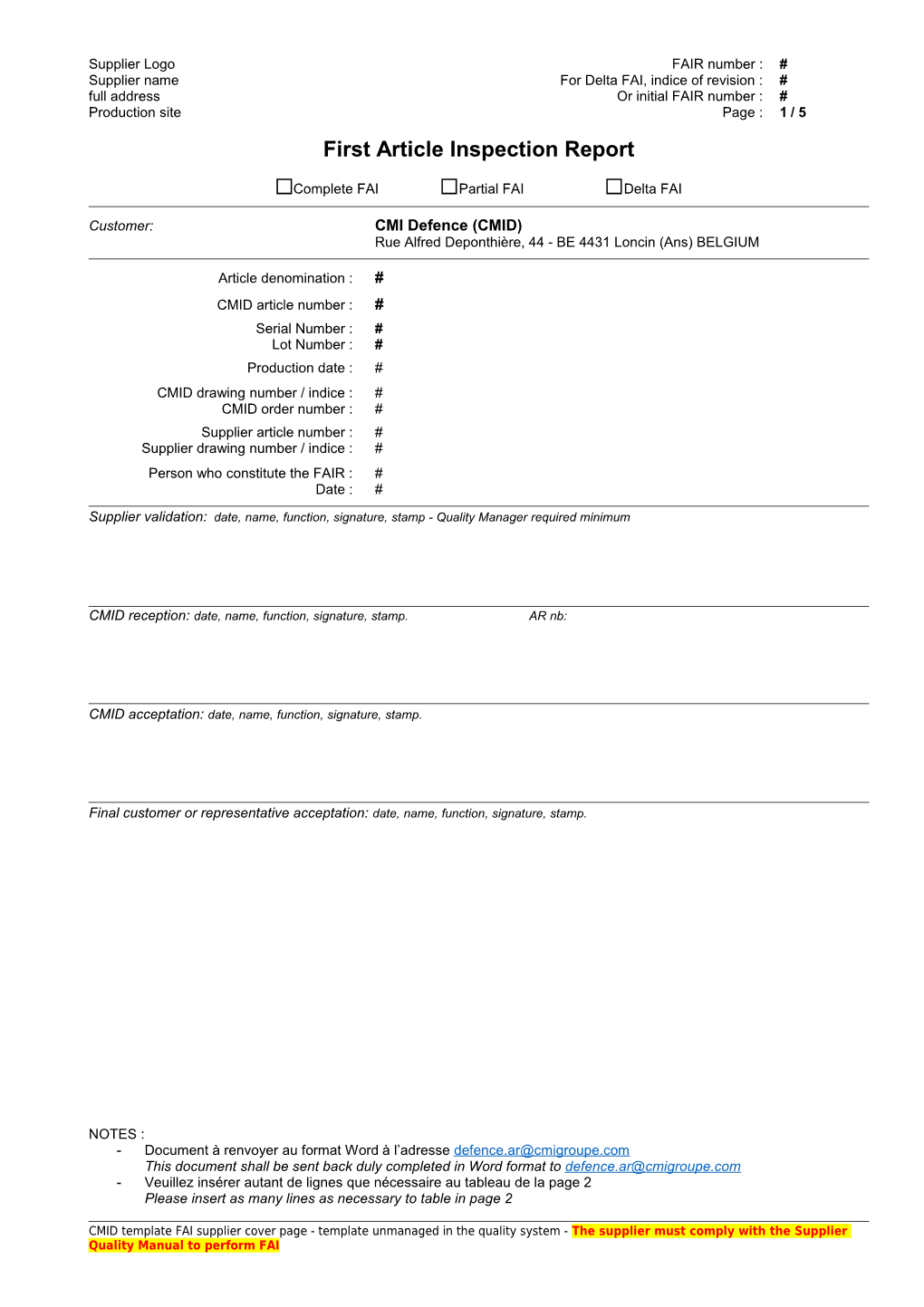

Supplier Logo FAIR number : # Supplier name For Delta FAI, indice of revision : # full address Or initial FAIR number : # Production site Page : 1 / 5 First Article Inspection Report

Complete FAI Partial FAI Delta FAI

Customer: CMI Defence (CMID) Rue Alfred Deponthière, 44 - BE 4431 Loncin (Ans) BELGIUM

Article denomination : # CMID article number : # Serial Number : # Lot Number : # Production date : # CMID drawing number / indice : # CMID order number : # Supplier article number : # Supplier drawing number / indice : # Person who constitute the FAIR : # Date : #

Supplier validation: date, name, function, signature, stamp - Quality Manager required minimum

CMID reception: date, name, function, signature, stamp. AR nb:

CMID acceptation: date, name, function, signature, stamp.

Final customer or representative acceptation: date, name, function, signature, stamp.

NOTES : - Document à renvoyer au format Word à l’adresse [email protected] This document shall be sent back duly completed in Word format to [email protected] - Veuillez insérer autant de lignes que nécessaire au tableau de la page 2 Please insert as many lines as necessary to table in page 2

CMID template FAI supplier cover page - template unmanaged in the quality system - The supplier must comply with the Supplier Quality Manual to perform FAI Supplier Logo FAIR number : # Supplier name For Delta FAI, indice of revision : # full address Or initial FAIR number : # Production site Page : 2 / 5

CMID template FAI supplier cover page - template unmanaged in the quality system - The supplier must comply with the Supplier Quality Manual to perform FAI Supplier Logo FAIR number : # Supplier name For Delta FAI, indice of revision : # full address Or initial FAIR number : # Production site Page : 3 / 5

A compléter par le fournisseur / To be completed by supplier QC Présent / présent CMI Check liste pour FAI / FAI check list ↓ Consultable sur site / Available on site D ↓ Absent / Absent ↓ Réf. N°document / Document ref. or Nb. 1.▲La page d’entête / the cover page 2. Formulaires EN9102 / EN 9102 form 3.▲Table des matières / table of contents 4. Plans détaillés du composant ou de l’ensemble / Detailed drawings of the component or assembly 5. Plan du sous-ensemble / Drawing of subassembly 6. Spécifications / Specifications 7.▲Organigramme de production / Production flow chart 8. Liste des articles à servir / Piking list 9. Gamme / Manufacturing and assembly processes, manufacturing orders 10. Feuilles de travail / Travellers/ job cards/ working sheet 11. Instruction de Contrôle / Inspection Instruction 12.▲Résultats des inspections avec identification des instruments utilisé / Results of inspections, with identification of instruments used 13.▲Certificat d’étalonnage des moyens de contrôle (consultable chez le fournisseur) / Calibration certificates for inspection equipment (can be consulted at the supplier site) 14.▲Certificat de Conformité des composants / Certificates of Conformity for components 15.▲Certificat des matières / Materials Certificates 16.▲Certificats de tous les traitements / All Treatments Certificates 17.▲Certificat de conformité / Certificate of conformity 18. Rapport de test traitement de surface et peinture (plaque témoin à conserver par le fournisseur) / Test report for surface treatment and paint (test plate to be kept by the supplier) 19.Spécification d’assemblage / Assembly specification 20.▲Document de non-conformité clôturé et validé / Non-conformance document, closed and validated 21.▲Rapport d’essais et de tests de qualification et environnementaux (si applicable) / Test reports, qualification and environmental testing reports (if applicable) 22.▲Rapport de tests pour les équipements électroniques, électriques, hydrauliques, mécaniques et informatiques FAT (si applicable) / Test reports for electronic, electrical, hydraulic, mechanical and computer equipment Factory Acceptance Tests (if applicable) 23.▲ATP / ATR (si applicable) / ATP / ATR (if applicable) 24. FAIR fournisseur inférieur / FAIR lower supplier 25. FAIR des sous-composants. (sauf si notification contraire) / FAIR for sub-components (unless otherwise notified) 26. Vérification et qualification du software (si ISO12207 applicable) / Verification and qualification of Audit spécifique séparé - Separate specific audit software (if ISO12207 applicable) 27.▲Liste des fournisseurs de niveau inférieur / List of lower level suppliers 28.▲Liste des fournisseurs qualifiés pour les procédés spéciaux / List of suppliers qualified for special processes ▲= Obligatoire / Mandatory

CMID template FAI supplier cover page - template unmanaged in the quality system - The supplier must comply with the Supplier Quality Manual to perform FAI Supplier Logo FAIR number : # Supplier name For Delta FAI, indice of revision : # full address Or initial FAIR number : # Production site Page : 4 / 5

A compléter par le fournisseur / To be completed by supplier QC Présent / présent CMI Check liste pour FAI / FAI check list ↓ Consultable sur site / Available on site D ↓ Absent / Absent ↓ Réf. N°document / Document ref. or Nb. Autre document / other document : 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 38. 40. 41. 42. 43. 44. 45. 46. 48. 49 50. ▲= Obligatoire / Mandatory

CMID template FAI supplier cover page - template unmanaged in the quality system - The supplier must comply with the Supplier Quality Manual to perform FAI Supplier Logo FAIR number : # Supplier name For Delta FAI, indice of revision : # full address Or initial FAIR number : # Production site Page : 5 / 5

Date Date de Date de N° Etape Description d’étape Lieu d’inspection d’inspection Commentaire début fin Step No Step description Inspection location Inspection Start date End date date

Repère 1 : sous-plan XXXXX rev W

Repère 2 : sous-plan YYYYYY rev Z

CMID template FAI supplier cover page - template unmanaged in the quality system - The supplier must comply with the Supplier Quality Manual to perform FAI