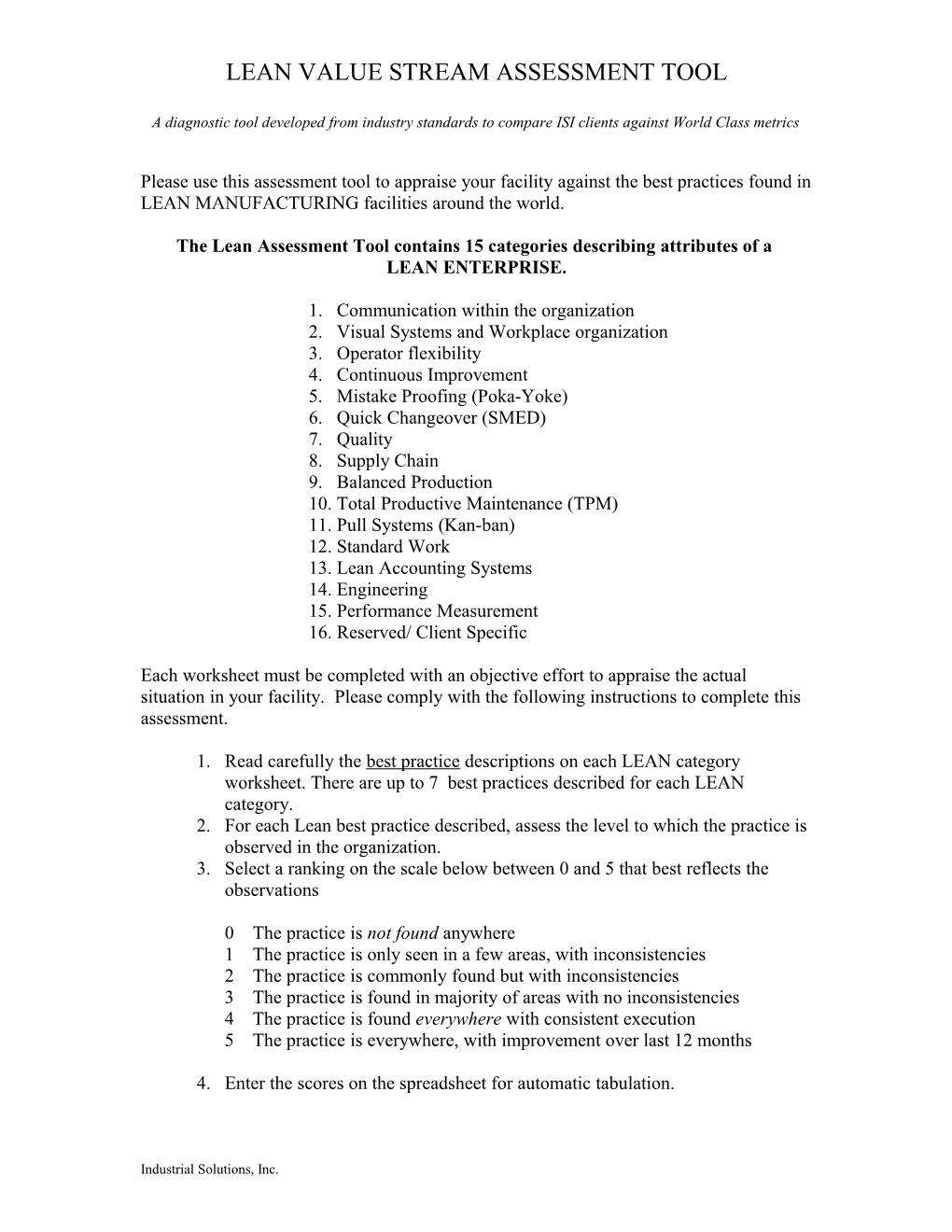

LEAN VALUE STREAM ASSESSMENT TOOL

A diagnostic tool developed from industry standards to compare ISI clients against World Class metrics

Please use this assessment tool to appraise your facility against the best practices found in LEAN MANUFACTURING facilities around the world.

The Lean Assessment Tool contains 15 categories describing attributes of a LEAN ENTERPRISE.

1. Communication within the organization 2. Visual Systems and Workplace organization 3. Operator flexibility 4. Continuous Improvement 5. Mistake Proofing (Poka-Yoke) 6. Quick Changeover (SMED) 7. Quality 8. Supply Chain 9. Balanced Production 10. Total Productive Maintenance (TPM) 11. Pull Systems (Kan-ban) 12. Standard Work 13. Lean Accounting Systems 14. Engineering 15. Performance Measurement 16. Reserved/ Client Specific

Each worksheet must be completed with an objective effort to appraise the actual situation in your facility. Please comply with the following instructions to complete this assessment.

1. Read carefully the best practice descriptions on each LEAN category worksheet. There are up to 7 best practices described for each LEAN category. 2. For each Lean best practice described, assess the level to which the practice is observed in the organization. 3. Select a ranking on the scale below between 0 and 5 that best reflects the observations

0 The practice is not found anywhere 1 The practice is only seen in a few areas, with inconsistencies 2 The practice is commonly found but with inconsistencies 3 The practice is found in majority of areas with no inconsistencies 4 The practice is found everywhere with consistent execution 5 The practice is everywhere, with improvement over last 12 months

4. Enter the scores on the spreadsheet for automatic tabulation.

Industrial Solutions, Inc. LEAN VALUE STREAM ASSESSMENT TOOL

Protocol for Administration of the Assessment

1. Notify the key people in the organization ahead of time that the assessment will be conducted. 2. Obtain an organizational chart and identify key functional leaders who will be the point of contact for each category 3. Send the assessment to the leaders if they need some time to prepare or think about the questions and evaluation criteria. 4. Explain the purpose of the assessment to every person contacted.

Tips for Collecting Valid Data

o It may be necessary to ask the same questions of several different people from different areas in order to get an average assessment score o If the question simply does not apply, put n/a in the score sheet and adjust the calculation of the score for that category.

Industrial Solutions, Inc.