamination check on Raw materials. Give feed back to the client after finishing the job.

Prepare reports and submit the documents to the client.

API 650 , ASME B31.3 and ASME SEC VIII is the procedures used in this project.

Work Experience :

Name of organization : Reliance Jamnagar (Gujarat) Designation : NDT inspector (Phased Array) Duration : From April 2015 to july2015 ROLES AND RESPONSIBILITIES :

Phased Array weld inspection of piping and plate weld joints. Phased Array weld scanning of Butt welds T structural Joints.

Lamination check on Raw materials. Give feed back to the client after finishing the job.

Prepare reports and submit the documents to the client.

Work Experience :

Name of organization : AMS marine pte ltd, Singapore (SUPPLY TO KEPPEL) Designation : NDT inspector Duration : From October 2014 to March 2015 Project : Kraken FPSO Electrical House Client : Bumi Armada

ROLES AND RESPONSIBILITIES :

Ultrasonic weld inspection of piping and structural weld joints. Ultrasonic weld scanning of Butt welds, Nodes, T structural & Nozzle Joints.

Lamination check on Raw materials. Give feed back to the client after finishing the job

Prepare reports and submit the documents to the client

Skilled in DNV OS-401 Oct 2010 and CN-7 May 2011 for structural.

Work Experience :

Name of organization : Aries Marine & Engineering Services,Sharjah.(supply) Designation : NDT inspector Duration : From January 2014 to June 2014 Project : Soolan Sost Client : primier oil.

ROLES AND RESPONSIBILITIES :

Ultrasonic weld inspection of Butt welds on Piping and Tky structural joints in DRY DROCKS WORLD, DUBAI.

Give feed back to the client after finishing the job

Prepare reports and submit the documents to the client

Skilled in DNV OS-401 Oct 2010 and CN May 2011 for structural

ASME B31.3 for piping and EN ISO 5817 for structural

Work Experience :

Name of organization : BIT inspection technology, chennai. Designation : NDT Trainer & inspector Duration : From Oct 2012 to jan 2014

ROLES AND RESPONSIBILITIES :

Ultrasonic weld inspection of pipe and Plate Defect specimens which was used and supplied to various training institutes UT LEVEL 2 Training for Level Candidates. Practical Teaching for LEVEL 2

LPT/PT inspection on defect samples which will be supplied to various training centers Work Experience :

Name of organization : quality metallurgical services, hyderabad (supply) Designation : NDT technician Duration : From Nov 2010 to Oct 2012.

ROLES AND RESPONSIBILITIES :

Ultrasonic weld inspection of piping and structural weld joints. Ultrasonic weld scanning of Butt welds, groove welds, fillet weld joints for structural and piping works at petrochemical plants, Fertilizer plants, Steel plants, power plants.

Lamination check on Raw materials Magnetic Particle inspection of Structural columns, beams Performing NDT (MT, PT) on various job, like welds, forgings, plates etc.

NDT Inspection carried out in welded joints and boiler drums as per client requirement.

Give feed back to the client after finishing the job

Prepare reports and submit the documents to the client

Water Pipe line inspection carried for a govt agency in hyderabad

Skilled in ASME Sec V, Sec VIII ASME B31.1 & b 31.3, AWS D 1.1 codes

I hereby declare that the information furnished above is true to the best of my knowledge.

D.M. Lava kumar Place: Date: