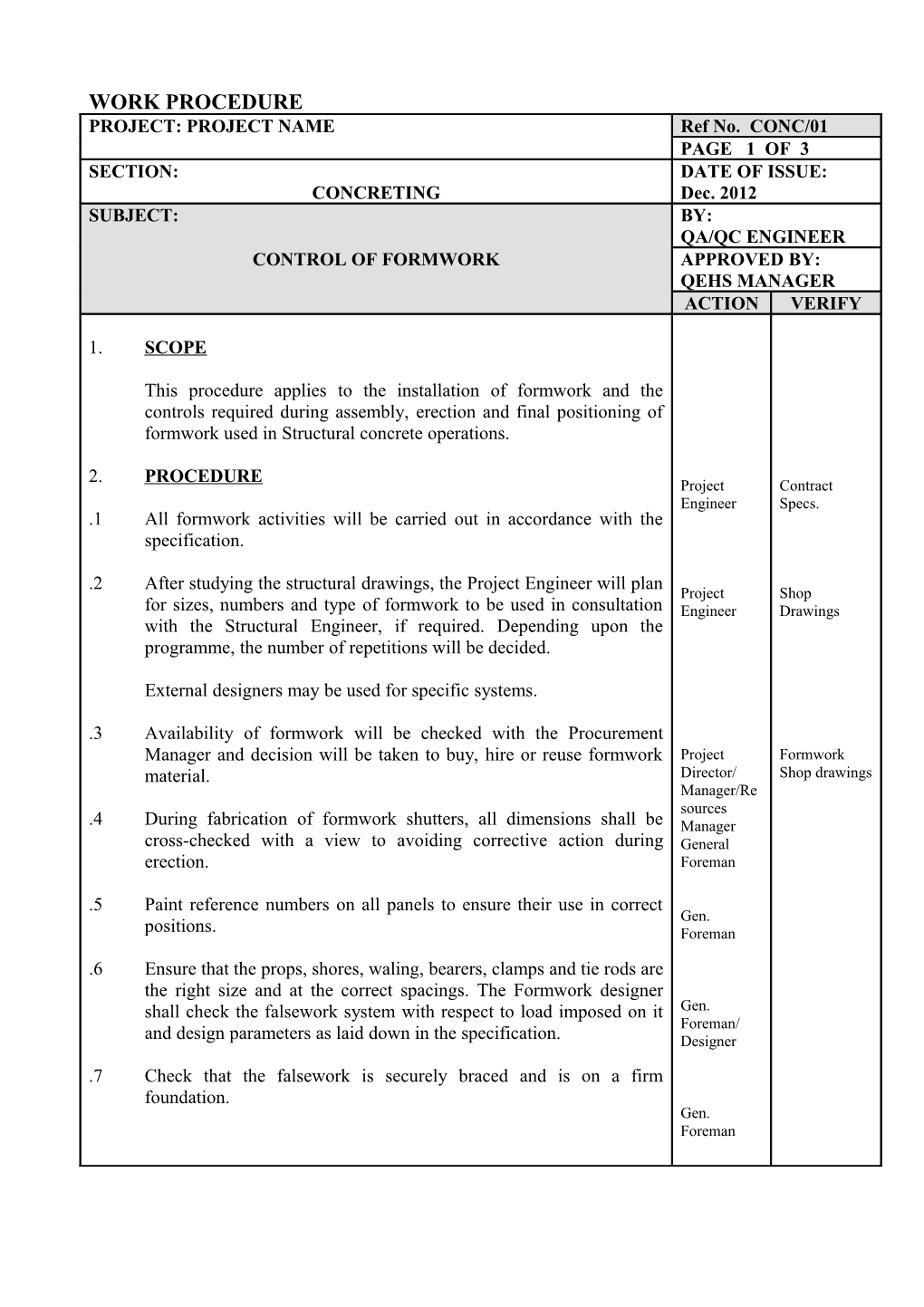

WORK PROCEDURE PROJECT: PROJECT NAME Ref No. CONC/01 PAGE 1 OF 3 SECTION: DATE OF ISSUE: CONCRETING Dec. 2012 SUBJECT: BY: QA/QC ENGINEER CONTROL OF FORMWORK APPROVED BY: QEHS MANAGER ACTION VERIFY

1. SCOPE

This procedure applies to the installation of formwork and the controls required during assembly, erection and final positioning of formwork used in Structural concrete operations.

2. PROCEDURE Project Contract Engineer Specs. .1 All formwork activities will be carried out in accordance with the specification.

.2 After studying the structural drawings, the Project Engineer will plan Project Shop for sizes, numbers and type of formwork to be used in consultation Engineer Drawings with the Structural Engineer, if required. Depending upon the programme, the number of repetitions will be decided.

External designers may be used for specific systems.

.3 Availability of formwork will be checked with the Procurement Manager and decision will be taken to buy, hire or reuse formwork Project Formwork material. Director/ Shop drawings Manager/Re sources .4 During fabrication of formwork shutters, all dimensions shall be Manager cross-checked with a view to avoiding corrective action during General erection. Foreman

.5 Paint reference numbers on all panels to ensure their use in correct Gen. positions. Foreman .6 Ensure that the props, shores, waling, bearers, clamps and tie rods are the right size and at the correct spacings. The Formwork designer shall check the falsework system with respect to load imposed on it Gen. Foreman/ and design parameters as laid down in the specification. Designer .7 Check that the falsework is securely braced and is on a firm foundation. Gen. Foreman WORK PROCEDURE PROJECT: PROJECT NAME Ref No. CONC/01 PAGE 2 OF 3 SECTION: DATE OF ISSUE: CONCRETING Dec. 2012 SUBJECT: BY: QA/QC ENGINEER CONTROL OF FORMWORK APPROVED BY: QEHS MANAGER ACTION VERIFY

.8 Forms fastened to previously cast concrete must be tightly fixed to Gen. prevent grout loss. Cellular foam plastic strips can be used to make a Foreman seal.

.9 Check quality of shutter lining, tightness of bolts and wedges, built- Gen. in items, inserts and other embedments. Foreman CONC/04/A

.10 Tie - rod holes to be made in the formwork shall be neat so that they Gen. can be patched or plugged later on. Foreman

.12 Particular attention will be paid to the rigidity and line of stop ends Gen. and joint formers. Foreman

.13 Remove all tie-wire clippings and nails, which may stain both the Gen. formwork and the concrete. Foreman CONC/04/A

.14 Ensure that adequate access and working platforms are in place for Gen. the concreting gang and that toe boards and guardrails are provided. Foreman

.15 A spreader or lifting beam shall be used to prevent distortion when Gen. placing formwork. Foreman

.16 Adjustable steel props shall be erected in plumb and verticality of Gen. props checked using a spirit level. Foreman

.17 A prop should not be used if it is bent, creased or, rusted or has a Gen. bent head or base plate, damaged pin etc. Foreman

.18 Proper release of agent shall be used so that it can be removed Gen. without damaging the surface finish of the concrete. Foreman CONC/04/A

.19 New timber and plywood forms shall be given first coat of the appropriate release agent 36 hours in advance, then a second coat just Gen. before they are used. Avoid excessive use of release agent as this can Foreman cause staining or retardation of the concrete.

.20 A close watch should be kept on all wedges and fastenings. Make Gen. sure that they do not work loose. Grout loss is an indication that Foreman some movement has occurred.

WORK PROCEDURE PROJECT: PROJECT NAME Ref No. CONC/01 PAGE 3 OF 3 SECTION: DATE OF ISSUE: CONCRETING Dec. 2012 SUBJECT: BY: QA/QC ENGINEER CONTROL OF FORMWORK APPROVED BY: QEHS MANAGER ACTION VERIFY

.21 When unsleeved tie bars are being used, ease them slightly before the Gen. concrete sets, and remove them as soon as it is safe. Foreman

.22 Striking the Formwork:

i) Always obtain approval before striking the formwork in the form of Appendix CONC/04/A. QA/QC Check sheet

ii) Ensure adequate safety measures while striking formwork. Gen. Foreman iii) Cleaning the face of forms shall start as soon as they have Gen. been struck. Foreman Gen. iv) Good storage is essential to ensure that formwork can be used Foreman again. Gen v) Paint code numbers on them so that they can be readily Foreman identified when next needed.

.23 Safety During Formwork Operations:

i) The weights of large prefabricated sections of formwork should be marked on them so that the lifting capacity of the crane at the working radius is not exceeded. Lifting points are Gen. usually provided. Foreman

ii) If necessary, a spreader or lifting beam shall be used to prevent distortion. Gen. Foreman iii) Where lifting is done by the vertical soldiers, check that they are adequately connected to the walings. Gen. Foreman iv) Fire extinguishers in working order shall be in close Project proximity to the stored formwork. Gen. Safety Plan Foreman/ Safety Officer