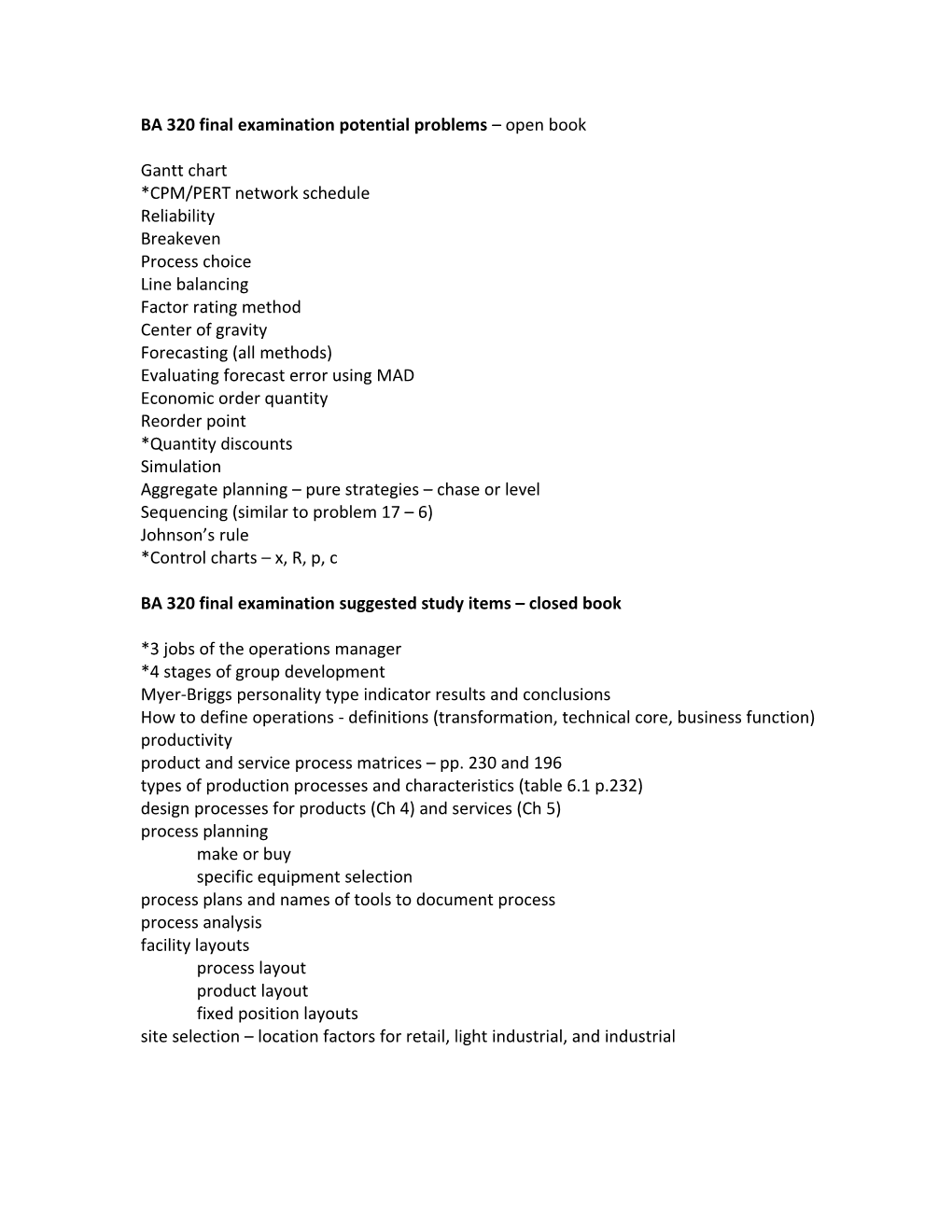

BA 320 final examination potential problems – open book

Gantt chart *CPM/PERT network schedule Reliability Breakeven Process choice Line balancing Factor rating method Center of gravity Forecasting (all methods) Evaluating forecast error using MAD Economic order quantity Reorder point *Quantity discounts Simulation Aggregate planning – pure strategies – chase or level Sequencing (similar to problem 17 – 6) Johnson’s rule *Control charts – x, R, p, c

BA 320 final examination suggested study items – closed book

*3 jobs of the operations manager *4 stages of group development Myer-Briggs personality type indicator results and conclusions How to define operations - definitions (transformation, technical core, business function) productivity product and service process matrices – pp. 230 and 196 types of production processes and characteristics (table 6.1 p.232) design processes for products (Ch 4) and services (Ch 5) process planning make or buy specific equipment selection process plans and names of tools to document process process analysis facility layouts process layout product layout fixed position layouts site selection – location factors for retail, light industrial, and industrial project management – planning, scheduling, control CPM/PERT critical path Gantt stakeholder target – cost, scope, time supply chain and supply chain management definitions transportation/logistics quantitative forecasting time series forecasting – naïve, moving average, exponential smoothing causal forecasting – regression analysis forecast error qualitative forecasting inventory role inventory costs – ordering, carrying, shortage inventory system types – periodic, continuous ABC reorder point service levels simulation sales and operations planning - production planning techniques - fig 14.1 p.610 strategies for adjusting capacity strategies for managing demand scheduling – loading, sequencing, monitoring quality management total quality management (TQM) principles – customer, count, culture Six sigma meaning of quality – fig. 2.1 p. 59 dimensions of product/service quality *Seven quality tools – draw, define/describe use *Deming wheel - fig 2.2 p.61 Deming’s red bead experiment – its meaning for YOU as a manager Statistical process control