AASHTO Technology Implementation Group Nomination of Technology Ready for Implementation 2012 NOMINATIONS DUE BY FRIDAY, SEPTEMBER 16, 2011

1. Sponsoring State DOT: Illinois DOT Nominations 2. Name: Christopher Hahin, MetE, CorrE, PE must be Title: Engineer of Structural Materials & Bridge Investigations r submitted by Mailing Address: 126 E. Ash St. o s an AASHTO City: Springfield State: IL Zip Code: 62704 n o member DOT E-mail: [email protected] Phone: 217 782-0574 Fax: 217 782-2572 p

S willing to help 3. Date Submitted: 09/06/2011 promote the 4. Is the Sponsoring State DOT willing to promote this technology to other states by participating technology. on a Lead States Team supported by the AASHTO Technology Implementation Group? Please check one: Yes No 5. Name the technology: New High Performance Grade 50 & 70 Weathering Steel ) s t

n 6. Please describe the technology: This steel uses precipitation hardening by copper-nickel-iron i o nano-sized particles that precipitate throughout a low carbon steel matrix that has remarkably high p

0 impact toughness at low temperatures, has high weldability, typically without preheat, and due to

1 The term (

its substantial copper content, has an atmospheric corrosion resistance superior to standard A588,

n “technology”

o A709 HPS 70W and 50W weathering steels. When painted, it has superior scratch resistance to i

t may include paint undercut and a lower corrosion rate than other conventional A709 bridge steels. The steel is p i processes, r hot rolled and is available in both Grade 70 and Grade 50 (70 ksi and 50 ksi yield strengths). c products, s Since it is hot rolled, it is no more costly than A588 or the quenched & tempered or thermo- e techniques, D

mechanical HP steels in A709. Since Grade 50 is used on most modern bridge designs, the

y procedures,

g Grade 50 copper-nickel-iron steel is easily substituted for A572 or the A709 HP steels.

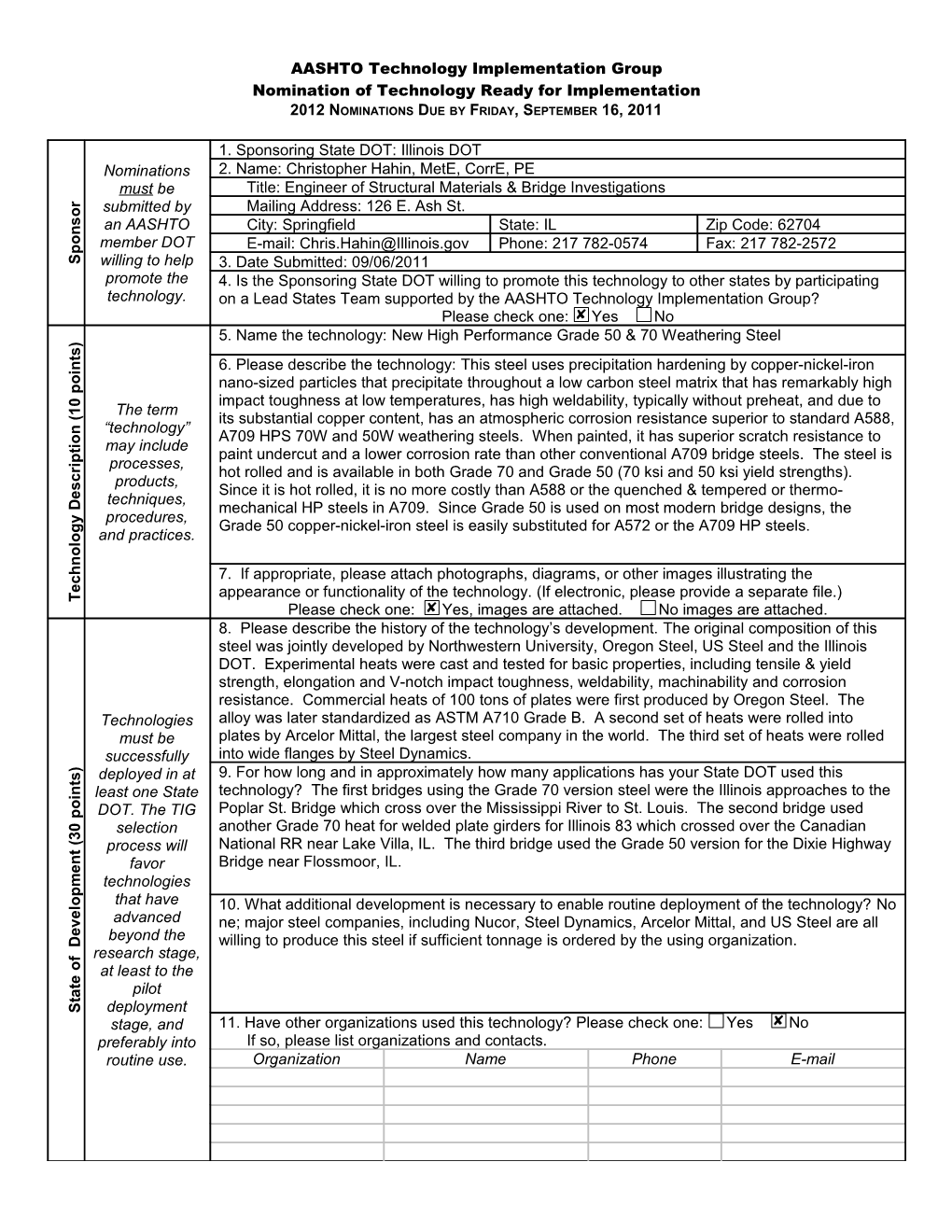

o and practices. l o n h 7. If appropriate, please attach photographs, diagrams, or other images illustrating the c e appearance or functionality of the technology. (If electronic, please provide a separate file.) T Please check one: Yes, images are attached. No images are attached. 8. Please describe the history of the technology’s development. The original composition of this steel was jointly developed by Northwestern University, Oregon Steel, US Steel and the Illinois DOT. Experimental heats were cast and tested for basic properties, including tensile & yield strength, elongation and V-notch impact toughness, weldability, machinability and corrosion resistance. Commercial heats of 100 tons of plates were first produced by Oregon Steel. The Technologies alloy was later standardized as ASTM A710 Grade B. A second set of heats were rolled into must be plates by Arcelor Mittal, the largest steel company in the world. The third set of heats were rolled successfully into wide flanges by Steel Dynamics. )

s deployed in at 9. For how long and in approximately how many applications has your State DOT used this t n technology? The first bridges using the Grade 70 version steel were the Illinois approaches to the i least one State o DOT. The TIG Poplar St. Bridge which cross over the Mississippi River to St. Louis. The second bridge used p

0 selection another Grade 70 heat for welded plate girders for Illinois 83 which crossed over the Canadian 3 ( process will National RR near Lake Villa, IL. The third bridge used the Grade 50 version for the Dixie Highway t n favor Bridge near Flossmoor, IL. e

m technologies p

o that have l 10. What additional development is necessary to enable routine deployment of the technology? No e advanced v ne; major steel companies, including Nucor, Steel Dynamics, Arcelor Mittal, and US Steel are all e beyond the

D willing to produce this steel if sufficient tonnage is ordered by the using organization.

f research stage, o

at least to the e t pilot a t

S deployment stage, and 11. Have other organizations used this technology? Please check one: Yes No preferably into If so, please list organizations and contacts. routine use. Organization Name Phone E-mail

Submit Submit Market Readiness (30 points) Payoff Potential (30 points) advantage over commensurate effort cost,and adopted adopted a with combinationof with the payoffthe with other currently and significant defined as definedas the technologies. formto technologies processwill applicability reasonable can bethat amount amount of benefitor potential. selection available Completed Payoffis The The TIG broad favor Illinois DOT Illinois Northwesternand DOT University. organizations18. What currently supplyand providetechnical for support technology?the the and DOT Illinois Uinversity.Northwestern ASTM A710.Othertraining technical materials, papers, weldingand availableprovisions are from already toavailable assist deployment? resources—such17. What technical as specifications,training and materials, user guides—are anotherorganization? isthe16. estimated What cost,effort, lengthand ofrequired time theto deploy technologyin machinabilityequivalent betteror than A36 ASTM steel whengroundmilled, or drilled. steel, a and weldingsupplementif welding is involved. applications,other For steelthehas a the would simplyuser need a special provisiondesign to their specifying A710the 50Gradeor 70 actions15. wouldWhat another organization need to taketo adopt this technology? ofeconomy.the whereimpacts are probable.This steel hastheapplications in private,public and sectors military involvingstructures, machinery, earthmoving vehicles, low in and temperatureenvironments factors. broadlymightHow technologythe bedeployed? type (includingbranchesother of government and private industry) size,and other or relevant 14. describethePlease potentialextent of implementation in termsof geography, organization iseasily heat treated without at 1000F ofany impact loss toughness. painted unpaintedand structures. If steeltherequires anincrease yield in tensilestrength,and it off-the-shelf electrodes.Its superior atmospheric corrosion makesresistance useful it both for essattemperatures, lowthis steelhas better tolerance.crack It can be weldedwith conventional, benefits, anyadvantagesor other over existingothertechnologies. costsavings, improvements, safety transportation or efficiency effectiveness, environmental type13. scaleWhat and of benefits hasyour realizedDOT from technology? usingthis Include idered use in for weathering steellight poles. organizationshave that it?used 12. the does How technologymeet customer or stakeholderneedsyour in Stateor DOT other his his technology. mightaffect ofease implementation. 19. describeanyPlease legal,environmental, social, intellectual property, barriersother or that http://transportation1.org/tig_solicitation/Submit.aspx No No effort more would bethan required other for conventional steels. Thesteelhas been used bridge in construction,and consis being We anticipatenoneWe ofbarriers the citedto implementationof t The isalready The alloy instandardized Gradethe in 70 form This This steel can bein used anyapplication Becauseof its superior toughn For bridges, For The The