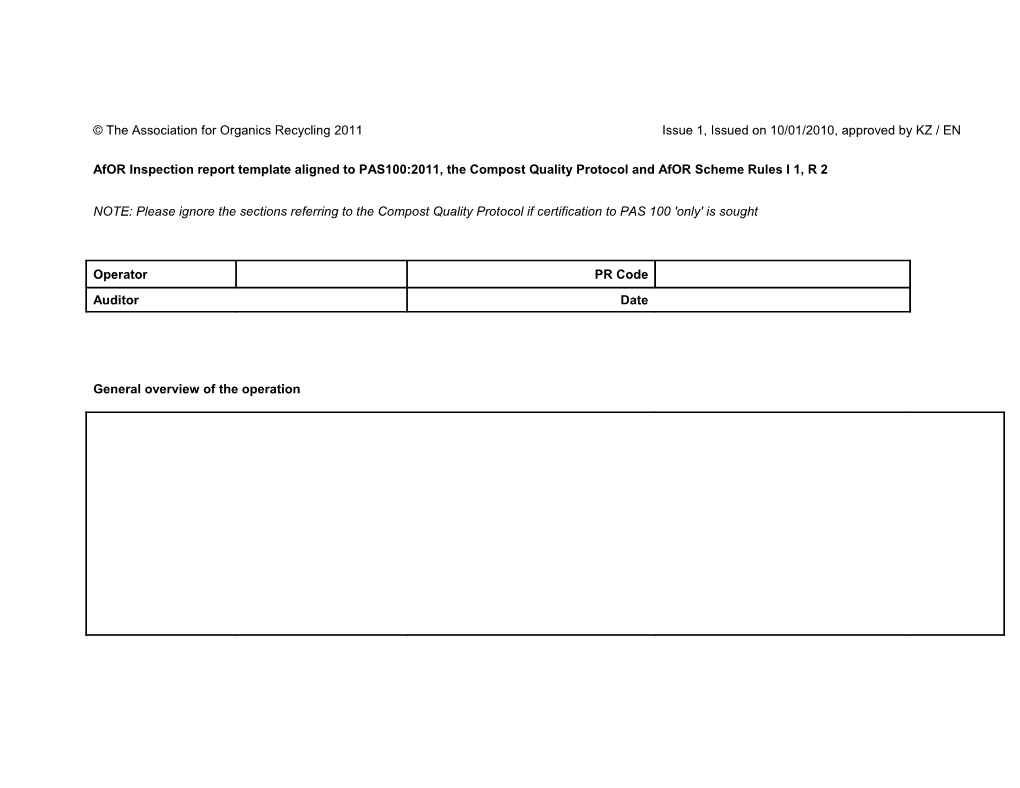

© The Association for Organics Recycling 2011 Issue 1, Issued on 10/01/2010, approved by KZ / EN

AfOR Inspection report template aligned to PAS100:2011, the Compost Quality Protocol and AfOR Scheme Rules I 1, R 2

NOTE: Please ignore the sections referring to the Compost Quality Protocol if certification to PAS 100 'only' is sought

Operator PR Code Auditor Date

General overview of the operation

Q No Standard/QP/Scheme Requirement Auditor’s comments Compliance Rule

Scope of certification

The composting process under Scheme rules I1 R2, assessment is kept separate from any 1 clause 4.2.1 other processes carried out at the same site Compost grades that are not under assessment shall not compromise the Scheme rules I1 R2, 2 quality of the compost grade(s) under clause 4.2.2 assessment for conformance with the Scheme requirements The validated Standard Operating Procedures (or those in the process of Scheme rules I1 R2, 3 being validated) shall be followed for clause 4.2.3 every batch the composting process produces

Application procedures and pre-requisites for application

The composting site holds a valid Scheme rules I1 R2, 4 planning consent/permission, if required clause 5.1.2 by the relevant planning authority.

The composting site holds a relevant Scheme rules I1 R2, 5 valid authorization to operate the clause 5.1.2 composting activity If animal by-products are treated, the Scheme rules I1 R2, composting site is approved or under the 6 clause 5.1.2 process of being approved by the Animal Health to treat animal by-products. If animal by-products are treated, the Scheme rules I1 R2, composting site is approved or under the 7 clause 5.1.2 process of being approved by the Animal Health to treat animal by-products.

All documents requested have been Scheme rules I1 R2, 8 provided to the CB in advance of the clauses 5.1.6 or 5.1.7 inspection

Certification milestones for applicants and renewals

The producer has submitted releavnt Scheme rules I1 R2, 9 application form and paid in full the clauses 6.1.3 or 6.2.2 related assessment fee Obligation to inform certification bodies of changes

Compost producers registered on AfOR’s Compost Certification Scheme shall inform the certification bodies when any changes are made in relation to: - mailing addresses; - person or contact details of the person responsible for implementing and Scheme rules I1 R2, 10 maintaining the certification scheme Clause 16.1 procedures and complying with the scheme requirements; - person or contact details of the person that is responsible for compost sales or related contact details; and - any other details relevant to this certification scheme

Composting process additives

If a product additive is used, this is either listed in AfOR's list of product additives Scheme rules I1 R2, 11 approved additives, or an application for section 17 its approval has been submitted to AfOR. The compost producer has included in the Standard Operating Procedures the name of any approved composting process additive used. The SOPs or a linked QMS document shall also state Scheme rules I1 R2, how often the additive is used (or 12 clause 17.8 exceptional circumstances in which it would be used if not used on a regular basis), how much is used ‘per use’, and how it would be applied / incorporated into the composting process (including the stage(s) at which it is applied). Any product used at the composting site more than once to control flies shall have been prior approved by AfOR, having undergone the same approval request Scheme rules I1 R2, 13 and check procedures as for composting clause 17.9 process additives. Any product used once at the composting site to control flies shall have been prior approved by AfOR.

Quality Management System

A quality management system (QMS) specific to a defined composting 14 PAS 100, clause 4.1.1 process, its resulting composts, and any products that contain those composts shall be established and maintained The input materials, the steps used to make the composts and their storage shall be kept separate from any other 15 PAS 100, clause 4.1.3 materials (inputs, outputs or by- products), processes and stores at the same site. The composting process shall be arranged such that compost that conforms to this PAS does not become contaminated, including when in storage 16 PAS 100, clause 4.1.3 after processing. The same principles apply to any product made by the composter that contains PAS 100 conforming compost. Senior management shall: b) define QMS responsibilities and authorities and

communicate them within the 17 PAS 100, clause 4.1.4 composter’s organization; Senior management shall: c) establish a quality policy for compost produced under the QMS;

Senior management shall appoint a member of the organization’s management who, irrespective of other responsibilities, has the responsibility and authority to:a) ensure that QMS processes are established, implemented 18 PAS 100, clause 4.1.5 and maintained;b) report to senior management on QMS performance and any need for its improvement; andc) ensure that awareness of compost customers’ requirements is promoted throughout the organization

Quality Policy

19 PAS 100, clause 4.2 The composter’s quality policy shall include: a) identification of the location of the composting process, the process steps and compost grades it produces; b) identification of each compost grade for which PAS 100 conformance is claimed, or intended to be claimed, c) the composter’s commitment to achieve the minimum quality and plant response requirements specified in clause 14 of PAS 100, as applicable to the grade, d) the composter’s commitment to fulfilling customers’ requirements regarding their fitness for purpose; and e) identification of any product that contains any compost grade for which PAS 100 conformance is claimed or intended to be claimed. PAS 100, clause 4.3.3 Each person whose activities affect compost quality shall be trained, 20 instructed and supervised commensurate with his/her duties. PAS 100, clause 4.3.3 The training record for each such person, including the manager with overall responsibility for the QMS, shall include the: a) training topic; b) training date or period; c) name and role of the person who 21 received the training on that topic; d) name of the person who delivered the training and organization he/she is representing / employed by (which can be the composter); and e) any certificate or qualification achieved. Standard Operating Procedures

PAS 100, clause 4.4.1 The composter shall write and implement standard operating procedures (SOPs) that cover all 22 production steps from arrival of input materials through to storage and dispatch of composts and any products that contain them. PAS 100, clause 4.4.1 The SOPs shall indentify each 23 production step that is a Critical Control Point (CCP) and its Critical Limits (CLs) PAS 100, clause 4.4.2 The SOPs shall include description of corrective action(s) normally taken in the event of deviation from a CL at its CCP, 24 quality failure of a sampled compost batch, or any other occurrence that causes, or may cause quality failure.

Composting process

Scheme rules I1 R2, The composter’s criteria for completion clause 21.1.1 of the composting process shall be clearly defined in the compost producer’s 25 Standard Operating Procedures. The criteria shall be specific to the compost grade.. Scheme rules I1 R2, Any batch that is dispatched before clause 21.1.4 composting process completion shall be 26 dispatched as non-PAS 100 conforming material. Validation

PAS 100, clause 4.5.1 The composter shall validate that the QMS is effective for the production of compost that conforms to the requirements of this PAS, i.e. is fit-for- 27 purpose and produced according to SOPs, based on the HACCP plan, that achieve all of the intended levels of control. PAS 100, clause 4.5.1 Until validation is achieved, no batch or part batch of the compost grade(s) under 28 assessment shall be dispatched with claim of PAS conformance. PAS 100, clause 4.5.3 Sampling and testing of batches of each compost grade shall continue until the results demonstrate three passes in a row for each applicable parameter 29 specified in clause 14 of PAS 100 and in any additional specification to which the composter has committed to meeting in his / her quality policy PAS 100, clause 4.5.3 For validation purposes, each sampled 30 batch may only be sampled once and as instructed in clause 12 of PAS 100

Documents and their control

PAS 100, clause 4.7.1 Documents appropriate to the scope of 31 the QMS shall be established PAS 100, clause 4.7.2 Each document that is part of the QMS shall include: a) a title; b) a version number; c) a date of issue; and 32 d) the name of the person who issued it. NOTE: weighbridge system and waste transfer note documents are exempt from the requirements in this clause, if each record includes a unique record number. PAS 100, clause 4.7.3 QMS documents shall be maintained in an orderly manner. Each QMS document shall be in place at its appropriate point(s) of use. Any document that 33 becomes obsolete shall be promptly removed from its point(s) of use and, where appropriate, replaced with a revised and approved version PAS 100, clause 4.7.4 The composter shall maintain records that demonstrate effective control of 34 production, storage and dispatch of composts PAS 100, clause 4.7.5 The records shall be: a) legible; b) genuine; 35 c) collated and maintained such that they are readily retrievable; and d) stored in good condition for at least five years Complaints and concerns

PAS 100, clause 4.8.1 The composter shall decide and implement any necessary action in response to any complaints or concerns 36 expressed by interested parties, including operatives, customers, clients and regulatory authorities about quality or usability of the compost. PAS 100, clause 4.8.2 The composter shall record the: a) name and contact details of the person who expressed concern or made a complaint; b) specific subject(s) of the concern or complaint; c) date and time communicated to the composter and name of the person to 37 whom it was communicated; d) nature and date(s) of any actions and checks and who carried them out; e) nature and date of any response to the person who expressed a concern or made the complaint; and f) name of the person who communicated the response. Internal audit of the QMS

PAS 100, clause 4.9.1 At planned intervals of at least once per year, the producer shall audit the QMS to determine whether ithe QMS: a) conforms to the QMS plan for 38 production of compost that is fit for purpose (as defined in the quality policy); and b) is effectively implemented and maintained. PAS 100, clause 4.9.2 The planned audit programme shall take into consideration the status and 39 importance of the processes and areas to be audited, as well as the results of previous audits. PAS 100, clause 4.9.2 The audit criteria, scope, frequency and 40 methods shall be defined.

PAS 100, clause 4.9.2 Selection of auditors and conduct of audits shall ensure objectivity and 41 impartiality of the audit process. Each auditor shall not audit his/her own work

PAS 100, clause 4.9.3 A documented QMS procedure shall define the responsibilities and 42 requirements for planning and conducting audits, and for reporting results and maintaining records PAS 100, clause 4.9.4 The management responsible for the area being audited shall ensure that actions are promptly taken without undue delay to eliminate any detected 43 non-conformities and their causes. Follow-up activities shall include verification of the actions taken and reporting of verification results

Management review of the QMS

PAS 100, clause 4.10.2 A formal, recorded review shall be undertaken at least once per year, or 44 sooner than scheduled if triggered by significant change before the scheduled date PAS 100, clause 4.10.3 Inputs to each review shall include information on: a) results of QMS audits by the composter’s personnel and any external auditors; b) any complaints and concerns expressed by interested parties, including operatives, customers, clients and regulatory authorities; c) composting process performance; 45 d) compost quality (i.e. conformance of relevant grades to the quality policy, including fitness for purpose); e) status of preventive and corrective actions; f) follow-up actions from previous management reviews; g) changes that could affect the QMS; and h) recommendations for improvement. PAS 100, clause 4.10.4 The output from the management review shall record any decisions and actions related to: i) improvement of the efficacy of the 46 QMS and its processes; j) improvement of compost quality as per customer requirements, and k) resource needs PAS 100, clause 4.10.5 If any non-temporary change occurs that affects compost quality, or if a non- temporary change in the required quality of compost occurs, the production process shall be re-validated. The following are examples of types of change that trigger a review: a) input material types; b) industrial plant and 47 equipment; c) staff levels and/or responsibilities; d) customers’ requirements; e) introduction of an additional compost grade or product containing compost; f) legislation, codes of practice or other requirements to which the composter subscribes in the country of production or, where appropriate, the country of marketing.

Hazard analysis and critical control point (HACCP) planning

48 PAS 100, clause 5.1.1 The hazards assessed shall include but not be limited to: a) adverse effects on the environment - including human and animal health - due to pathogens in compost; b) adverse effects on plant health due to pests, pathogens, toxins or intermediate biodegradation breakdown by-products in compost; c) adverse effects on plant health where compost is used in sensitive applications (e.g. ingredient in growing medium) due to immaturity of the compost; d) adverse effects on the environment – including human, animal and plant health - due to toxics in compost; e) odours offensive to people who live or work close to where the compost is used due to odours released from compost when being used; f) introduction of or increase in weed seeds or propagules to soil, growing media or any other substrate due to use of compost; g) damage to equipment for handling, mixing or applying compost or blended materials that contain it due to stones or any man-made particles in compost; h) adverse effects on human, animal or plant health due to sharps in compost; and i) pollution of the environment or adverse effects on human, animal or plant health due to inappropriate use of compost PAS 100, clause 5.1.2 For the hazards above and any other identified hazard, one critical control point (CCP) in the production process shall be identified that, together with the composter’s designated Critical Limits (CLs) for the CCP, controls the 49 associated risk within an acceptable level. If the composter has identified any hazards in addition to those set above, he/she shall assign to it a CCP which, when operated according to the designated CLs, reduces the associated risk to an acceptable level. PAS 100, clause 5.1.3 Each composting batch shall undergo the CCP for each hazard. Each composting batch shall be monitored 50 and managed such that the process step operates within the defined CLs for the CCP. This requirement applies both during and after process validation. PAS 100, clause 5.1.4 Procedures shall be established for verification that the HACCP plan and its implemented CCPs and CLs are under 51 control and the HACCP system is working effectively. The HACCP plan and related procedures shall be documented.

Input materials, composting process additives and composting batch formation

52 PAS 100, clause 6.1.1 Input materials shall be source segregated biowastes and / or source segregated biodegradable materials. Care shall be taken to avoid any potentially polluting wastes, products or materials from becoming mixed or otherwise included with the input materials

PAS 100, clause 6.1.2 Sewage sludge and any derivatives from 53 it, or any mixtures of materials that contain it, are not permitted. PAS 100, clause 6.1.3 Packaged former foodstuffs, catering wastes, other types of ABP and non- ABP food wastes shall only be fed into the composting process if they comply with the composter’s relevant input materials acceptance criteria. If such 54 biowastes are delivered for processing but include packaging that does not comply with the requirements in clause 6.1.4, a pre-composting treatment step shall remove any non-biodegradable prior to feeding those biowastes into the composting process. PAS 100, clause 6.1.4 Biodegradable polymers, bags and packaging or other products made of such material are permitted input materials only if they are independently certified as conforming to the 55 ‘compostable’ criteria within quality standard BS EN 13432, BS EN 14995, DIN V 54900, ASTM D6400 or AIB- Vincotte International S.A.'s 'Program OK 2' criteria for ‘home compostable’ packaging or plastics (or equivalent) 56 PAS 100, clause 6.1.5 Wood- and wood-derived wastes impregnated with preservatives, painted, or with any non-biodegradable layer shall not be permitted

PAS 100, clause 6.1.6 Digestate from an anaerobic digestion process that complies with PAS 110 and is derived from input materials that are allowed in PAS 110 shall be allowed as an input material to the composting 57 process. Digestate from a non-PAS 110 anaerobic or aerobic digestion process shall only be added to a PAS 100 composting process if the digestate is made only from input materials allowed by PAS 100 PAS 100, clause 6.1.7 The composter’s appropriate QMS document(s) shall state criteria for the 58 acceptance of input materials and rejection of unsuitable wastes / materials, based on the HACCP plan. 59 PAS 100, clause 6.1.7 The criteria shall also require the input material supplier to demonstrate that all practicable measures have been taken to prevent contamination of input materials with unsuitable wastes / materials. The composter is responsible for ensuring the criteria are effective and practicable, and making each input material supplier aware of the specific acceptance / rejection criteria and obligation to demonstrate prevention of contamination. Attention to exclusion of sharps and minimisation of the associated risks is particularly important. Any contractual arrangement between the composter and an input material supplier should contain provisions that enable the composter to i) charge a higher gate fee for any delivery that needs clean up before being accepted for composting, or ii) refuse or reject any delivery that is too contaminated for clean up.

PAS 100, clause 6.1.8 For each load of input material delivered, the composter shall make and keep a record of the: a) input material type(s) and its / their List of Wastes code(s) (see [16] for 60 England, [17] for Wales, [15] for Scotland, and [18] for Northern Ireland); b) source; c) quantity; d) date delivered; and e) delivery location on site. PAS 100, clause 6.1.9 Each delivery of input material shall be inspected at a location where there is adequate control of risk of cross- contamination between the delivered 61 load and any input materials accepted for composting, materials undergoing composting or fully composted materials in storage PAS 100, clause 6.1.10 For each of any input material load or part-load rejected after delivery, the composter shall make and keep a record of the: a) input material type(s) and its / their List of Wastes code(s) (see [16] for 62 England, [17] for Wales, [15] for Scotland, and [18] for Northern Ireland); b) source; c) quantity; d) date rejected; e) reason for rejection; and f) to whom it was sent. Compost Quality Protocol, Only those waste types listed in 63 clause 2.2.2 Appendix B may be used Scheme rules I1 R2, Any skip waste stream that mixes clause 20.3 biowaste with inert and/or any other types of non biodegradable waste or materials, at any stage, are not 64 acceptable as inputs under this certification scheme, even after the biowaste has been separated from the mixture.

Composting batch formation PAS 100, clause 6.3.1 Composting batch formation procedures 65 shall be stated in the composter’s appropriate QMS document(s). PAS 100, clause 6.3.1 For each batch, the composter shall record: a) activities carried out when forming it; 66 b) formation start and finish dates; and c) the composting batch code assigned. Sanitisation PAS 100, clause 7.1.1 Each composting batch shall undergo an identifiable sanitization step, in 67 accordance with the HACCP plan and SOPs PAS 100, clause 7.1.2 The composter’s appropriate QMS document(s) shall state a) routine procedures for managing, monitoring, recording and evaluating each composting batch in this step; b) the critical limits (CLs) for each sanitization parameter; c) corrective action options for when 68 monitoring results and composting batch management records show that a CL result is outside its CL; d) measures that will be taken if corrective action fails to bring one or more of the CL-parameters within corresponding CLs; and e) procedures in the event of system or equipment failure PAS 100, clause 7.1.3 CL-parameters, derived from the HACCP plan, shall include: a) temperature; b) a minimum amount of time during which composting batch temperature is 69 within its CL range; c) moisture; and d) turning / mixing if this is necessary for exposing the entire composting batch to the sanitizing conditions PAS 100, clause 7.1.4 Each composting batch shall be monitored during this step in accordance 70 with clause 8 of PAS 100, and the monitoring results shall be recorded. PAS 100, clause 7.1.5 The composter shall apply an appropriate corrective action to any composting batch where evaluation of 71 monitoring and management records for that batch show that any CL result went outside its critical limit(s) PAS 100, clause 7.1.6 The composter shall only pass the composting batch as sanitized : a) if the monitoring and management record shows the composting conditions and batch management comply with the 72 CLs for this CCP have been maintained within critical limits, or b) by taking a representative sample of the composting batch and establishing proof of conformity to pathogen quality requirements by analysis PAS 100, clause 7.1.7 If any input material is added after a composting batch has completed its sanitization step, this step shall be repeated. The results of monitoring and outcome of re-sanitization shall be recorded on the composting batch 73 record. If input material is routinely added after the initial sanitization step, the composter shall include the re- sanitization step and the CLs of this CCP in his / her appropriate QMS document(s)

Stabilisation

74 PAS 100, clause 7.2.1 Each composting batch shall undergo an identifiable stabilization step, in accordance with the HACCP plan and SOPs

PAS 100, clause 7.2.2 The composter’s appropriate QMS document(s) shall state: a) routine procedures for managing, monitoring, recording and evaluating stabilization of each composting batch; b) the critical limits (CLs) for each stabilization parameter; c) corrective action options for when 75 monitoring results and composting batch management records show that a CL- result has gone outside its CL; d) measures that will be taken if corrective action fails to bring the results of any CL-parameter within its corresponding CLs; and e) procedures in the event of system or equipment failure. 76 PAS 100, clause 7.2.3 CL-parameters, derived from the HACCP plan, shall include: a) temperature (see clause 8, Table 1 and Annex B); b) a minimum amount of time during which composting batch temperature is within its CL range; NOTE In the case of stabilization by means of windrow turning, the minimum amount of time can comprise a number of shorter, non-consecutive time periods. This allows for temporary temperature drops that occur when turning a windrow. c) moisture (see clause 8, Table 1 and Annex B); and d) turning / mixing if this is necessary for achieving consistent stabilization throughout the composting batch.

PAS 100, clause 7.2.4 Each composting batch shall be monitored during this step in accordance 77 with clause 8, and the monitoring results shall be recorded PAS 100, clause 7.2.5 The composter shall apply the appropriate corrective action to any composting batch where evaluation of 78 monitoring and management records for that batch shows that any CL-result went outside its critical limit(s). PAS 100, clause 7.2.6 The composter shall only pass the composting batch as stabilized: a) if the monitoring and management record shows that the composting conditions and batch management have 79 been maintained within critical limits, or b) by taking a representative sample of the composting batch and establishing proof of conformity to the stability quality requirements by analysis. PAS 100, clause 7.2.7 If any composting batches are combined during stabilization, the corresponding 80 records shall include the codes of the combined batches and the overall code assigned to the combined batches. Monitoring

PAS 100, clause 8.1 Composting process monitoring shall not 81 be less than the minimum required in Table 1 of PAS 100 PAS 100, clause 8.2 The composter’s appropriate QMS document(s) shall include a diagram and / or description of composting batch surface, core and base zones, as appropriate to typical batch size (in tonnes or m3), the composting system / 82 technology and steps in the process (sanitization, stabilization and if applicable, maturation). Typical composting batch size shall also be stated together with expected maximum and minimum sizes. PAS 100, clause 8.3 and The composter’s appropriate QMS Scheme Rules, clause 22 document(s) shall: a) state the routine frequency and procedure for checks of temperature monitoring system, those carried out by the composter and any carried out by an organization independent of the composter b) commit to taking immediate corrective action when any part of the temperature monitoring system causes inaccurate temperature data, with re-check of the affected part of the system immediately following completion of the corrective 83 action; and c) record data obtained during each calibration check on the temperature monitoring system, and record details of any repairs or adjustments undertaken and the outcome (and obtain such records if the check is carried out by an organisation independent of the composter). I additon, the composter shall commit to calibration checks on the temperature monitoring system by an organisation independent of the composter, at a minimum frequency of once per 12 months.

Product preparation

PAS 100, clause 9.1 The composter’s appropriate QMS document(s) shall state product 84 preparation procedures, as applicable to the compost grade and any product that includes such compost as an ingredient. PAS 100, clause 9.2 The composter shall record how and when product preparation is carried out 85 on each composted batch that undergoes this production step PAS 100, clause 9.3 If compost, or a product containing it that is made on behalf of the composter, is packaged at a location different from the composting facility, the composter’s appropriate QMS document(s) shall 86 include: a) the name and contact details of the person or organization that carries out the activity; and b) a description of the activity and which compost grade(s) it applies to.

Maturation

PAS 100, clause 10.1 The composter’s appropriate QMS document(s) shall state each compost grade to which maturation applies, the 87 corresponding CLs of this step, and whether it is carried out before or after product preparation. PAS 100, clause 10.2 If monitoring is carried out the composter’s appropriate QMS 88 document(s) shall state the CLs for any parameters monitored and the monitoring regime PAS 100, clause 10.3 For each composting batch that undergoes maturation, a record of any CL-parameter monitoring or sample test 89 results shall be made, and shall include the date on which the batch achieved maturation PAS 100, clause 10.4 The composter shall only pass each composting batch that has undergone maturation as ‘mature’: a) if the monitoring and management record shows that the composting conditions and batch management were maintained within the validated CLs, 90 including any CL for the maturation step applicable to the compost grade; or b) by taking a representative sample of the composting batch and establishing that the test result conforms with the maturity criteria stated in the composter’s appropriate QMS document for that compost grade. PAS 100, clause 10.5 If any composting batches are combined during maturation, the corresponding 91 records shall include the codes of the combined batches and the overall code assigned to them Compost storage

PAS 100, clause 11.1 The composter’s appropriate QMS document(s) shall describe provisions for 92a storage of compost and any products containing it, prior to their dispatch PAS 100, clause 11.2 Compost / product batches shall be 92b identifiable when in storage 93 Scheme Rules, clause 27 If compost is stored in an unpermitted area (please note that in Scotland this is not allowed) the following criteria are met: • the composting process and resulting compost grade(s) that are moved into the unpermitted / unlicensed area are certified to PAS 100 and the CQP; • the certificate of compliance with PAS 100 &CQP is valid during the period the compost is stored on the unpermitted / unlicensed area; • prior to being moved onto the unpermitted / unlicensed storage area: - the compost batch(es) have completed the minimum composting process duration that the process has been validated for; this includes any maturation applicable to the graded compost; - the compost batch(es) have been screened to one or more of the certfiied compost grades; - the resulting compost grade(s) are fit for all their intended purposes throughout the storage before dispatch to the customer;

• if sampled and tested, test results for those graded compost batch(es) show compliance with all quality policy minimum quality criteria; • the graded compost batch(es) stored have not become contaminated such that quality policy minimum quality criteria are no longer met; • the compost is stored awaiting dispatch or to be used in a market sector designated by the Compost Quality Protocol; and • the records kept enable traceability checks. PAS 100, clause 11.1 The composter’s appropriate QMS document(s) shall describe provisions for 92 storage of compost and any products containing it, prior to their dispatch PAS 100, clause 11.2 Compost / product batches shall be 93 identifiable when in storage

Sampling

94 PAS 100, clause 12.1 Each such compost grade shall be sampled and sent for testing: a) during the week after the batch has completed the minimum composting process applicable to the grade (including a maturation step if applicable); b) after particle size screening, if applicable; and c) before any blending with wastes, materials, composts, products or additives

PAS 100, clause 12.4 The composter’s appropriate QMS document shall include the sampling 95 procedure or refer to the published sampling procedure used PAS 100, clause 12.5 For each sample, the following information shall be included in the record kept by the composter: a) sampling date; b) compost grade (if screened, e.g. 0 to 25 mm); c) code of the batch from which the sample was taken; d) sample code (this can be the same as 96 c); e) information that identifies the composting process; f) name of the person who carried out the sampling; and g) if the sample taker is not employed by the composter, on whose behalf the sample taker is acting and his / her contact details. PAS 100, clause 12.6 Each sample tested in order to demonstrate compliance with this PAS 97 shall be tested by a laboratory that is independent of the composter PAS 100, clause 12.7 Each sample tested in order to demonstrate compliance with this PAS 98 shall be sent to an appropriate laboratory within 1 working day after the sample was taken PAS 100, clause 12.8 The laboratory that receives the sample shall be informed of the information 99 required in a), b), c), d) and e) in 12.5 above. Scheme rules, I1 R2, Re-sampling and re-testing of a batch clause 23.2 that does not conform to the minimum quality requirements of PAS 100 is allowed only under the circumstances described in clause 15.2a of PAS 100:20110. If the re-sampled batch test 100 result(s) for the failed parameter is / are pass(es), the batch can be released as PAS 100 compliant (‘positive release’). However, any such pass does NOT count towards regaining the passes for proving the efficacy of the routine composting process.

Minimum frequencies for compost sampling and testing

PAS 100, clause 13 Each compost grade under assessment shall undergo routine batch sampling and testing at the minimum frequencies specified in Table 2 of PAS 100, 101 according to whether the process is being validated or is operating after validation and according to whether the compost grade is principal or additonal Minimum compost quality

PAS 100, clause 14.1 The tests specified in Tables 3 and 4 of PAS 100 shall be performed on the 102 principal compost grade for which PAS 100 conformance is claimed, or intended to be claimed. PAS 100, clause 14.1 Samples of that grade shall achieve the: a) minimum quality requirements in 103 Table 3 of PAS 100, and b) minimum plant response requirements in Table 4 of PAS 100. PAS 100, clause 14.2 Each additional compost grade for which PAS 100 conformance is claimed, or intended to be claimed, shall undergo the tests specified in Table 3 and achieve the corresponding minimum 104 quality requirements set in Table 3, except for the weeds propagules test and its upper limit and the plant response test, minimum response level and absence of abnormalities criteria PAS 100, clause 14.3 If the stability test has not been carried out for an additional compost grade, this 105 is because the grade consists of particles too coarse to pass through a screen with 20 mm apertures PAS 100, clause 14.4 If the composter chooses to apply the stones limit specified in 13b instead of the limit in 13a in Table 3 to any coarse, woody compost grade, the composter 106 shall describe that grade only as a ‘mulch’ in labelling and when placing it on the market, and instruct its use only as a mulch. Non-conforming batches

PAS 100, clause 15.1 Any composting batch that does not undergo all applicable CCPs or conform to one or more of the CLs applicable to a CCP shall: a) undergo corrective action then be evaluated for conformance to the composter’s relevant CCP and/ CL criteria; b) undergo recomposting with or without 107 addition of further input material as appropriate, then be evaluated for conformance to the composter’s relevant CP and CL criteria; or c) be dispatched from the site for use, processing elsewhere or disposal, and the recipient notified of its PAS 100 non- conformity as well as the nature of the non-conformity. PAS 100, clause 15.2 Any sampled and tested compost batch that does not conform to the minimum quality and plant response requirements of this PAS or any additional criteria the composter has subscribed to in his / her quality policy (applicable to the compost grade as per clause 14) shall: a) undergo corrective action then be sampled and tested in terms of the parameter(s) relevant for evaluating 108 efficacy of the corrective action; b) undergo recomposting with or without addition of further input material as appropriate, then be sampled and tested in terms of the parameter(s) relevant for evaluating efficacy of the corrective action; or c) be dispatched for use, processing elsewhere or disposal, and the recipient and regulator notified of the nature of its non-conformity with PAS 100 PAS 100, clause 15.3 The composter shall take action appropriate to the nature of the non- 109 conformity and record the action(s) applied to the affected composting / compost batch PAS 100, clause 15.4 This applies after validation, to any compost batch sampled for testing is dispatched with claim of PAS 100 conformance before its test results have 110 been reported and evaluated. When the test results are evaluated, if any failure has occurred the composter shall inform the compost customer and the regulator of the nature of the failure. Scheme rules I1 R2, in the event that a sampled and tested clause 24.1 compost batch fails on one or more potentially toxic elements, AfOR’s Compost Certification Scheme requires 111 that it is dispatched for use, processing elsewhere or disposal and the recipient and regulator are notified of the nature of its non-conformity with PAS 100.

Investigating the efficacy of the QMS in the event of a test result failure after validation

PAS 100, clause 16.1 After validation, if a tested compost sample fails any PAS 100 minimum criteria or any additional criteria the composter has subscribed to in his / her 112 quality policy, the composter shall immediately investigate why it happened and decide whether the QMS needs to be changed PAS 100, clause 16.1 If QMS requires a change, the 113 composter shall implement the change and evaluate its effects PAS 100, clause 16.1 If QMS does not require a change, the 114 composter shall implement a corrective action and evaluate its effects PAS 100, clause 16.1 The actions of the investigation, the investigation period and its outcome 115 shall be recorded. The actions required shall be carried out as quickly as possible. PAS 100, clause 16.2 If the QMS is changed, extra batch(es) of the compost grade produced according to the changed QMS shall be sampled and tested. The test 116 parameter(s) and number of extra batches of the compost grade that are sampled and tested shall be appropriate to the nature of the failure and sufficient for checking the efficacy of the change PAS 100, clause 16.3 If corrective action is implemented (rather than change to the QMS), extra batch(es) of the compost grade shall be sampled and tested after the corrective action has been implemented, after batch re-evaluation if necessary given 117 the nature of the corrective action. The test parameter(s) and number of further batches of the compost grade that are sampled and tested shall be appropriate to the nature of the failure and sufficient for checking the efficacy of the corrective action Scheme rules I1 R2, During the investigation required in clause 24.2.1 clause 16.1 of PAS 100 no batch of compost produced after the batch that failed shall be dispatched as PAS 100 118 conforming unless it is sampled, tested on the parameter(s) corresponding with the failure(s), and found to have passed the test(s). Scheme rules I1 R2, During the investigation, if the batch clause 24.2.2 sampled and tested after the ‘triggering fail batch’ fails on the same parameter, the composter shall immediately inform the certification body and supply details of the failures and actions taken to date. The composter shall do the same if any other incident of two or more consecutive failures on the same parameter occurs during the investigation. The certification body shall 119 evaluate such information within 10 working days of its receipt and decide whether to suspend the certificate of compliance, having taken account of the severity of the failures and progress of the investigation. N.B.: Suspension of certification may be actioned before the composter has completed the investigation, as appropriate to the severity of the failures and progress of the investigation.

Dispatch information

120 PAS 100, clause 17 All information listed in section 17 of PAS 100 about each consignment of PAS 100 conforming compost dispatched shall be printed on packaging or on a separate document supplied to the compost recipient. Please note that in addition to the previous PAS 100, the labelling section requires that test results or typical values for each parameter applicable to the compost grade are supplied to the customer if compost is supplied for use in agriculture or soil- / field-grown horticulture

Scheme rules I1 R2, Any compost producer that supplies clause 25.1 compost with a ‘waste’ status for use in: o agriculture & soil/field-grown horticulture, o soft landscaping, o land restoration, o professional & amateur horticulture, and 121 o any other market shall ensure that compost is supplied in accordance with waste regulatory controls. Any such compost producer shall ensure that the compost recipient is informed that compost dispatched is a ‘waste’ and, thus, that it has to be transported, stored and used according to waste regulatory controls. Scheme rules I1 R2, the compost producer shall ensure that clause 25.3 the information supplied about the specific compost grade includes: • AfOR’s certification mark for this scheme, • the compost grade’s unique certification number, • all the information required in section 122 17 of PAS 100 on ‘Labelling and Marking’, and one of the following: o a declaration of conformance with the PAS 100 & Compost Quality Protocol if the compost is to be used in England, Wales or Northern Ireland, or o a declaration of conformance with PAS 100, in connection with the relevant compost grade. Scheme rules I1 R2, Those producing compost made from clause 25.4 animal by-products that have been treated in accordance with Regulation EC No. 1774/2002 or the relevant national regulations shall make the compost recipient aware that it is derived 123 from animal by-products and that if regulatory rules on its use and recording of its consignment and use on grazing land or land used for growing fodder crops (see clauses 25.5 and 25.6 below) are not adhered to, an offence will have been committed. 124 Scheme rules I1 R2, The compost recipient shall be made clause 25.5 aware that pasture land shall not be grazed or cropped for feedingstuffs during the following periods after compost application: • at least two months for pigs. • at least 3 weeks for any other farmed animals

Scheme rules I1 R2, When dispatching / supplying / selling clause 26.1 any of his / her certified compost grade(s) in bags, the compost producer shall ensure that the packaging (and/or separate document stuck to each packaging item) for the specific compost grade includes:

• AfOR’s certification mark for this scheme, • compost grade’s unique certification 125 number, • all the information required in section 17 ‘Labelling and Marking’ of PAS, and one of the following: o a declaration of conformance with the PAS 100 & Compost Quality Protocol if the compost is to be used in England, Wales or Northern Ireland, or o a declaration of conformance with PAS 100, in connection with the relevant compost grade. Scheme rules, clause 26.3 The information on the packaging (and/or separate document stuck to the packaging) shall enable checks on which graded compost batch, or part batch, was filled into each compost bag. Such 126 checks may cover any bagging date(s). Maintenance of traceability is an important PAS 100 requirement and enables checks on compost production and quality in the event of a complaint Scheme rules I1 R2, Bagged compost with a ‘waste’ status clause 26.4 shall not be supplied unless requirements in clauses 25.1 and 25.2 127 are complied with (compost is dispatched as ‘waste’ and, thus, it transported, stored and used according to waste regulatory controls

Contracts of Supply Compost Quality Protocol, Producer demonstrates compliance with sub-section 3.2.1 requirement 2.2.4 of the CQP by providing the customer with contracts of supply (or equivalent) for each 128 consignment of compost, and keeping copies of them. Contracts of supply meet conditions laid down in Appendix G of the Protocol. Compost Quality Protocol, Contracts of supply are not required for 3.2.2 compost sent for domestic use or for the producer’s own use. However, delivery 129 should be accompanied by the compost certification number, and a declaration that the compost was produced in conformance with this Quality Protocol. Compost Quality Protocol, A contract of supply must include the Appendix G, paragraphs 1 elements listed / text required in 130 to 6. paragraphs 2 to 6 of Annex G of the CQP

Use of AfOR's Compost Certification Mark

Scheme rules I1 R2, certification mark only in association with 131 Clause 12.1 the certified compost grade(s).

The mark shall only be used in association with a product that contains Scheme rules I1 R2, 132 a certified compost grade if scheme Clause 12.2 requirements on providing information about the compost ingredient are fulfilled

The consent to use the mark is limited to Scheme rules I1 R2, 133 using the certification mark in an Clause 12.4 identical form to that supplied by AfOR

A supply chain company may use the certification mark, subject to: a) meeting the requirements associated Scheme rules I1 R2, with its use, set out in these documents, 134 Clause 12.7 and b) compliance being verified and confirmed in writing by the certification body. Traceability

PAS 100, clause 18.1 The composter shall carry out operations such that input materials, composting batches and compost batches (whether 135 screened or not) are identified and traceable, from arrival on site for composting to dispatch from the site, whether PAS 100 conforming or not PAS 100, clause 18.2 The following shall also be traceable: a) product containing PAS 100 conforming compost, b) compost bagged off-site by or on behalf of the composter, c) product containing PAS 100 conforming compost bagged off-site by or on behalf of the composter, d) oversize material, 136 e) any compost batch that is reprocessed, f) any composting batch or part-batch that has been partially processed then sent for disposal or any other suitable regulated use, and g) any composting batches that are combined after successful completion of their respective sanitization steps PAS 100, clause 18.4 The composter shall make and keep 137 records that enable traceability checks Compost blending with other material(s) Compost Quality Protocol, If the quality compost is blended with Appendix G waste materials, the resulting mix will be 138 considered to be a waste and will be subject to waste regulatory controls. Compost Quality Protocol, If quality compost is blended with other Appendix G non-waste materials, all output from this manufacturing / blending process will not be considered as a waste. However, regulatory controls (other than waste 139 regulatory controls) may apply to the blending activity, e.g. where quality compost is transferred to a brownfield site to be mixed with soils to improve their quality.

Agriculture and ‘soil grown’ horticulture (only if CQP certification is sought) Compost Quality Protocol, In the case of agriculture and soil-grown Appendix E, section 2 horticulture, the compost producer is not responsible for applying the compost. Records should be made available or 140 given to the original compost producer to allow the producer to demonstrate to the certification body that environmental harm did not occur when the compost was used. Scheme Rules I1 R2, Compost shall be applied by the Clause 29.1 grower/land manager within 12 months of being received. This minimises the 141 risk of compost being stored on a user’s site indefinitely with no intention of being used Scheme Rules I1 R2, The grower/land manager shall record Clause 29.1 the application of compost as soon after 142 the compost has been applied.

Scheme Rules I1 R2, Prior to intial certification, for at least one Clause 29.2 compost consignment supplied for use in agriculture / soil-grown horticulture, the following record shall be evaluated by the certification body prior to initial certification: - the compost producer’s deliveries of the compost batch to farms; - the compost producer’s supply of compost actual or typical analysis (including at least total N, P, K, S pH, moisture, organic matter, organic carbon, PTEs, and water soluble N) to the relevant farmers or their appointed 143 consultants; - the land manager’s soil analyses covering PTEs (lead, chromium, mercury, cadmium, copper, zinc and nickel) pH, and Nutrients (Olsen’s P, available K and Mg) - the land manager’s records covering the compost’s storage and at least the planned field application(s) for that compost (including field soil PTE test results). - If all of part of that compost has been applied to one or more fields, the land manager’s records including usage details. Scheme Rules I1 R2, After initial certification, a random Clause 29.3 selection of the producer’s compost batches supplied for use in agriculture / soil-grown horticulture shall be evaluated prior to renewal of certification (see AfOR’s inspection template for further details). For conforming batches, the following records shall be checked:- the compost producer’s deliveries of the compost batches to farms;- the compost producer’s supply of compost actual or typical analysis (including at least total N, P, K, S pH, moisture, organic matter, 144 organic carbon, PTEs, and water soluble N) to the relevant farmers or their appointed consultants; - the land manager’s soil analyses covering PTEs (lead, chromium, mercury, cadmium, copper, zinc and nickel) pH, and Nutrients (Olsen’s P, available K and Mg);- the land manager’s records covering the compost’s storage and at least the planned field application(s) for that compost (including field soil PTE test results). - If that compost has been used, the land manager’s records including usage details. Scheme Rules, Clause Compost can be dispatched to a trader 29.4 providing that the following conditions are met: - the compost producer supplies to the trader a contract of supply for each compost consignment and retain copies of it; - the trader supplies each grower to whom he/she supplies compost with a contract of supply for each compost 145 consignment; - the trader returns copies of each contract of supply to the compost producer; and the compost producer retain their copies; and - each grower to whom the merchant supplies compost records compost applications in the web tool for recording compost use in agriculture and soil- grown horticulture (or equivalent system). Compost Quality Protocol, Advice should be taken from an advisor Appendix H, Application qualified under the Fertiliser Advisers 146 requirements, paragraph 1. Certification and Training Scheme (FACTS) (or equivalent) Compost Quality Protocol, Compost applications should adhere to Appendix H, Application the soil PTE limit values set out in the requirements, paragraph 4. Code of Practice for the Agricultural Use 147 of Sewage Sludge (the ‘Sludge Code’). Compost Quality Protocol, All chemical analysis should be carried Appendix H, Sampling and out by laboratories using appropriate analysis requirements, methods that are accredited by UKAS to paragraph 1. ISO/IEC 17025 for the Environment 148 Agency’s MCERTS performance standard for the chemical testing of soil.

Protocol Appendix H, Soil sampling for major nutrients should Sampling and analysis be carried out regularly and include requirements, paragraphs extractable phosphorus (Olsen method), 2, 3 and 4. available potassium, available magnesium and total sulphur. Nitrogen 149 should be calculated using Soil Nitrogen Supply except where RB209 requires soil analysis. Compost should not be applied unless the soil has been analysed within the last five years (in accordance with RB209). Compost Quality Protocol, The compost producer should arrange Appendix H, Sampling and for the compost to be analysed, and the analysis requirements, land manager should arrange for the paragraph 5. receiving soil to be analysed for PTEs 150 (lead, chromium, cadmium, mercury, copper, zinc, nickel) to ensure that the limit values set out in the Sludge (Use in Agriculture Regulations) 1989 are not exceeded. Compost Quality Protocol, Soil analysis for PTEs should be carried Appendix H, Sampling and out before the first application of analysis requirements, compost and then at least every five paragraph 6. years or sooner when the predicted concentrations approach 75 % of the limit values set out in the Code of 151 Practice for the Agricultural Use of Sewage Sludge. If the predicted concentrations exceed 100% of the limit values set out in the Code of Practice for the Agricultural Use of Sewage Sludge, compost should NOT be applied.