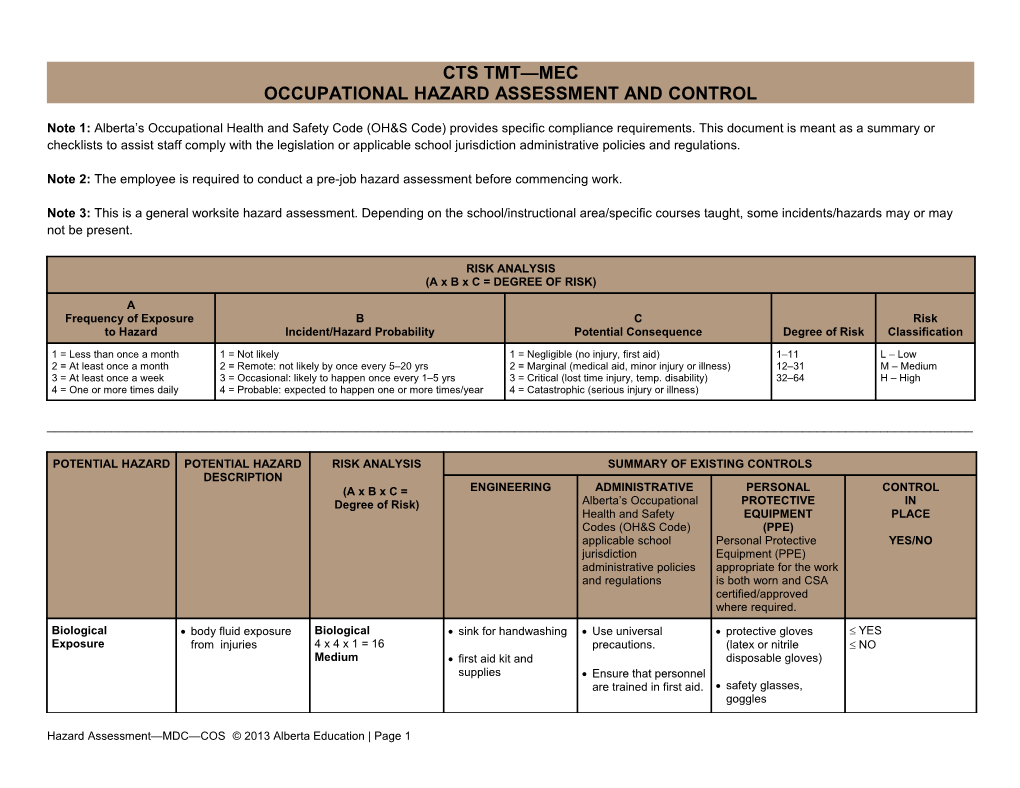

CTS TMT—MEC OCCUPATIONAL HAZARD ASSESSMENT AND CONTROL

Note 1: Alberta’s Occupational Health and Safety Code (OH&S Code) provides specific compliance requirements. This document is meant as a summary or checklists to assist staff comply with the legislation or applicable school jurisdiction administrative policies and regulations.

Note 2: The employee is required to conduct a pre-job hazard assessment before commencing work.

Note 3: This is a general worksite hazard assessment. Depending on the school/instructional area/specific courses taught, some incidents/hazards may or may not be present.

RISK ANALYSIS (A x B x C = DEGREE OF RISK)

A Frequency of Exposure B C Risk to Hazard Incident/Hazard Probability Potential Consequence Degree of Risk Classification

1 = Less than once a month 1 = Not likely 1 = Negligible (no injury, first aid) 1–11 L – Low 2 = At least once a month 2 = Remote: not likely by once every 5–20 yrs 2 = Marginal (medical aid, minor injury or illness) 12–31 M – Medium 3 = At least once a week 3 = Occasional: likely to happen once every 1–5 yrs 3 = Critical (lost time injury, temp. disability) 32–64 H – High 4 = One or more times daily 4 = Probable: expected to happen one or more times/year 4 = Catastrophic (serious injury or illness)

______

POTENTIAL HAZARD POTENTIAL HAZARD RISK ANALYSIS SUMMARY OF EXISTING CONTROLS DESCRIPTION (A x B x C = ENGINEERING ADMINISTRATIVE PERSONAL CONTROL Degree of Risk) Alberta’s Occupational PROTECTIVE IN Health and Safety EQUIPMENT PLACE Codes (OH&S Code) (PPE) applicable school Personal Protective YES/NO jurisdiction Equipment (PPE) administrative policies appropriate for the work and regulations is both worn and CSA certified/approved where required.

Biological body fluid exposure Biological sink for handwashing Use universal protective gloves YES Exposure from injuries 4 x 4 x 1 = 16 precautions. (latex or nitrile NO Medium first aid kit and disposable gloves) supplies Ensure that personnel are trained in first aid. safety glasses, goggles

Hazard Assessment—MDC—COS © 2013 Alberta Education | Page 1 Post emergency procedures.

Identify and establish sanitary and safe housekeeping practices.

Establish handwashing practices.

Chemical exposure to metal Chemical eyewash station Ensure WHMIS Welding goggles YES Exposure cleaners, battery acid, 4 x 4 x 3 = 48 training is available. NO solvent-based paints High equipment in safe and Welding helmet and thinners proper working order Provide up-to-date MSDS. Protective gloves and ventilation system leather apron Follow safe handling and storage information on labels or MSDS.

Ensure regular cleaning and maintenance of ventilation system.

Establish handwashing practices.

exposure to carbon Chemical local exhaust Ensure WHMIS n/a YES monoxide and other 4 x 4 x 3 = 48 ventilation and training is available. NO fumes/vapours from High general ventilation vehicle exhaust within the shop (i.e., Provide up-to-date tail pipe connected to MSDS. local ventilation) Follow safe handling and storage information on labels or MSDS.

Ensure regular cleaning and

Hazard Assessment—MDC—COS © 2013 Alberta Education | Page 2 maintenance of ventilation system.

Minimize vehicle running within shop area.

exposure to fumes Chemical local ventilation Ensure WHMIS n/a YES from welding/brazing 4 x 4 x 3 = 48 systems in welding training is available. NO High areas Provide up-to-date portable local exhaust MSDS. system when welding in general shop area Follow safe handling and storage information on labels or MSDS.

Ensure regular cleaning and maintenance of ventilation system.

exposure to dust from Chemical local exhaust system Minimize dry safety glasses or YES grinding and sanding 4 x 4 x 3 = 48 attached to hand sweeping and, goggles NO High grinders whenever possible, use vacuums with eyewash station filters to clean up dust.

Ensure regular cleaning and maintenance of ventilation system.

exposure to sand Chemical eyewash station Minimize dry safety glasses or YES blasting (parts 4 x 4 x 3 = 48 sweeping and, goggles NO cleaner) and cabinet High whenever possible, use vacuums with filters to clean up dust.

Ensure regular cleaning and maintenance of ventilation system.

Hazard Assessment—MDC—COS © 2013 Alberta Education | Page 3 exposure to vapours Chemical local and general Ensure regular respirator YES from paints and 4 x 4 x 3 = 48 ventilation cleaning and NO thinners, fillers High spray booth maintenance of ventilation system.

fire risk from Chemical spray booth Ensure WHMIS n/a YES flammable solvent- 4 x 4 x 3 = 48 ventilation training is available. NO based paints and High thinners Provide up-to-date MSDS.

Follow safe handling and storage information on labels or MSDS.

Ensure regular cleaning and maintenance of ventilation system.

Store chemicals in a separate room and in fire-rated cabinets.

explosion hazard from Chemical compressed gases Check hoses for leaks n/a YES compressed gases 4 x 4 x 3 = 48 stored in and replace damaged NO High trolley/secured to or leaking hoses. trolley Test regulators on flashback arrestor cylinders for leaks. and reverse flow check valve The gas torch is to be used by trained staff local exhaust only. ventilation Extra cylinders are securely stored in the vertical position with a protective cap covering the valve.

Store chemicals in a separate room and in fire-rated cabinets.

Hazard Assessment—MDC—COS © 2013 Alberta Education | Page 4 Ergonomic lifting and moving Ergonomic n/a Provide training in Gloves YES Exposure awkward and/or heavy 4 x 4 x 3 = 48 proper lifting NO parts, equipment, and High technique. safety boots (CSA materials approved) Get help with heavy or awkward loads if a lifting aid is not available.

Assess the load; bend your knees; grasp the load with a firm grip; hold the load close to your body; and lift with your legs, keeping your back straight.

Use lifting and positioning aids to accommodate work posture.

Store heavy objects at waist height.

Try to use better designed work tools and workstations.

Use tools with a weight counter- balancer.

working in awkward Ergonomic n/a Rotate jobs as n/a YES positions for long 4 x 4 x 3 = 48 frequently as NO periods of time High possible.

Avoid working in one position for long periods of time.

Take frequent breaks to stretch.

Minimize awkward postures.

Hazard Assessment—MDC—COS © 2013 Alberta Education | Page 5 injury caused by Ergonomic n/a Learn to recognize n/a YES repetitive motions 4 x 4 x 3 = 48 repetitive stress NO High injuries.

Ensure repetitive tasks are properly paced.

Take regular breaks.

Physical confined space (e.g., Physical n/a Be familiar with safe n/a YES Exposure autobody spray 4 x 4 x 3 = 48 operating and NO booth, if cleaning High maintenance downdraft area below requirements. grade) Follow proper procedures for working in confined spaces.

fire hazard and Physical reverse-flow check Compressed gases n/a YES explosion hazard due 4 x 4 x 3 = 48 valves to prevent cylinders are stored NO to compressed-gas High flashback and handled in carts cylinders (never on side).

Regulators are tested for leaks.

Store and protected against damage and secure against falling.

contact with Physical nozzle with pressure Do not use n/a YES compressed air that 4 x 4 x 3 = 48 relief holes compressed air to NO may penetrate skin High clean clothing or skin.

burns from hot Physical n/a Maintain good welding goggles (CSA YES surfaces 4 x 4 x 3 = 48 housekeeping. approved) NO High metal splashes during welding helmet welding, cutting protective gloves and handling hot tools clothing and equipment leather apron

Hazard Assessment—MDC—COS © 2013 Alberta Education | Page 6 contact with portable Physical pedestal grinder work Dress the pedestal face shield YES and pedestal grinders 4 x 4 x 3 = 48 rest adjusted properly grinder wheel NO that are improperly High (3 mm gap max) regularly. guarded or adjusted

contact with sharp Physical n/a Cover sharp materials n/a YES edges and materials, 4 x 4 x 3 = 48 with tape or other NO auto parts High protective material.

entanglement in Physical equipment guards Secure loose clothing, protective gloves and YES rotating machinery, 4 x 4 x 3 = 48 tie back long hair, and clothing NO parts, belts, and tools High remove all jewellery. leather apron

pinch points on Physical equipment guards Secure loose clothing, n/a YES equipment and/or 4 x 4 x 3 = 48 tie back long hair, and NO machinery with V-belt High remove all jewellery. drives (e.g., compressors)

electrical shock from Physical n/a Equipment that is gloves YES damaged or exposed 4 x 4 x 3 = 48 being repaired and/or NO connections, High maintained is glasses with side inadequate locked/tagged out shields grounding, welding (zero energy state). processes, worn or face shield damaged Tag and remove cables/cords, lack of defective non-conductive proper gloves, and tools/equipment footwear (high working in wet from use. voltage) for welding conditions Check electrical cords hearing protection and cables for damage. Repair or replace damaged cords and cables.

falling objects, Physical n/a Materials or vehicles n/a YES including vehicles 4 x 4 x 3 = 48 that are elevated NO High must be secured against falling.

Make sure the hoist is rated to handle the load.

Communicate with others when moving

Hazard Assessment—MDC—COS © 2013 Alberta Education | Page 7 materials.

Use safety stands whenever working underneath a vehicle.

noise from grinding Physical n/a n/a hearing protection YES and certain types of 4 x 4 x 3 = 48 NO welding High

fire and explosion from Physical local ventilation Use flammable leather gloves YES welding or cutting 4 x 4 x 3 = 48 liquids and gases in safety glasses NO close to combustible High fire extinguishers well-ventilated areas. leather apron materials or welding or and evacuation cutting gases from procedures Secure and use the poorly fitting and leaky least toxic materials hoses for both students and the environment. fire risk from flammable/combustible liquids and wastes (i.e., rags)

slip hazard from Physical n/a Use good n/a YES vehicle fluids, spilled 4 x 4 x 3 = 48 housekeeping NO paints, or water High practices.

trip hazards from Put away all tools, cables, hoses, and equipment, and debris materials in their proper storage areas.

Clean up spills immediately.

welding arc flash Physical n/a Follow electrical gloves YES (UV light or infrared 4 x 4 x 3 = 48 safety procedures. NO radiation) High glasses with side Ensure cables are in shields good condition and are properly face shield grounded. non-conductive Avoid standing in footwear (high water or on wet voltage) for welding surfaces. hearing protection Avoid wearing sweaty

Hazard Assessment—MDC—COS © 2013 Alberta Education | Page 8 clothes.

Turn the disconnect switch off before plugging in or unplugging the high- voltage input cable.

Ensure welding equipment is correctly connected before using.

Ensure that main power terminals are located inside welding machine cover; ensure terminals are accessible only with tools.

Protect cables form damage.

Never touch wire spool while the wire is being fed.

fire hazards due to Physical n/a Do not cut or use a welding shields YES welding 4 x 4 x 3 = 48 torch to cut old paint and/or welding NO High containers/drums or glasses containers that may have contained helmet flammable liquids. clothing made for welding (i.e., resistant to spark, flame, and heat)

non-conductive footwear

Hazard Assessment—MDC—COS © 2013 Alberta Education | Page 9 unsafe vehicle (e.g., Physical n/a Perform a circle n/a YES not road worthy, faulty 4 x 4 x 3 = 48 check on any vehicle NO brakes, leaking oil or High that is under power gasoline) (brakes, leaks, or engine malfunction).

Drive safely.

Communicate movement of vehicles in/out of shop.

Use safety stands.

vibration from Physical vibration isolation Rotate jobs as often n/a YES tools/equipment 4 x 4 x 3 = 48 suspension systems as possible. NO High Take frequent rest periods.

Reduce intensity and duration of exposure.

Provide and document ongoing safety education and training, including mandatory equipment and tool orientation.

falls from height Physical n/a Use proper ladders anchor point, lanyard, YES 4 x 4 x 3 = 48 when working at and full body harness NO High heights (three-point contact).

Psycho-social bullying and verbal Psychosocial n/a Follow visitor n/a YES Exposure harassment with 1 x 4 x 1 = 4 procedures. NO adults and students Low Follow working alone procedures for school staff (including security and door locking procedures).

Follow safe and secure school

Hazard Assessment—MDC—COS © 2013 Alberta Education | Page 10 procedures.

© Calgary Board of Education

Hazard Assessment—MDC—COS © 2013 Alberta Education | Page 11