Production Engineering MSC/ENM 541 Production Planning

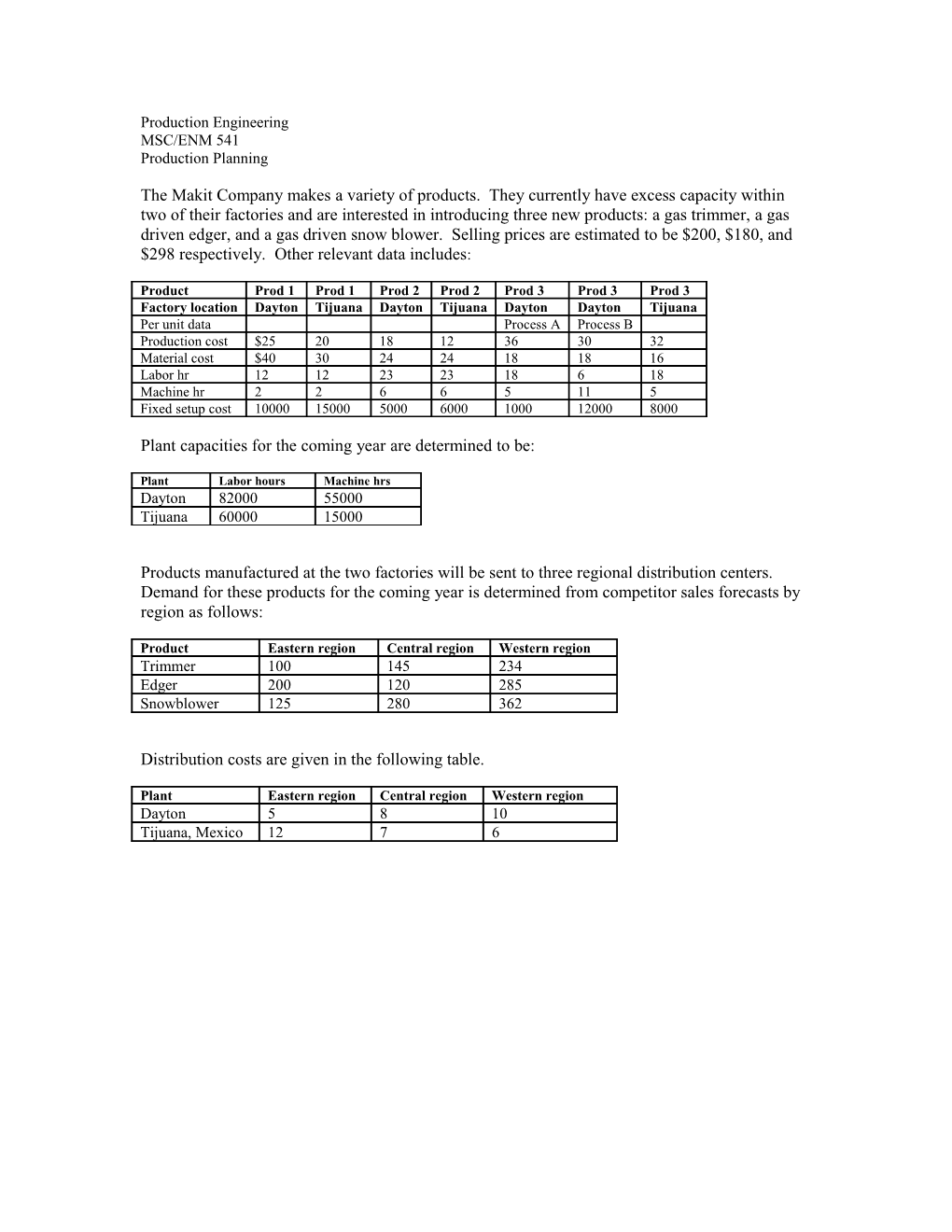

The Makit Company makes a variety of products. They currently have excess capacity within two of their factories and are interested in introducing three new products: a gas trimmer, a gas driven edger, and a gas driven snow blower. Selling prices are estimated to be $200, $180, and $298 respectively. Other relevant data includes:

Product Prod 1 Prod 1 Prod 2 Prod 2 Prod 3 Prod 3 Prod 3 Factory location Dayton Tijuana Dayton Tijuana Dayton Dayton Tijuana Per unit data Process A Process B Production cost $25 20 18 12 36 30 32 Material cost $40 30 24 24 18 18 16 Labor hr 12 12 23 23 18 6 18 Machine hr 2 2 6 6 5 11 5 Fixed setup cost 10000 15000 5000 6000 1000 12000 8000

Plant capacities for the coming year are determined to be:

Plant Labor hours Machine hrs Dayton 82000 55000 Tijuana 60000 15000

Products manufactured at the two factories will be sent to three regional distribution centers. Demand for these products for the coming year is determined from competitor sales forecasts by region as follows:

Product Eastern region Central region Western region Trimmer 100 145 234 Edger 200 120 285 Snowblower 125 280 362

Distribution costs are given in the following table.

Plant Eastern region Central region Western region Dayton 5 8 10 Tijuana, Mexico 12 7 6 Formulation (LINDO) Variable definitions:

Xijk = number of units of product i produced at plant j using process k Yijl = number of units of product i produced at plant j and sent to region l Zij = fixed cost of producing product i at plant j

MAX Profit: - 10000 Z11 - 15000 Z12 - 5000 Z21 - 6000 Z22 - 1000 Z311 - 12000 Z312 - 8000 Z32 + 135 X11 + 150 X12 + 138 X21 + 144 X22 + 244 X311 + 250 X312 + 250 X32 - 5 Y111 - 8 Y112 - 10 Y113 - 12 Y121 - 7 Y122 - 6 Y123 - 5 Y211 - 8 Y212 - 10 Y213 - 12 Y221 - 7 Y222 - 6 Y223 - 5 Y311 - 8 Y312 - 10 Y313 - 12 Y321 - 7 Y322 - 6 Y323

SUBJECT TO Regional demands: 2) Y111 + Y121 = 100 3) Y211 + Y221 = 200 4) Y311 + Y321 = 125 5) Y112 + Y122 = 145 6) Y212 + Y222 = 120 7) Y312 + Y322 = 280 8) Y113 + Y123 = 234 9) Y213 + Y223 = 285 10) Y313 + Y323 = 362 Plant capacities: 11) 12 X11 + 23 X21 + 18 X311 + 6 X312 <= 82000 12) 12 X12 + 23 X22 + 18 X32 <= 60000 13) 2 X11 + 6 X21 + 5 X311 + 11 X312 <= 55000 14) 2 X12 + 6 X22 + 5 X32 <= 15000 Fixed costs: 15) - 10000 Z11 + X11 <= 0 16) - 10000 Z21 + X21 <= 0 17) - 10000 Z311 + X311 <= 0 18) - 10000 Z312 + X312 <= 0 19) - 10000 Z12 + X12 <= 0 20) - 10000 Z22 + X22 <= 0 21) - 10000 Z32 + X32 <= 0 Production – Distribution dependency: 22) - X11 + Y111 + Y112 + Y113 = 0 23) - X21 + Y211 + Y212 + Y213 = 0 24) - X311 - X312 + Y311 + Y312 + Y313 = 0 25) - X12 + Y121 + Y122 + Y123 = 0 26) - X22 + Y221 + Y222 + Y223 = 0 27) - X32 + Y321 + Y322 + Y323 = 0 END INT Z11 Z12 Z21 Z22 Z311 Z312 Z32

OBJECTIVE FUNCTION VALUE

1) 309064.0

VARIABLE VALUE REDUCED COST Z11 0.000000 -2780000.000000 Z12 1.000000 15000.000000 Z21 0.000000 -5000.000000 Z22 1.000000 6000.000000 Z311 1.000000 1000.000000 Z312 0.000000 -48000.000000 Z32 0.000000 -2492000.000000 X11 0.000000 0.000000 X12 479.000000 0.000000 X21 0.000000 0.000000 X22 605.000000 0.000000 X311 767.000000 0.000000 X312 0.000000 0.000000 X32 0.000000 0.000000 Y111 0.000000 287.000000 Y112 0.000000 295.000000 Y113 0.000000 298.000000 Y121 100.000000 0.000000 Y122 145.000000 0.000000 Y123 234.000000 0.000000 Y211 0.000000 0.000000 Y212 0.000000 8.000000 Y213 0.000000 11.000000 Y221 200.000000 0.000000 Y222 120.000000 0.000000 Y223 285.000000 0.000000 Y311 125.000000 0.000000 Y312 280.000000 0.000000 Y313 362.000000 0.000000 Y321 0.000000 251.000000 Y322 0.000000 243.000000 Y323 0.000000 240.000000

ROW SLACK OR SURPLUS DUAL PRICES 2) 0.000000 138.000000 3) 0.000000 132.000000 4) 0.000000 239.000000 5) 0.000000 143.000000 6) 0.000000 137.000000 7) 0.000000 236.000000 8) 0.000000 144.000000 9) 0.000000 138.000000 10) 0.000000 234.000000 11) 68194.000000 0.000000 12) 40337.000000 0.000000 13) 51165.000000 0.000000 14) 10412.000000 0.000000 15) 0.000000 279.000000 16) 0.000000 1.000000 17) 9233.000000 0.000000 18) 0.000000 6.000000 19) 9521.000000 0.000000 20) 9395.000000 0.000000 21) 0.000000 250.000000 22) 0.000000 144.000000 23) 0.000000 -137.000000 24) 0.000000 -244.000000 25) 0.000000 -150.000000 26) 0.000000 -144.000000 27) 0.000000 0.000000

NO. ITERATIONS= 91

Solution summary:

Product Prod 1 Prod 1 Prod 2 Prod 2 Prod 3 Prod 3 Prod 3 Factory location Dayton Tijuana Dayton Tijuana Dayton Dayton Tijuana Process A Process B Units produced 479 605 767

Distribution Eastern region 100 200 125 Central region 145 120 280 Western region 234 285 362