Senior Design I Project # P07009 Warfarin Automatic Home Medication Dispenser Date Revised: 1/11/2007 Summary of External and Internal Searches

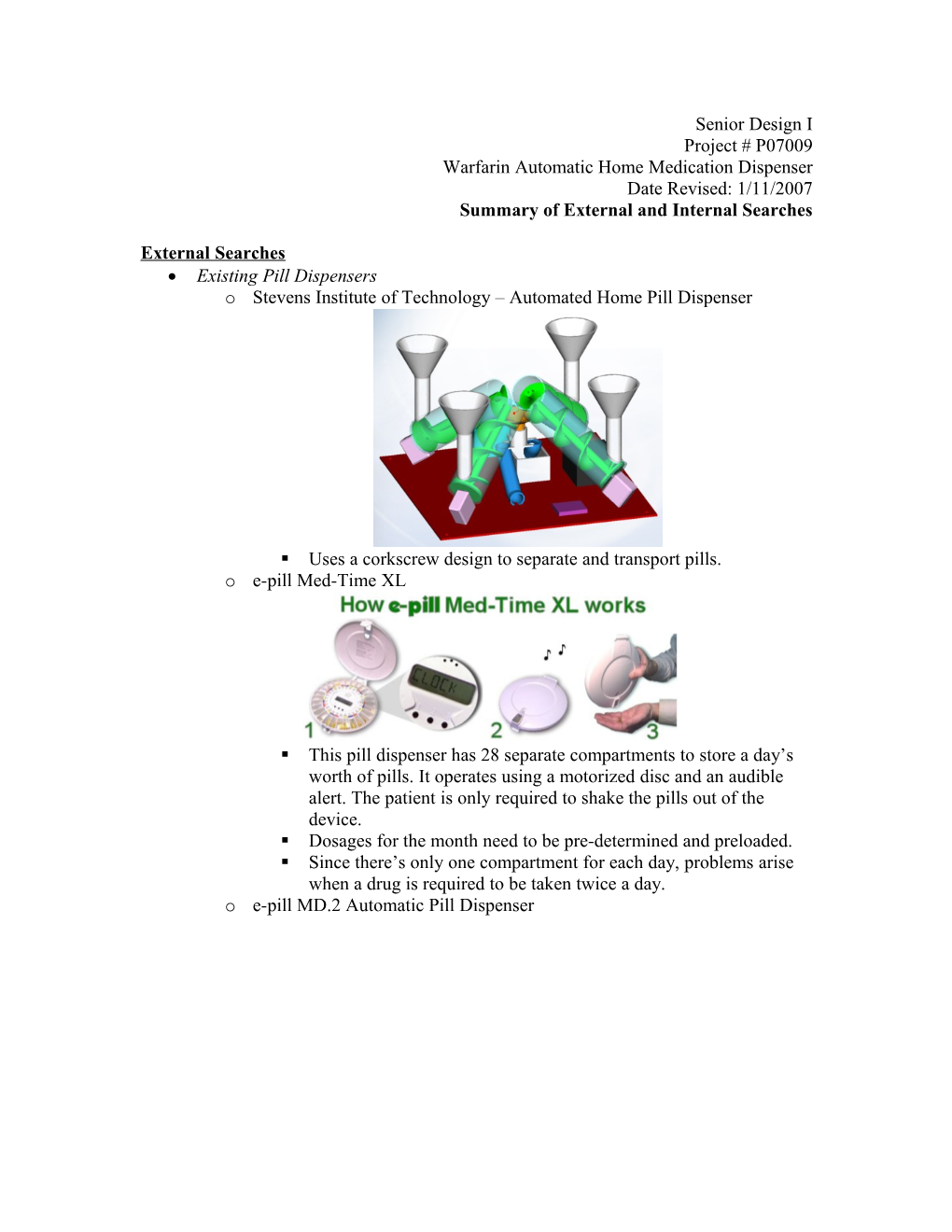

External Searches Existing Pill Dispensers o Stevens Institute of Technology – Automated Home Pill Dispenser

. Uses a corkscrew design to separate and transport pills. o e-pill Med-Time XL

. This pill dispenser has 28 separate compartments to store a day’s worth of pills. It operates using a motorized disc and an audible alert. The patient is only required to shake the pills out of the device. . Dosages for the month need to be pre-determined and preloaded. . Since there’s only one compartment for each day, problems arise when a drug is required to be taken twice a day. o e-pill MD.2 Automatic Pill Dispenser . This pill dispenser also holds 28 separate cups, one per day. . An audio and visual alert notifies the patient that it’s time to take the medication. . The patient pushes the red button and a cup will come down the slide. . Dosages for the month need to be pre-determined and preloaded. . Since there’s only one compartment for each day, problems arise when a drug is required to be taken twice a day.

Existing Technologies o Gumball machine . Dispenses only one item at a time while preventing damage to the remaining gumballs. . Susceptible to jamming. . Limited to spherical objects. o Vending machine . Only works using manually loaded objects. . Mechanism is susceptible to jamming and damaging the product. o Coin sorter . Uses predetermined slots to separate different sized coins. . For our uses we adopted the idea of a slot and chute to transport the dispensed pills. o Paintball gun . Limited to spherical objects. . Susceptible to jamming. . Most reliable design requires cartridges. o Production bulk bin sorter . Uses vibration to move a single item from a bulk bin. . Good for asymmetrical objects of varying size. . Loud and requires additional complex components. o Vacuum . Loud operation. . May cause damage to pill coating. . Pills do not need to be pre-sorted. . Require complex plenums. . Complicated control system. o Cement truck . Uses a corkscrew design that separates material based on density. . May require a lot of space and fine adjustments to the helical structure. . Can cause damage to pill’s coating. o Pez dispenser . Dispenses one tablet at a time while preventing the remaining tablets from moving. . Requires manual loading. . Small range of motion and limited moving parts.

Internal Searches Tubes o Storing the pills in tubes will keep them in a well constrained container. They have the added benefit of letting the pharmacist know if a pill has been incorrectly loaded and how many are left. Magazines o Stores the pills in a very well constrained container that is both predictable and reliable. Pushers o A reciprocating or linear motor can literally push the pill to a designated spot. Rotating discs o The rotating disc will have pill slots that will cycle through the various tubes, taking one pill at a time and then guiding it to a secondary or tertiary disc below it that can be a trap door. Cam actuation o The cam can be used as a rotating arm that sweeps the pill or it can open a spring loaded gate. Funnels o The pharmacist can load the device in larger quantities therefore making the process quicker. Brushes o Creates a temporary wall that cannot be easily breach unless properly pushed by a motor. Clic eraser / notches o A metal tab can click in with notches such that each successive notch will dispense a pill. Rack and pinion o Using a rack and pinion set up, but instead of an actual rack with notches, it can be row of compartments that open when it reaches a designated spot. Wheel o Pills can be arranged in a ring formation (in their own compartments) within a tube with one opening the size of a pill. The ring can rotate and dispense one pill at a time.