Project Readiness Package Rev 5/22/12

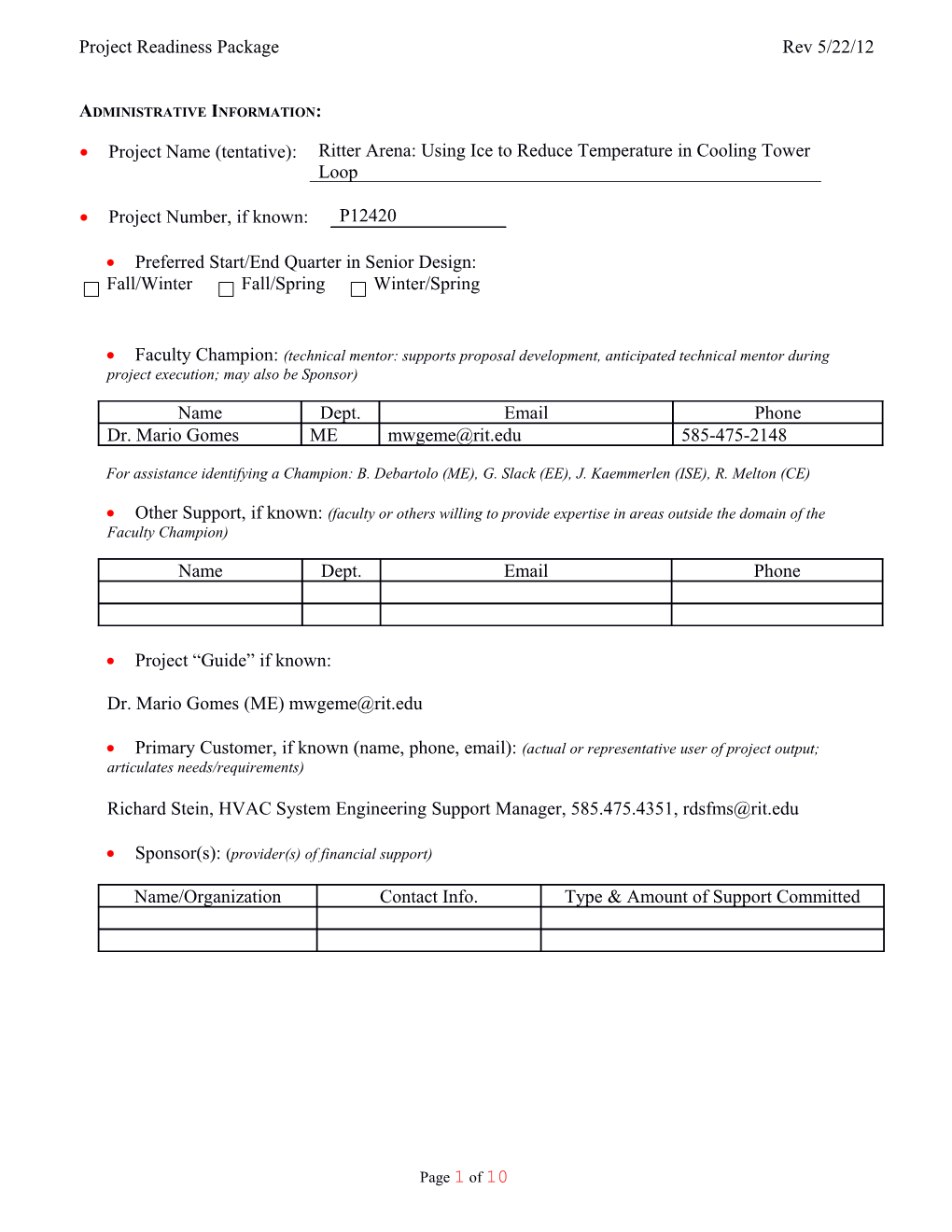

ADMINISTRATIVE INFORMATION:

Project Name (tentative): Ritter Arena: Using Ice to Reduce Temperature in Cooling Tower Loop

Project Number, if known: P12420

Preferred Start/End Quarter in Senior Design: Fall/Winter Fall/Spring Winter/Spring

Faculty Champion: (technical mentor: supports proposal development, anticipated technical mentor during project execution; may also be Sponsor)

Name Dept. Email Phone Dr. Mario Gomes ME [email protected] 585-475-2148

For assistance identifying a Champion: B. Debartolo (ME), G. Slack (EE), J. Kaemmerlen (ISE), R. Melton (CE)

Other Support, if known: (faculty or others willing to provide expertise in areas outside the domain of the Faculty Champion)

Name Dept. Email Phone

Project “Guide” if known:

Dr. Mario Gomes (ME) [email protected]

Primary Customer, if known (name, phone, email): (actual or representative user of project output; articulates needs/requirements)

Richard Stein, HVAC System Engineering Support Manager, 585.475.4351, [email protected]

Sponsor(s): (provider(s) of financial support)

Name/Organization Contact Info. Type & Amount of Support Committed

Page 1 of 10 Project Readiness Package Rev 5/22/12

PROJECT OVERVIEW: Currently RIT consumes large amounts of energy, and 20% - 30% of the total energy usage is due to poor behavior. To scope down this, the focus of the project is the Ritter Ice Arena, which is one of the buildings that consume most of the energy on campus, and at the same time it can be considered a very inefficient building.

The Ice Arena consist on three different water loops; cold water to make the ice, warm loop to prevent freezing of the underslab, and warm loop to cool down the pumps (Cooling towers loop). The goal is to reduce the energy consumption in the Cooling Towers by reducing the temperature of the water in the loop by using the ice dumped by the Zamboni. To do so, a heat exchanger will be incorporated to the loop.

The following PRP will present the information gathered, and a brief analysis of it.

DETAILED PROJECT DESCRIPTION:

Customer Needs and Objectives: Customer Importance Description Need # CN1 3 Reduce energy consumption CN2 1 Easy and intuitive to use CN3 2 Safe for human operation CN4 1 Easy to maintain CN5 3 Low operating costs CN6 2 Little downtime CN7 2 Resistant to working conditions CN8 2 Only one initial investment CN9 1 Sufficient capacity for game-day ice volume CN10 3 Automatic temperature monitoring and system adjustment CN11 3 Easy input of raw material (ice) CN12 1 Feasible size CN13 1 Low maintenance costs CN14 2 Realistic payback period CN15 1 Able to use together with cooling tower CN16 1 Provide support to cooling tower

Page 2 of 10 Project Readiness Package Rev 5/22/12

System Overview:

Page 3 of 10 Project Readiness Package Rev 5/22/12

Functional Decomposition:

Page 4 of 10 Project Readiness Package Rev 5/22/12

Function Interface:

Page 5 of 10 Project Readiness Package Rev 5/22/12

Fill Tank Ice from Zamboni (To be Figured) (Heat Exchanger)

Fit to Space Provided Warm Water Input

Thermometer

Measure Temperature Pipe (Warm Water) Exchange Heat Connection Thermometer Pipe Measure Temperature Pipe Connection Pipe (Cold Water) Connection Connection Pump Water Thermometer (To Exchanger) Data Data Data Cold Water Output

Thermometer Regulate Pump Speed Spray Water Cooling Pipe Towers Connection Measure Temperature Data (Ice Tank Water) Melted Ice Out

BLUE: Interface 1 – Elaborate system that will effectively output water at the desired temperature. GREEN: Interface 2 – Plan that will provide ice pile to interface 1 given the transport constraints. RED: Interface 3 – Use of by product of interface 1 in current cooling tower loop system.

Page 6 of 10 Project Readiness Package Rev 5/22/12

Specifications (or Engineering/Functional Requirements): Comments/Status Function Specification (metric) Unit of Measure Marginal Value Ideal Value S1 Input Ice Input from Zamboni Cubic Feet 180 Related to water S2 Analysis Warm Water Input Flow Gal/min pump flow rate and specifications Data obtained from S3 Monitoring 65-95 65 Warm Water Input Temperature Degrees F current system Data obtained from S4 Monitoring 45-55 55 Cold Water Output Temperature Degrees F current system S5 Installation Tank (Heat Exchanger) Size Cubic Feet >150 180 Depends on heat exchange capacity and rate. It relates S6 Monitoring Pump Flow Rate Gal/min 810 to the maximum and minimum heat transfer rate of the system Is the time from when temperature readings are taken S7 Monitoring Pump Flow Adjustment Time Seconds <120s 60s and water flow is adjusted to get desired outflow water temperature When the heat exchanger begins to be inefficient because the heat S8 Monitoring Melted Ice Temperature Degrees F transfer has become to small due to warming of melted water S9 Analysis Melted Ice Output Flow Gal/Min Required for the S10 Installation Electrical Power KJ pumps and the electrical system S11 Installation Sensor + Electrical Lifetime Years S12 Installation Heat Exchanger Lifetime Years S13 System Dimensions Cubic 4.00 4.86 Based on daily

Page 7 of 10 Project Readiness Package Rev 5/22/12

input ice from Zamboni on a Meters regular day (non- game day)

Page 8 of 10 Project Readiness Package Rev 5/22/12

Constraints: - Must determine an effective way to get the ice from Zamboni into the system. - During winter the system can be restricted due to the possibility of freezing. - The water table under the Ice Arena might limit the possibility of digging to implement the system. - Scaling the model to proof concept might encounter problems due to complexity of system. - Integrating proposed system to existing one can be challenging due to lack of space.

Project Deliverables: - 3D scaled model - Temperature model for tested data - Temperature interface specifications and control system - Bill of materials - Estimate costs for large scale model

Budget Estimate (Scale Model);

$700

Intellectual Property (IP) considerations:

As a federally funded project, any IP generated as a result of this project will belong to RIT

STUDENT STAFFING:

Anticipated Staffing Levels by Discipline:

How Discipline Anticipated Skills Needed Many? EE 1: Design the temperature reading system and integrate to the project EE 1 working together with the CE 1. ME 1: Determine heat exchange rates between ice and water, water flow rates and the requirements the system needs do have to fulfill the specifications in water temperature. ME 2: Design the ice container and the heat exchanger, according to the ME 3 specifications working together with ME 1 to validate theoretical calculations. ME 3: Model the system using computer-based software. Collaborate with ME 1 and ME 2. Determine and acquire the components needed in the system. CE 1: Elaborate system that will command water flow according to the CE 1 temperature readings, and the water flow specifications determined by the team. Work together with the EE 1. ISE 1: Elaborate design according to the requirements so the design fits ISE 1 the designated space. Work on ergonomic and human factors for the system and focus on system integration.

Page 9 of 10 Project Readiness Package Rev 5/22/12

OTHER RESOURCES ANTICIPATED:

Resource Category Description Available?

Faculty EE, CE consultants

ME consultant

Environmen MSD Design Center t

EE Senior Design lab

Machine Shop & Brinkman lab

Equipment 2010-11 tactile interface device

Materials RFID reader, antenna, tags

2010-11 tactile interface team documentation

Other 2010-11 navigation team documentation

Prepared by: DIEGO GUINEA Date: 5/22/12

Page 10 of 10